Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158 results about "Co pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Co-pyrolysis is a process which involves two or more materials as feedstock. Many studies have shown that the use of co-pyrolysis is able to improve the characteristics of pyrolysis oil, e.g. increase the oil yield, reduce the water content, and increase the caloric value of oil.

Method for manufacturing wet fuel by rapid common thermal decomposition of biomass and coal

InactiveCN101108970AFast co-pyrolysisSimple processLiquid hydrocarbon mixture productionChemical industryHeat carrier

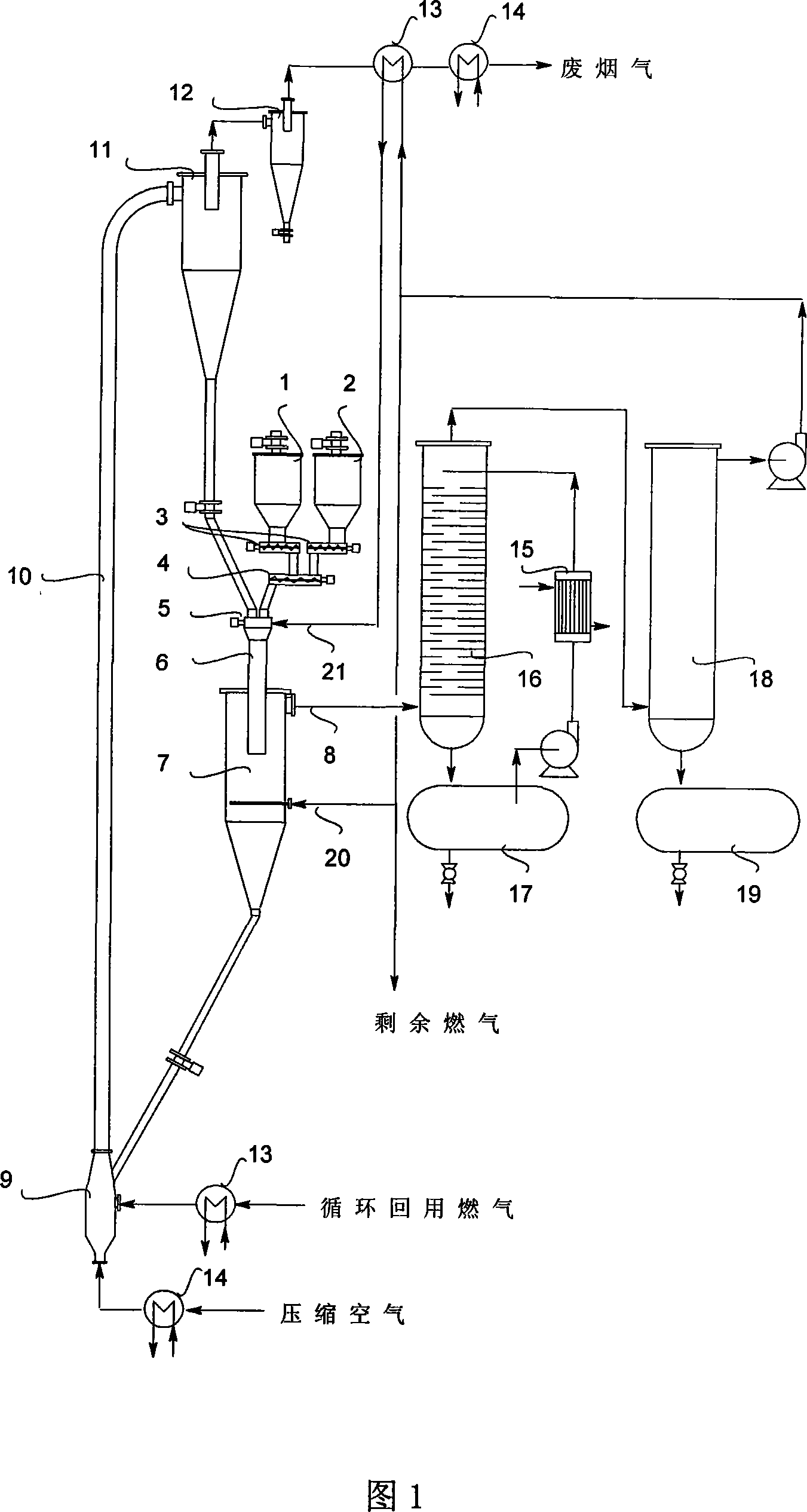

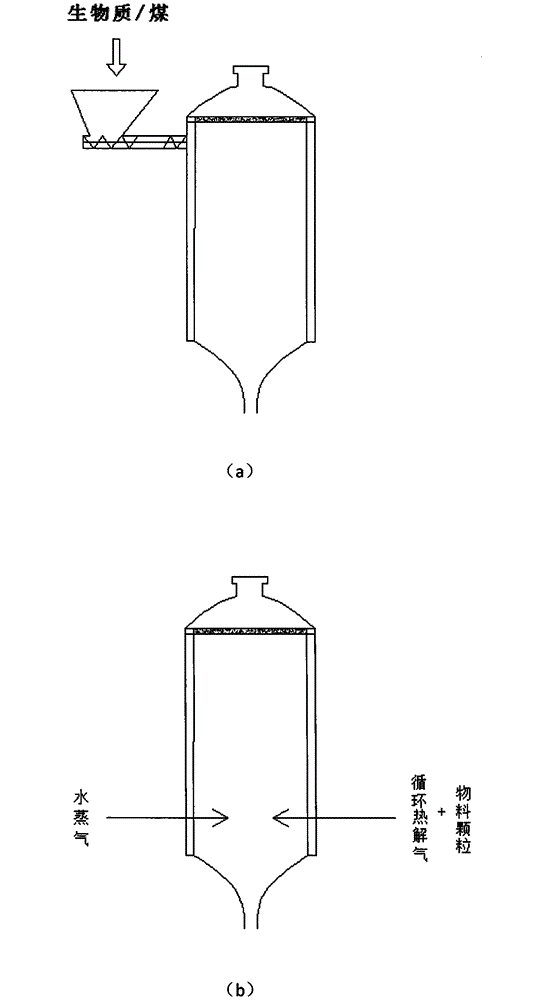

The invention provides a method that a biomass and coal are pyrolyzed rapidly to prepare liquid fuel, which belongs to the technology field of energy and chemical industry. The reaction system consists of a riser combustion reactor (10) and a biomass / coal rapid co-pyrolysis reactor. The two reactors are linked circularly through a solid heat carrier. A pyrolysis reactor consists of an upper pyrolysis reactor mixing section (5), a middle pyrolysis reactor cocurrent pyrolysis section (6) and a lower pyrolysis reactor gas-solid separation section (7); the quality ratio of the biomass and the coal is 95 / 5 to 50 / 50; the byproduct hydrogen rich gas led for circular reuse in the pyrolysis reactor is regarded as carrier gas and quenching gas; the co-pyrolysis char is completely burnt in the riser combustion reactor (10). The beneficial effects of the invention are capable of operating under normal temperature, simple in process, high in heat efficiency, high in liquid fuel yield, good in quality and suitable for the co-pyrolysis liquefaction of the solid biomass and low rank coal.

Owner:DALIAN UNIV OF TECH

New method for preparing fuel oil by co-pyrolysis of biomass and waste plastic

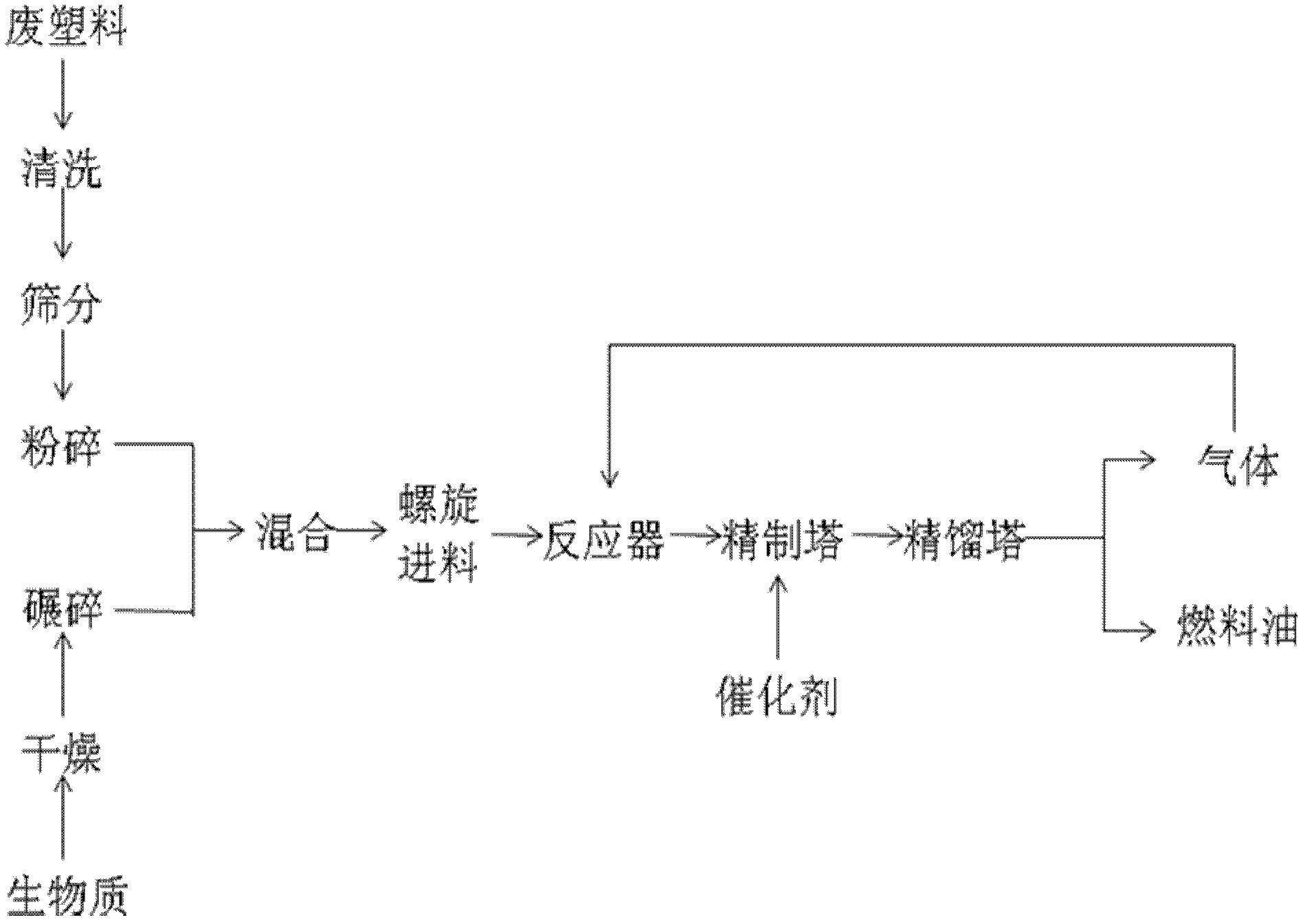

ActiveCN102618312ARenewableOvercoming and mitigating pollution problemsLiquid hydrocarbon mixture productionCatalytic reformingLiquid product

The invention discloses a new method for preparing fuel oil by co-pyrolysis of biomass and waste plastic, belonging to the field of solid waste disposal and utilization technology and biomass energy. The method comprises the following steps: mixing evenly the biomass and the waste plastic according to a certain ratio; placing the mixture in a pyrolysis reactor; heating the mixture to the needed pyrolysis temperature for a pyrolytic reaction; introducing the gas generated from the pyrolysis into a refined reaction tower for catalytic reforming; carrying out rectification on the reformed liquid product to obtain fuel oil with different cut fractions; and returning a small quantity of the combustible gas and the residues to the pyrolysis reactor for burning and being used as supplementary heat source. In the method, the biomass and the waste plastic are comprehensively utilized in co-pyrolysis and synergetic promotion is generated by the biomass and the waste plastic, so that the oil productivity and the oil quality are improved. The novel method not only resolves the environmental problems caused by white pollution, but also relieves the energy crisis caused by petrochemical resource exhaustion, thereby having wide application prospect and being able to generate huge social and economic benefits.

