Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Reduce thermal mismatch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

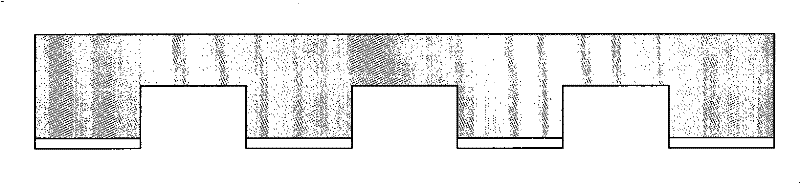

Low-temperature glass solder bonding and encapsulating method based on disc level glass micro-chamber

InactiveCN101497422AGuaranteed reliabilityLower packaging costsTelevision system detailsPrecision positioning equipmentCMOSFritted glass

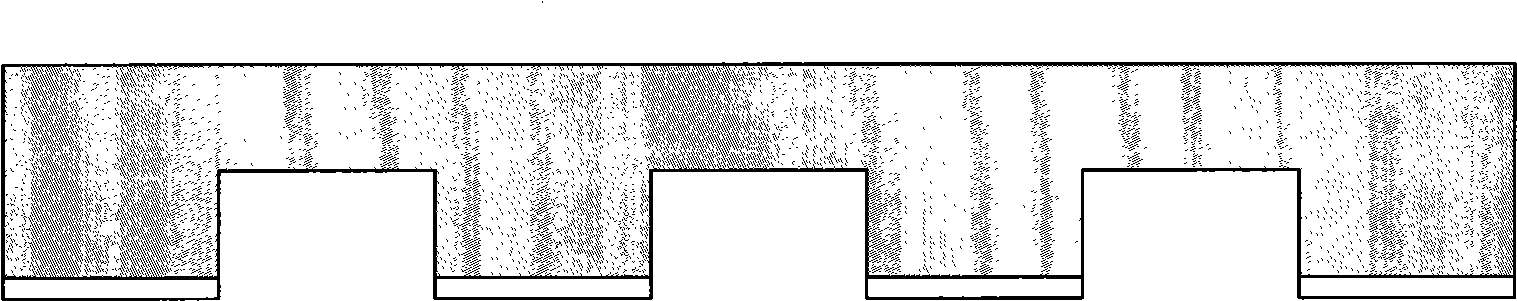

The invention discloses a low-temperature glass solder bonding and packaging method based on wafer-level glass microcavities, which comprises the following steps: firstly, utilizing a silk-screen printing process to coat low-temperature glass solder on a packaging contact part of a Pyrex7740 glass substrate provided with a microcavity structure, preliminarily drying the low-temperature glass solder, and making the low-temperature glass solder be cured and cling to the Pyrex7740 glass substrate provided with the microcavity structure; secondly, aligning a Pyrex7740 glass packaging wafer which is cured with the low-temperature glass solder and a silicon substrate wafer comprising an MEMS device or a CMOS circuit, and making the microcavity structure on the Pyrex7740 glass substrate correspond to the position of the MEMS device or the CMOS circuit to be packaged of a silicon substrate; and thirdly, using a clamper to firmly clamp the two aligned wafers, applying the pressure, sintering the glass solder in a specified packaging atmosphere, and cooling the glass solder. The whole process is based on integral processing of the silicon wafer and the Pyrex7740 glass wafer, belongs to a process for manufacturing and packaging a wafer-level MEMS, and has the characteristics of simple method, adjustable packaging space and low cost.

Owner:SOUTHEAST UNIV

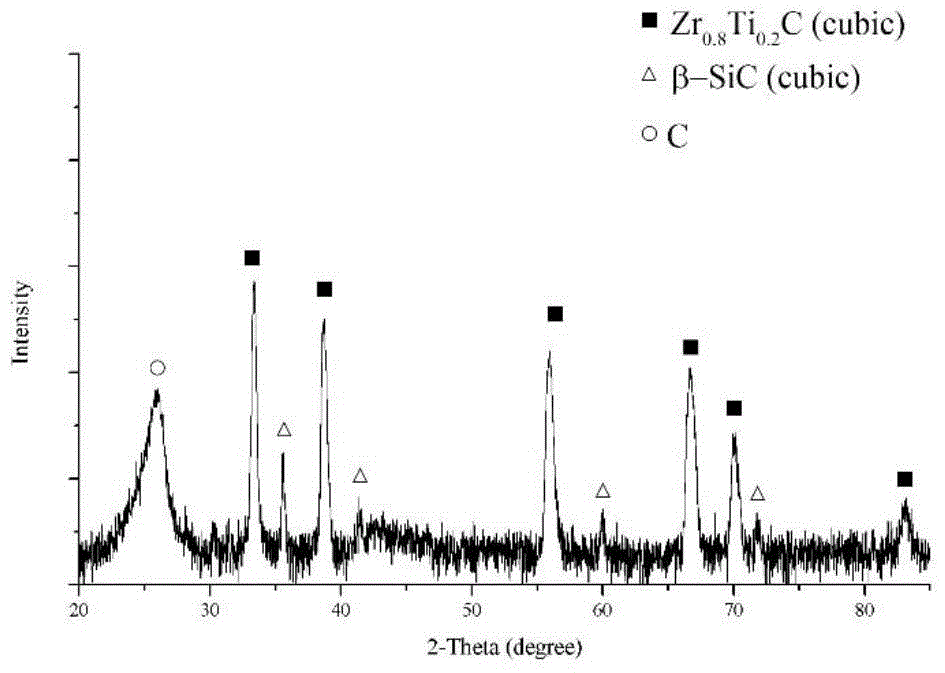

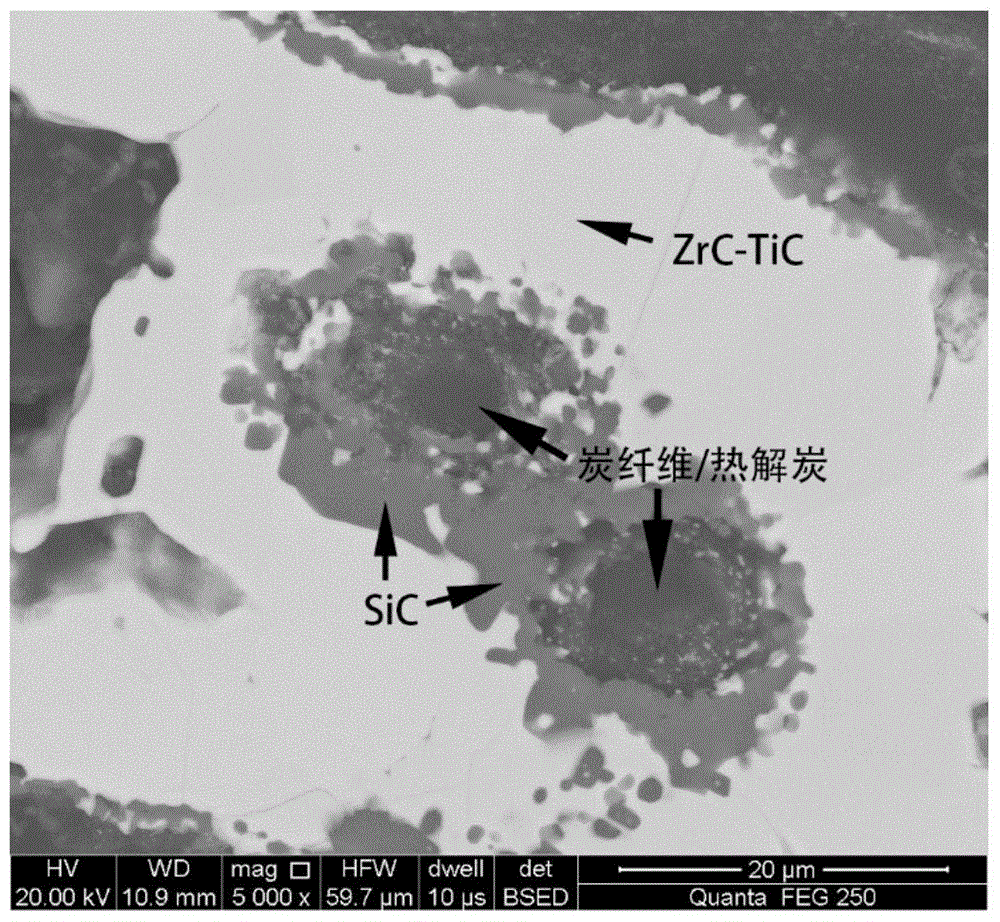

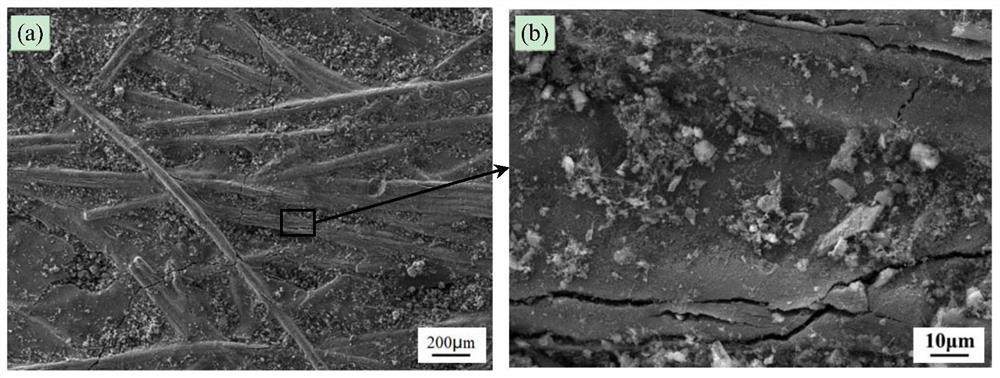

C/C-SiC-ZrC-TiC composite material and preparation method thereof

ActiveCN104671814AReduce thermal mismatchRelieve stress concentrationInterface layerPyrolytic carbon

