Waste incineration fly ash all-solid waste solidification stabilization material and its solidification method

A waste incineration fly ash and solidification method technology, which is applied in cement production and other directions, can solve the problems of low strength of solidified body, resource waste environment, and difficult-to-handle solid waste, etc., and achieves simple preparation method, compact and stable structure, and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

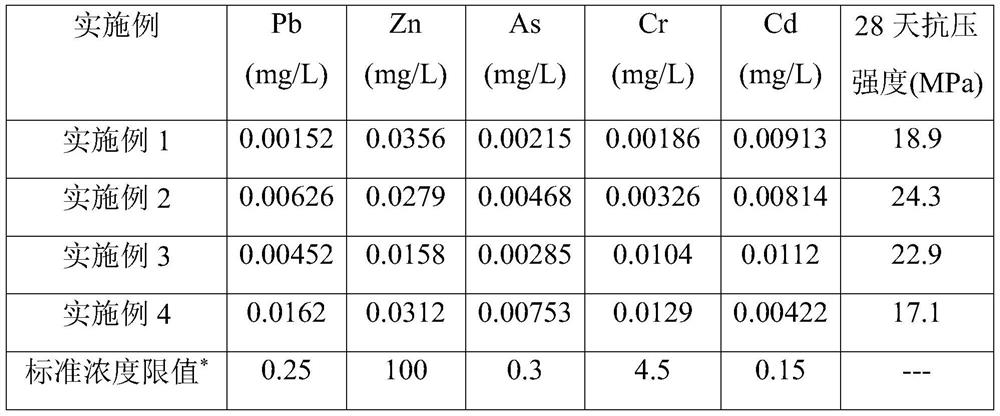

Examples

Embodiment 1

[0044] A waste incineration fly ash solid waste solidification stabilization material is prepared from the following raw materials in weight percentage:

[0045] Slag powder: 25%, steel slag powder: 35%, desulfurization ash: 15%, calcium phosphate slag: 25%.

[0046] A solidification method for all solid waste solidification stabilization material solidification waste incineration fly ash, specifically comprises the following steps:

[0047] (1) Dry the slag, steel slag, desulfurization ash and calcium phosphate slag to a moisture content of 0.01% to 0.1%, and then grind the slag, steel slag, desulfurization ash and calcium phosphate slag to a specific surface area of 510, 445, 670, 650m 2 / g, 4 kinds of raw materials are mixed homogeneously in mixer, obtain all solid waste curing stabilization material;

[0048] (2) Mix solid waste solidification and stabilization materials with waste incineration fly ash A at a dry weight of 1:4, and add water to the above mixture at a w...

Embodiment 2

[0052] A waste incineration fly ash all-solid waste solidification stabilization material is prepared from the following raw materials in weight percentage: slag micropowder: 35%, steel slag micropowder: 30%, desulfurization ash: 10%, calcium phosphate slag: 25%.

[0053] A solidification method for all solid waste solidification stabilization material solidification waste incineration fly ash, specifically comprises the following steps:

[0054] (1) Dry the slag, steel slag, desulfurization ash and calcium phosphate slag to a moisture content of 0.01% to 0.1%, and then grind the slag, steel slag, desulfurization ash and calcium phosphate slag to a specific surface area of 582, 515, 720, 824m 2 / g, 4 kinds of raw materials are mixed homogeneously in mixer, obtain all solid waste curing stabilization material;

[0055] (2) Mix solid waste solidification and stabilization materials with waste incineration fly ash B at a dry weight of 1:3.5, and add water to the above mixture ...

Embodiment 3

[0059] A waste incineration fly ash all-solid waste solidification stabilization material is prepared from the following raw materials in weight percentage: slag micropowder: 18%, steel slag micropowder: 37%, desulfurization ash: 12%, calcium phosphate slag: 33%.

[0060] A solidification method for all solid waste solidification stabilization material solidification waste incineration fly ash, specifically comprises the following steps:

[0061] (1) Dry the slag, steel slag, desulfurization ash and calcium phosphate slag to a moisture content of 0.01% to 0.1%, and then grind the slag, steel slag, desulfurization ash and calcium phosphate slag to a specific surface area of 476, 595, 525, 642m 2 / g, 4 kinds of raw materials are mixed homogeneously in mixer, obtain all solid waste curing stabilization material;

[0062] (2) Mix solid waste solidification and stabilization materials with waste incineration fly ash C at a dry weight of 1:3, and add water to the above mixture at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com