Owner:TSINGHUA UNIV

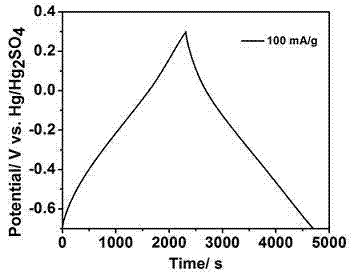

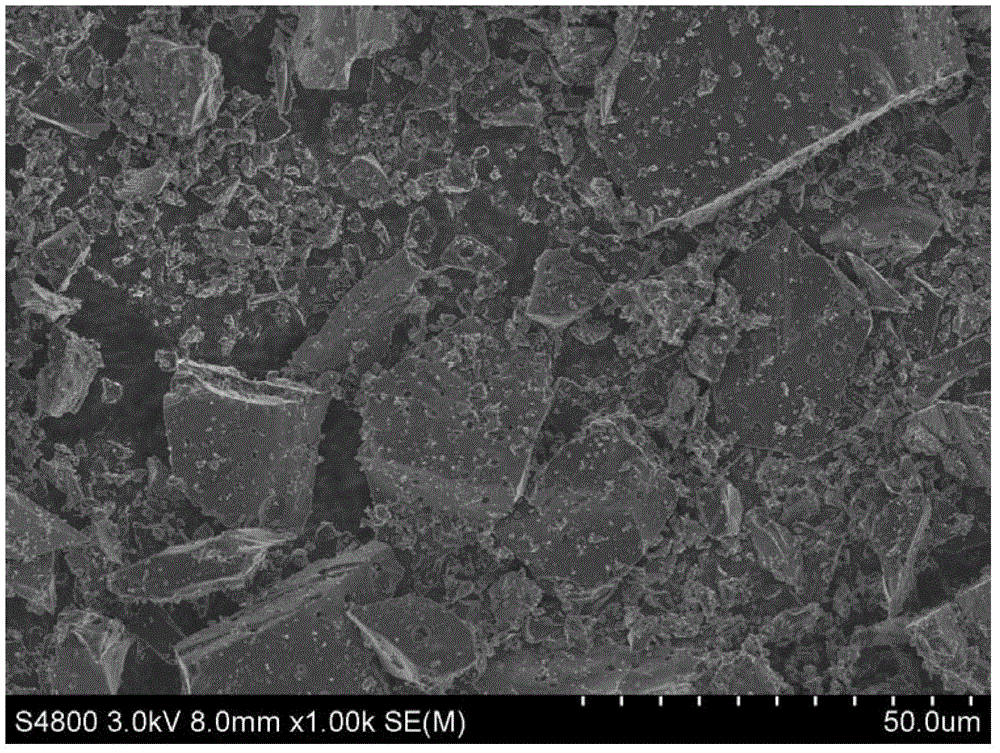

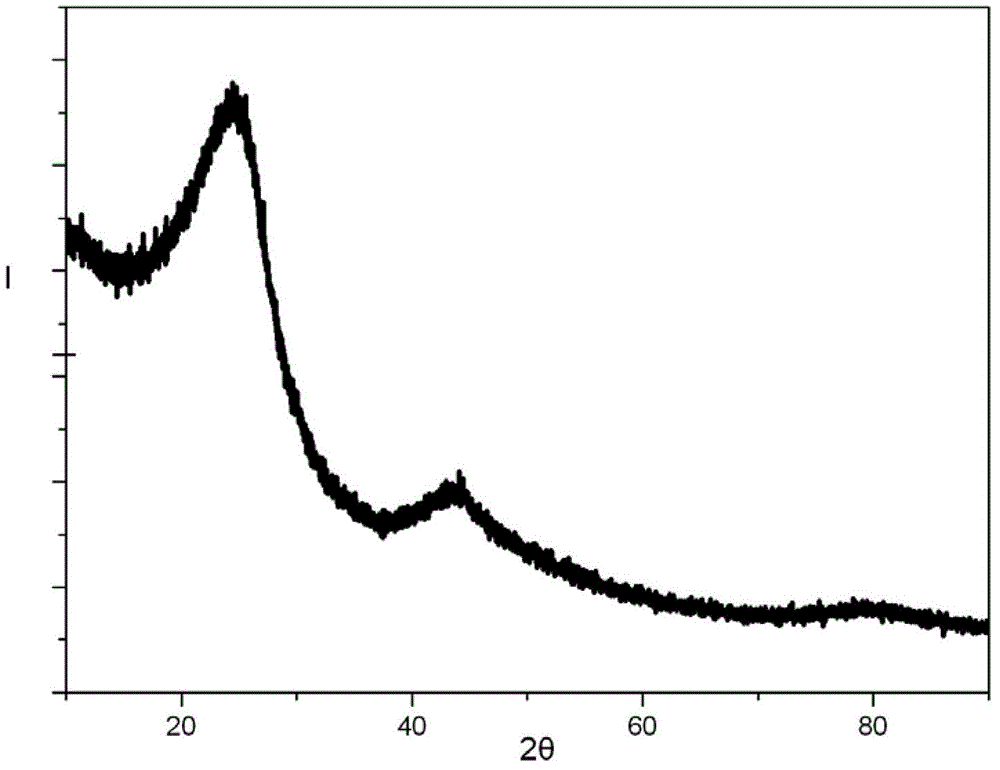

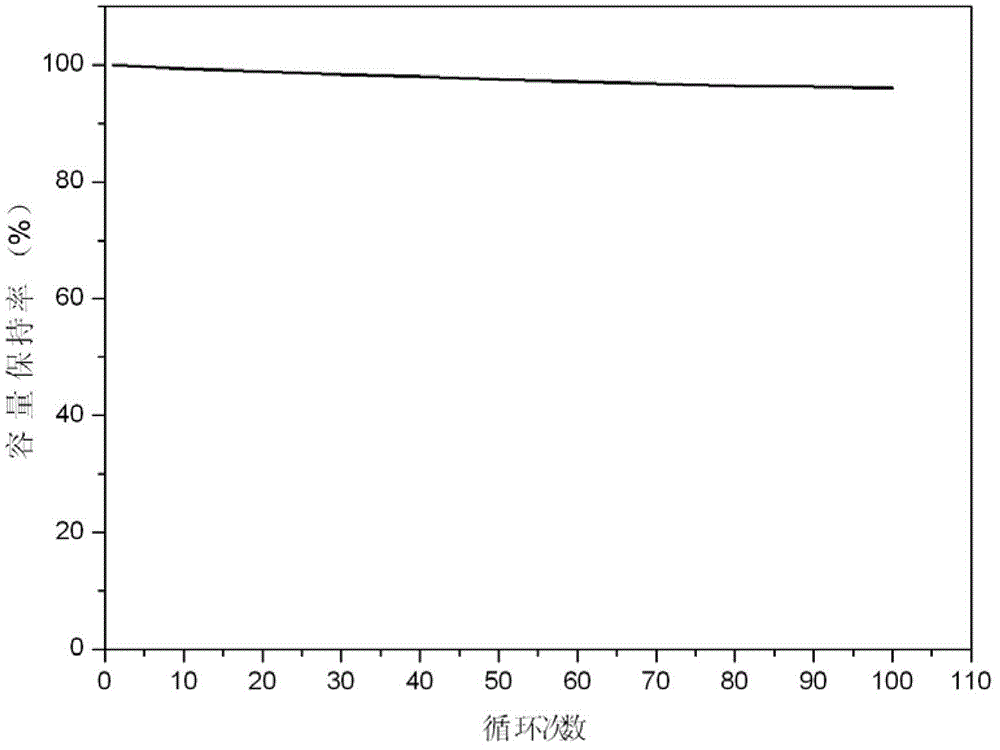

Boron and nitrogen co-doping chitosan-base activated carbon and method for preparing same

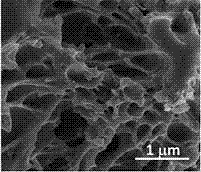

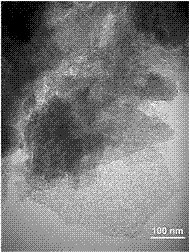

ActiveCN102951637AHigh nitrogen contentHigh specific capacitanceCarbon compoundsProtonationStrong acids

The invention provides a boron and nitrogen co-doping activated carbon which is prepared through utilizing biomass. The boron and nitrogen co-doping chitosan-base activated carbon takes chitosan and boric acid as raw materials, wherein boron in the activated carbon accounts for 1-3wt%, nitrogen in the activated carbon accounts for 4.1-9.2wt%, the specific surface area is 500-1000m<2> / g, and the pore size distribution is 0.46-2nm. The boron and nitrogen co-doping chitosan-base activated carbon takes the chitosan and the boric acid as raw materials and is prepared through co-pyrolysis. According to a method, the combining quantity of the boron in a carbon source and the dispersion degree of the boron in the carbon source are increased under the mutual action of the protonated chitosan and the boric acid, and the boron and nitrogen co-doping chitosan-base activated carbon is obtained through the co-pyrolysis. An environmental-friendly technology for preparing the activated carbon without consuming strong acid and strong alkali is realized, so that a costly and non-environmental-friendly process which consumes a great deal of activating agent and water during the traditional process for preparing the activated carbon is avoided. Moreover, the boron and nitrogen co-doping chitosan-base activated carbon has the advantages of short time consumption, simplicity in preparation technology, simplicity and easiness in equipment and the like.

Owner:DALIAN UNIV OF TECH

Method for preparing hard carbon material and lithium ion battery

ActiveCN102723492AWell developed porosityImprove cycle stabilityCell electrodesSecondary cellsPorosityBituminous materials

The invention discloses a method for preparing a hard carbon material and a lithium ion battery and aims to solve the technical problems of low lithium intercalation capacity and reversible capacity of the lithium ion battery and low high-power charging and discharging performance. The method for preparing the hard carbon material comprises the following steps of: adding an asphalt material into an organic polymer solution which contains an epoxy group to form a cracking precursor; carbonizing to form carbide; crushing to form a hard carbon matrix; adding a coating precursor for coating; and pyrolyzing. The hard carbon material is coated on a cathode of the lithium ion battery and prepared by using the preparation method which comprises the steps of formation of the cracking precursor, carbonization, crushing, coating and pyrolysis. Compared with the prior art, the invention has the advantages that by co-pyrolysis of high-molecular weight organic molecules and asphalt, the hard carbon material which is high in porosity and highly-ordered is synthesized; and the hard carbon material is high in cycle stability, simple in preparation method, low in cost and applicable to the occasions of high capacity, low temperature and high-power discharge.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +3

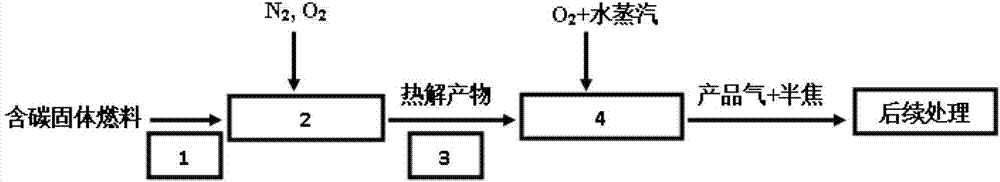

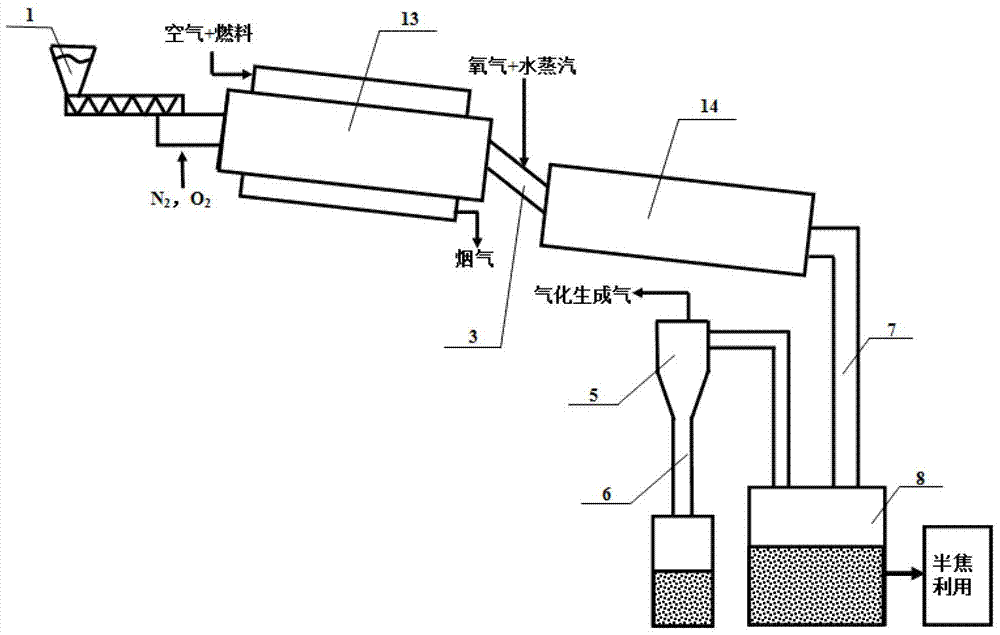

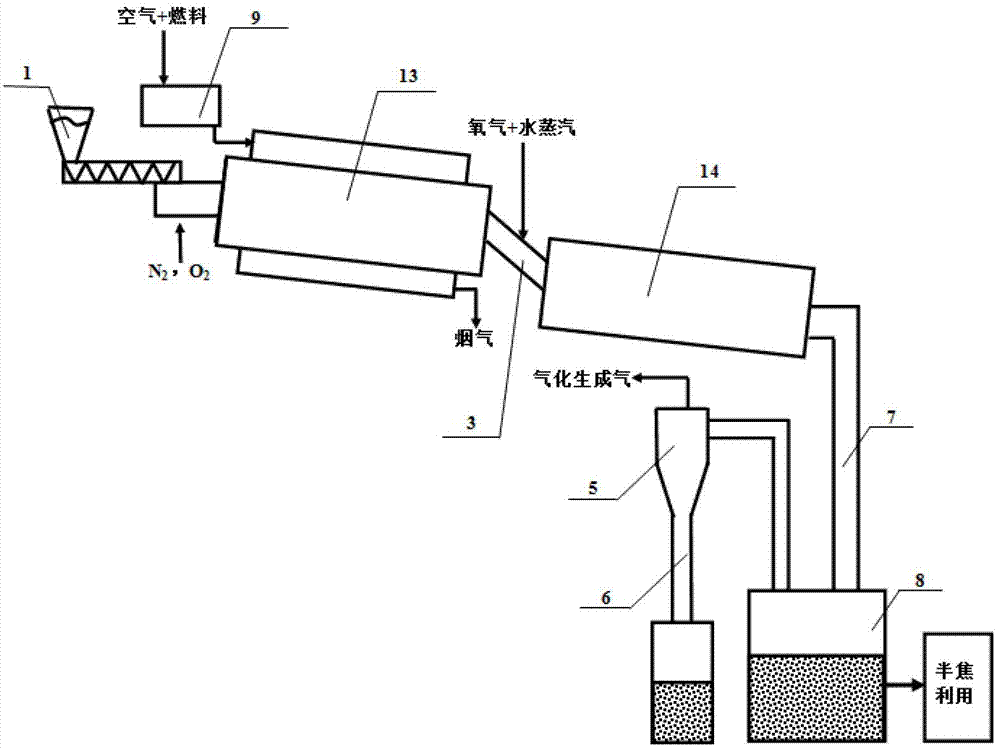

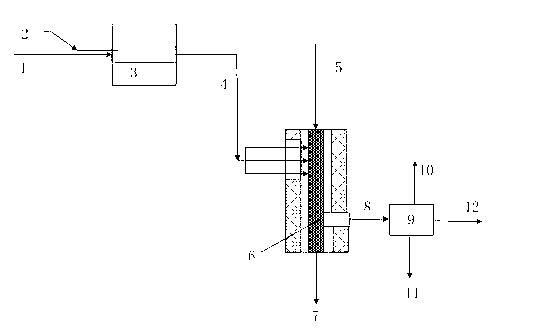

Pyrolysis and gasification method and device for preparing tar-free hydrogen-rich gas

ActiveCN103045307AReduce loadAvoid problems such as large reforming reaction processing volumeCombustible gas productionChemical industryCatalytic pyrolysis

The invention relates to the technical field of solid fuel energy and chemical industry, in particular to a pyrolysis and gasification method and device for preparing tar-free hydrogen-rich gas. The pyrolysis and gasification method for preparing the tar-free hydrogen-rich gas includes steps as follows: (1) feeding a carbonic solid raw material through a feed device to an upstream pyrolysis reactor for aerobic pyrolysis, and generating a pyrolysis gas-phase product and a solid product; and (2) feeding the pyrolysis gas-phase product and the solid product generated in the step (1) into a downstream tar pyrolysis reactor, and removing the tar through high temperature pyrolysis, partial oxidation and pyrolysis char catalytic pyrolysis reactions; and simultaneously, pyrolysis char performing partial gasification to obtain pyrolysis gas and the pyrolysis char. The method and device avoid the problem in the prior art that fuel burns to provide heat when burns volatile matters together, and causes the problems of low content of H2 and CH4 in the pyrolysis gas, large capacity for follow-up gas composition reforming reactions and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

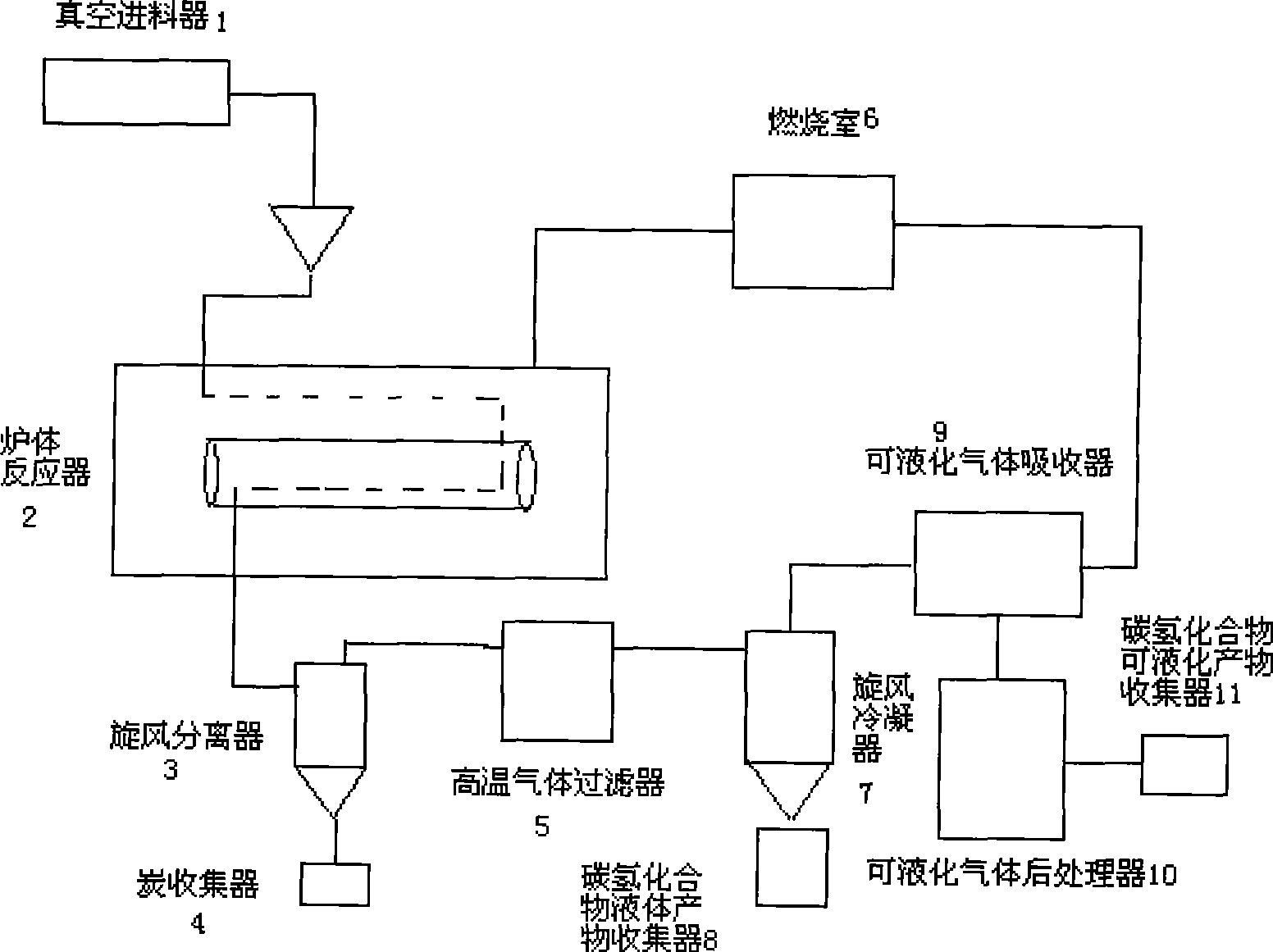

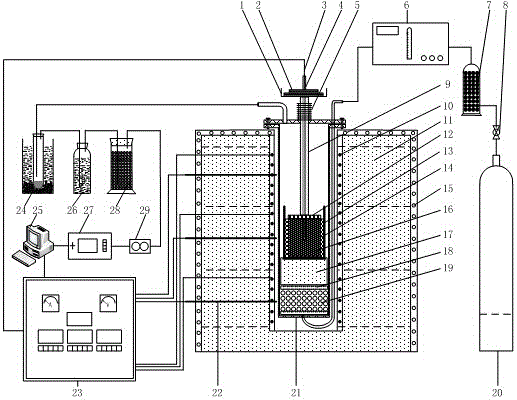

Method for preparing hydrocarbon with catalysis copyrolysis of biomass and polymer

