Anti-radiation concrete produced from slag aggregate, and production method thereof

A radiation protection and concrete technology, applied in the field of concrete, can solve the problems of adverse effects of concrete durability, increased cracking tendency of concrete, poor homogeneity, etc., so as to improve the shielding performance and service life, reduce the cracking tendency, and reduce the movement rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

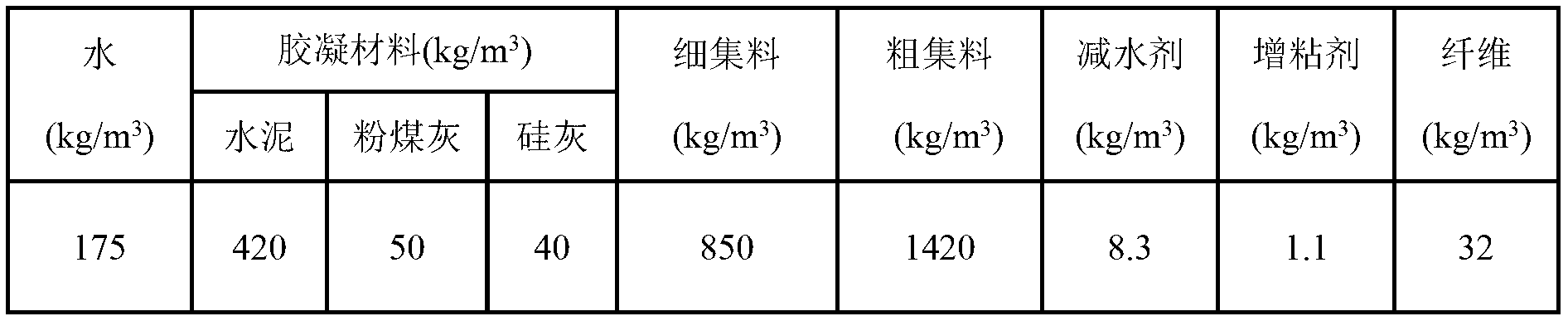

[0052] Select the raw materials according to the raw material ratio in Table 1, pour the cementitious material, coarse aggregate, fine aggregate, tackifier and fiber into the concrete mixer for dry mixing, then add water reducer and water, and continue mixing, that is have to. Its physical performance technical index and linear attenuation coefficient are listed in Table 5 and Table 6.

[0053] Table 1 Ratio of Raw Materials for Radiation-proof Concrete Prepared from Slag Aggregate

[0054]

[0055] Among them, the cement is a mixture of barium cement and ordinary Portland cement, and the blending mass ratio of ordinary Portland cement and barium cement is 5:1; the density of fly ash is 0.8g / cm 3 ~1.1g / cm 3 ;The density of silica fume is 2.0g / cm 3 ~2.4g / cm 3 , the average particle size is 0.16μm-0.19μm; the fine aggregate is high-titanium heavy slag sand and lead powder, the blending mass ratio is 1:3, and the fineness modulus of the fine aggregate is 2.5-3.5; the coars...

