Heat treatment method for obtaining near-lamellar texture of peritectic casting TiAl alloy

A heat treatment method and over-peritectic technology, applied in the field of metal heat treatment, can solve the problems of long production cycle and loss, and achieve the effect of eliminating casting segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

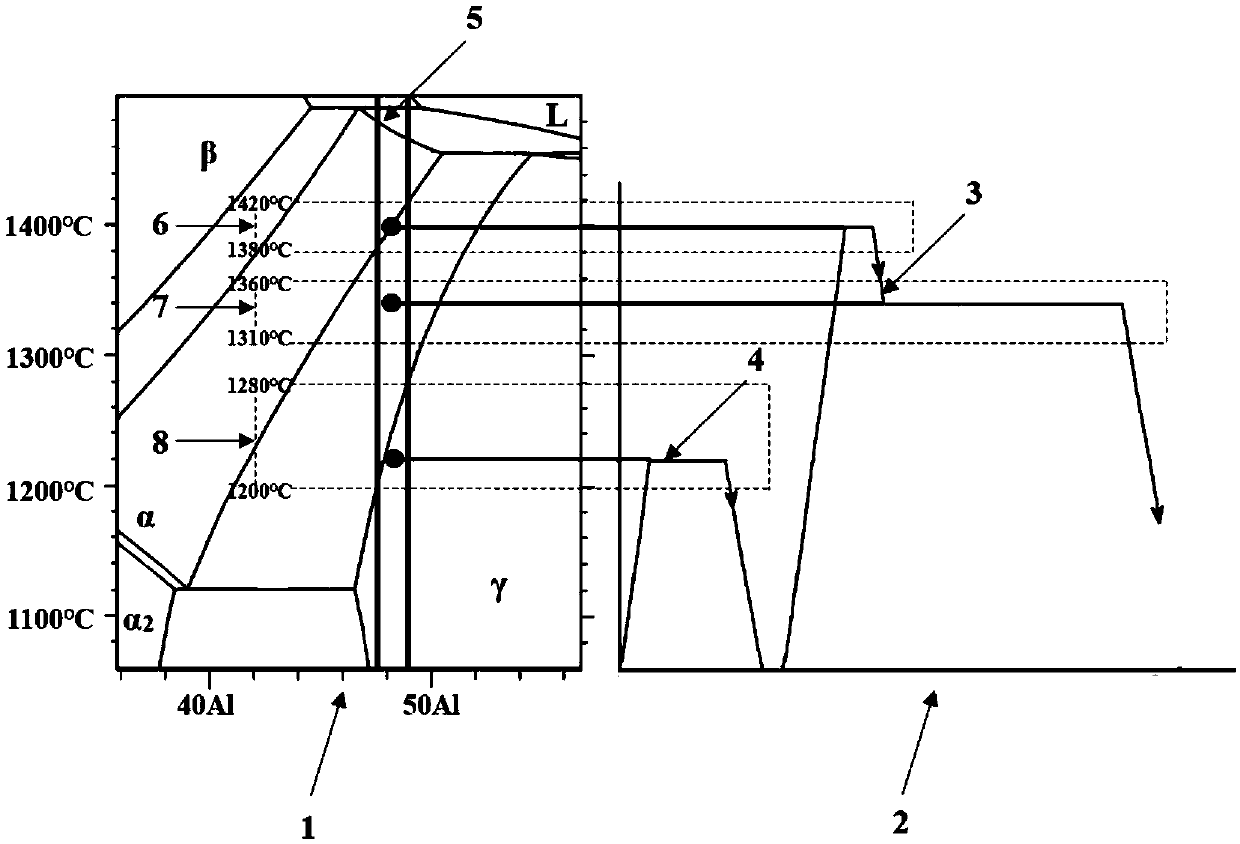

[0049] This example is a heat treatment method for obtaining the nearly lamellar structure of cast TiAl alloy with the characteristics of peritectic solidification through hot isostatic pressing treatment and multi-step heat preservation and cooling treatment, and cast Ti-49.0Al-2Nb-2Cr-X Alloy as an example, to be described in detail.

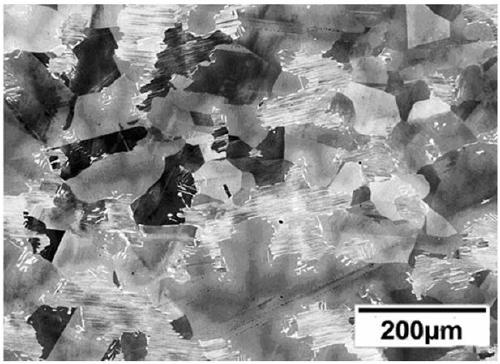

[0050] The cast Ti-49.0Al-2Nb-2Cr-X alloy is obtained by vacuum electrode self-consumption + cold crucible induction melting anti-gravity casting method, and has the characteristics of peritectic solidification, such as image 3 As shown in a, the cast microstructure is composed of coarse irregular lamellar clusters with an average size of 500 μm and equiaxed coarse gamma grains with an average size of 100 μm between the lamellar clusters.

[0051] The concrete process of this embodiment is:

[0052] Step 1, hot isostatic pressing treatment. Place the cast TiAl alloy in a hot isostatic pressing furnace, raise the temperature to 1200° C., rai...

Embodiment 2

[0058] This example is a heat treatment method for obtaining the near-lamellar structure of cast TiAl alloy with the characteristics of peritectic solidification through hot isostatic pressing treatment and multi-step heat preservation and cooling treatment, and cast Ti-47.8Al-2Nb-2Cr-X Alloy as an example, to be described in detail.

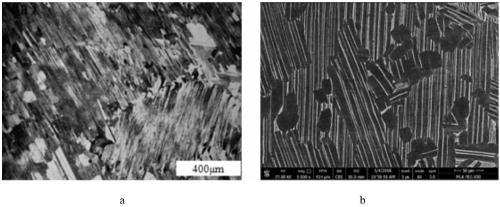

[0059] The cast Ti-47.8Al-2Nb-2Cr-X alloy is obtained by vacuum electrode self-consumption + water-cooled copper crucible induction melting centrifugal casting method, and has the characteristics of peritectic solidification, such as Figure 4 As shown in a, the casting microstructure is completely composed of coarse irregular lamellar clusters with an average size of 500 μm.

[0060] The concrete process of this embodiment is:

[0061] Step 1, hot isostatic pressing treatment. Put the cast TiAl alloy in a hot isostatic pressing furnace, raise the temperature and increase the pressure in an atmosphere of argon protective gas, keep the pressure...

Embodiment 3

[0068] This example is a heat treatment method for obtaining the near-lamellar structure of cast TiAl alloy with peritectic solidification characteristics through hot isostatic pressing treatment and multi-step heat preservation and cooling treatment, and cast Ti-48.3Al-4Nb-2Cr-X Alloy as an example, to be described in detail.

[0069] The cast Ti-48.3Al-4Nb-2Cr-X alloy is obtained by vacuum electrode self-consumption + water-cooled copper crucible induction melting gravity casting method, and has the characteristics of peritectic solidification, such as Figure 5 As shown in a, its cast microstructure is completely composed of irregular lamellar clusters with an average size of 250 μm.

[0070] The concrete process of this embodiment is:

[0071] Step 1, hot isostatic pressing treatment. Put the cast TiAl alloy in a hot isostatic pressing furnace, raise the temperature and increase the pressure under the atmosphere of argon protective gas, keep the pressure at 150 MPa and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com