InactiveCN101508619AImprove conversion rateSimple processHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon crackingPolystyreneCo pyrolysis

The invention provides a method for preparing carbon-hydrogen compound by catalytic co-pyrolysis of biomass and polymer. The biomass and polymer waste are taken as raw material and the carbon-hydrogen compound is prepared by catalytic co-pyrolysis technology. The pyrolysis is carried out in a pressure-proof reactor; the biomass comprises agriculture and forestry processing waste of rice hull, wheat straw, mao bamboo, corn and the like; the polymer waste comprises polystyrene, polyethylene, polypropylene, scrap tire, daily waste plastic and the like. The reaction conditions are as follows: thepressure is 2-6 KPa, the reaction gas is hydrogen or nitrogen, vacuum and no oxygen, the pyrolysis temperature is 320-450 DEG C and the time is 30 minutes to 6 hours. The conversion rate of the overall mixed waste is 55-64%, carbon-hydrogen compound gas accounts for 20-33% of overall product, carbon-hydrogen compound liquid accounts for 60-58% of overall product and residua accounts for 14-19% ofoverall product.

Owner:ZHEJIANG UNIV

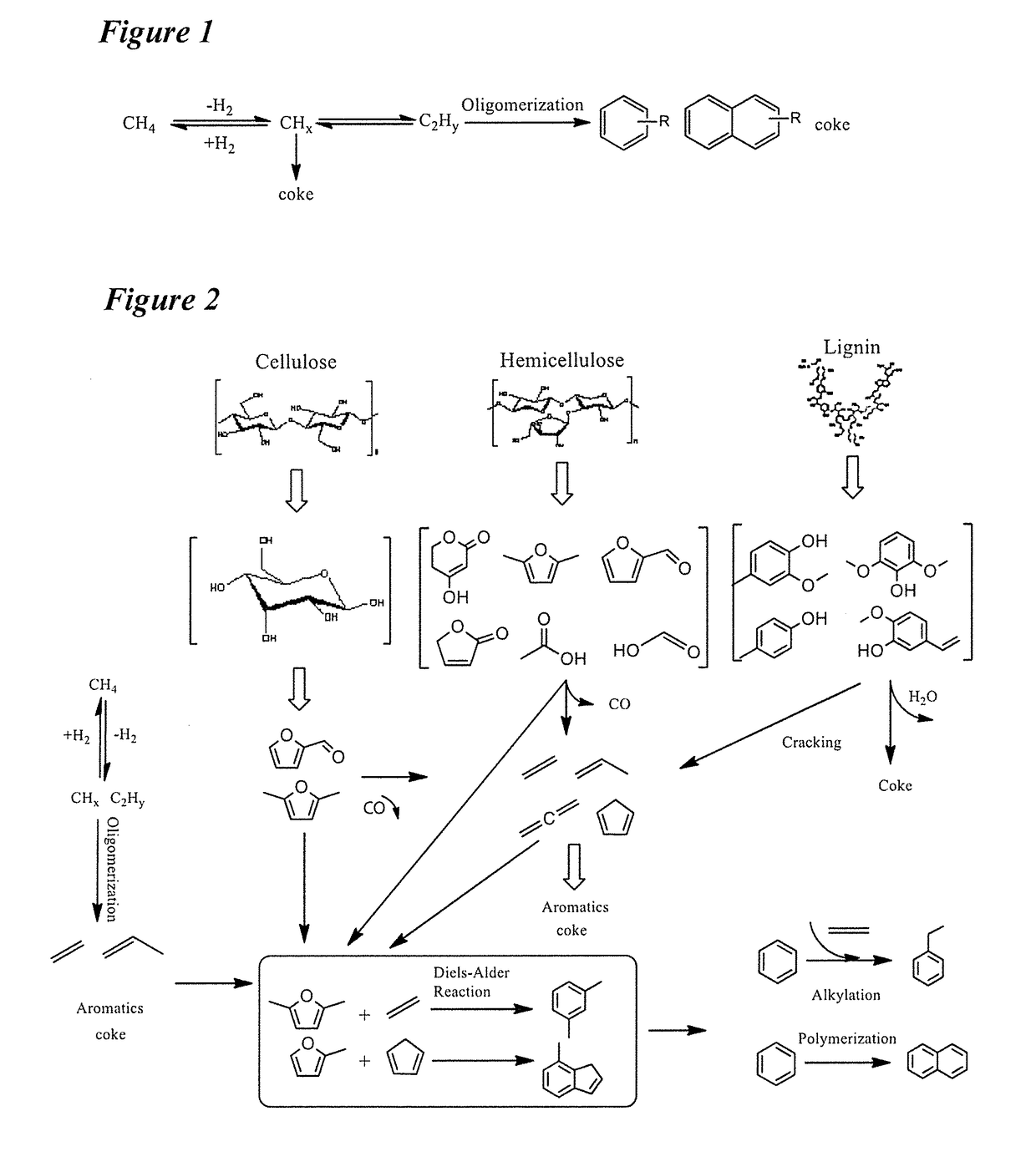

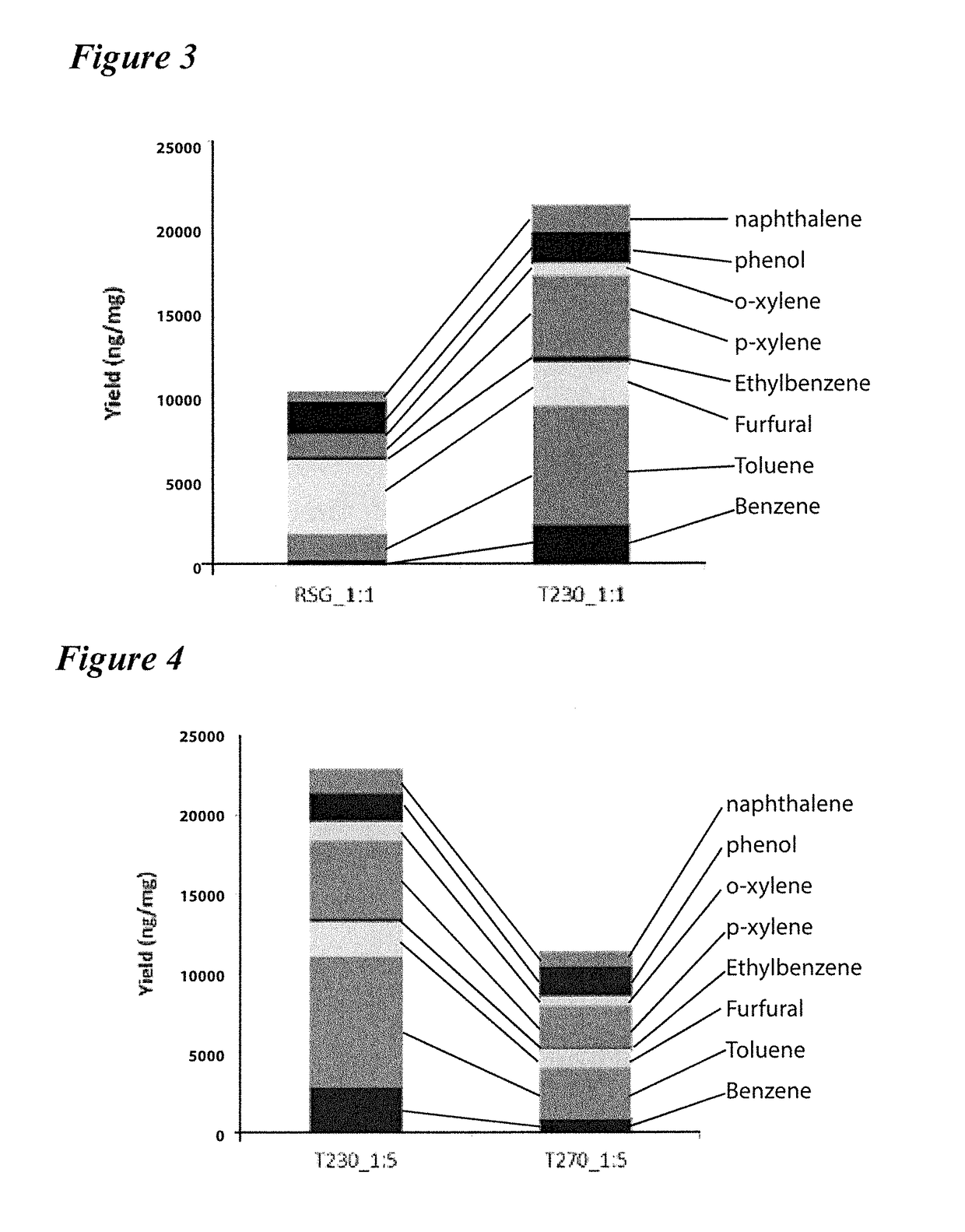

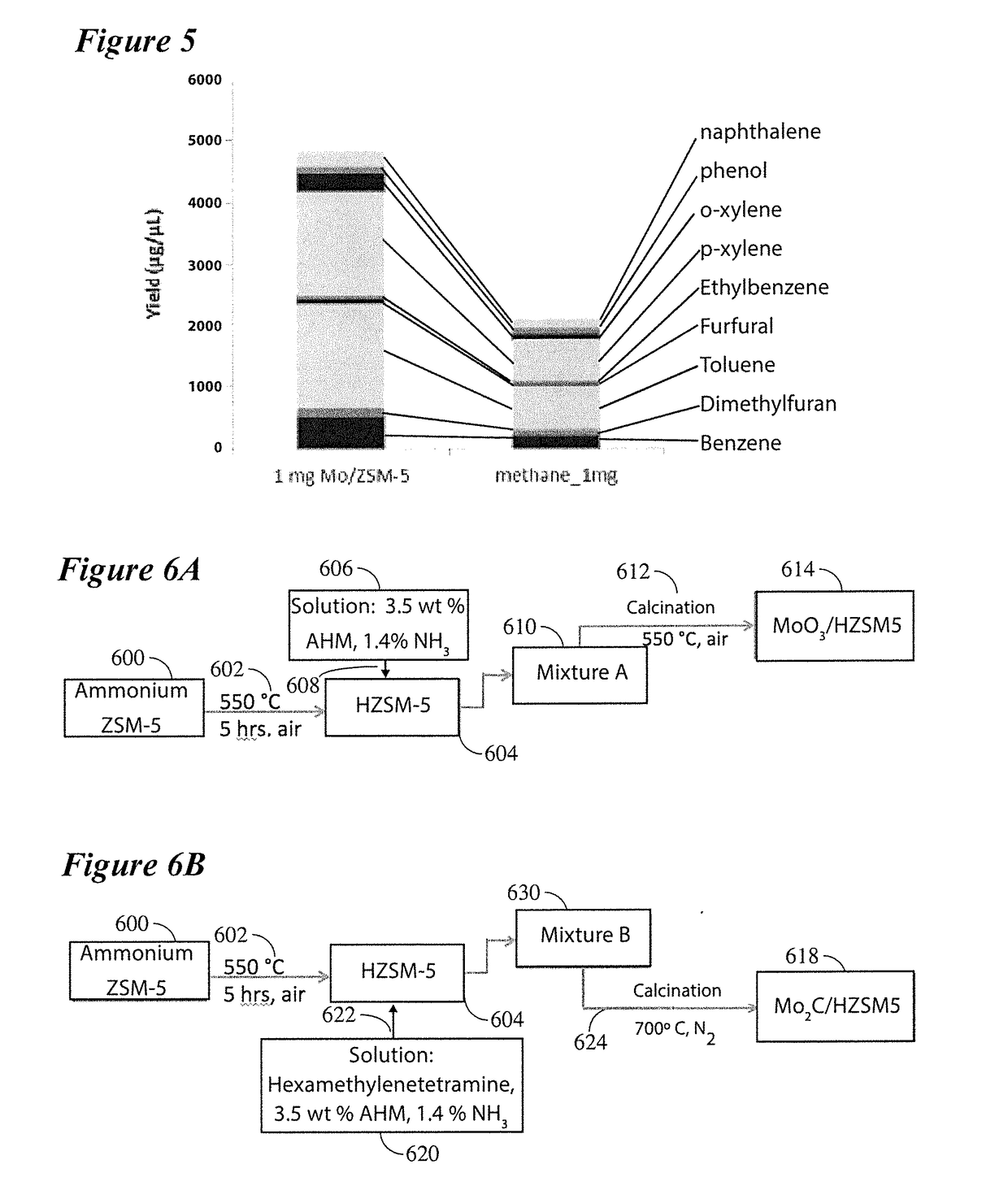

Synergistic co-pyrolysis of biomass and methane for hydrocarbon fuels and chemicals production

InactiveUS20180142159A1Low costFast reaction conditionMolecular sieve catalystsChemical industryCo pyrolysisBiological activation

There are provided herein novel catalytic approaches of producing deoxygenated bio-oil in fast pyrolysis reaction conditions. In one embodiment, HZSM-5 zeolite was modified by loading bimetallic catalyst compounds, resulting in new catalysts including MoAg / HZSM-5 and MoZn / HZSM-5. Both catalysts showed higher reactivity towards methane activation than molybdenum-only loaded catalysts. MoAg / HZSM-5 tended to catalyze dealkylation of alkylated benzenes thus yielded a product with high selectivity towards benzene. A dramatic increase in the yield of aromatic hydrocarbons was noticed when MoZn / HZSM-5 was used for catalysis of switchgrass under methane atmosphere. The final liquid hydrocarbons targeted according to this embodiment are benzene, toluene, ethylbenzene, xylene, naphthalene (BTEXN).

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

Oil producing technology for co-pyrolysis of municipal sewage sludge and agricultural waste

InactiveCN101643687AEliminate secondary pollutionSolve the problem of self-sufficiencyFatty oils/acids recovery from wasteFatty substance recoveryThermal energySorbent

The invention discloses an oil producing technology for co-pyrolysis of municipal sewage sludge and agricultural wastes, which comprises the following steps: mixing the municipal sewage sludge and theagricultural wastes in proportion; heating the mixture of the municipal sewage sludge and the agricultural wastes for pyrolyzing under the condition of air insulation after drying the mixture properly, and then forming pyrolysis gas product and pyrolysis solid product; and then carrying out condensation and cooling on the pyrolysis gas product to obtain oil-soluble liquid and water-soluble liquidand non-condensable combustible gas, the oil-soluble liquid and the water-soluble liquid can be further processed into useful down-stream product, and the non-condensable combustible gas is used forsupplying heat for pyrolyzing furnace; grinding on the pyrolysis solid product as an active carbon adsorbent. The oil producing technology of the invention solves the self-supporting problem of the heat energy needed in sewage sludge pyrolysis, changes waste into wealth, can meet balance of self-energy, and obtains fuel oil and water-soluble organism, and carbon powder of the solid product also can be taken as an adsorbent which can be widely used in the following fields, such as sewage treatment, soil improvement and flower gardening and the like. The oil producing technology of the inventionalso has the characteristics of reduction, recycling, high value-added and low cost of the municipal sewage sludge.