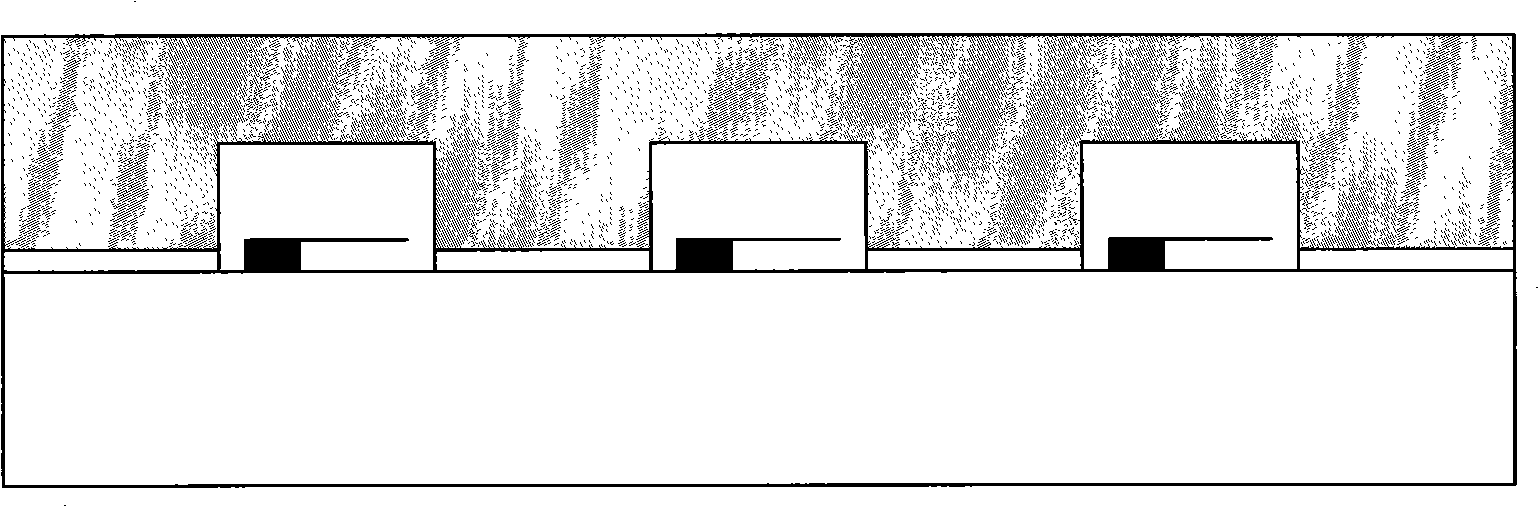

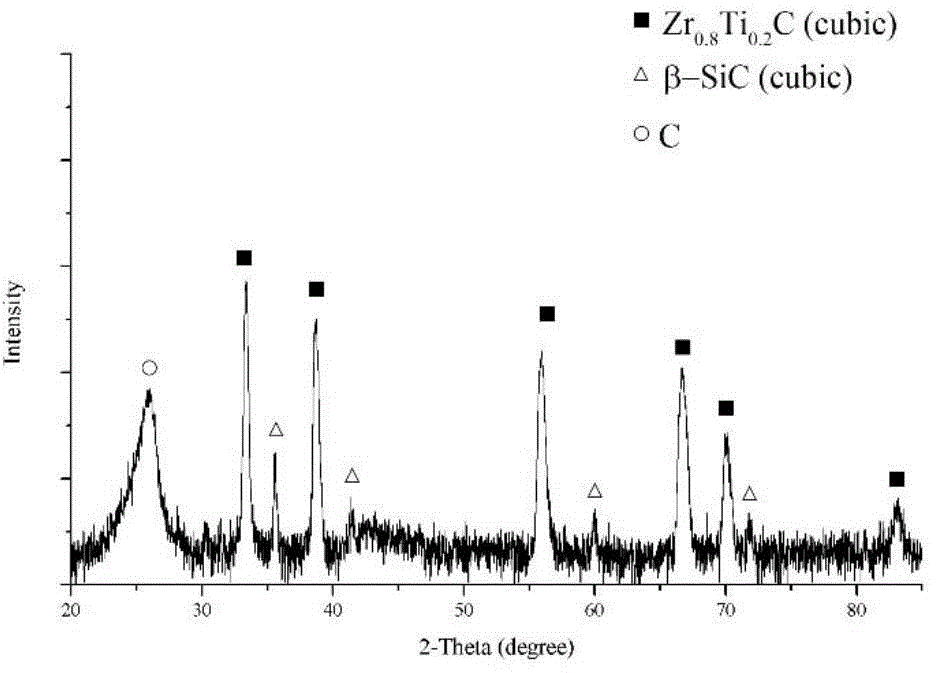

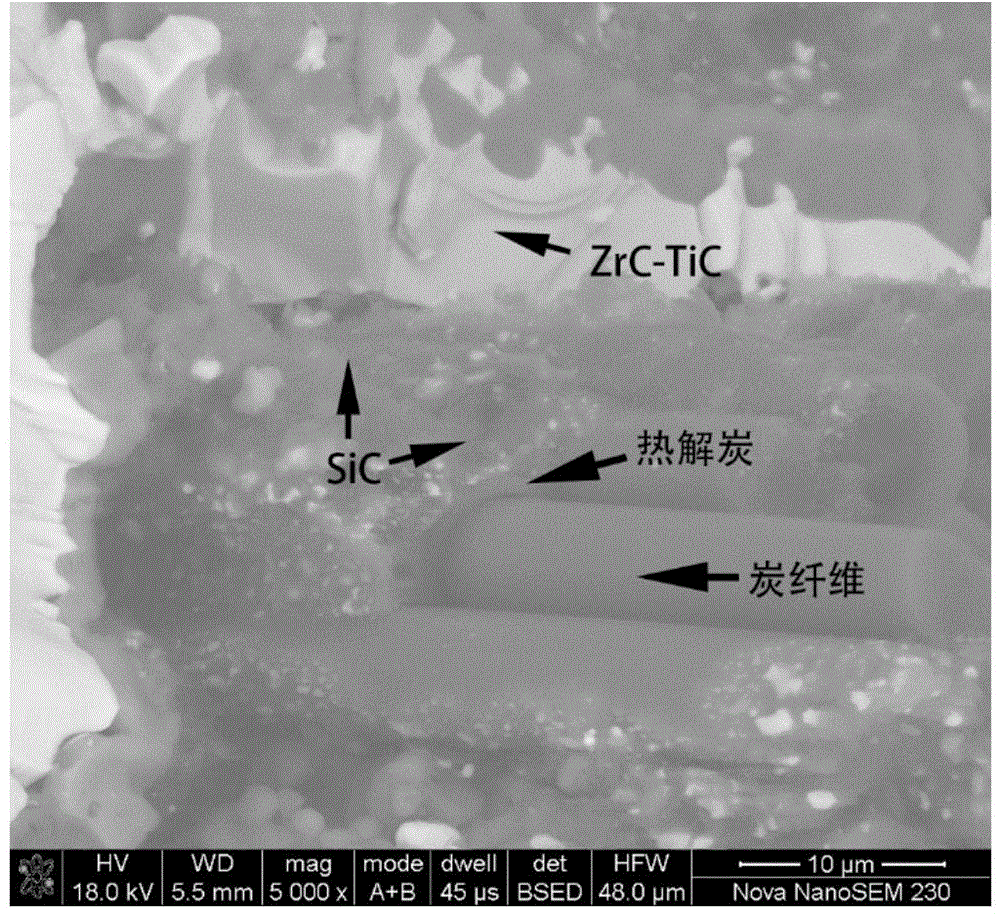

The invention discloses a C / C-SiC-ZrC-TiC composite material and a preparation method thereof. The composite material is composed of a carbon fibre, a pyrolytic carbon, a main matrix phase ZrC-TiC and a sub matrix phase SiC. The composite material is characterized in that the SiC is used as an interface layer for separating the pyrolytic carbon from the ZrC-TiC. The preparation method comprises the following steps: melting the mixed powder of Zr, Ti and Si, permeating into the inside of the low-density C / C composite material through a capillary action, forming a ceramic phase in a hole through an in situ reaction to obtain the C / C-SiC-ZrC-TiC composite material. The preparation method is rapid and effective and low in cost; the prepared composite material has excellent super-high temperature ablation resistance performance and simultaneously has excellent strength, breaking tenacity and thermal shock resistance.

Owner:深圳金羽先进材料有限公司

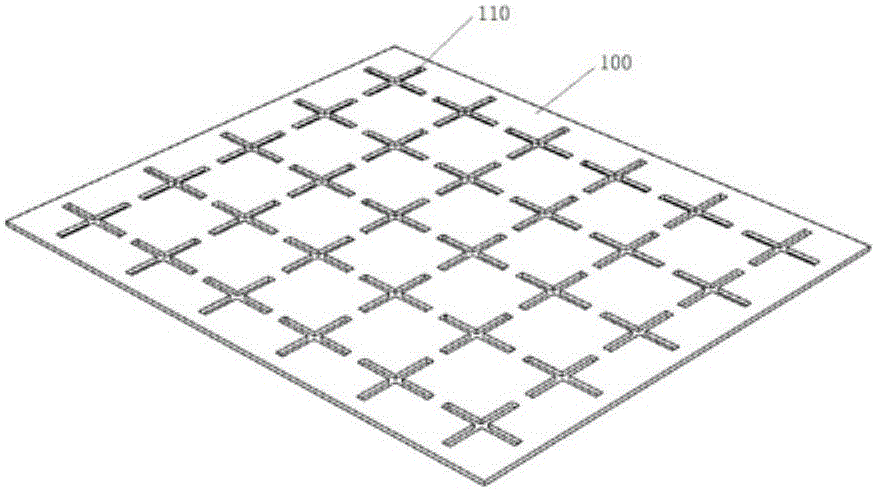

Graphene film frequency selective surface

ActiveCN105161803AImprove adaptabilityReduce Thermal MismatchSynthetic resin layered productsWaveguide type devicesCvd grapheneResin composite

The invention discloses a graphene film frequency selective surface comprising a substrate and a graphene film layer disposed on the substrate. The substrate is prepared from fiber reinforced polymer composite material. The graphene film layer comprises a graphene film with periodically-arranged holes or graphene film chips arranged periodically. The graphene film frequency selective surface is simple in technique implementation, well matches the fiber reinforced resins composite material substrate, is low in weight increment, resistant to corrosion, and can be widely applied to devices such as composite material radomes or filters.

