Slab continuous casting manufacturing method for medium-manganese wear-resistant steel

A production method and steel slab technology are applied in the field of casting production of medium manganese wear-resistant steel, which can solve problems such as high temperature sensitivity and inability to solve crack problems, and achieve wide process applicability, strong equipment and process versatility, and high yield. Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

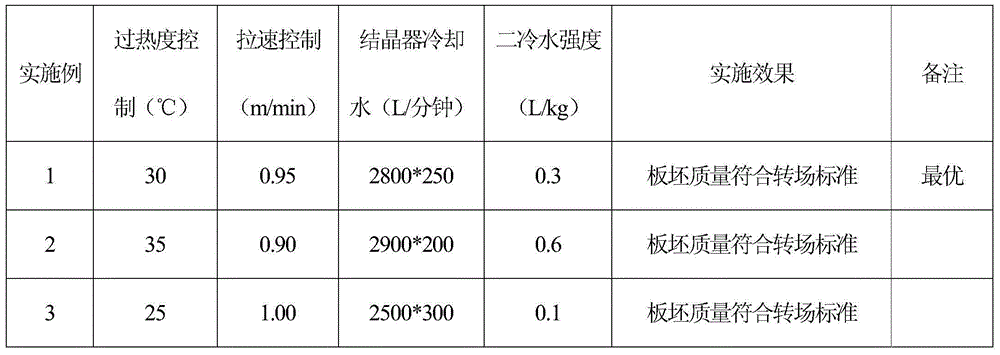

Embodiment 1

[0039] Medium manganese wear-resistant steel (BTW1) is produced by slab continuous casting production method:

[0040] Its technological process is: AC electric arc furnace of 40 tons and above (tapping from slot furnace, adding slag, various necessary alloys, recarburizers and aluminum deoxidizers)→refining in ladle furnaces of corresponding tonnage (bottom blowing argon )─→Slab continuous casting to produce medium manganese wear-resistant steel (BTW1) (150mm*1250mm) (slab thickness*slab width)

[0041] In the primary smelting process of the electric arc furnace, the low phosphating of the primary molten steel is carried out in an AC electric arc furnace of 40 tons or more. By passing in alternating current and blowing in oxygen, and adding lime ≤ 8 kg / ton of steel in the process, intermittently flowing out oxidative slag, melting the charged charge into molten steel in the temperature range of 1620 ° C, and making the steel The residual phosphorus content in the liquid is r...

Embodiment 2

[0046] Medium manganese wear-resistant steel (BTW1) is produced by slab continuous casting production method:

[0047] Its technological process is: AC electric arc furnace of 40 tons and above (tapping from slot furnace, adding slag, various necessary alloys, recarburizers and aluminum deoxidizers)→refining in ladle furnaces of corresponding tonnage (bottom blowing argon )─→Slab continuous casting to produce Cr20AlY (150mm*1250mm) (slab thickness*slab width)

[0048] In the primary smelting process of the electric arc furnace, the low phosphating of the primary molten steel is carried out in an AC electric arc furnace of 40 tons or more. By passing in alternating current and blowing in oxygen, and adding lime ≤ 8 kg / ton of steel in the process, intermittently flowing out oxidative slag, melting the charged charge into molten steel in the temperature range of 1620 ° C, and making the steel The residual phosphorus content in the liquid is reduced to below 0.015%.

[0049] In ...

Embodiment 3

[0053] Medium manganese wear-resistant steel (BTW1) is produced by slab continuous casting production method:

[0054] Its technological process is: AC electric arc furnace of 40 tons and above (tapping from slot furnace, adding slag, various necessary alloys, recarburizers and aluminum deoxidizers)→refining in ladle furnaces of corresponding tonnage (bottom blowing argon )─→Slab continuous casting to produce Cr20AlY (150mm*1250mm) (slab thickness*slab width)

[0055] In the primary smelting process of the electric arc furnace, the low phosphating of the primary molten steel is carried out in an AC electric arc furnace of 40 tons or more. By passing in alternating current and blowing in oxygen, and adding lime ≤ 8 kg / ton of steel in the process, intermittently flowing out oxidative slag, melting the charged charge into molten steel in the temperature range of 1620 ° C, and making the steel The residual phosphorus content in the liquid is reduced to below 0.015%.

[0056] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com