Owner:CHINA UNIV OF MINING & TECH

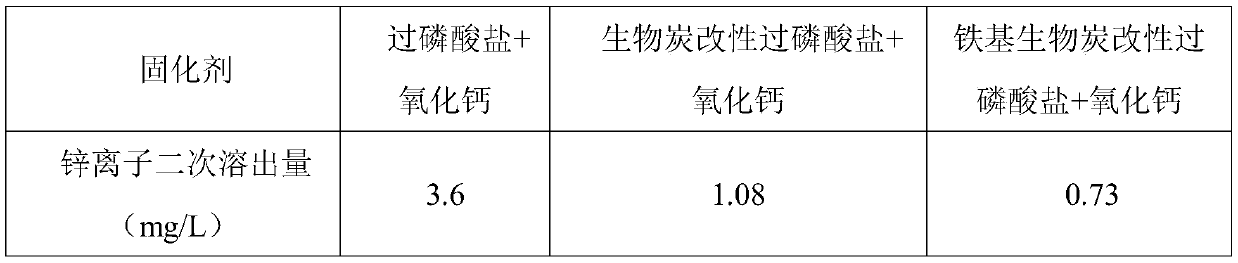

Heavy metal polluted soil solidification and repairing composite compound and solidification and repairing method

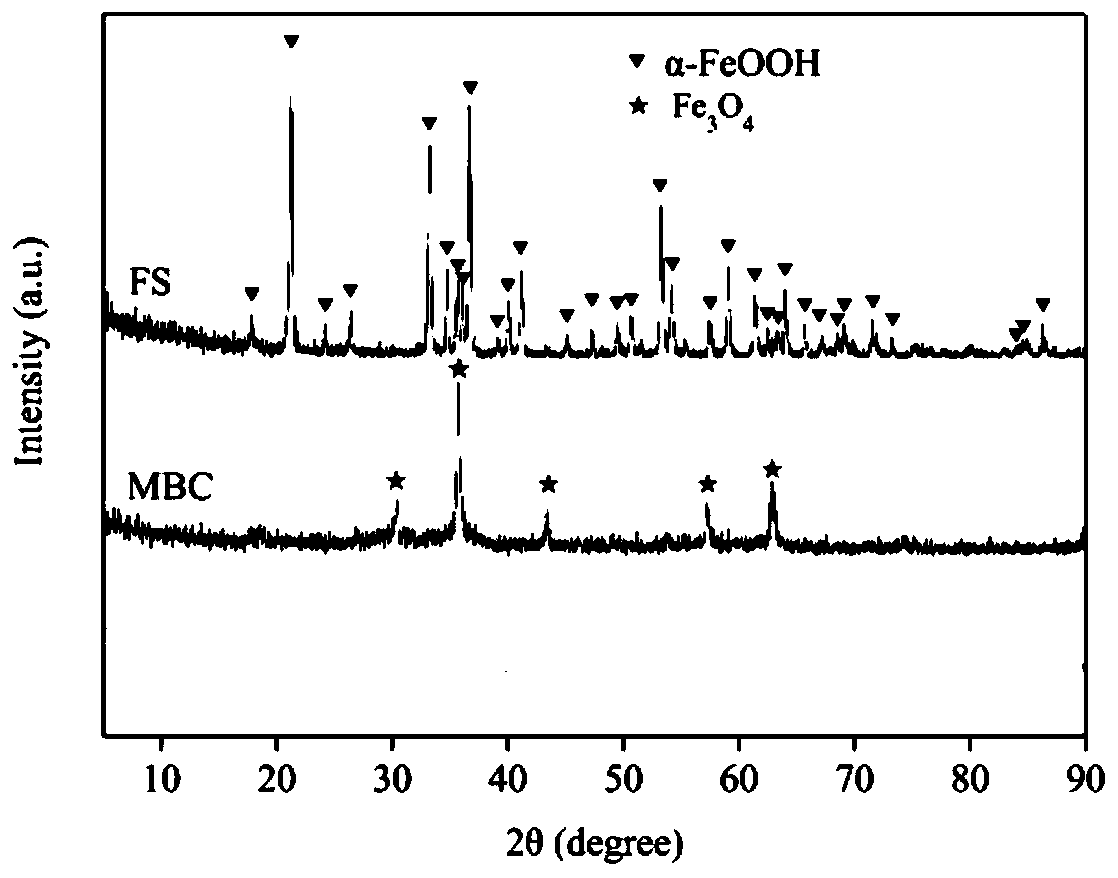

ActiveCN110699084AInhibit oxidative decompositionReduced risk of secondary dissolutionOther chemical processesContaminated soil reclamationIron saltsSoil heavy metals

The invention discloses a heavy metal polluted soil solidification and repairing composite compound and a solidification and repairing method. The composite compound comprises the following componentsin percentage by mass: 20-40% of quicklime and 60-80% of an iron-based biochar modified phosphate mineral, wherein the iron-based biochar modified phosphate mineral is obtained by uniformly mixing and drying an iron salt and biomass, further mixing the mixture with a phosphate mineral uniformly and performing co-pyrolysis. The method for solidifying and repairing heavy metal polluted oil by usingthe composite compound comprises the following steps: firstly, uniformly mixing the iron-based biochar modified phosphorate mineral with quicklime so as to obtain the heavy metal polluted soil solidification and repairing composite compound; applying the composite compound into heavy metal polluted soil, adding water, and performing uniform stirring; and performing maintenance of the best standards, so as to complete solidification repairing on the heavy metal polluted soil. By adopting the heavy metal polluted soil solidification and repairing composite compound, secondary dissolution of heavy metals can be greatly avoided, and the long-term stability of solidification of the heavy metal polluted soil can be greatly enhanced.

Owner:SOUTHEAST UNIV

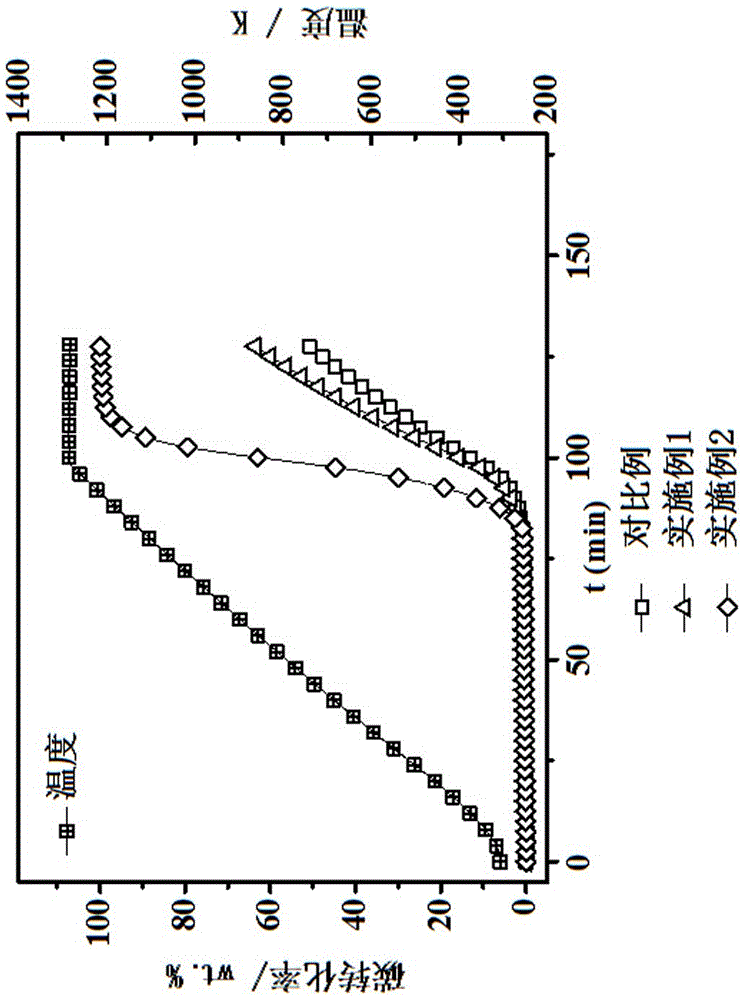

Method for preparing activated charcoal from paper mill sludge and pine through co-pyrolysis

The invention discloses a method for preparing activated charcoal from paper mill sludge and pine through co-pyrolysis. The method is characterized by comprising the following steps: (1) pretreating paper mill sludge; (2) airing and grinding pine sawdust; (3) fully mixing the sludge and the pine sawdust; (4) arranging the mixture in a pyrolyzing furnace feeding hopper, and performing constant temperature pyrolysis in an inert atmosphere; (5) heating for reacting at constant temperature until no gas is generated, and naturally cooling to room temperature, thereby obtaining charcoal; and (6) putting the charcoal into a sulfuric acid solution with the concentration of 2.5-3.5 mol / L, introducing nitrogen, reacting at the constant temperature of 500-600 DEG C for 20-40 minutes, and naturally cooling to room temperature, thereby obtaining the activated charcoal. The activated charcoal is prepared by a paper mill sludge and pine co-pyrolysis process, a sludge drying process is not needed, chemical components of adsorbents are improved, and a certain effect of activating the charcoal can be achieved by steam formed by moisture in the sludge at high temperature, so that the adsorption capacity of the charcoal is improved, and an ideal adsorption effect is obtained.

Owner:ZHEJIANG MARINE DEV RES INST

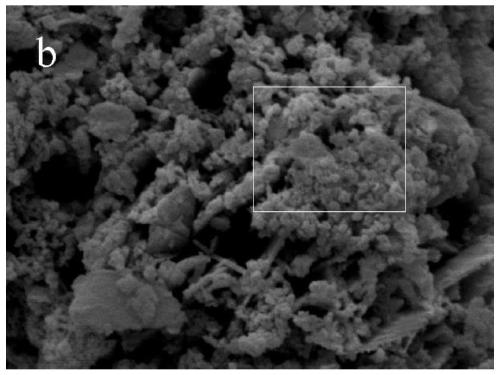

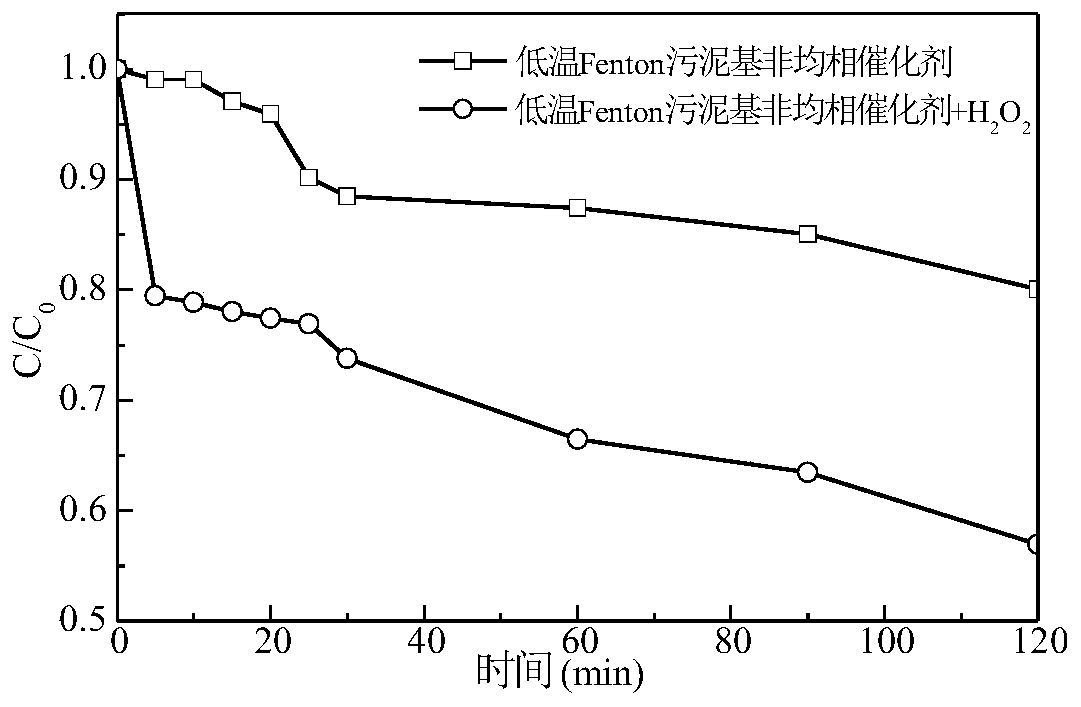

Preparation and application of hierarchical pore-low valent iron Fenton sludge-based heterogeneous catalyst

ActiveCN111359610AImplement resourcesReduce disposal costsWater treatment compoundsWater contaminantsPtru catalystReduction treatment

The invention discloses preparation and application of a hierarchical pore-low valent iron Fenton sludge-based heterogeneous catalyst, and belongs to the technical field of water treatment catalysis.The preparation process of the heterogeneous catalyst comprises the following steps: taking Fenton sludge as a raw material, mixing the raw material with biochemical sludge, then carrying out co-pyrolysis to obtain low valent iron biochar; and constructing pores with different sizes in the low valent iron biochar by utilizing a steam explosion method so as to obtain the hierarchical pore-low valent iron Fenton sludge-based heterogeneous catalyst. The heterogeneous catalyst is used for replacing homogeneous Fe<2+> to realize efficient degradation of organic pollutants in wastewater. The heterogeneous catalyst has the advantages of wide pH value application range, high catalytic efficiency and strong stability. The heterogeneous catalyst has the advantages that the reduction treatment and resource utilization of dangerous solid waste namely Fenton sludge can be realized, the cost of exogenous iron and the subsequent treatment cost of Fenton sludge can be saved, and the heterogeneous catalyst has a wide prospect in organic wastewater treatment.

Owner:CHINA UNIV OF MINING & TECH

Co-pyrolysis method for alkaline residues and discarded printed wiring board

InactiveCN108413400AEfficient recyclingEmission reductionIncinerator apparatusMetallic materialsEngineering

The invention discloses a co-pyrolysis method for alkaline residues and a discarded printed wiring board. The method includes the steps that the discarded printed wiring board is subjected to heat treatment, soldering tin is removed and electronic components are dismantled; the discarded printed wiring board subjected to heat treatment and the alkaline residues are mixed and then are put into an atmosphere pyrolyzing furnace for oxygen-deficient non-sufficient combustion; after a pyrolysis volatile component is washed and purified, pyrolysis oil and pyrolysis gas are recovered, the pyrolysis gas serves as fuel gas to return to the atmosphere pyrolyzing furnace, a pyrolysis residue phase component is screened and separated, an oversize component is crushed and winnowed, and a metallic material and an inorganic nonmetallic material are recovered; and a screen underflow component returns to the atmosphere pyrolyzing furnace to be recycled. By adoption of the method, the alkaline residuesand the discarded printed wiring board are cooperatively treated, and various sorts of metal, nonmetal and organic matter in the discarded printed wiring board are fully recycled; and moreover, the alkaline residues can be fully utilized, the characteristics of being environmentally friendly and low in energy consumption are achieved, and full-resourcing clean recycling of the alkaline residues and the discarded printed wiring board is truly realized.

Owner:CENT SOUTH UNIV

Catalyst for coal gasification, preparation method and application thereof

The invention relates to a catalyst for coal gasification, a preparation method and application thereof. The preparation method of the catalyst for coal gasification comprises the step of carrying out co-pyrolysis on feed coal and biomass rich in alkali metal K and Na. The invention provides a preparation method of the catalyst for coal gasification. The preparation method has simple process, is low-cost, and is green and environment-friendly. In addition, technical problems in the prior art, such as alkali metal recovery, recycling and cost, which restrain the catalytic coal gasification process, are solved.