Owner:NAT UNIV OF DEFENSE TECH

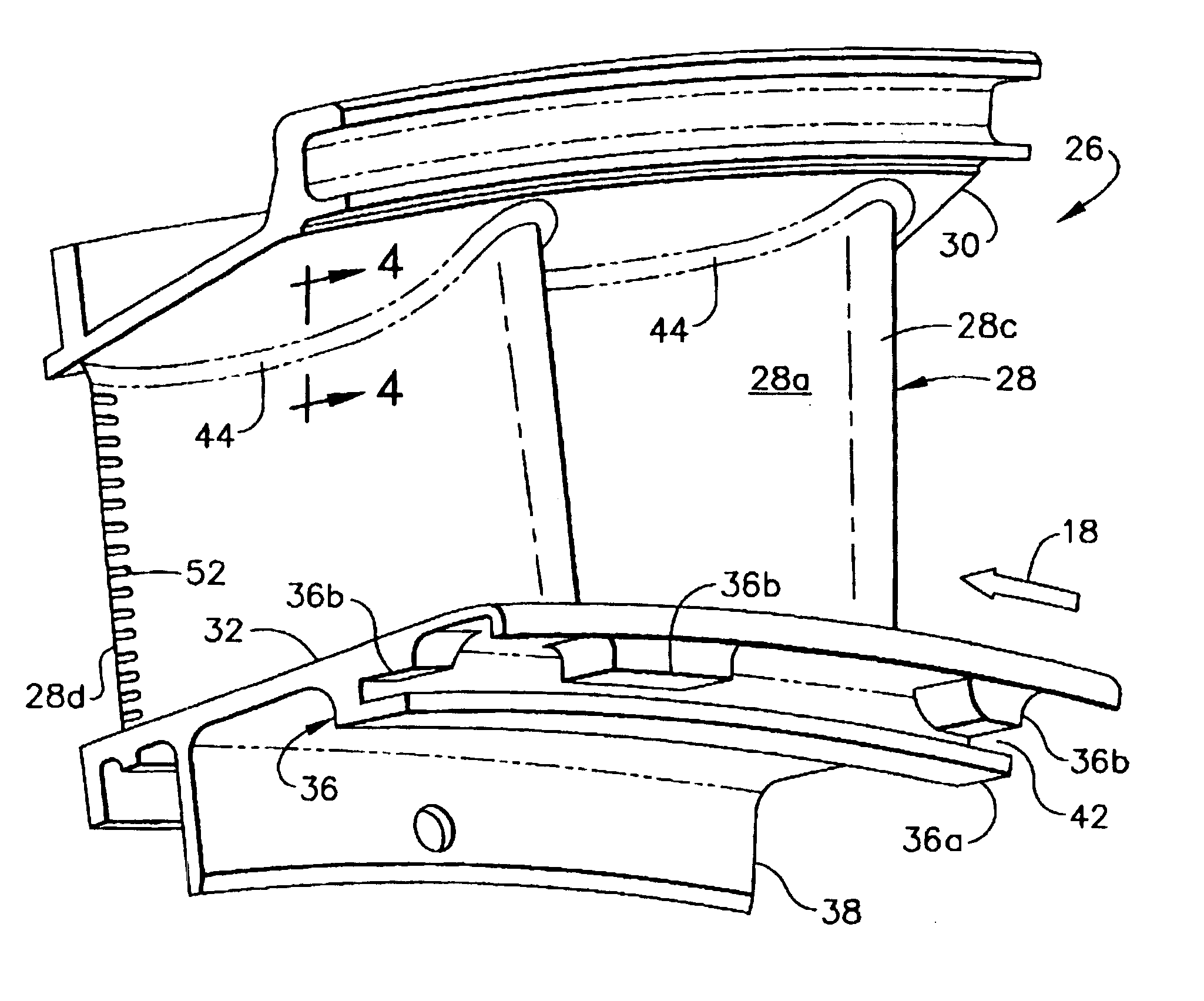

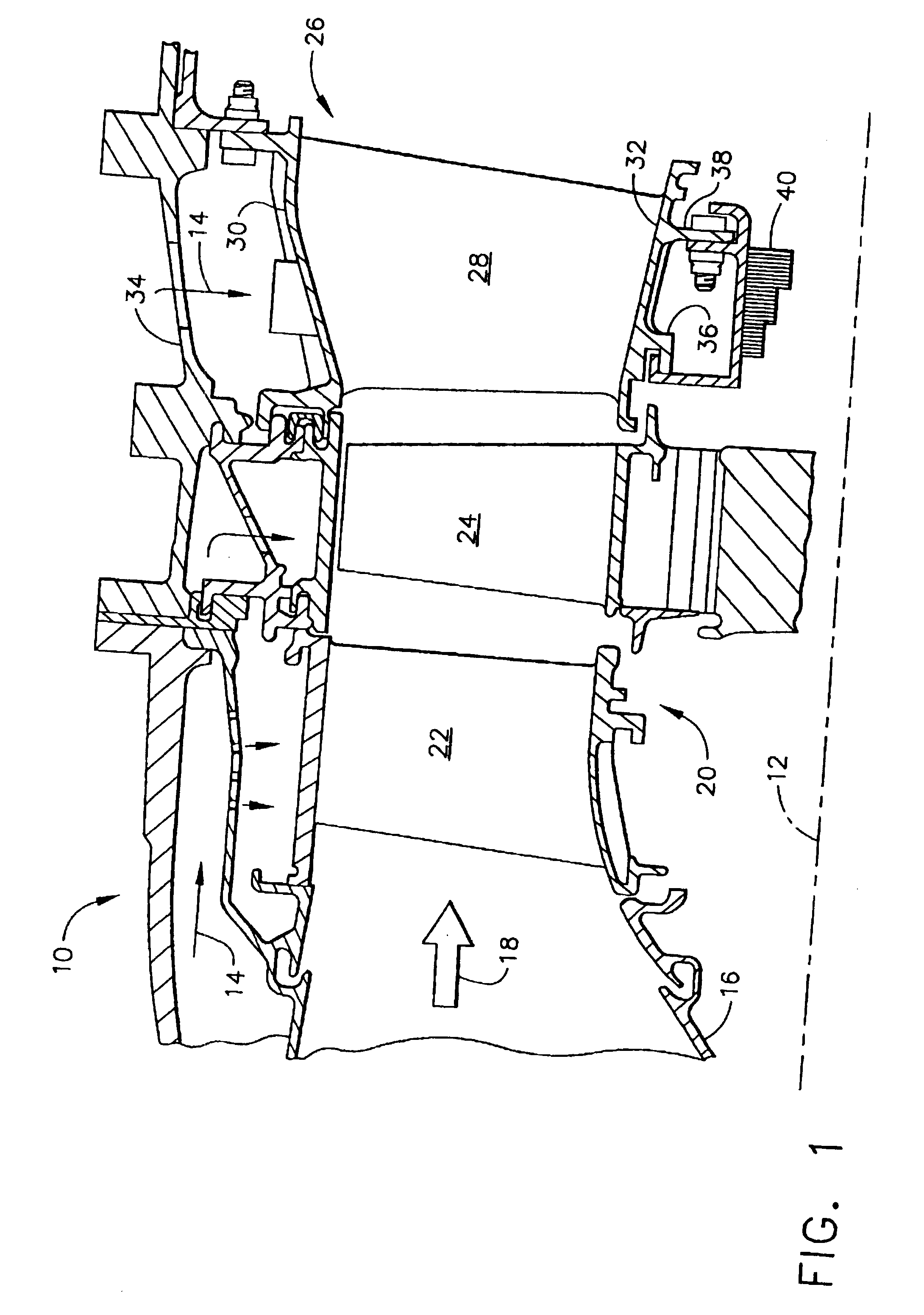

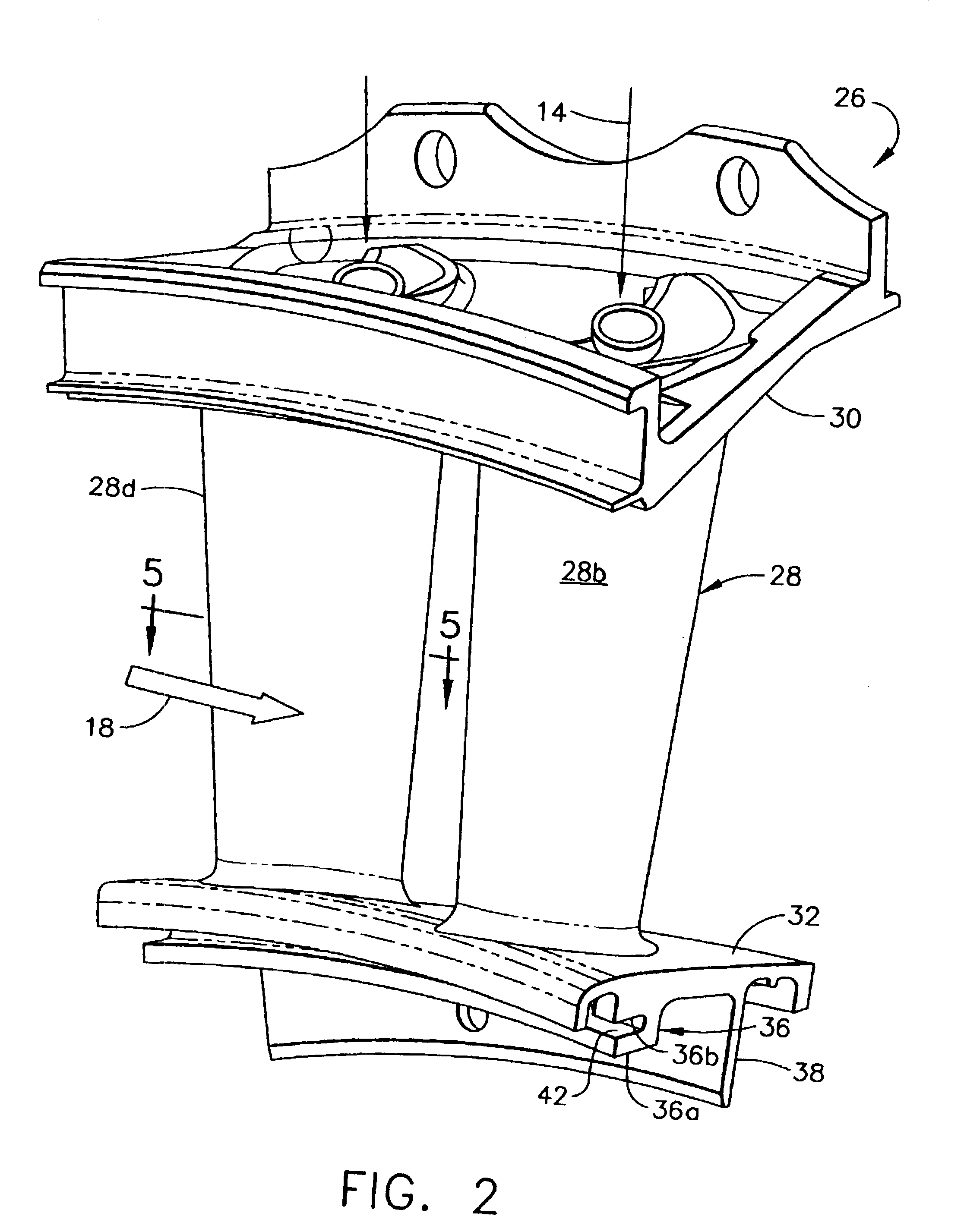

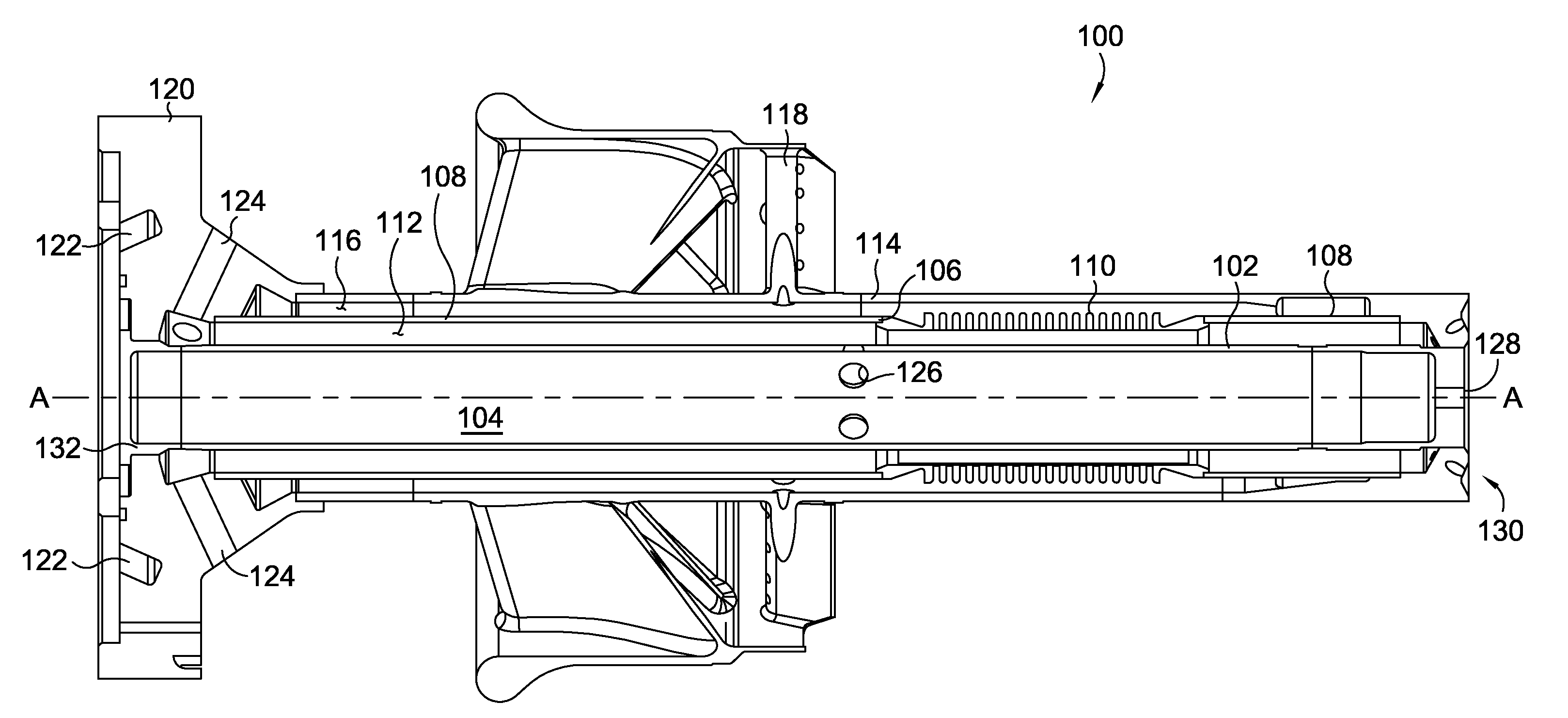

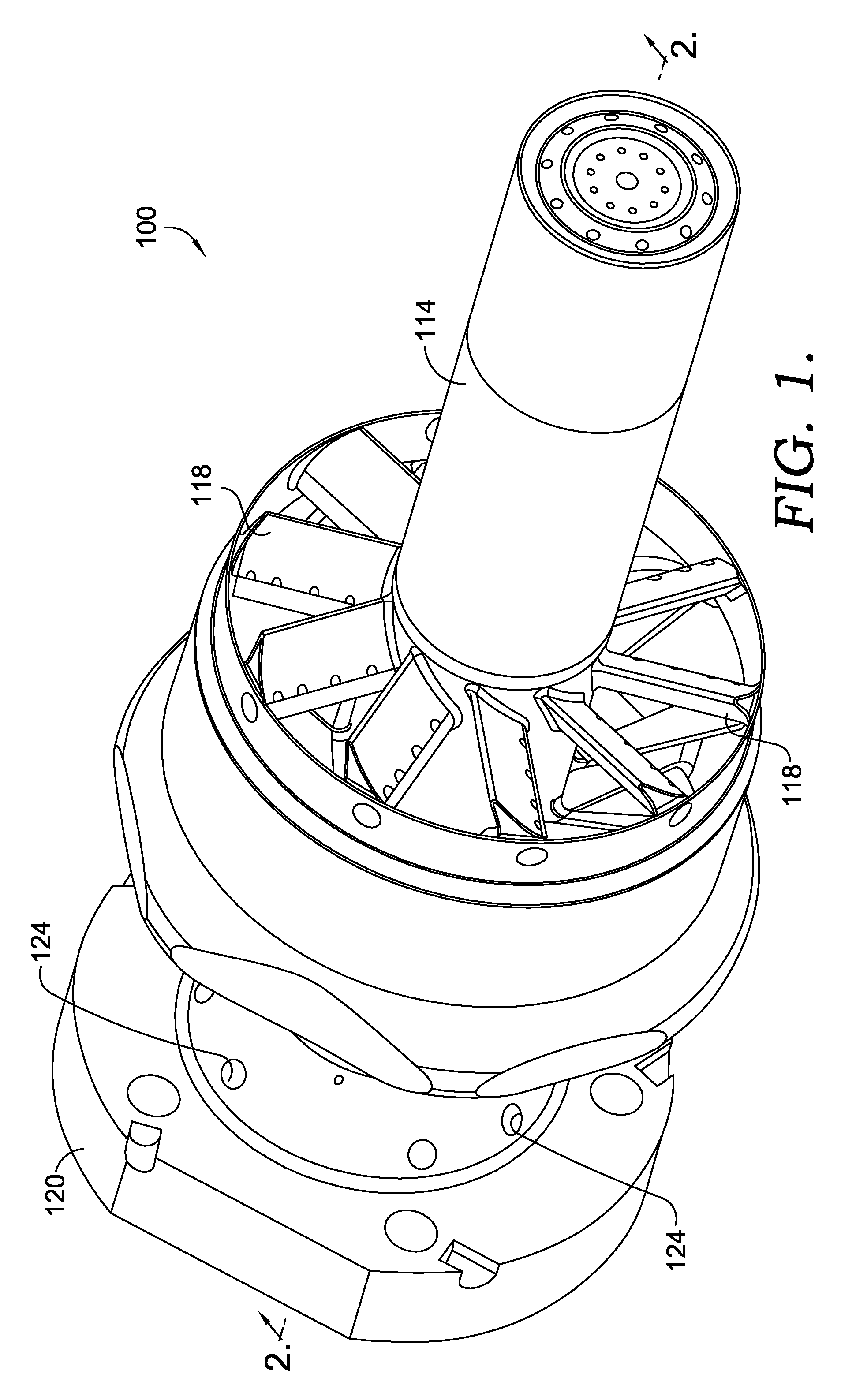

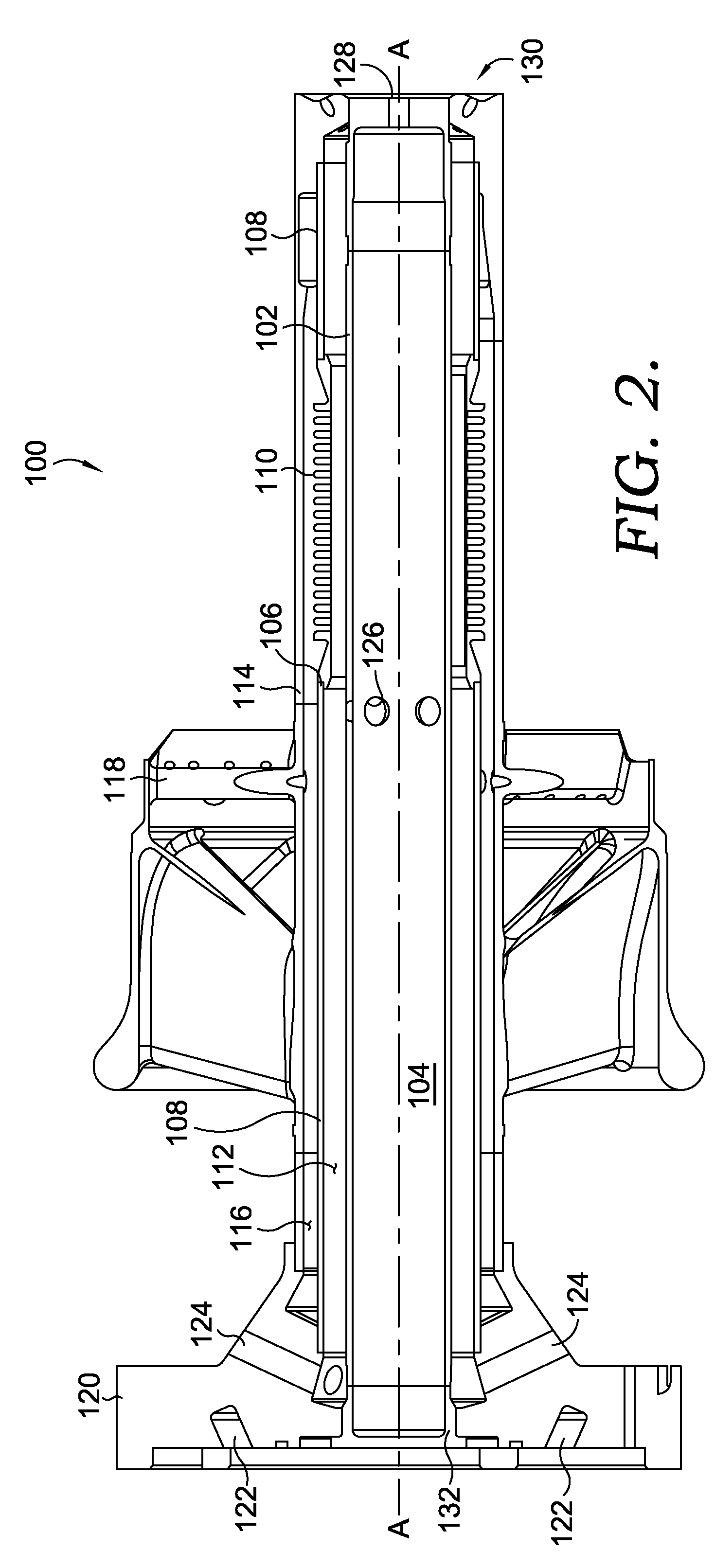

Gas turbine fuel nozzle having improved thermal capability

ActiveUS8136359B2Minimizing thermal growthReduce heat stress levelsBurnersContinuous combustion chamberCombustorEngineering

