Method for co-pyrolysis of solid waste and coal

A solid waste, co-pyrolysis technology, applied in the direction of educts, biofuels, special forms of dry distillation, etc., can solve the problem that the gas is not enough to meet the heat required for pyrolysis, so as to solve the problem of resource utilization, stabilize production, and save The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

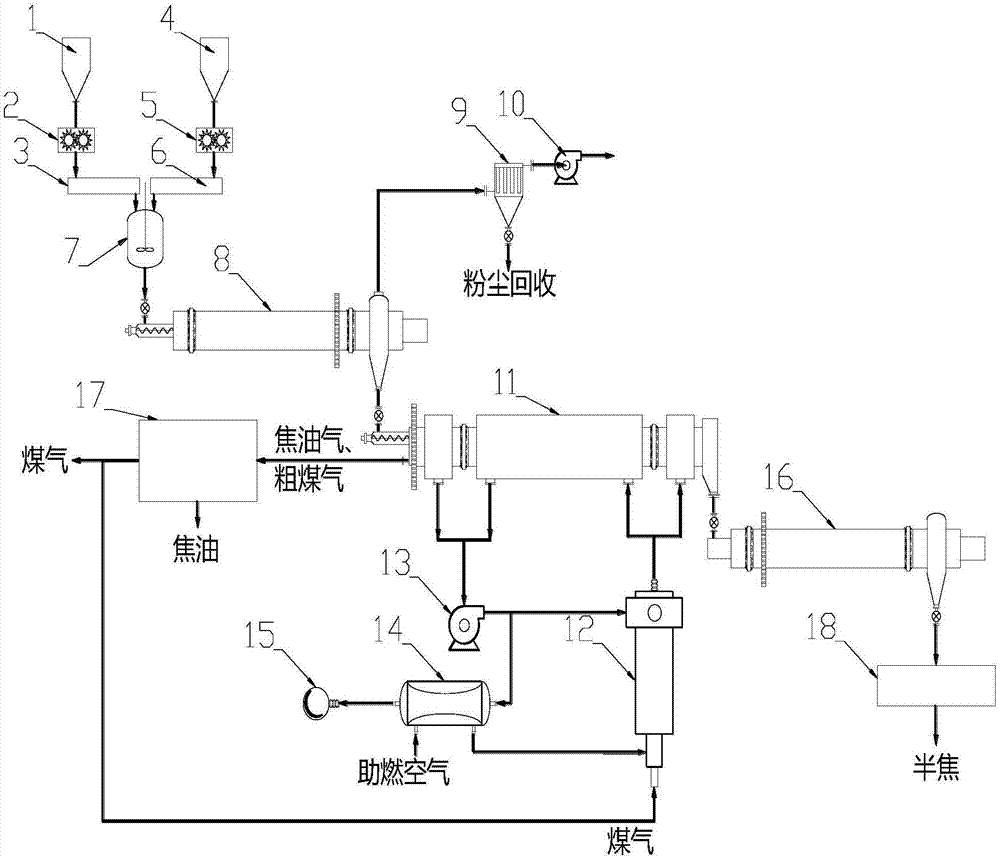

[0046]Taking waste rubber and Shanbei coal as an example, the waste rubber and coal with a water content of ≤13% are broken into particles with a particle size of ≤30mm by the solid waste material bin 1 and the coal bin 2 through the crushers 2 and 5, respectively. Metering equipment 3 and 6 measure waste rubber and coal at a ratio of 1:1, and add them to the mixing silo 7 for mixing, and then transport them to the mixing silo in front of the drying furnace by a belt at a flow rate of 200kg / h.

[0047] Analysis index of waste rubber

[0048]

[0049] Raw coal coal quality analysis index

[0050]

[0051]

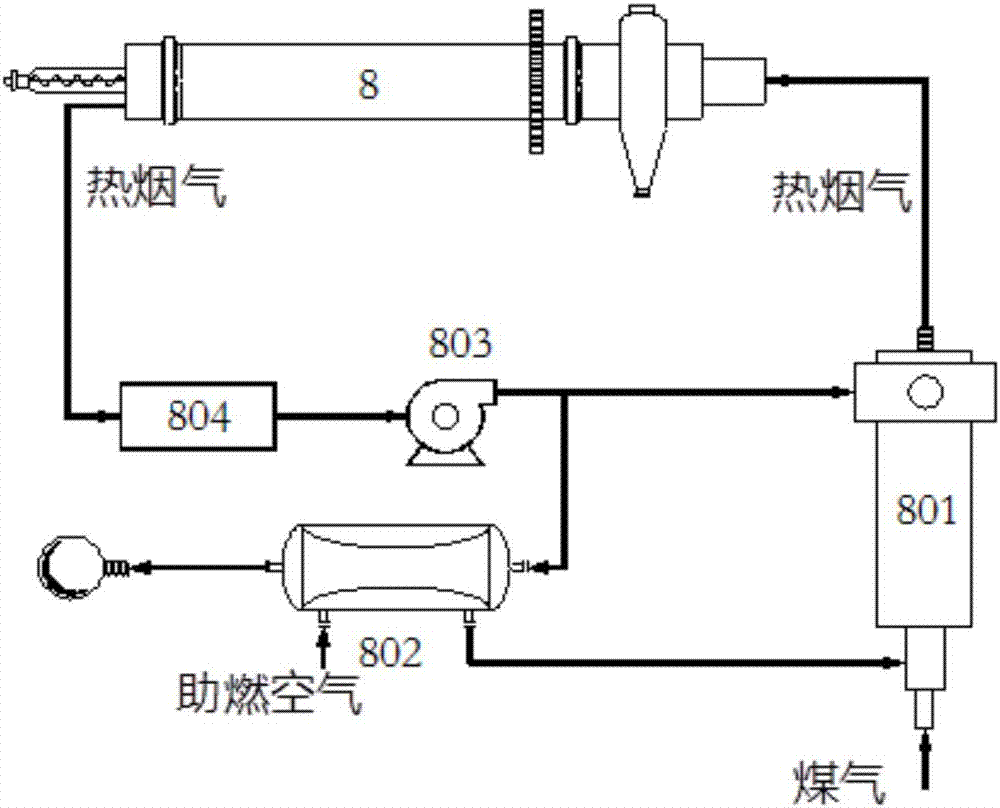

[0052] The mixed material in the mixing silo enters the drying equipment 8 through the rotary valve and the feeding screw of the drying equipment, where it is dried and heated to 80°C. The water content after drying is ≤5%, and the final temperature of the dried and heated material is 80°C. It is discharged from the outlet of the drying equipment through a rotary v...

Embodiment 2

[0067] Taking wheat straw and Xinjiang coal as an example, wheat straw and coal with a moisture content of ≤21% are crushed into solid waste material bin 1 and coal bin 2 by crushers 2 and 5 to particles with a particle size of 1 to 30 mm, respectively Equipment 3 and 6 are measured according to the 3:1 ratio of straw and coal, and are added to the mixing silo 7 for mixing, and then transported by the belt to the mixing silo in front of the drying furnace at a flow rate of 150kg / h.

[0068] Straw Analysis Indicators

[0069]

[0070] Raw coal coal quality analysis index

[0071]

[0072] The mixed material in the mixing silo passes through the rotary valve and the drying equipment feeding screw and enters the drying equipment 8, where it is dried and heated to 95°C, the water content after drying is ≤5%, and the final temperature of the dried and heated material is 150°C , The dried and heated material is discharged from the outlet of the dryer through the rotary valve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com