Owner:TAIYUAN UNIV OF TECH

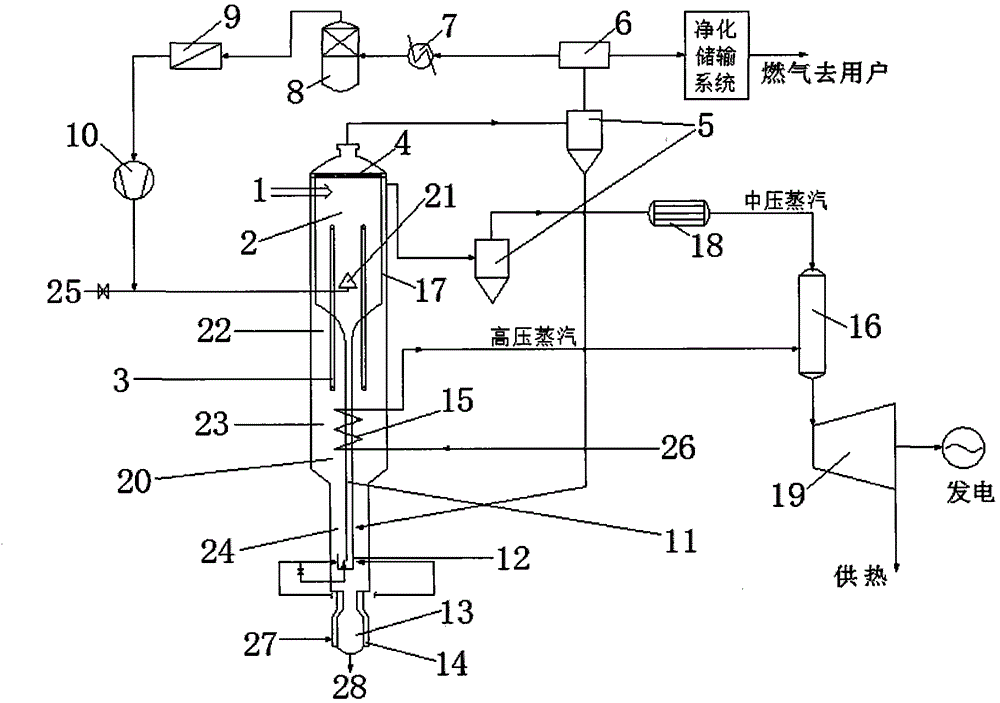

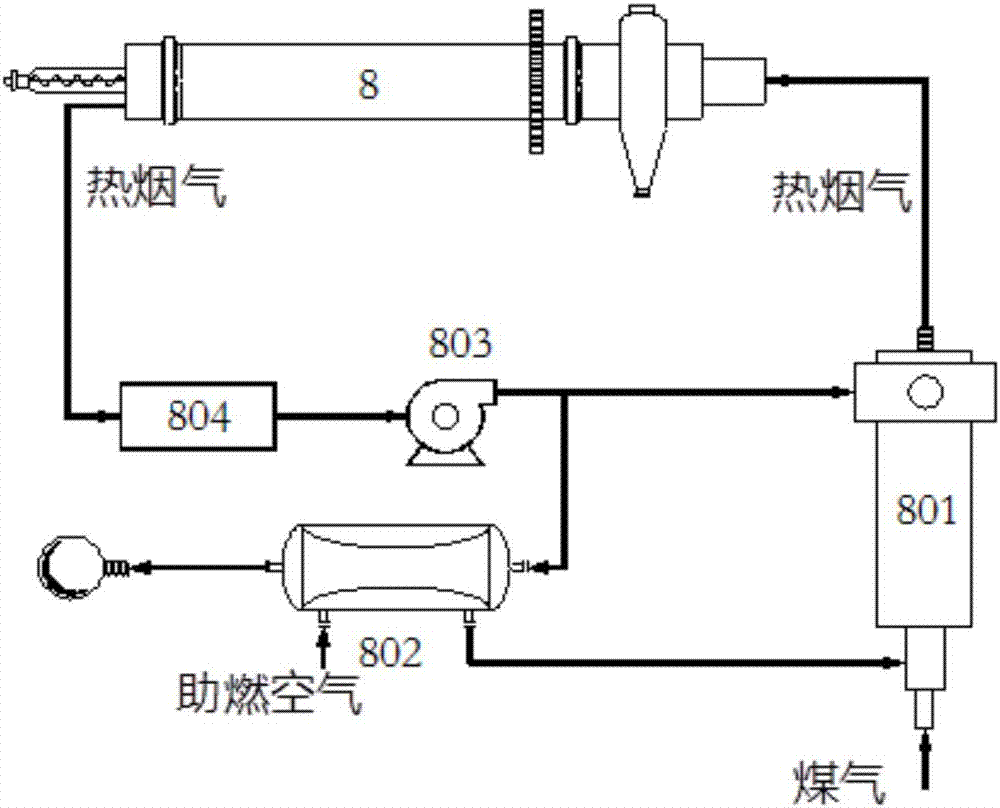

Heat pipe heating fluidized bed biomass and coal co-pyrolysis system

InactiveCN104974772AImprove gasification efficiencyAddress seasonality in supplyDirect heating destructive distillationBiofuelsThermal energyCombustion

The invention relates to a heat pipe heating fluidized bed biomass and coal co-pyrolysis system. A heat pipe heating fluidized bed biomass and coal co-pyrolysis device is utilized, the main body is divided into two parts, the upper part is a pyrolysis furnace, and the lower part is a combustion furnace; a high temperature heat pipe vertically penetrates through the pyrolysis furnace and the combustion furnace, one end of the combustion furnace is a heat absorption section for absorbing heat released by semi-coke combustion, and then the heat is upwards transferred to the pyrolysis furnace; one end of the pyrolysis furnace is a heat release section for releasing heat for indirect pyrolysis of biomass and coal. The system overcomes the defect of low calorific value of pyrolysis gas generated by existing up-absorption or down-absorption direct pyrolysis (can reach 4300kcal / Nm<3>). The waste heat of ash is sufficiently utilized to preheat air, the waste heat of pyrolysis gas and smoke is utilized to generate water vapor, a part of the water vapor is used as a pyrolysis gasification agent, and the other part of the water vapor can be used for generating power and supplying heat. The system realizes multistage utilization of heat energy, and the device is simple in structure, high in heat transfer efficiency and high in reliability.

Owner:北京中矿科能煤炭地下气化技术研究中心

Coal pyrolysis method for increasing oil yield by introducing fusel

InactiveCN102746861ARealize comprehensive utilizationHigh yieldDirect heating destructive distillationAlcoholReaction temperature

The invention belongs to the technical field of chemical engineering. A Coal pyrolysis method for increasing oil yield by introducing fusel comprises the following steps: (1) injecting the fusel through pumping into a preheater and preheating the fusel into steam; (2) introducing the fusel steam or fusel steam mixed with a carrier gas into a coal pyrolysis reactor, and carrying out a coal pyrolysis reaction on the fusel and coal at a reaction temperature of 450-650 DEG C for 10-30min; (3) purifying and condensing a reaction product of raw coke oven gas, recovering tar, and sending coal gas out; and (4) discharging a product semi coke through bottom of a moving-bed reactor. According to the invention, fusel is introduced into a low-temperature coal pyrolysis reaction system for the first time; pyrolysis products of the fusel in the reactor react with debris free radicals generated by coal pyrolysis to generate a free radical stable product, so as to improve oil yield of the coal pyrolysis; meanwhile, due to existence of effects like hydrogenation in the coal pyrolysis process, portion of the oil product is converted into a light fraction, and utilization of fusel is realized.

Owner:DALIAN UNIV OF TECH

Method for improving yield of coal microwave pyrolysis tar by using methane and carbon dioxide as reactant gases

InactiveCN105925317AHigh activityHigh yieldGasification catalystsGasification processes detailsMicrowave pyrolysisHydrogen

The invention discloses a method for improving the yield of coal microwave pyrolysis tar by using methane and carbon dioxide as reactant gases. The method is characterized in that: methane of which the volume ratio is 50-90% and carbon dioxide of which the volume ratio is 10-50% are used as reactant gases, methane and carbon dioxide are mixed together, then the mixed gas is introduced into a pyrolysis reactor and is subjected to co-pyrolysis with a mixture containing coal of which the mass percent is 30-90% and semi-coke of which the mass percent is 10-70% under the condition that the microwave heating temperature is 400-700 DEG C for a constant temperature time of 10-40min, volatile products after pyrolysis leave the reactor and then enter a condensing system for gas-liquid separation, and then a tar product is collected. The method disclosed by the invention has the advantages that the semi-coke is used as a catalyst, and methane and carbon dioxide replace hydrogen and serve as hydro-pyrolysis reactant gases, so that the yield of the pyrolysis tar can be obviously improved, and the hydro-pyrolysis cost is reduced; and the semi-coke is used as a catalyst for activating methane and carbon dioxide, the catalyst does not need to be recovered and separated from the product, the semi-coke is generated continuously during pyrolysis, and the problem of catalyst deactivation is avoided.

Owner:HENAN POLYTECHNIC UNIV

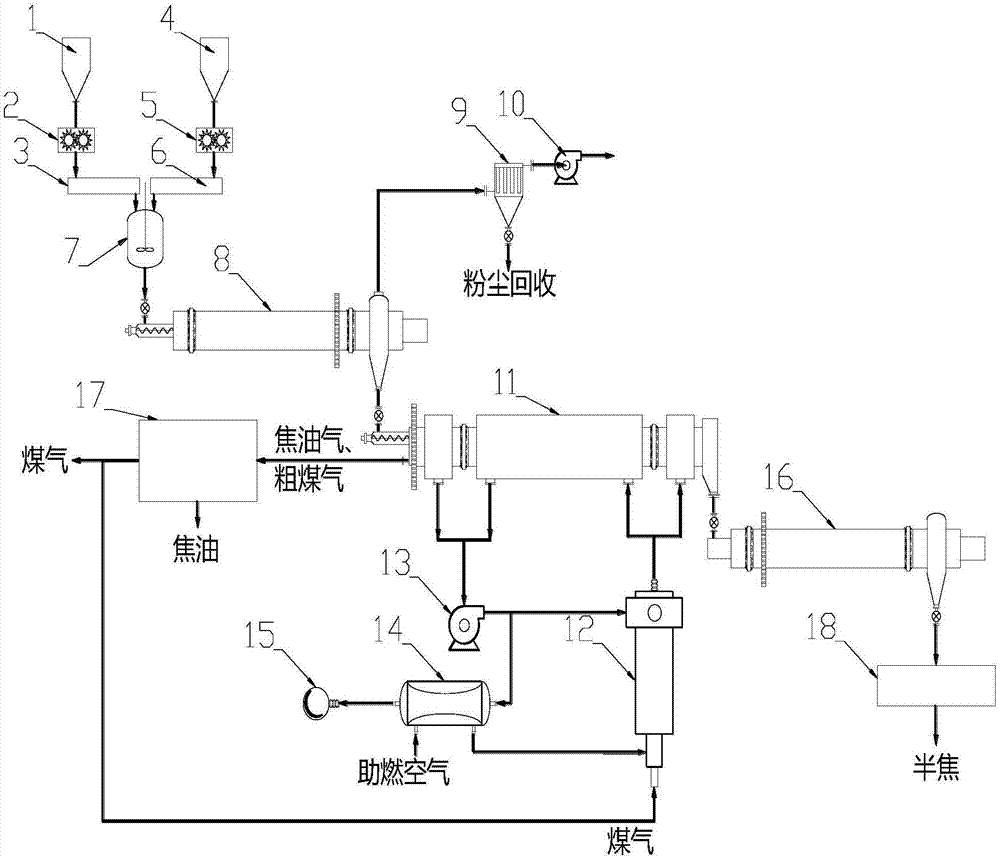

Method for co-pyrolysis of solid waste and coal

ActiveCN107057730ASolve resource problemsNo need for additional investmentProductsReagentsTarCo pyrolysis

The invention discloses a method for co-pyrolysis of solid waste and coal. The method comprises the following steps: mixing solid waste with coal metered, drying, heating, carrying out destructive distillation pyrolysis, so as to obtain solid-state pyrolysis product semi-coke and gas-state pyrolysis product coal gas containing tar gas; cooling and sieving the semicoke, so as to obtain semi-coke with different particle sizes; and carrying out oil-gas separation on coal gas containing tar gas, so as to obtain tar and coal gas, wherein partial coal gas is taken as a heat source for pyrolysis of mixed materials, and rest coal gas is taken as a coal gas product. According to the method, the co-pyrolysis of solid waste and coal is realized by virtue of a horizontal rotary kiln, and the semi-coke, tar oil and coal gas are obtained after the pyrolysis of the mixed materials in the rotary kiln at a certain temperature. The method has the beneficial effects that a technical process is simple, the operation is reliable and stable, the problem that coal gas produced by pyrolysis of solid waste is less than heat required by the pyrolysis of solid waste is solved, and the method has obvious superiority on the treatment of solid waste with great composition change.

Owner:西安三瑞实业有限公司

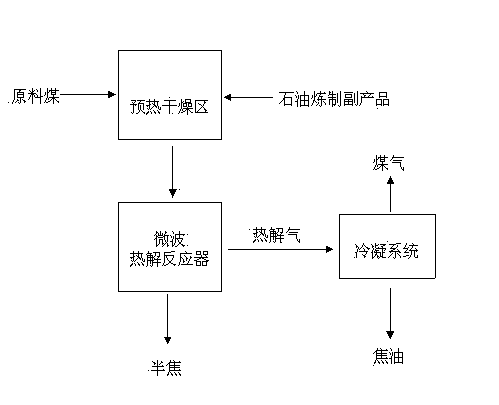

Combined process for co-pyrolysis of coal and petroleum refining by-product

ActiveCN103788969AHigh yieldIncrease polaritySpecial form destructive distillationMicrowave pyrolysisTar

The invention discloses a combined process for co-pyrolysis of coal and petroleum refining by-products. Feed coal is mixed with petroleum refining by-products a preheating drying zone; the preheated mixture of coal and petroleum refining by-products is sent into a microwave pyrolysis reactor to generate the semi coke and pyrolysis gas; and the pyrolysis enters into a condenser system for separation into tar and coal gas. The combined process can realize simultaneous pyrolysis of coal and petroleum refining by-products in the same temperature range to generate synergistic effect, so as to increase the yield of coal tar and improve the quality of coal tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biochar prepared by co-pyrolysis of excess sludge and hazelnut shells and photocatalytic modification method of biochar

InactiveCN112387269AReduce use costSignificant areaWater/sewage treatment by irradiationWater treatment compoundsPhoto catalyticCo pyrolysis

The invention relates to biochar prepared by co-pyrolysis of excess sludge and hazelnut shells and a photocatalytic modification method of the biochar. The method comprises the following steps: dryingand crushing the excess sludge and hazelnut shells, proportionally mixing, adding a potassium carbonate solution, soaking, drying, carrying out vacuum pyrolysis, sequentially washing with diluted hydrochloric acid and deionized water, and drying to obtain the biochar. The method comprises the following steps: dissolving zinc chloride in deionized water, adding a corresponding amount of sodium hydroxide under a stirring condition, completely dissolving and adding biochar, placing the prepared solution in a glass bottle, standing at a constant temperature under a closed condition until the reaction is complete, and cooling to room temperature to obtain the nano ZnO composite biochar material. According to the method, the residual sludge and hazelnut shells containing a large amount of organic matters are mixed and pyrolyzed to prepare the biochar, and the activated pore-forming method of potassium carbonate solution soaking is combined, so that the pyrolysis process is easier to occur,compared with crop pyrolysis modes such as direct incineration, pyrolysis and addition of corn straw, the method is simple, and the biochar product which is high in yield, large in specific surface area and good in porosity and has photocatalytic performance is more favorably formed.