Embodiments for minimizing relative thermal growth within a fuel nozzle of a gas turbine combustor are disclosed. Fuel nozzle configurations are provided in which a heating fluid is provided to one or more passages in a fuel nozzle from feed holes in the fuel nozzle base. The heating fluid passes through the fuel nozzle, thereby raising the operating temperature of portions of the fuel nozzle to reduce differences in thermal gradients within the fuel nozzle. Various fuel nozzle configurations and passageway geometries are also disclosed.

Owner:ANSALDO ENERGIA SWITZERLAND AG

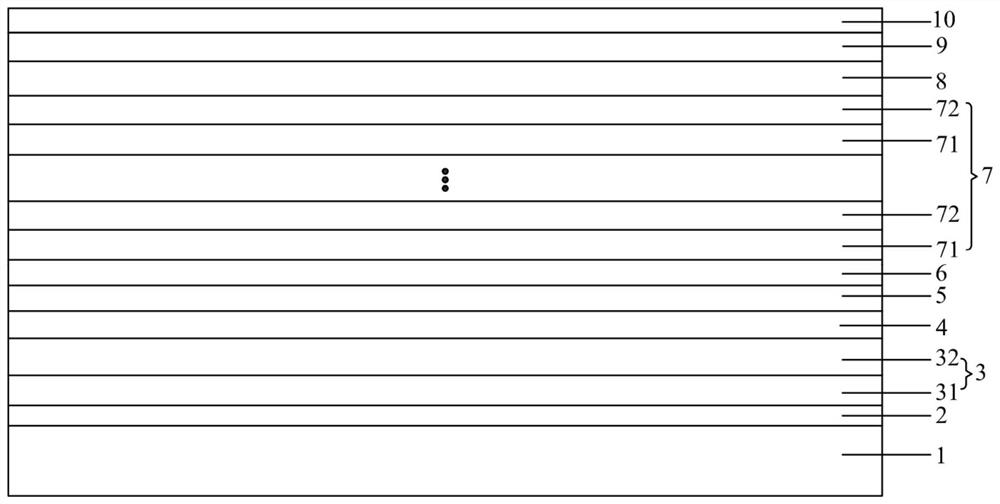

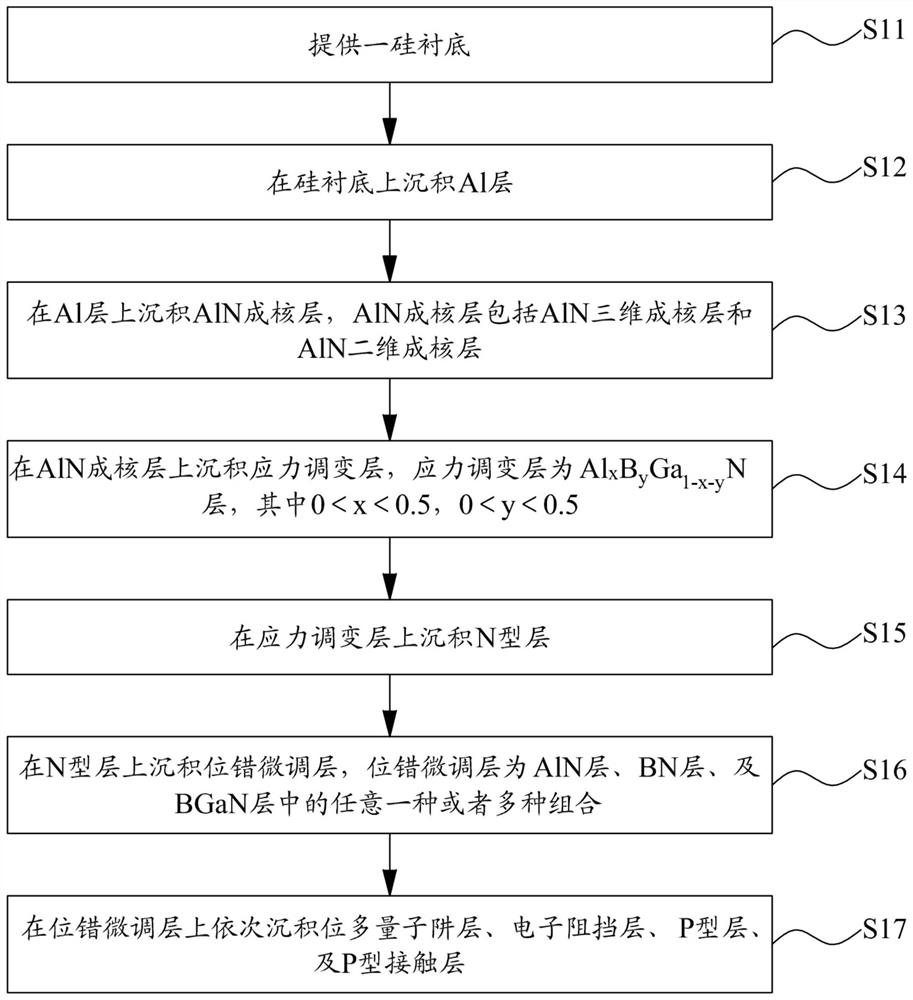

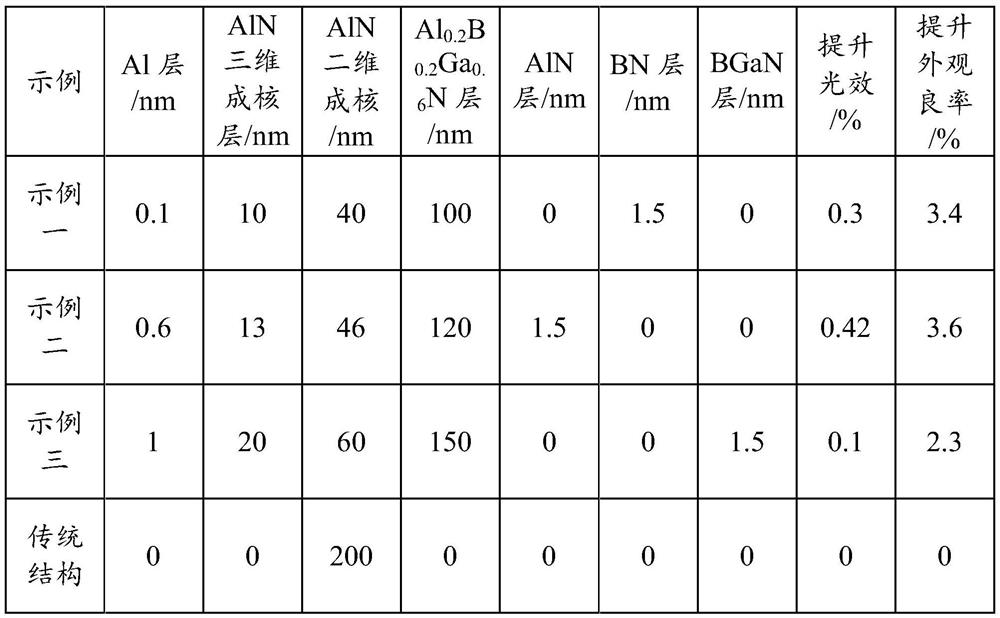

Silicon-based gallium nitride epitaxial wafer and manufacturing method thereof

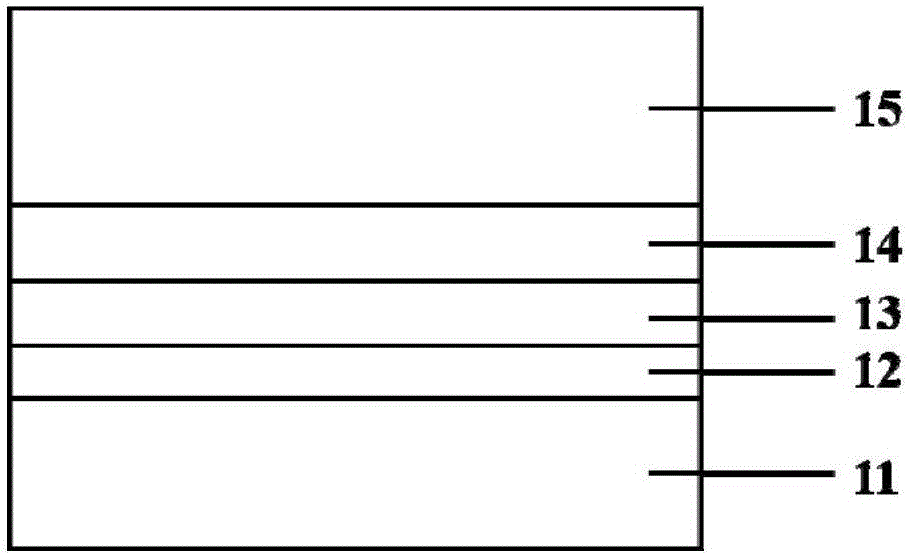

PendingCN114864770ALower free energyLay crystalline qualityFinal product manufactureSemiconductor devicesEngineeringContact layer

The invention provides a silicon-based gallium nitride epitaxial wafer and a manufacturing method thereof. The silicon-based gallium nitride epitaxial wafer comprises a silicon substrate, an Al layer, an AlN nucleating layer, a stress modulation layer, an N-type layer, a dislocation fine tuning layer, a multi-quantum well layer, an electron blocking layer, a P-type layer and a P-type contact layer, the AlN nucleating layer comprises an AlN three-dimensional nucleating layer and an AlN two-dimensional nucleating layer; the stress modulation layer is an Al < x > B < y > Ga < 1-x-y > N layer, x is more than 0 and less than 0.5, and y is more than 0 and less than 0.5; the dislocation fine tuning layer is any one or a combination of more of an AlN layer, a BN layer and a BGaN layer. According to the invention, the problem of large dislocation density of the existing gallium nitride epitaxy adopting the silicon substrate is solved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

