Non-oriented silicon steel RH refinement and deoxidation control method

A technology of oriented silicon steel and control method, applied in the metallurgical field of non-oriented silicon steel, can solve the problems of inability to deoxidize finely control, affect product quality, etc., and achieve the effects of product performance improvement, iron loss improvement, and wide process applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

[0028] The smelting composition mass percentage of the non-oriented silicon steel of the present invention is: C≤0.005%, Si: 0.25%-2.5%, Mn: 0.10%-0.50%, P≤0.08%, Al≤0.005%, S≤0.008%, N≤0.003%, the balance is Fe and unavoidable inclusions;

[0029] The composition of the above molten steel is obtained through converter and RH refining treatment. After the molten steel is poured into billets, it is a non-oriented silicon steel product obtained after hot rolling, pickling, cold rolling, annealing and coating.

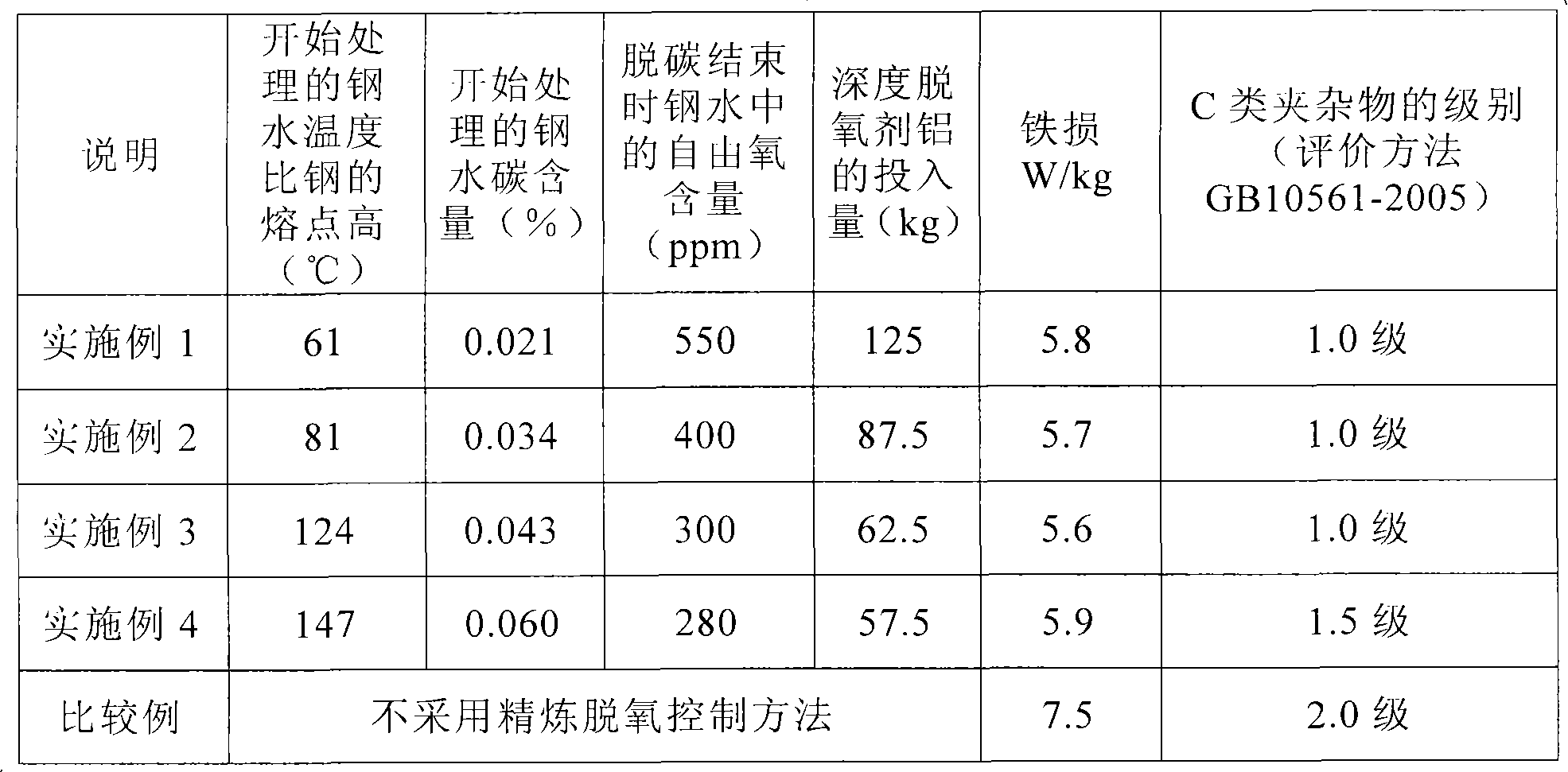

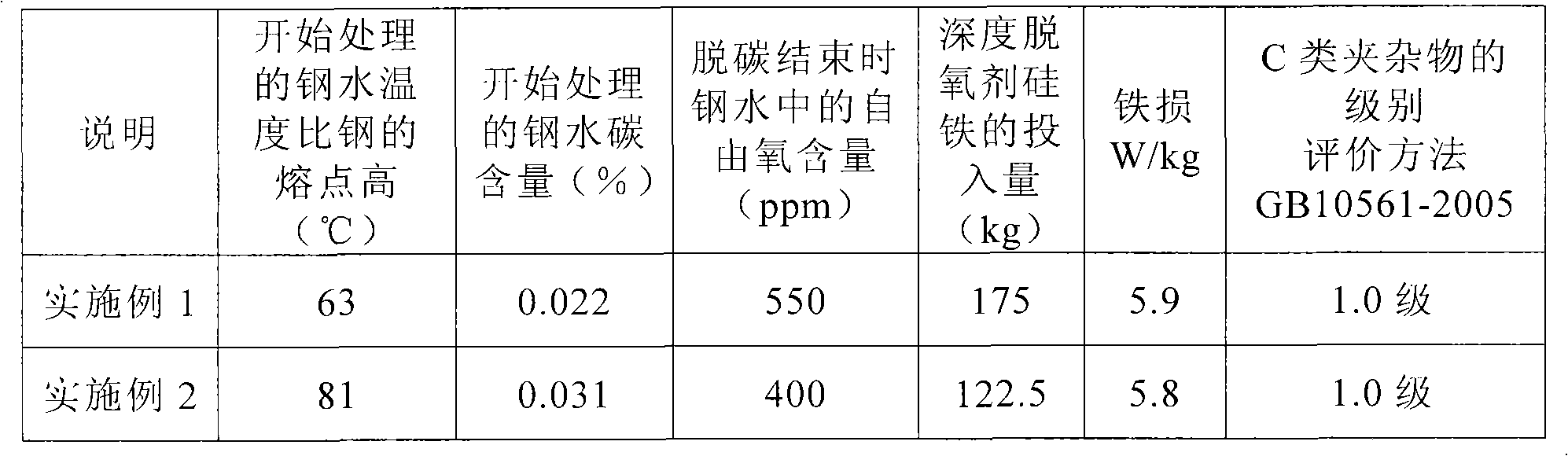

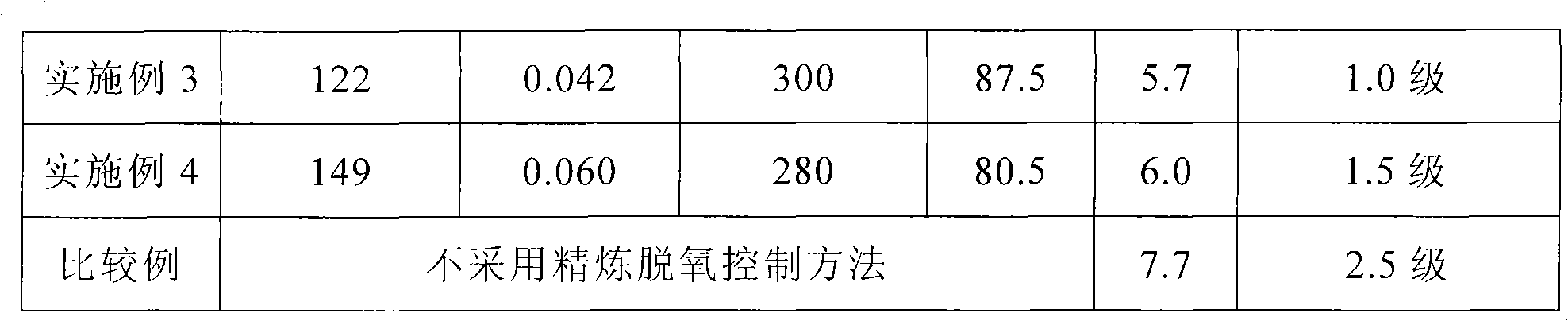

[0030] RH refining begins to process, and the temperature of molten steel is 60°C to 150°C higher than the melting point of steel. The carbon content of molten steel treated at the beginning of RH refining is controlled at 0.02% to 0.06%;

[0031] At the end of RH refining and decarburization, the free oxygen content in molten steel is 250-550ppm;

[0032] Calculation model o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com