Owner:NORTHEASTERN UNIV

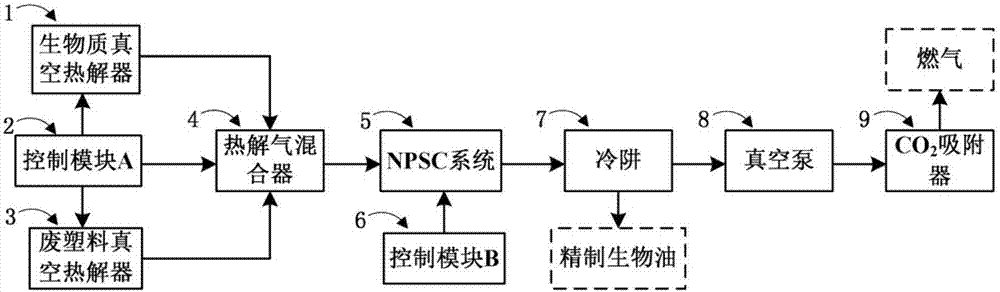

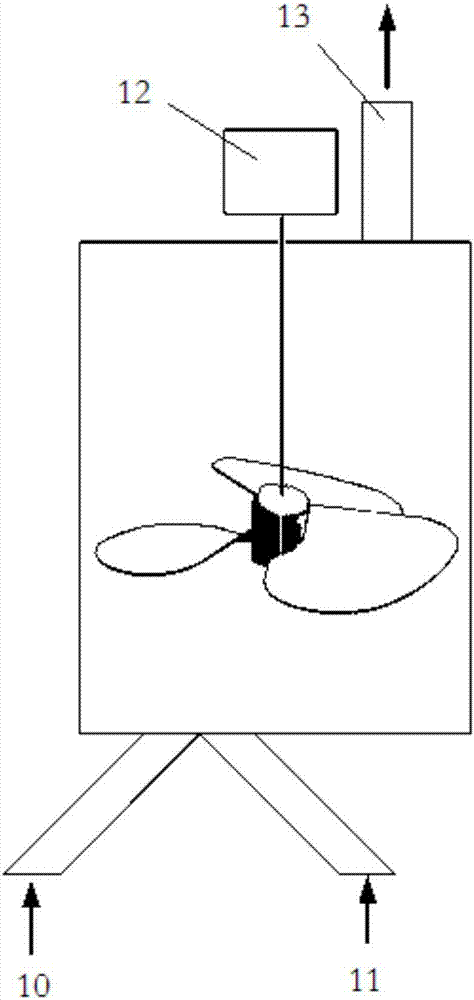

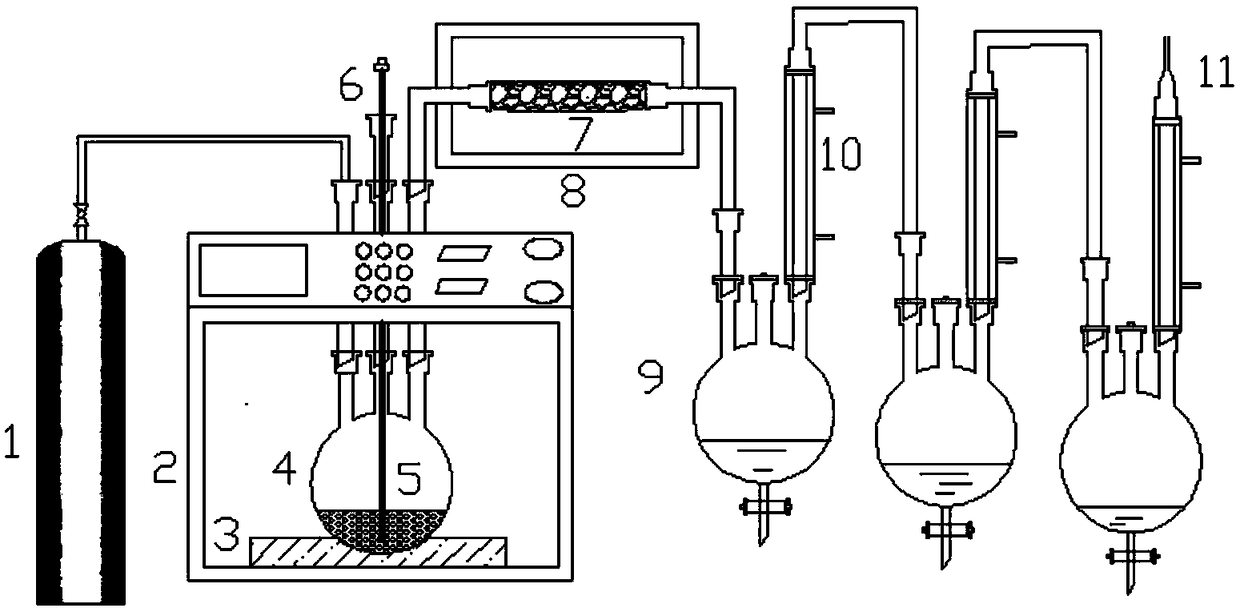

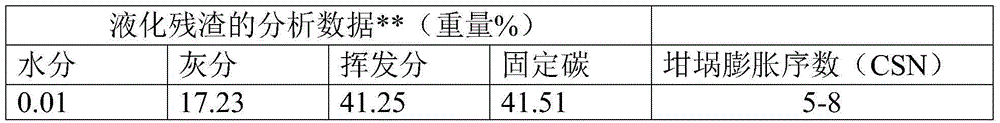

Device for preparing bio-oil and fuel by using biomass and waste plastic and use method

PendingCN107987864AImprove conversion efficiencyImprove qualityProductsReagentsNew energyProduct gas

The invention belongs to the field of development, utilization and study of new energy sources, and relates to a device for preparing bio-oil and fuel by using biomass and waste plastic and a use method. The device comprises a biomass vacuum pyrolyzer, a waste plastic vacuum pyrolyzer, a pyrolysis gas mixer, a control module A, a plasma synergistic catalyzing system, a control module B, a cold trap, a vacuum pump and a CO2 (carbon dioxide) adsorber, wherein the biomass vacuum pyrolyzer is used for decomposing biomass; the waste plastic vacuum pyrolyzer is used for decomposing waste plastic; the pyrolysis gas mixer is used for receiving the gas produced by the biomass vacuum pyrolyzer and the waste plastic vacuum pyrolyzer; the control module A is used for respectively adjusting the temperatures and heating rates of the biomass vacuum pyrolyzer, the waste plastic vacuum pyrolyzer and the pyrolysis gas mixer; the plasma synergistic catalyzing system is used for catalyzing the gas produced by the pyrolysis gas mixer. The device has the advantage that the defects in the existing method for preparing the bio-oil or fuel by using the co-pyrolysis of the biomass and the waste plastic canbe effectively overcome.

Owner:YANCHENG INST OF TECH

Preparation device and method of biomass crucible coke

ActiveCN106635084AEasy to installThe method is easy to operateBiofuelsSpecial form destructive distillationCrucibleCo pyrolysis

The invention discloses a preparation device and method of biomass crucible coke. The device comprises a heating furnace, a reaction tube device, a protective gas supply device, a pressurizing device and a tail gas analyzing and processing device. The preparation method includes: preparing raw materials, loading the materials, pressurizing in a sealed manner, removing air, performing co-pyrolysis, forming the coke and the like. The preparation device and method has the advantages that by the preparation device and method, the high-quality biomass coke can be obtained, heat impact of protective gas on a crucible is reduced, tail gas component data can be used for the research of the biomass and coal mixed co-pyrolysis mechanism, the device is simple to mount, the method is simple, and environment pollution is avoided; in addition, the problem that the utilization approaches of the biomass which is used by the preparation device and method and is the only renewable clean carbon source are few is solved; another biomass utilization approach is provided to solve problems such as current high-quality coal resource shortage and environment pollution, and energy conservation and emission reduction of steel industry can be promoted.

Owner:CHONGQING UNIV

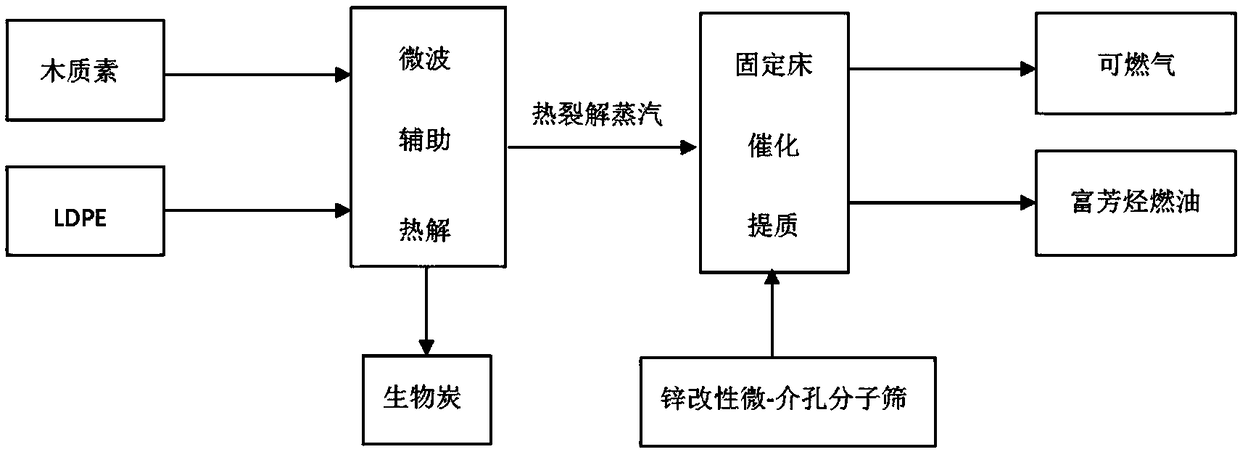

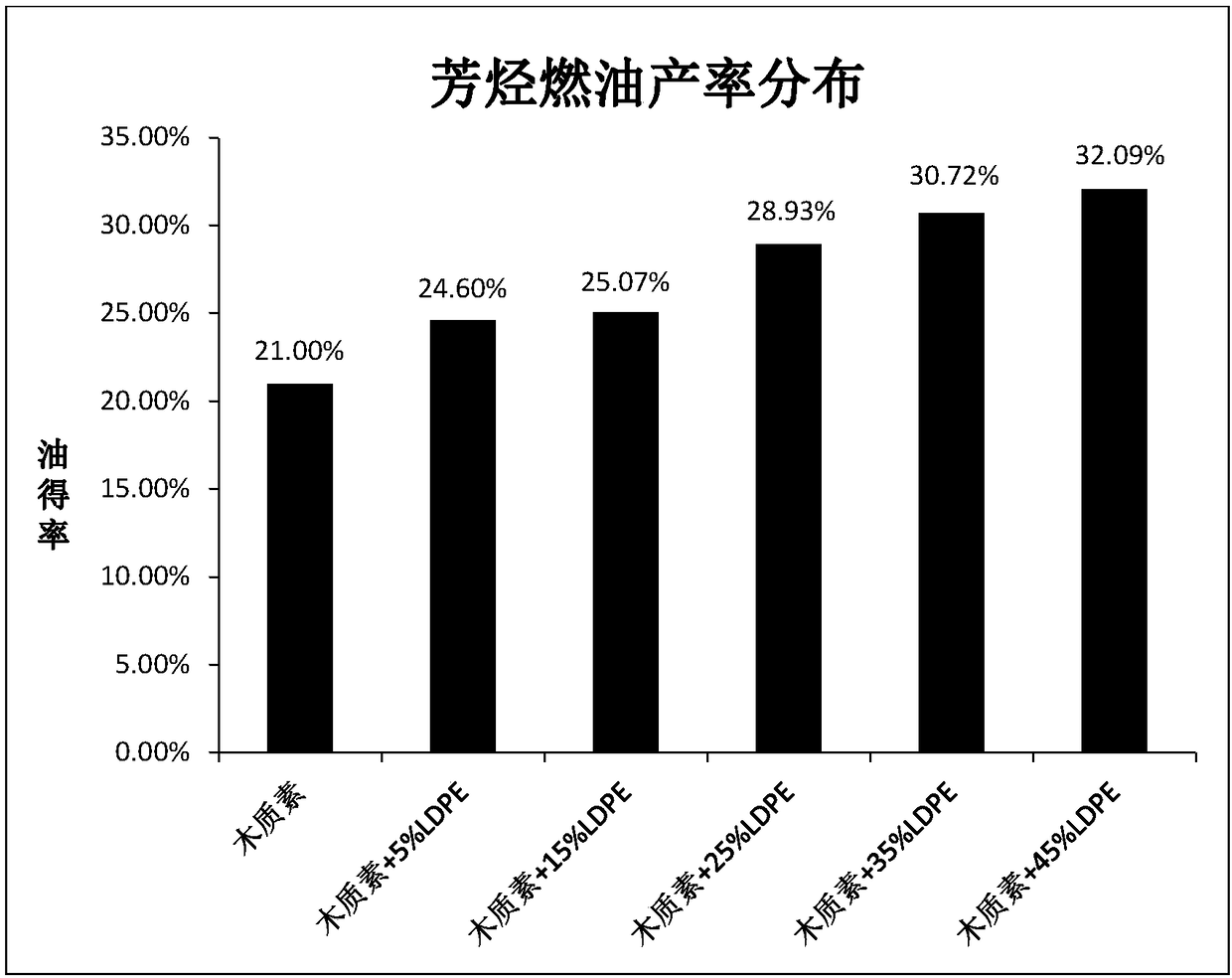

Method for preparing arene-rich fuel oil by co-pyrolysis of lignin and low-density polyethylene

InactiveCN109370632AHigh yieldHigh selectivityLiquid hydrocarbon mixture productionEnergy based chemical/physical/physico-chemical processesLow-density polyethyleneCatalytic reforming

The invention belongs to the technical field of biomass pyrolysis, and particularly relates to a method for preparing arene-rich fuel oil by co-pyrolysis of lignin and low-density polyethylene. A pyrolysis-catalytic reforming method combining a microwave pyrolysis device and a fixed bed catalytic reactor is adopted with a mixture of the lignin and the low-density polyethylene (LDPE) as a researchobject to determine the optimum addition ratio of the LDPE and the optimum reaction temperature of the catalytic reforming reaction. The arene-rich fuel oil is prepared directionally by co-pyrolysis of the lignin and the LDPE.