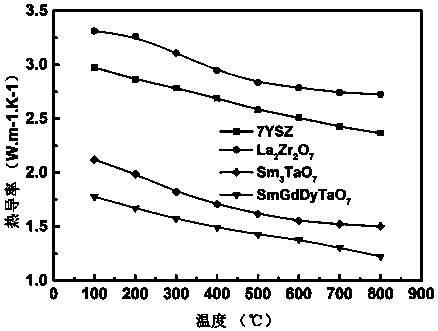

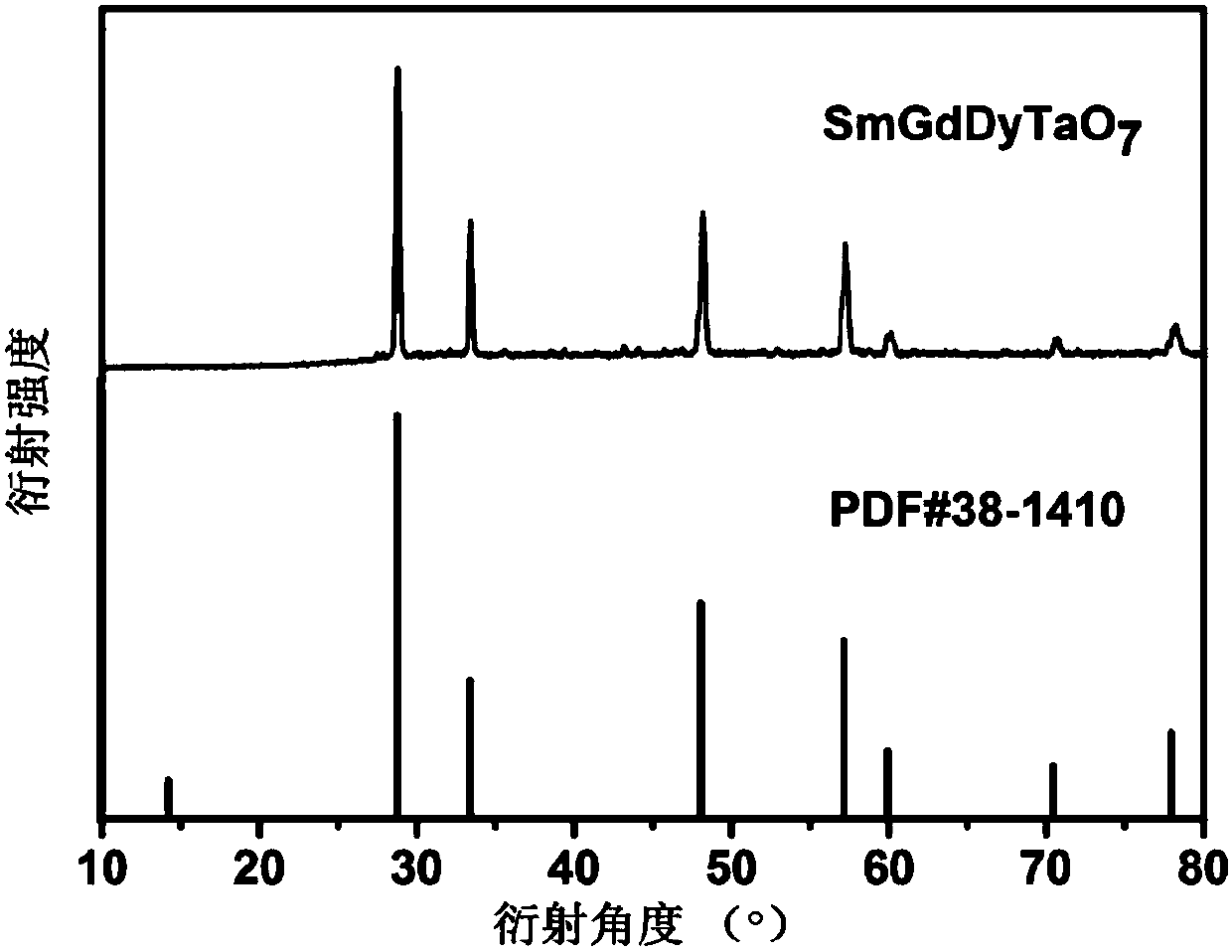

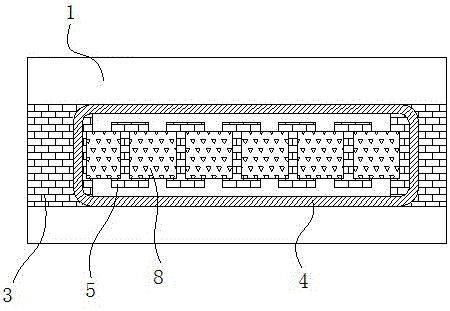

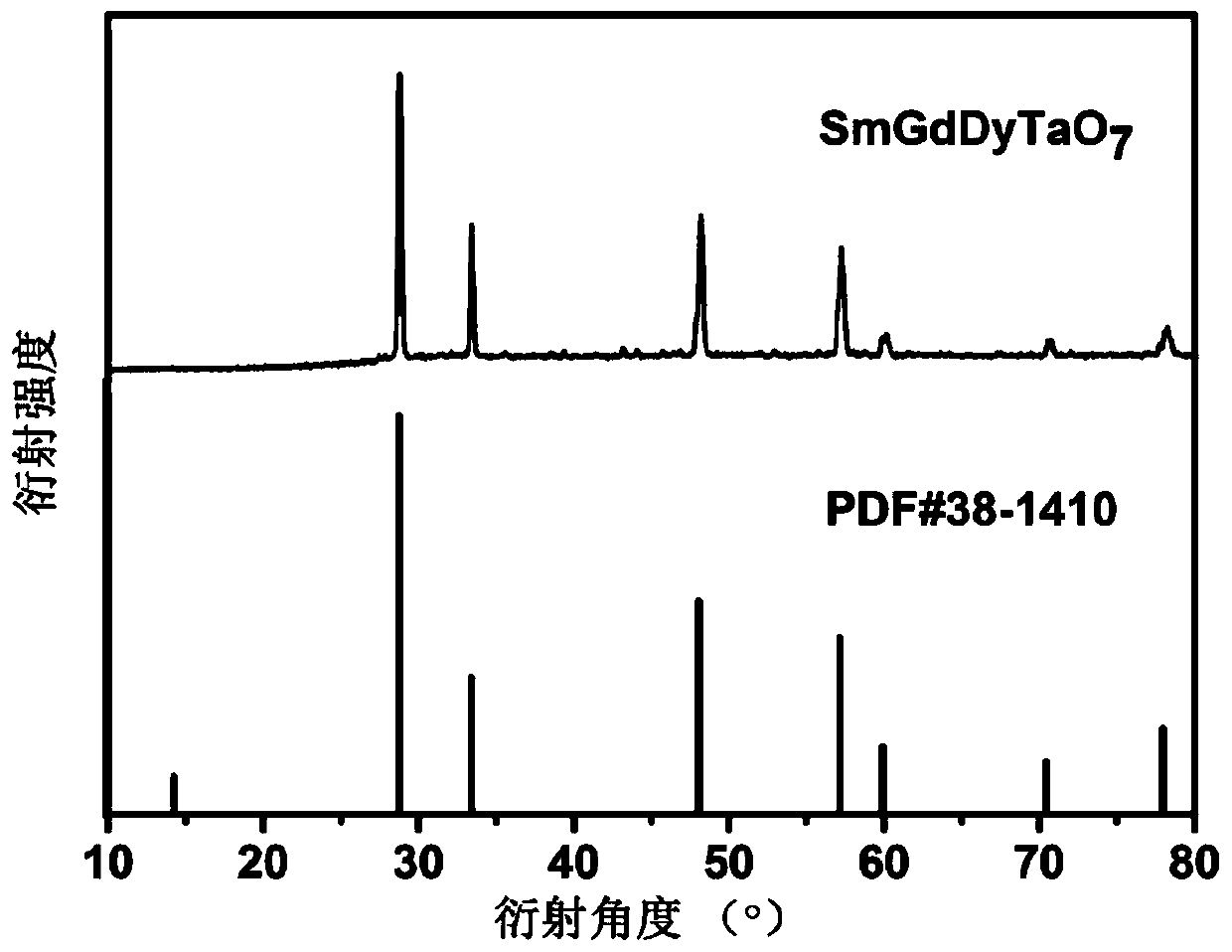

Sm-Gd-Dy tri-rare-earth ion tantalate and preparation method and application thereof

The invention discloses a Sm-Gd-Dy tri-rare-earth ion tantalate and a preparation method and application thereof. The general chemical formula of the Sm-Gd-Dy tri-rare-earth ion tantalate is SmGdDy<c>TaO<7>, wherein the a, b and c meet the relationship of a+b+c=3 and are separately in a range of 0.8-1.2. The preparation method comprises the following steps: (1) weighing samarium nitrate, gadolinium nitrate, dysprosium nitrate and tantalum oxalate according to a stoichiometric ratio, performing mechanical mixing with citric acid with a preset amount under a heat preservation condition, adding a concentrated ammonia water neutralization solution during the mixing process, and carrying out mechanical mixing to promote a complexation reaction under a heat preservation condition; and (2)drying the obtained solution, and then carrying out calcination at a high temperature to remove carbon impurities to obtain the Sm-Gd-Dy tri-rare-earth ion tantalate powder. The Sm-Gd-Dy tri-rare-earth ion tantalate has good high-temperature thermal stability and low thermal conductivity, and can be used as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

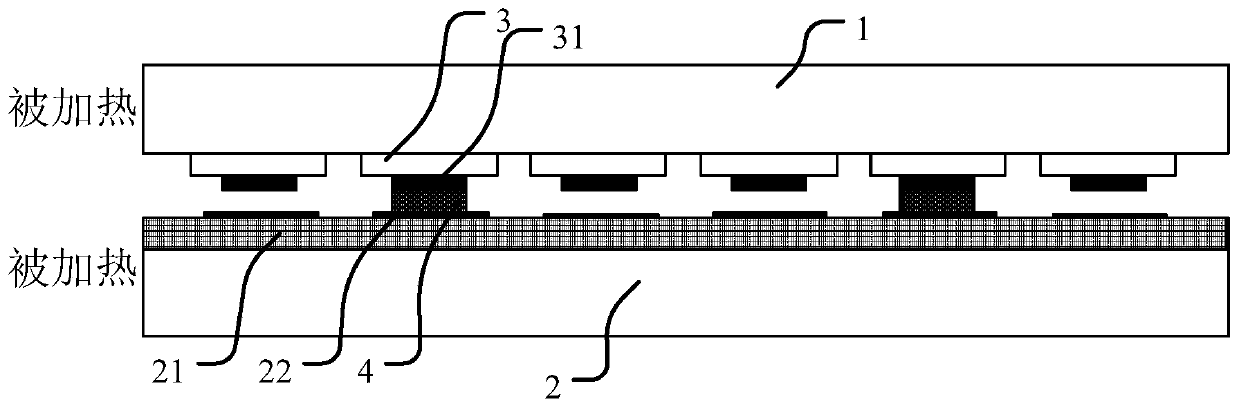

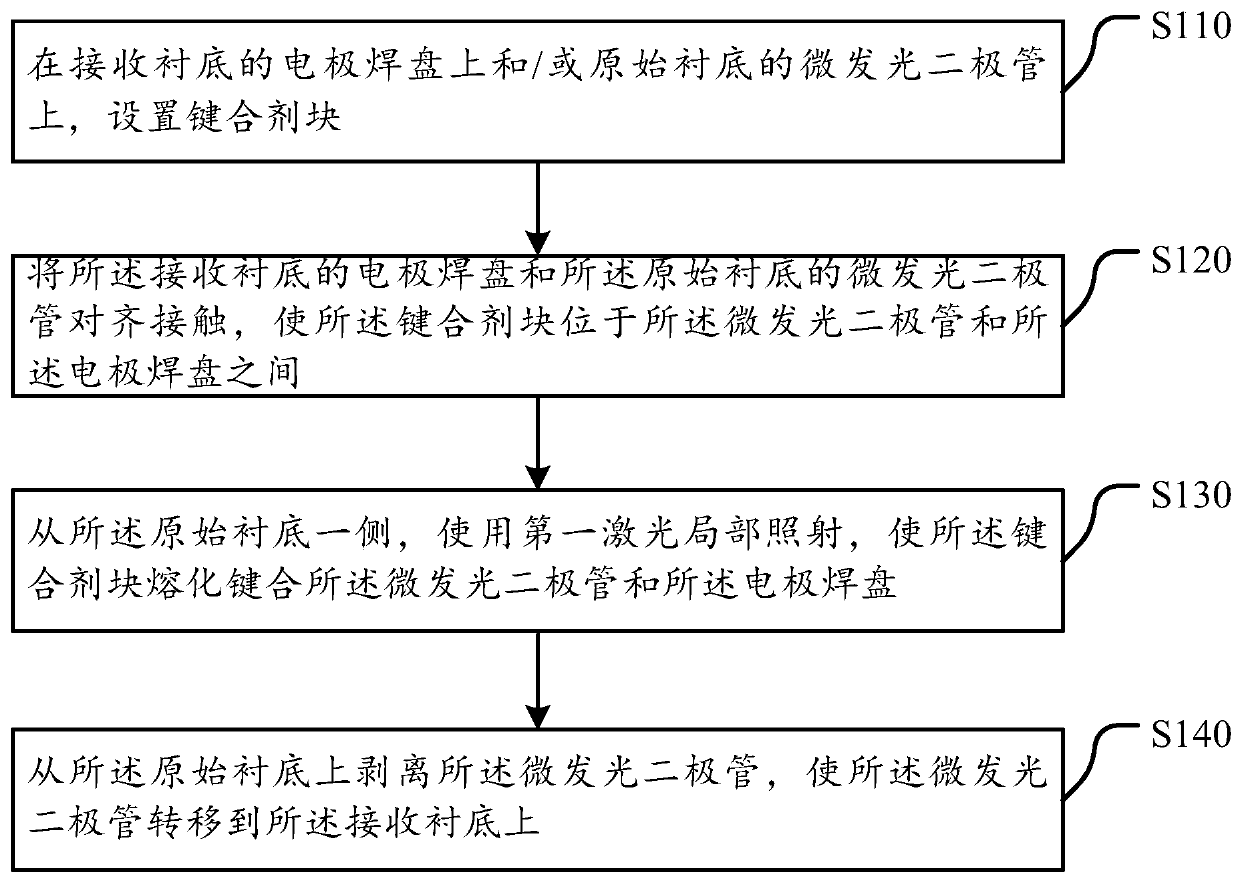

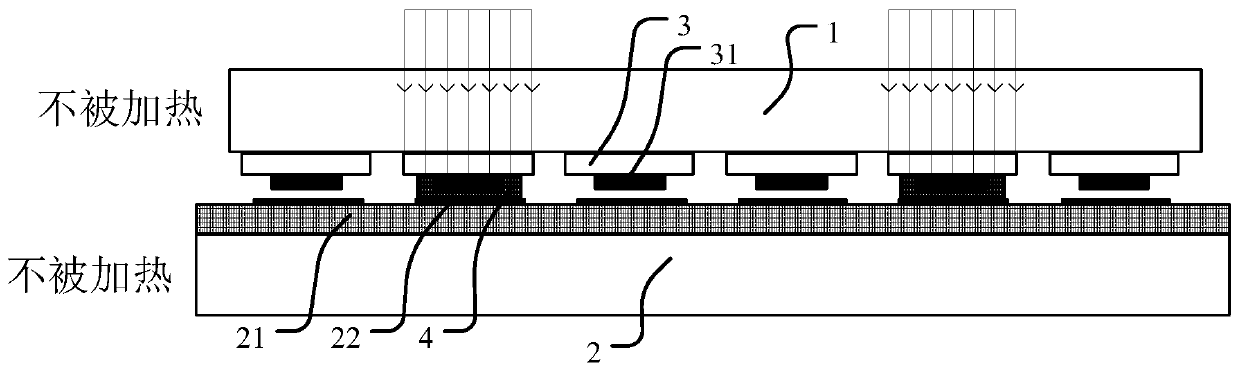

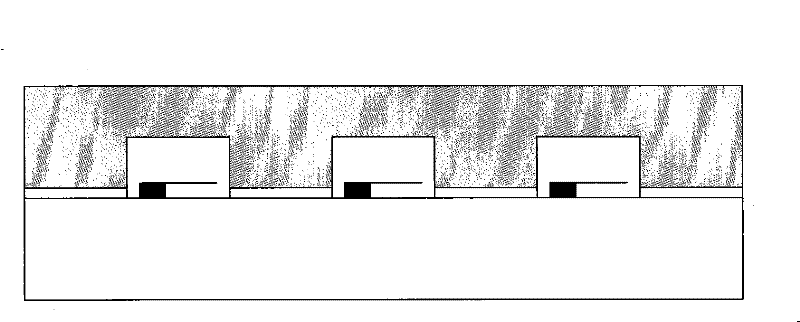

Method for transferring micro-light emitting diodes, micro-light emitting diode device and electronic device

