Method for preparing semicoke and tar by virtue of co-pyrolysis of organic waste and coal

A technology of organic waste and co-pyrolysis, which is used in coke ovens, educts, petroleum industry, etc., can solve the problems of low tar yield, low recycling efficiency of waste rubber and waste plastics, etc. Excessive cost, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

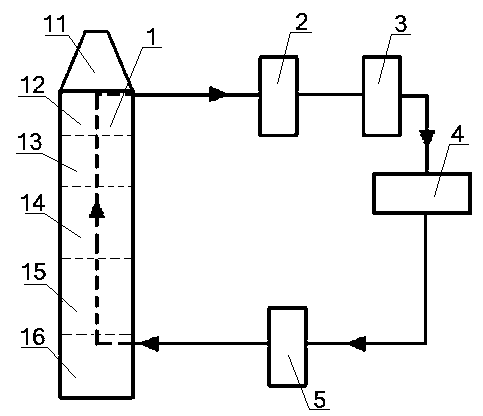

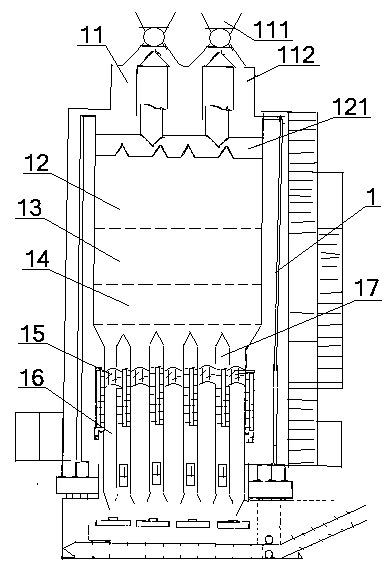

[0082] see figure 1 , figure 2 , a method for producing semi-coke and tar by co-pyrolysis of organic waste and coal, the method adopts a vertical carbonization furnace 1 to produce semi-coke and tar, and the vertical carbonization furnace includes a feed section 11 connected sequentially from top to bottom , a drying section 12, a preheating section 13, a low-temperature dry distillation section 14, a medium-temperature dry distillation section 15, and a semi-coke cooling section 16. The feeding section 11 is sequentially provided with interconnected discharge drums 111 and auxiliary coal boxes from top to bottom 112, the drying section 12 is provided with an air-collecting array umbrella 121, and the area where the medium-temperature dry distillation section 15 and the semi-coke cooling section 16 are located is provided with a flower wall 17;

[0083] The method comprises the following steps in turn:

[0084] Drying and preheating: First, the material formed by mixing org...

Embodiment 2

[0089] Step is with embodiment 1, and difference is:

[0090] In the drying and preheating step, the organic waste is waste plastics, the length of which is 60-180mm, and its added weight is 12% of the added weight of coal.

Embodiment 3

[0092] Step is with embodiment 1, and difference is:

[0093] In the drying and preheating step, the organic waste is a mixture of waste tires and waste plastics, wherein the length of the waste tires is 170-190mm, and its added weight is 7% of the added weight of coal; the length of the waste plastics is 60-180mm , its added weight is 8% of coal added weight;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com