Owner:JIANGSU UNIV

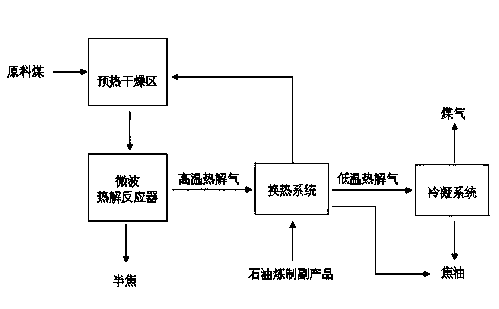

Combined process for co-pyrolysis of coal and petroleum refining by-product

ActiveCN103788968AIncrease polarityImprove microwave absorption performanceDirect heating destructive distillationSpecial form destructive distillationMicrowave pyrolysisTar

The invention discloses a combined process for co-pyrolysis of coal and petroleum refining by-products. Feed coal is crushed, sent into a preheating drying zone, and mixed with petroleum refining by-products from a heat transfer system; and the mixture of coal and petroleum refining by-products is sent into a microwave pyrolysis reactor to generate semi coke and high temperature pyrolysis gas, the pyrolysis gas carries out heat exchange with the petroleum refining by-products in the heat transfer system and is separated into tar and low temperature pyrolysis gas, and the low temperature pyrolysis gas enters into a condenser system for further separation into tar and coal gas. The combined process can realize simultaneous pyrolysis of coal and petroleum refining by-products in the same temperature range to generate synergistic effect, so as to increase the yield of coal tar and improve the quality of coal tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

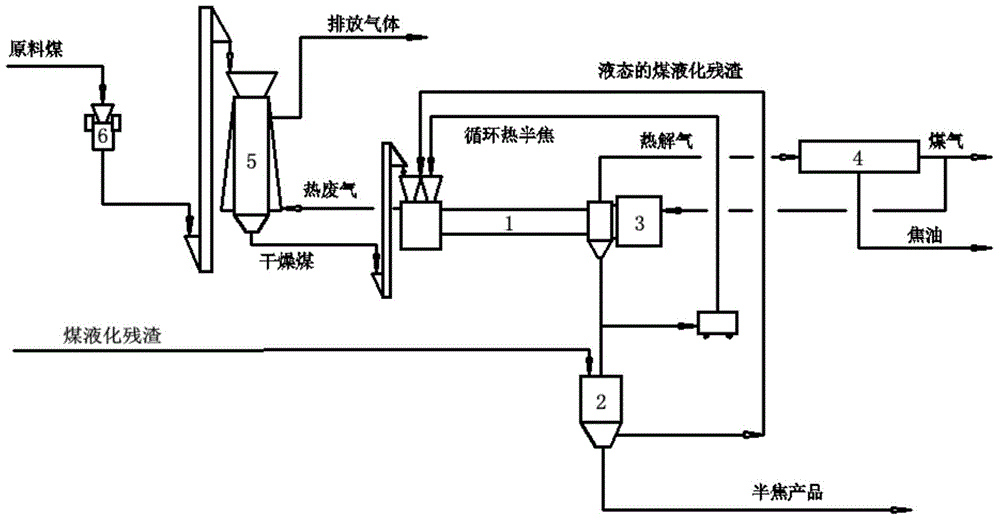

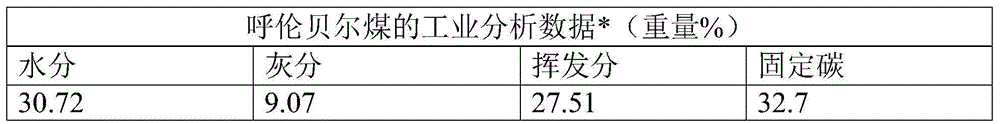

Method and device for preparing semi-coke

ActiveCN105295965AReduce powder cokeHigh yieldDirect heating destructive distillationEnergy inputCo pyrolysisTar yield

The invention discloses a method and a device for preparing semi-coke. The method comprises the following steps: under the condition of co-pyrolysis reaction, mixing hot liquefied residues with dry coal, and carrying out co-pyrolysis so as to obtain hot semi-coke and pyrolysis gas, wherein the liquefied residues are substances generated by direct liquefaction of coal, and the temperature of the co-pyrolysis is 450 to 650 DEG C. The method provided by the invention can reduce the content of powder coke generated in the process of preparing the semi-coke, thereby increasing long-period stable operation of a pyrolysis system; meanwhile, obtained coal gas and tar have high yield and good quality.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

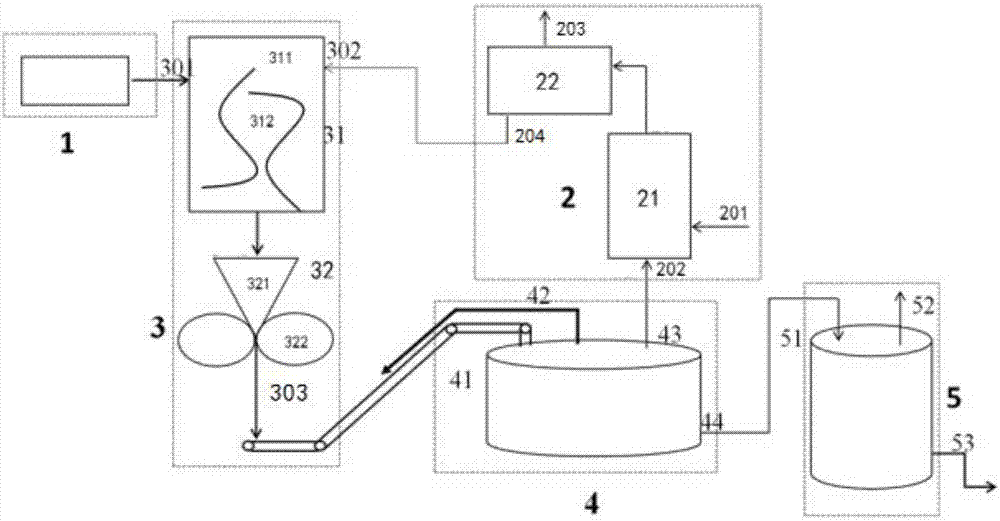

System and method for comprehensive treatment of garbage and carbide slag

PendingCN107541223ARealize resourcesHarmlessHydrogen productionSpecial form destructive distillationSyngasSlag

The invention relates to a system and method for comprehensive treatment of garbage and carbide slag. The system comprises a carbide slag treatment unit, a mixed forming unit, a pellet pyrolysis unitand a high-temperature roasting unit; the carbide slag treatment unit comprises a carbide slag inlet, a raw coke-oven gas inlet, a syngas outlet and a dried carbide slag outlet; the mixed forming unitcomprises a dried carbide slag inlet, a garbage inlet and a mixed pellet outlet; the pellet pyrolysis unit comprises a mixed pellet inlet, a flue gas outlet, a raw coke-oven gas outlet and a high-temperature pyrolysis pellet outlet; the high-temperature roasting unit comprises a high-temperature pyrolysis pellet inlet, a CO2-rich gas outlet and a roasted ceramsite outlet. The system and method ofthe comprehensive treatment of the garbage and carbide slag disclosed by the invention use an anaerobic pyrolysis furnace to carry out co-pyrolysis on the garbage and the carbide slag, and an obtained product is in direct contact with the carbide slag, so that the high-quality syngas is obtained while the carbide slag is dried; furthermore, the solidification effect of calcium oxide in the carbide slag on garbage heavy metals is fully utilized to prepare safe and high-performance building ceramsite.

Owner:SHENWU TECH GRP CO LTD

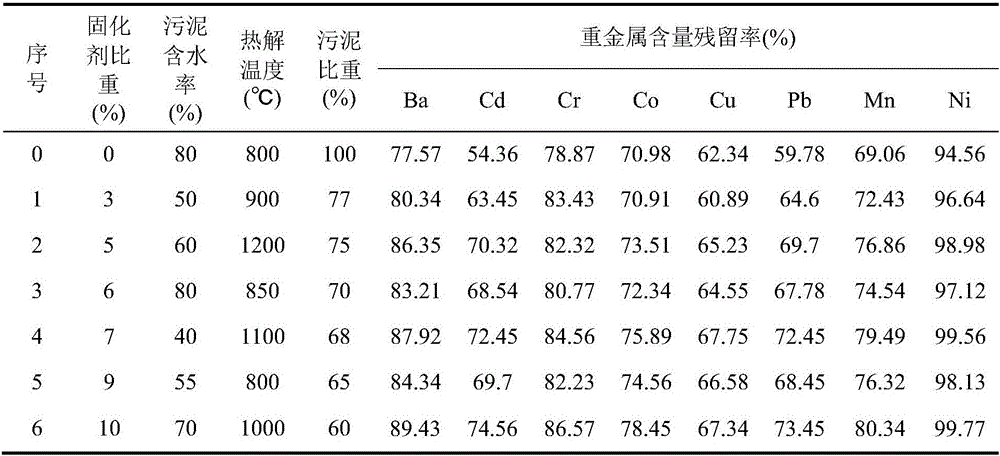

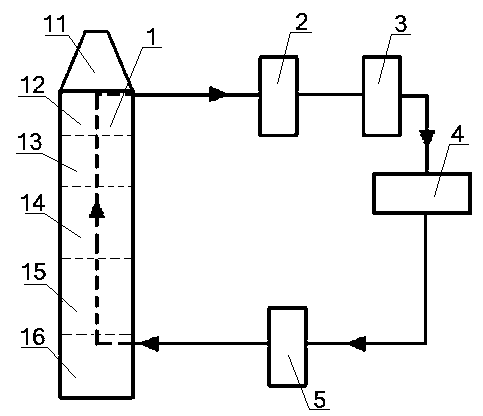

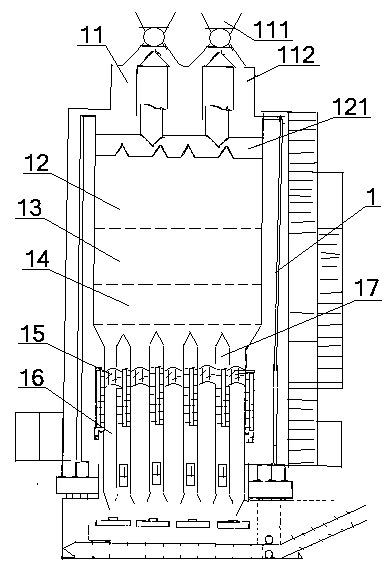

Method for compounding and directly pyrolyzing sludge

InactiveCN106396329AEasy disposalResource optimizationSludge treatment by pyrolysisByproduct vaporizationResource utilizationSludge

The invention relates to a method for compounding and directly pyrolyzing sludge. The method is characterized by comprising the following steps of adding a curing agent and biomass into the sludge to carry out co-pyrolysis, wherein the mass percent of the cuing agent is 3 to 10 percent, the mass percent of the biomass is 20 to 30 percent, and the mass percent of the sludge is 60 to 77 percent; uniformly agitating the sludge, the biomass and the curing agent, which are mixed according to a certain proportion, then putting an obtained mixture into a pyrolyzing furnace, raising temperature to 500 to 700 DEG C, preserving heat for 20min to 30min, then further raising the temperature to a pyrolysis temperature of 800 to 1200 DEG C, preserving the heat for 10min to 20min, and completing the drying, the gasification and the cracking of raw materials at the same time. The method for compounding and directly pyrolyzing the sludge is wide in scope of application, and has low requirements on the types and the water content of the sludge; the harmless disposal and the resource utilization of the sludge can be realized in a more broad-spectrum manner.

Owner:NANJING UNIV OF TECH

Method for preparing semicoke and tar by virtue of co-pyrolysis of organic waste and coal

The invention provides a method for preparing semicoke and tar by virtue of co-pyrolysis of organic waste and coal. The method comprises the steps of firstly, mixing the organic waste with the coal to form a mixture and drying and preheating the mixture, secondly, orderly performing low-temperature carbonization at 450-650 DEG C and medium temperature carbonization at 650-800 DEG C on the preheated material to obtain low-volatile semicoke and gas, next, recovering the semicoke and the tar, and finally, purifying the gas. The method for preparing the semicoke and the tar by virtue of co-pyrolysis of the organic waste and the coal has the advantages that the tar yield, the resource utilization efficiency of waste rubber and waste plastics and the quality of the semicoke can be obviously improved, and the effects of economic efficiency, environmental friendliness and low production cost can be achieved, based on the principle that the pyrolysis final temperature of the waste rubber and the waste plastics is lower than that of the coal under the same working condition, so that the gas generated by the pyrolysis of the organic waste and the waste is recovered and purified together.

Owner:陈卫

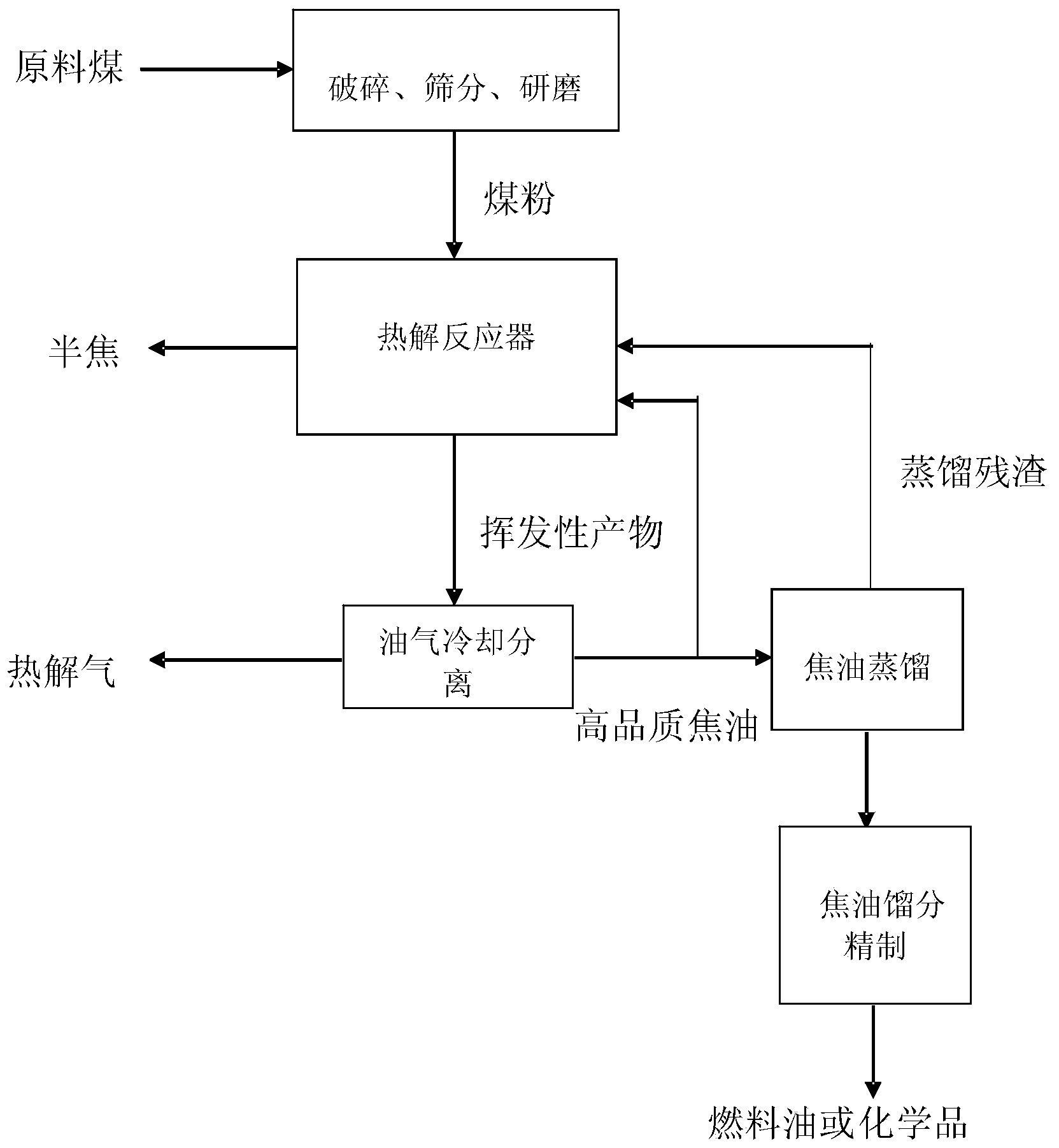

Method for improving quality of low-temperature tar during coal pyrolysis

InactiveCN103756700AHigh yieldImprove qualitySpecial form destructive distillationDistillationCo pyrolysis

The invention provides a method for improving the quality of pyrolysis tar during co-pyrolysis of low-temperature coal tar and coal. According to the novel preparation method, the low-temperature coal tar or the distillation residues of the low-temperature coal tar are added into the feed coal for co-pyrolysis to obtain tar and gaseous hydrocarbon products, wherein the mass ratio of the low-temperature coal tar or the distillation residues of the low-temperature coal tar to the feed coal is (0.5 to 100) to (20 to 100), and the reaction conditions are that the pyrolysis temperature is 400-800 DEG C and the pyrolysis time is 0-90 minutes. Through the method, the yields of the pyrolysis tar and pyrolysis gas are increased, the content of light components with high added values in the pyrolysis tar is greatly increased, and the problems of processing and utilization of heavy pyrolysis tar are solved.