ActiveCN110546771AOptimizing the Bonding ProcessAvoid heatingSolid-state devicesSemiconductor devicesEngineeringIrradiation

The present disclosure discloses a method for transferring micro-light emitting diodes, a micro-light emitting diode device and an electronic device. The method for transferring micro-light emitting diodes comprises: providing bumps of bonding agent on electrode bonding pads of a receiving substrate and / or on micro-light emitting diodes of an original substrate; aligning and contacting the electrode bonding pads of the receiving substrate and the micro-light emitting diodes of the original substrate, to position the bumps of bonding agent between the micro-light emitting diodes and the electrode bonding pads; irradiating locally by using a first laser from the original substrate side, to melt the bumps of bonding agent to bond the micro-light emitting diodes and the electrode bonding pads;and stripping off the micro-light emitting diodes from the original substrate, to transfer the micro-light emitting diodes to the receiving substrate. The present disclosure, by heating quickly and locally by laser irradiation, avoids the overall warming-up of the receiving substrate and the original substrate, reduces the heat mismatch phenomenon, optimizes the flow of the bonding of the micro-light emitting diodes, and facilitates the controlling.

Owner:GOERTEK INC

GaN film growing on magnesium aluminate scandium substrate as well as preparation method and application of GaN film

InactiveCN106158592AEasy to manufactureMature production processLaser detailsFinal product manufactureNucleationScandium

The invention discloses a GaN film growing on a magnesium aluminate scandium substrate. The GaN film comprises a GaN buffer layer, a GaN nucleation layer, a GaN amorphous layer and a GaN film which sequentially grow on an ScMgAlO4 substrate, wherein a (0001) surface, which deviates from a (11-20) surface by 0.5-1 degrees, of the ScMgAlO4 substrate is an extension surface. The invention fuehrer discloses a preparation method and application of the GaN film. Compared with the prior art, the preparation method has the advantages that the growing process is simple, and the preparation cost is low; and meanwhile, by utilizing an amorphous layer technique, the GaN film prepared by virtue of the preparation method has the characteristics of good crystalline quality, low defect density and the like.