Embodiment 2

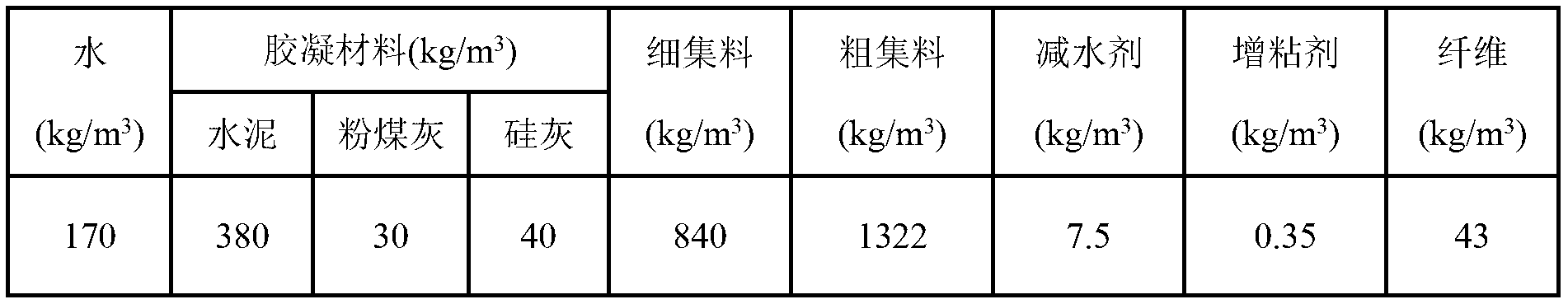

[0058] Select the raw materials according to the raw material ratio in Table 2, pour the cementitious material, coarse aggregate, fine aggregate, tackifier and fiber into the concrete mixer for dry mixing, then add water reducer and water, and continue mixing, that is have to. Its physical performance technical index and linear attenuation coefficient are listed in Table 5 and Table 6.

[0059] Table 2 Mixing ratio of various raw materials for radiation-proof concrete prepared from slag aggregates

[0060]

[0061] Among them, the cement is barium cement and ordinary Portland cement, and the blending mass ratio of ordinary Portland cement and barium cement is 3:1; the density of fly ash is 0.8g / cm 3 ~1.1g / cm 3 ; Silica fume density 2.0g / cm 3 ~2.4g / cm 3 , the average particle size is 0.16μm-0.19μm, the fine aggregate is high-titanium heavy slag sand and lead powder, the blending mass ratio is 1:2, and the fineness modulus is 2.5-3.5; the coarse aggregate is High-titaniu...

Embodiment 3

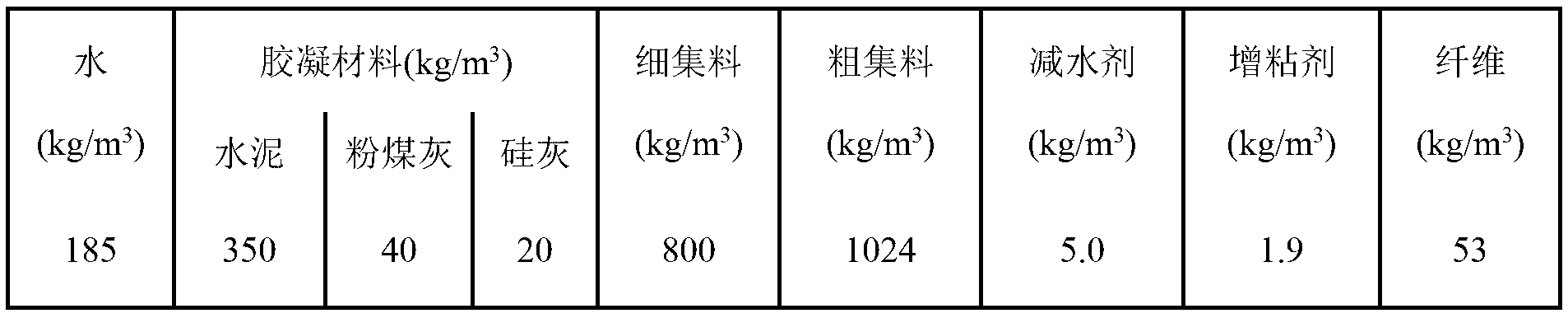

[0063] Select the raw materials according to the raw material ratio in Table 3, pour the cementitious material, coarse aggregate, fine aggregate, tackifier and fiber into the concrete mixer for dry mixing, then add water reducer and water, and continue mixing, that is have to. Its physical performance technical index and linear attenuation coefficient are listed in Table 5 and Table 6.

[0064] Table 3 Mixing ratio of various raw materials for radiation-proof concrete prepared from slag aggregates

[0065]

[0066] Among them, the cement is barium cement and ordinary Portland cement, the blending mass ratio of ordinary Portland cement and barium cement is 2:1; the density of fly ash is 0.8g / cm 3 ~1.1g / cm 3 ;The density of silica fume is 2.0g / cm 3 ~2.4g / cm 3 , the average particle size is 0.16μm-0.19μm; the fine aggregate is high-titanium heavy slag sand and lead powder, the blending mass ratio is 1:1, and the fineness modulus of the fine aggregate is 2.5-3.5; the coarse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com