Owner:EAST CHINA UNIV OF SCI & TECH

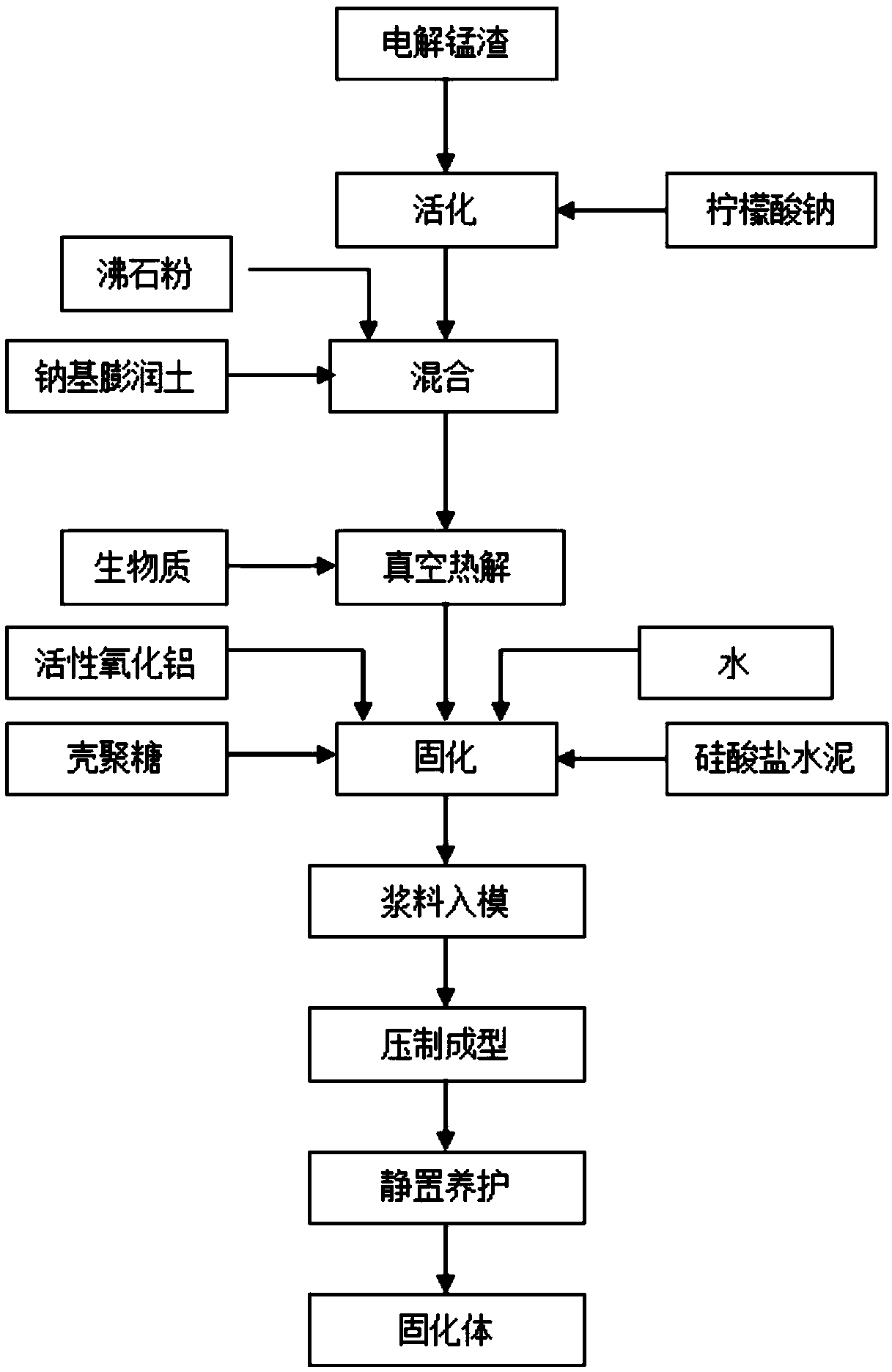

Treatment method for electrolytic manganese residues

InactiveCN109133812AThe concentration of leaching increasesImprove adsorption capacitySolid waste managementBrickElectrolysis

The invention provides a treatment method for electrolytic manganese residues. The treatment method comprises the following steps: crushing the electrolytic manganese residues into powder and adding sodium citrate to soak the electrolytic manganese residues and filtering the mixture; mixing zeolite powder with sodium bentonite, adding the screened powder into the electrolytic manganese residue powder and stirring the mixture to obtain mixed powder; carrying out vacuum co-pyrolysis on the mixed powder and biomass, adding chitosan powder which accounts for 2-5% by mass of a pyrolysis product, and mixing and stirring the mixture to obtain a mixture; adding cement powder activated aluminium oxide into the mixture, adding a proper amount of water, stirring and mixing the mixture in a stirrer toform slurry; and adding the slurry into a building block forming mold, adopting a forming process to vibrate and press the mold at constant temperature and constant pressure, leaving the mold to stand for 12-30 hours, and moisturizing and naturally curing the same for 20-30 days to obtain a cured body. The treatment method is simple in process, little in needed engineering equipment and suitablefor scaled production. Meanwhile, the prepared cured body can be used as a regenerated brick.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

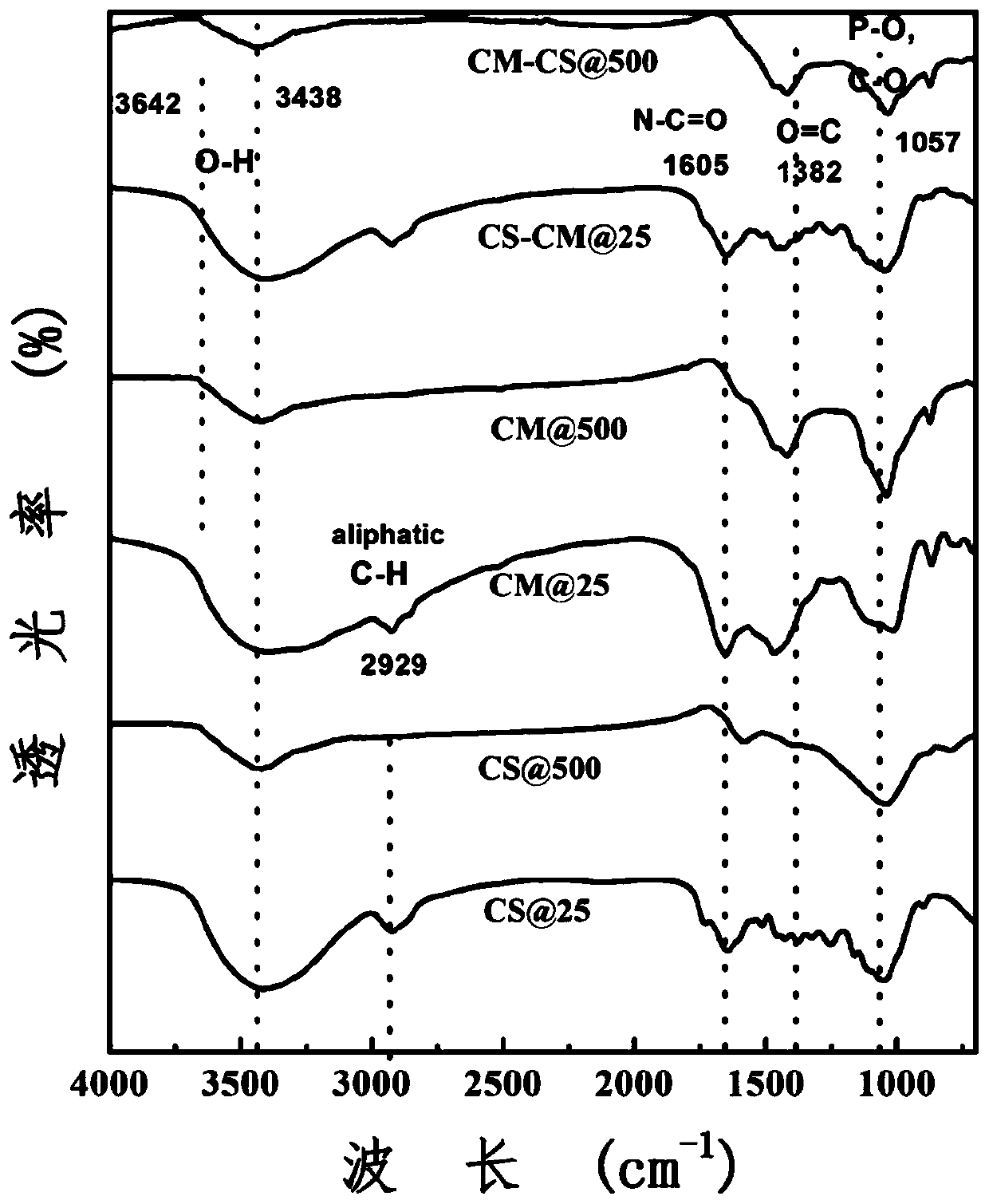

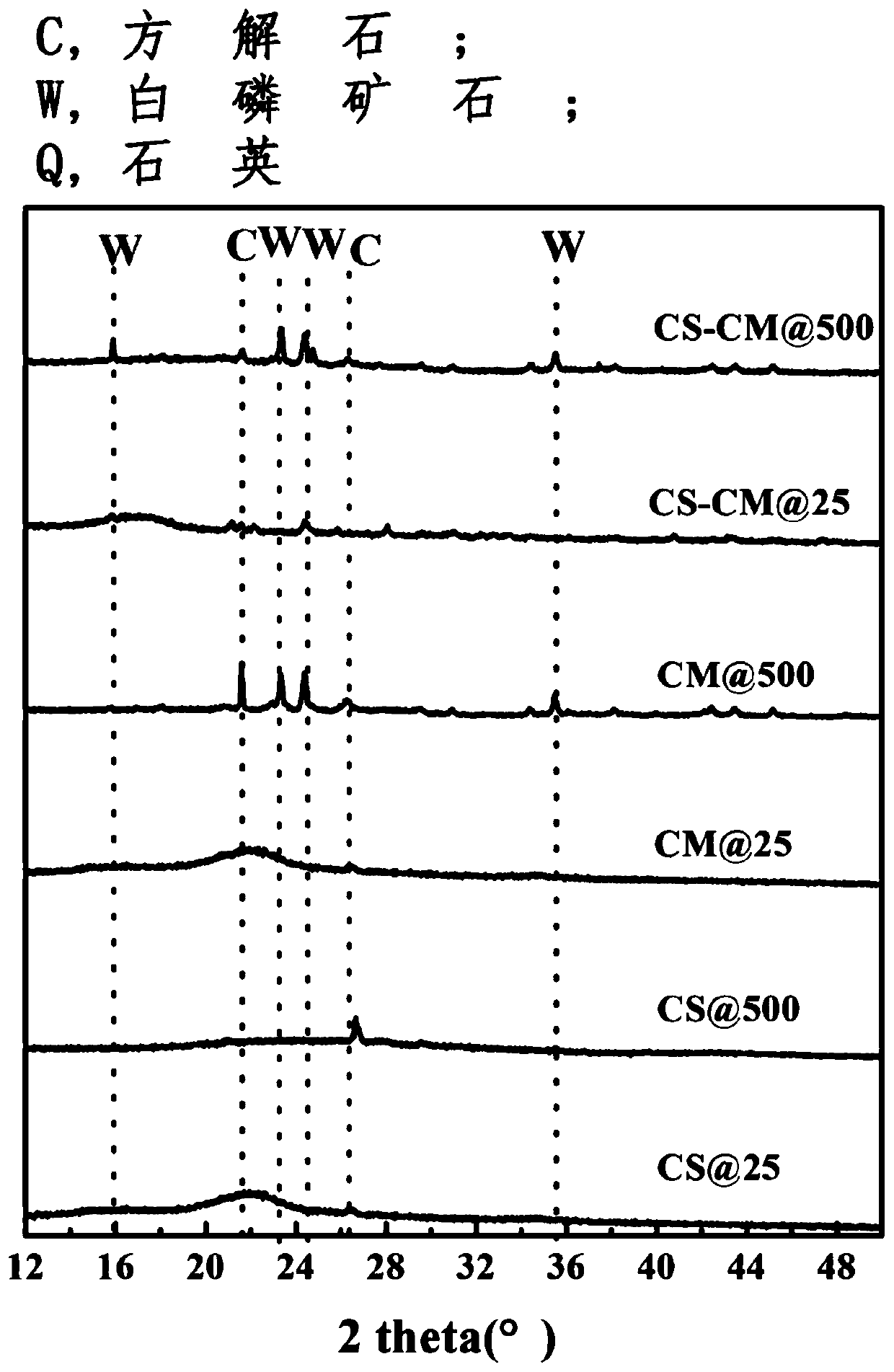

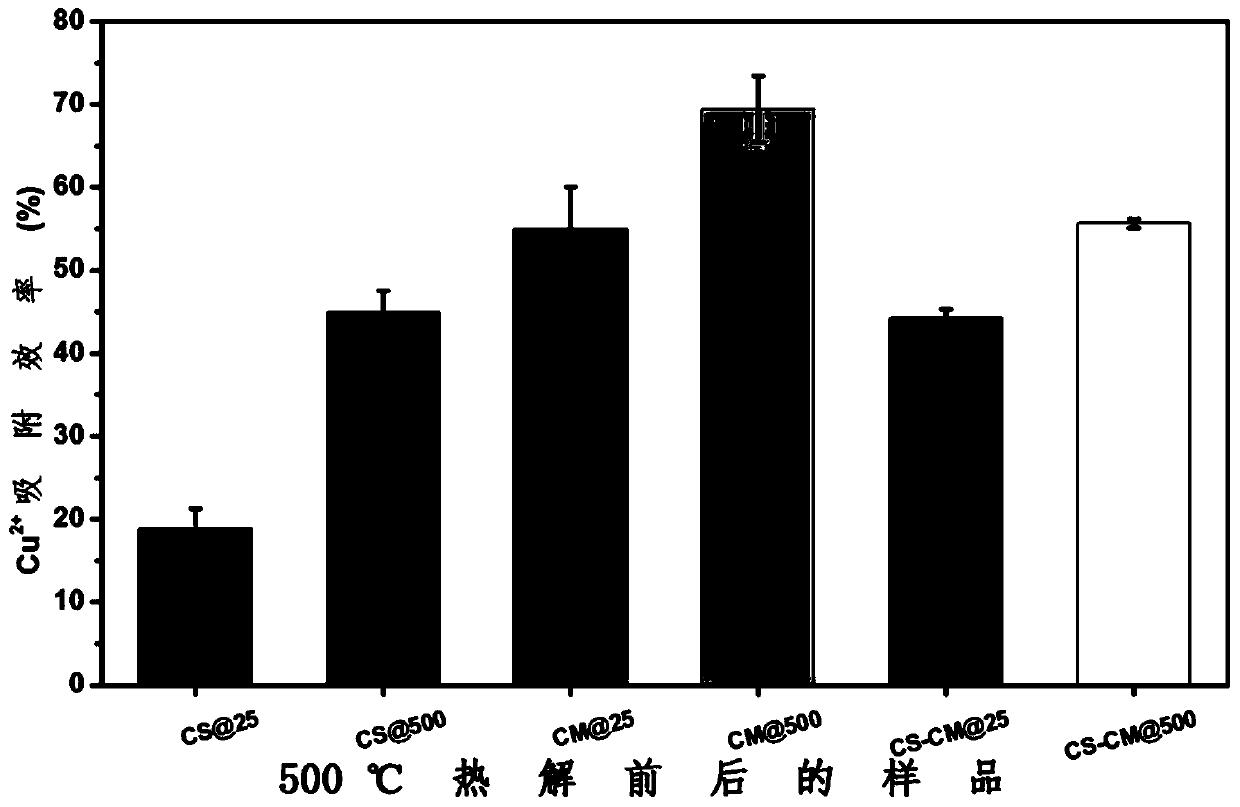

Chicken manure/corn straw composite co-pyrolysis activated carbon soil remediation agent, preparation method thereof and application of remediation agent

ActiveCN110304630AWell-developed pore structureGood for chemical adsorptionCarbon compoundsOther chemical processesActivated carbonSoil remediation

The invention discloses a chicken manure / corn straw composite co-pyrolysis activated carbon soil remediation agent, a preparation method thereof and an application of the remediation agent. The methodincludes the steps: (1) drying chicken manure and corn straws, crushing the dried chicken manure and the dried corn straws, and screening the crushed chicken manure and the crushed corn straws to obtain chicken manure powder and corn straw powder; (2) uniformly mixing the chicken manure powder and the corn straw powder, adding binding agents, uniformly heating and stirring mixture, and granulating and drying the mixture to obtain composite spherical particles; (3) heating the composite spherical particles to reach the temperature of 400-600 DEG C to carbonize the particles for 1-2 hours, heating the particles to reach the temperature of 750-850 DEG C, leading in water vapor to activate the particles for 20-40 minutes, and cooling the particles to reach room temperature to obtain the chicken manure / corn straw composite co-pyrolysis activated carbon soil remediation agent. The prepared activated carbon soil remediation agent is high in specific surface area and has rich pore structures,and physical absorption is facilitated, so that the soil remediation agent can be used for adsorbing soil heavy mental, organic coloring agent methylene blue and the like.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com