Owner:SOUTH CHINA UNIV OF TECH

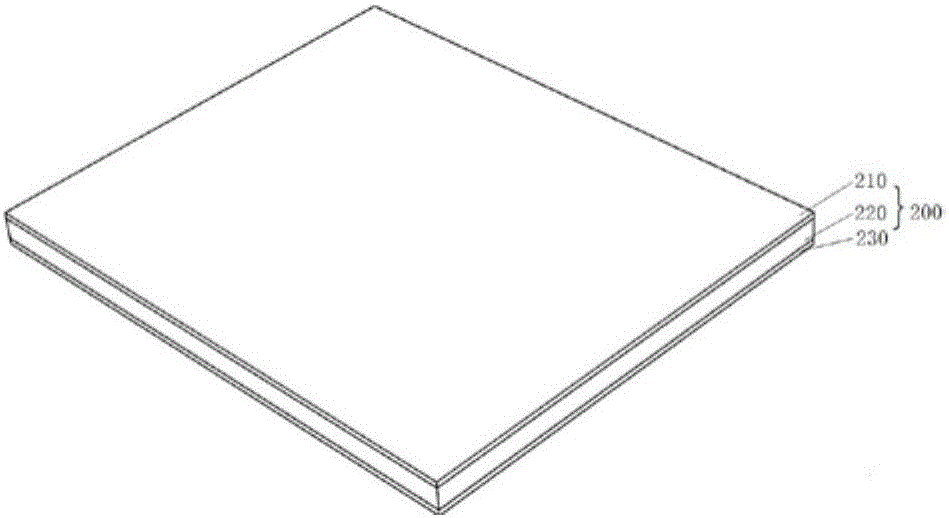

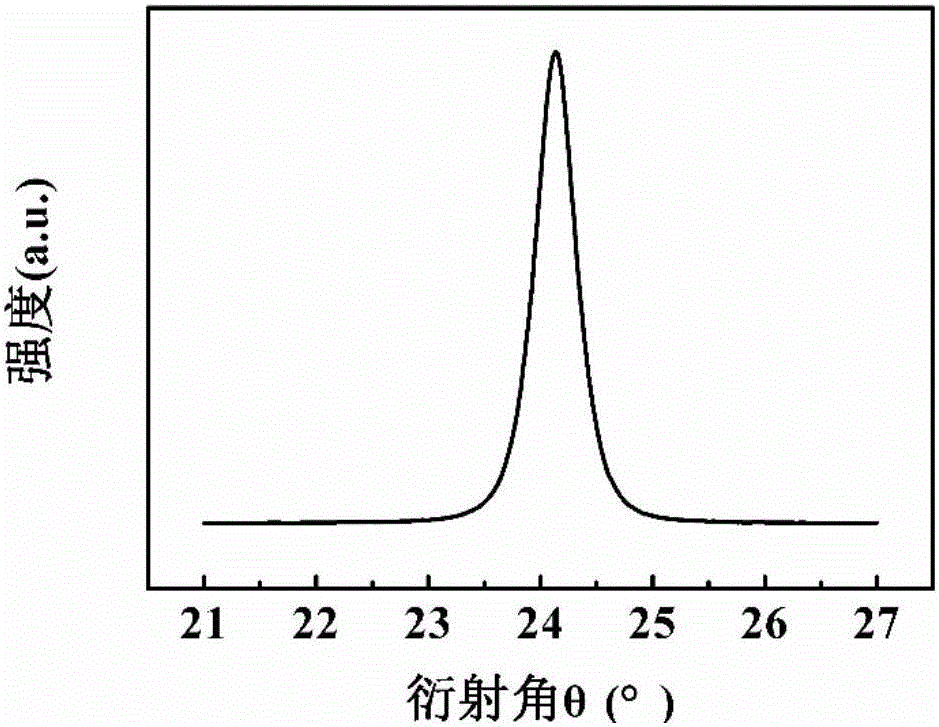

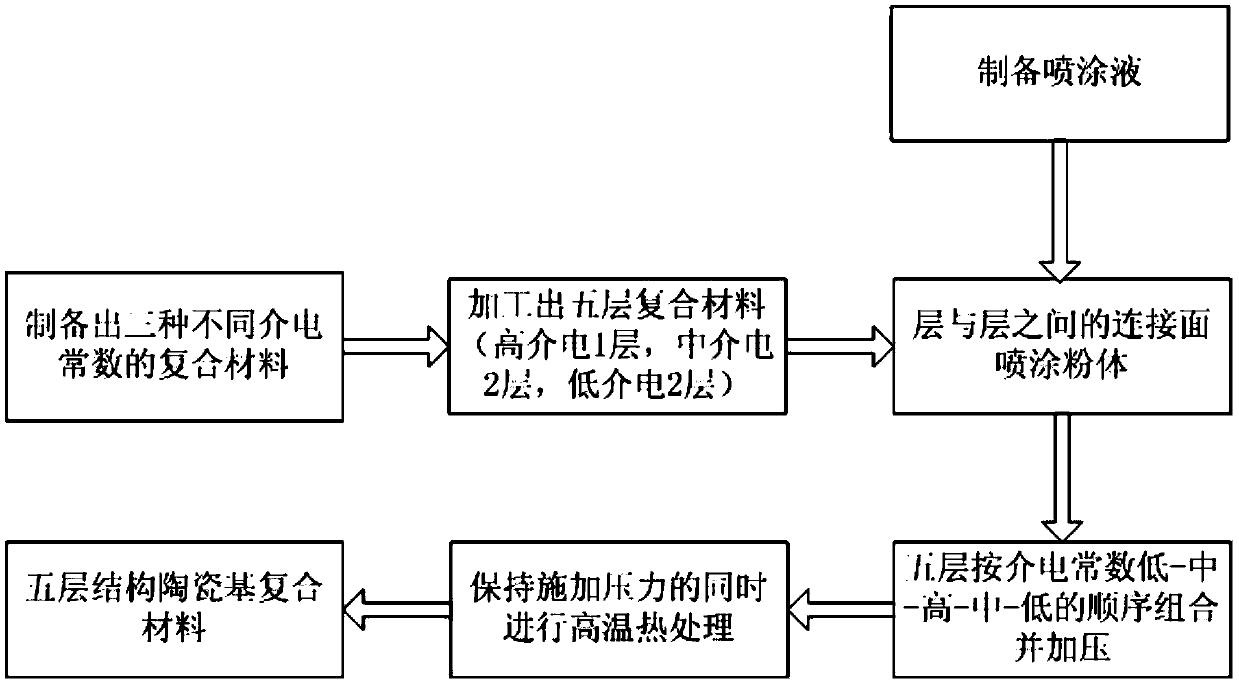

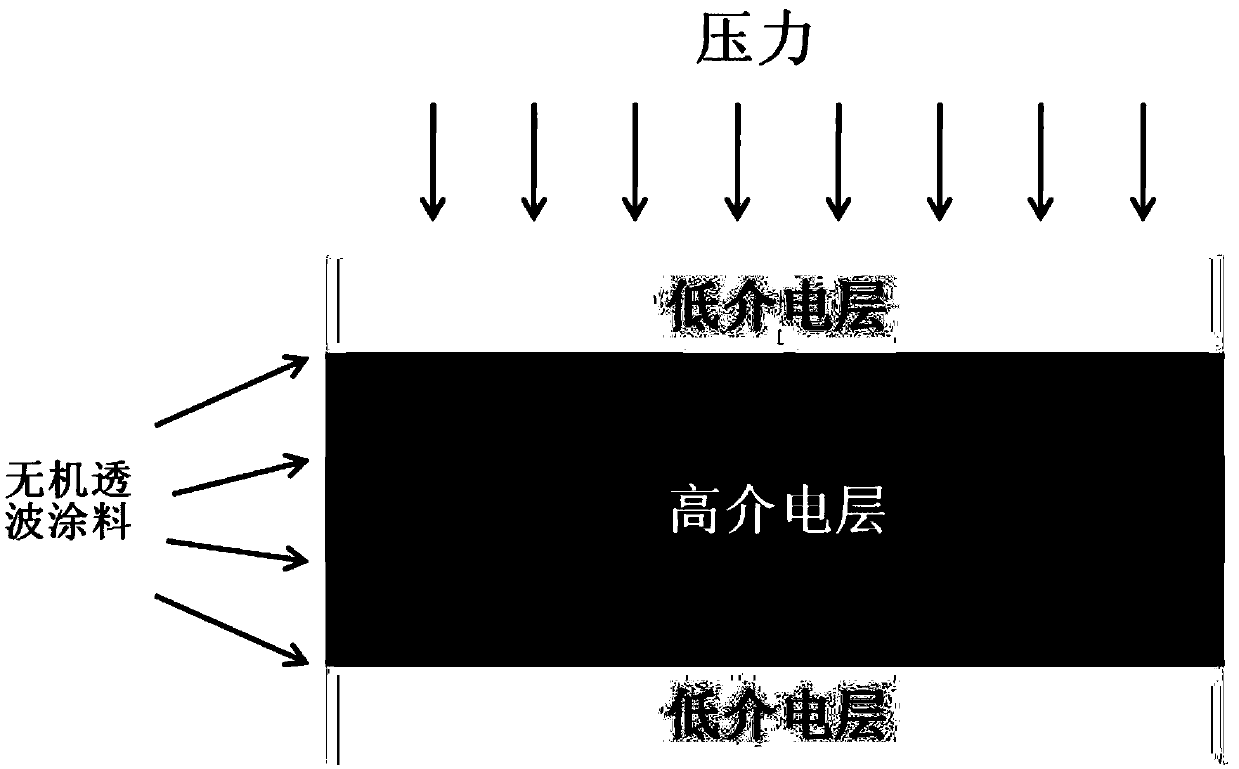

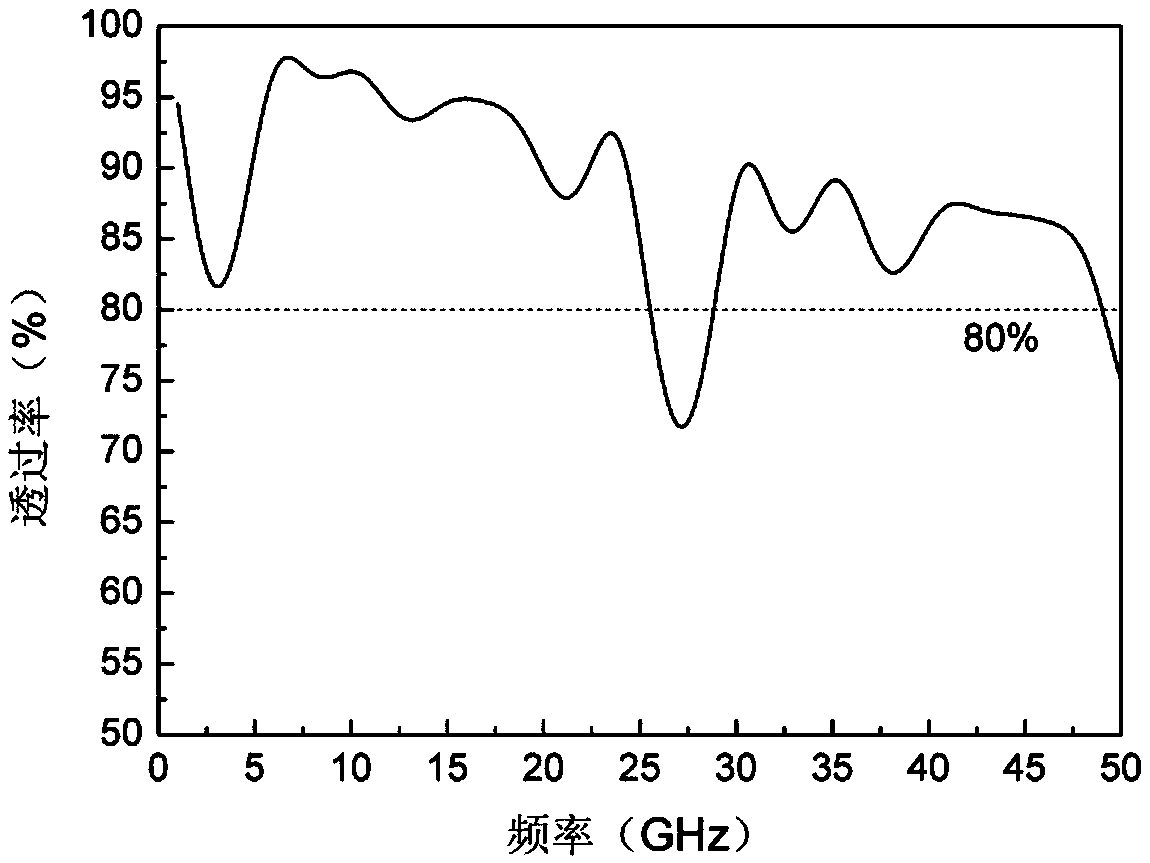

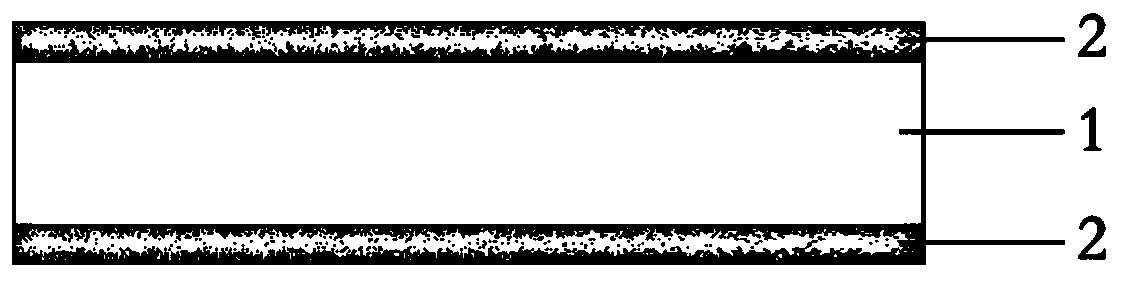

Broadband wave transmission multilayer structural ceramic-based composite material and method for preparing same

ActiveCN109664568AExcellent broadband wave transmission performanceExcellent dielectric propertiesLaminationLamination apparatusTransmittanceBroadband

The invention relates to a broadband wave transmission multilayer structural ceramic-based composite material and a method for preparing the same, and belongs to the technical field of composite materials. An odd number layers of inorganic wave transmission fiber reinforced ceramic-based composite materials are laminated to form the broadband wave transmission multilayer structural ceramic-based composite material. The dielectric constants of the odd number layers of inorganic wave transmission fiber reinforced ceramic-based composite materials are sequentially increased from outer layers to intermediate layers, and the various layers are fixedly adhered with one another by inorganic wave transmission coating. The broadband wave transmission multilayer structural ceramic-based composite material and the method have the advantages that the transmittance of the broadband wave transmission multilayer structural ceramic-based composite material at X / Ku / Ka wavebands (the maximum bandwidthscan be close to 50 G) can reach 80% at least, and the broadband wave transmission multilayer structural ceramic-based composite material can be used in high-temperature environments at the temperatures higher than 1000 DEG C for a long time and is high in reliability.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Low-heat-dissipation motorcycle engine manufacturing method

ActiveCN107034429AReduce bond strengthImprove cohesionMolten spray coatingSand blastingCylinder head

The invention relates to a low-heat-dissipation motorcycle engine manufacturing method. The manufacturing method includes the following steps that a piston, an air cylinder cover and an air cylinder body of an engine are subject to ultrasonic cleaning, and a spraying zone is subject to sand blasting through No.40 corundum gravels after washing is finished; a low temperature high velocity flame spraying is adopted for spraying the top surface of the piston and the inner surface of the air cylinder cover to form NiCoCrAlYTa bonding layers, and atmospheric plasma spraying is adopted for spraying the outer surface of the air cylinder body to form a NiCrAl bonding layer; and after the bonding layers are formed through spraying, the top surface of the piston, the inner surface of the air cylinder cover and the outer surface of the air cylinder body are subject to 7YSZ ceramic layer atmosphere plasma spraying. By means of the manufacturing method, through compounding of a ceramic material and a metal material, advantages of the two kinds of materials can be integrated, the defect that in the prior art, a view is given to manufacture pure ceramic engine parts is overcome, and therefore a motorcycle engine which is low in cost, high in heat isolation, resistant to oxidation, resistant to corrosion and long in service life is obtained.

Owner:GUANGDONG INST OF NEW MATERIALS

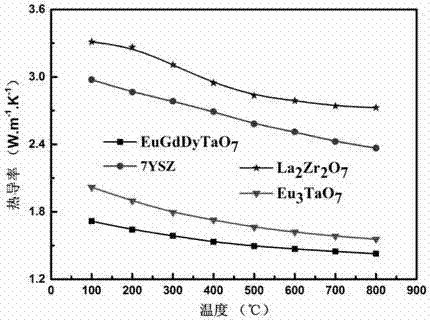

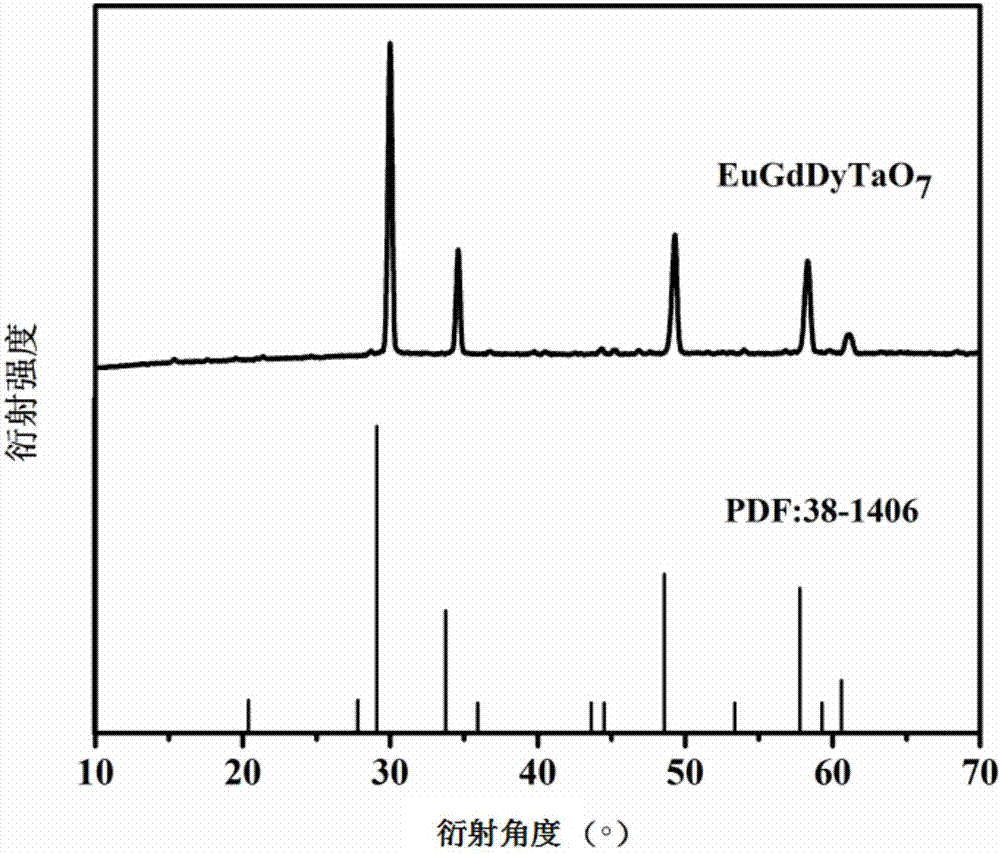

Eu-Gd-Dy trirare earth ion tantalate and preparation method and application thereof

The invention discloses Eu-Gd-Dy trirare earth ion tantalate and a preparation method and an application thereof, the Eu-Gd-Dy trirare earth ion tantalate has the chemical general formula of EuaGdbDycTaO7, wherein a+b+c=3, and a, b and c is 0.8-1.2. The preparation method comprises the following steps: 1) according to the stoichiometric ratio, weighing europium chloride, gadolinium nitrate, dysprosium nitrate and tantalum oxalate, mechanically mixing with citric acid with a set amount under a heat-retaining condition, adding strong aqua ammonia in the mixing process to neutralize the solution,and then mechanically mixing to promote the process of the reaction under a heat-retaining condition; and 2) drying the obtained solution, then calcining at high temperature to remove carbon impurities, and thus obtaining an Eu-Gd-Dy trirare earth ion tantalate powder. The Eu-Gd-Dy trirare earth ion tantalate has the advantages of good high temperature thermal stability and low thermal conductivity coefficient, and can be used as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

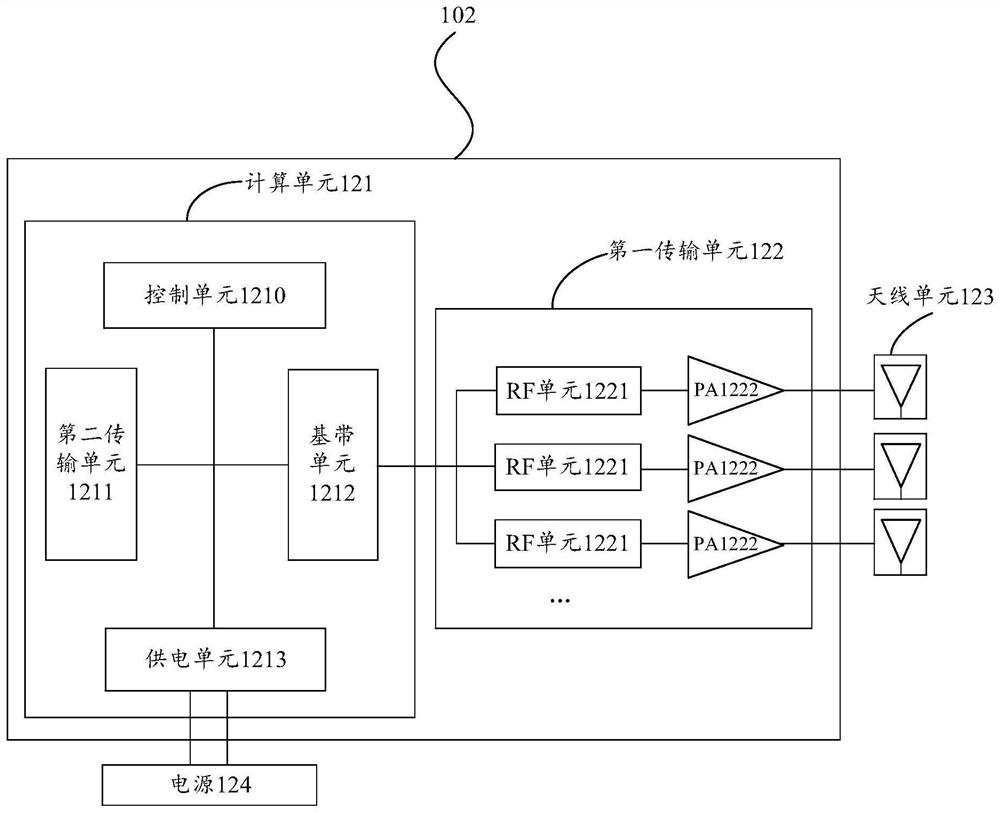

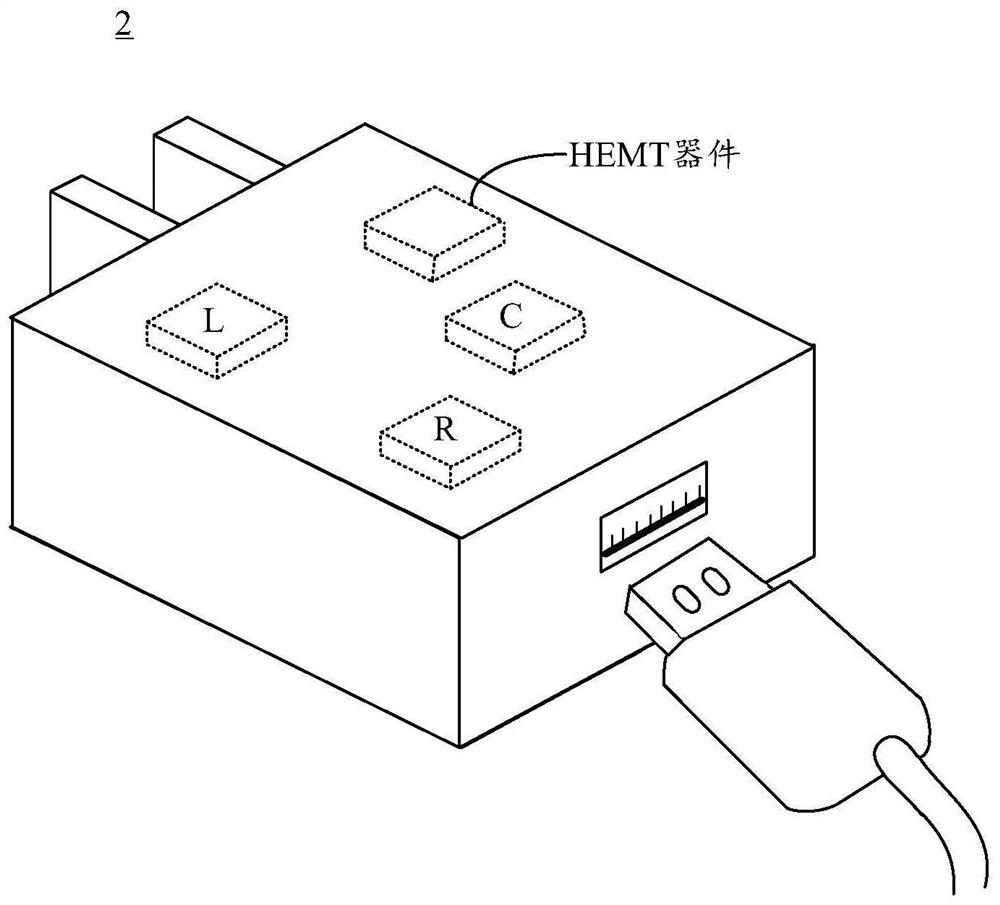

Composite substrate and preparation method thereof, semiconductor device and electronic equipment

PendingCN113658849AIncrease profitReduce cutting lossSemiconductor/solid-state device manufacturingSemiconductor devicesCarbide siliconDevice material

The embodiment of the invention provides a composite substrate and a preparation method thereof, a semiconductor device and electronic equipment, relates to the technical field of semiconductors, and is used for solving the problem of high cost of an AlxGayN-based semiconductor device due to high cost of SiC. The composite substrate comprises a bearing layer, a silicon carbide layer and at least one epitaxial layer, wherein the silicon carbide layer is arranged on the bearing layer and is bonded with the bearing layer; and the material of the silicon carbide layer comprises monocrystalline silicon carbide. At least one epitaxial layer is arranged on one side of the silicon carbide layer away from the bearing layer.

Owner:HUAWEI TECH CO LTD

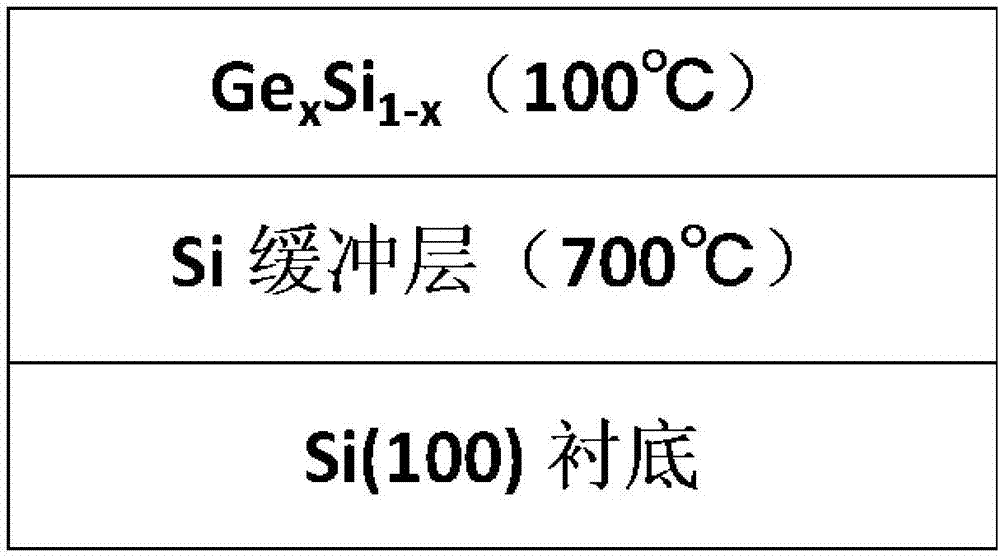

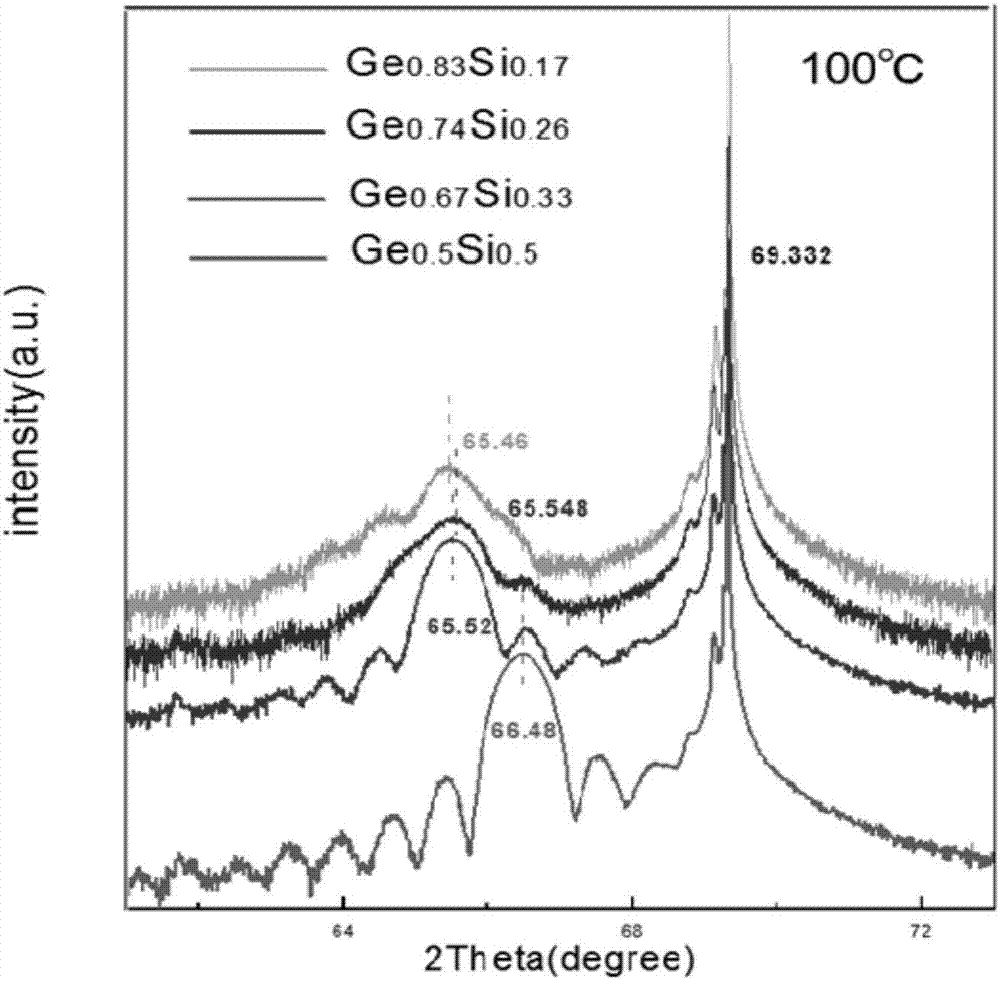

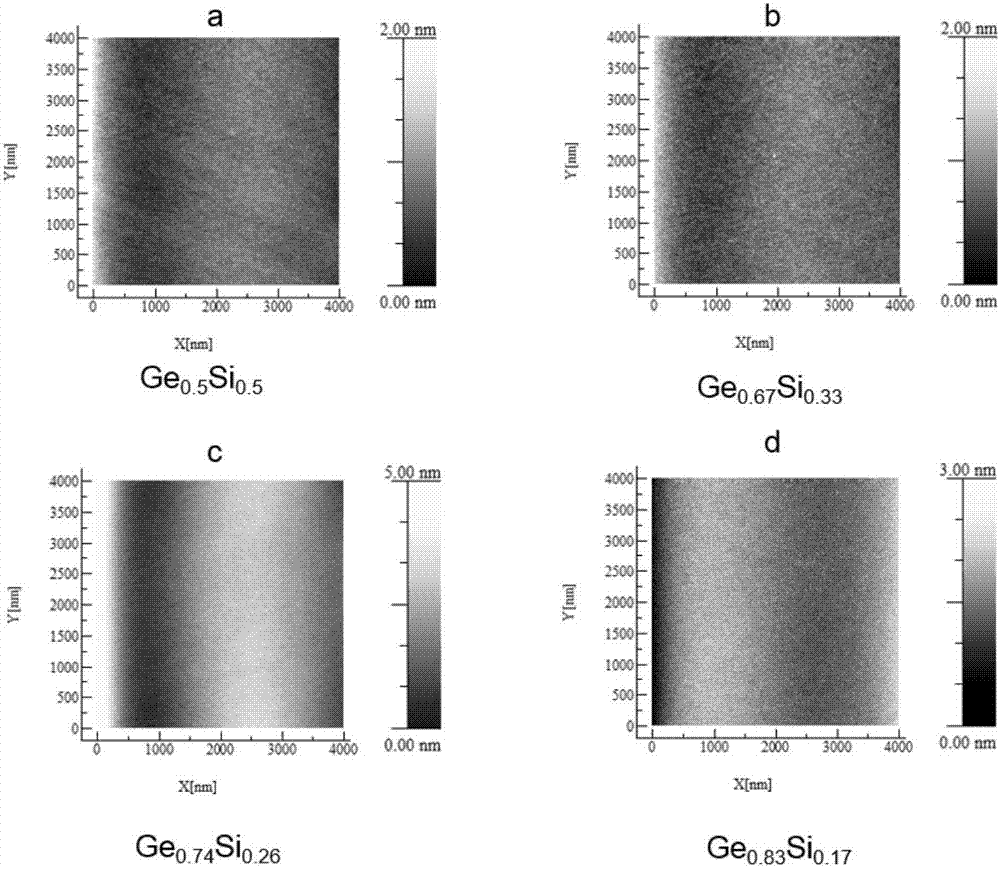

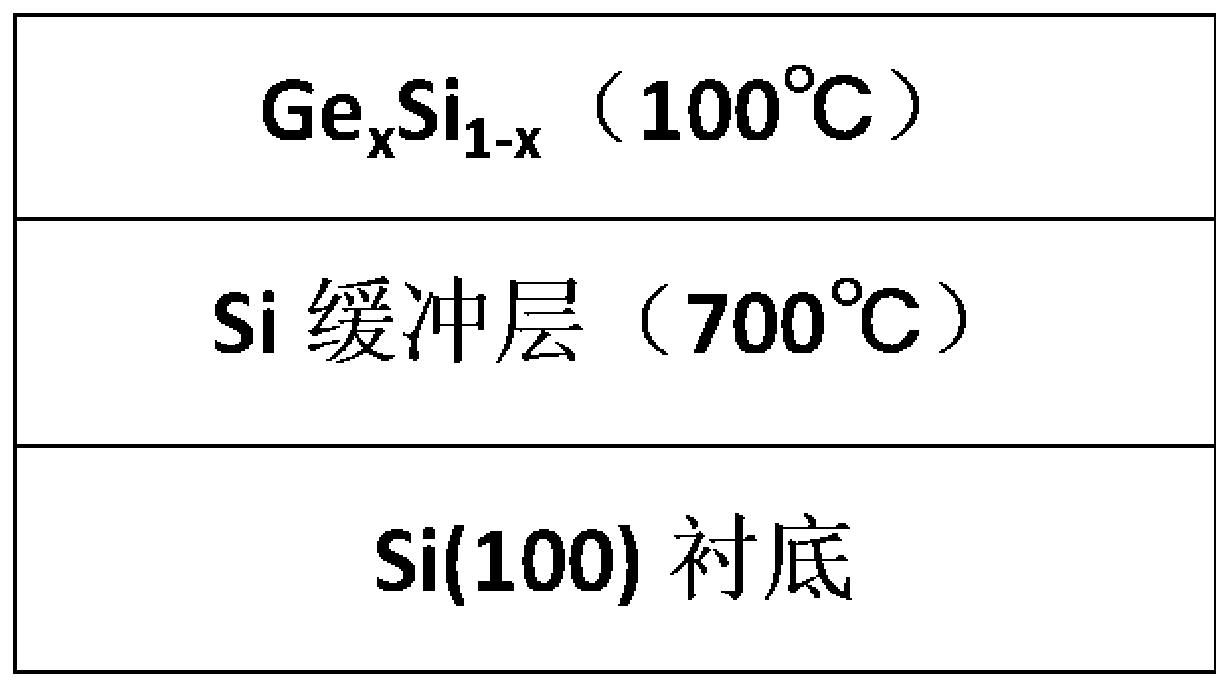

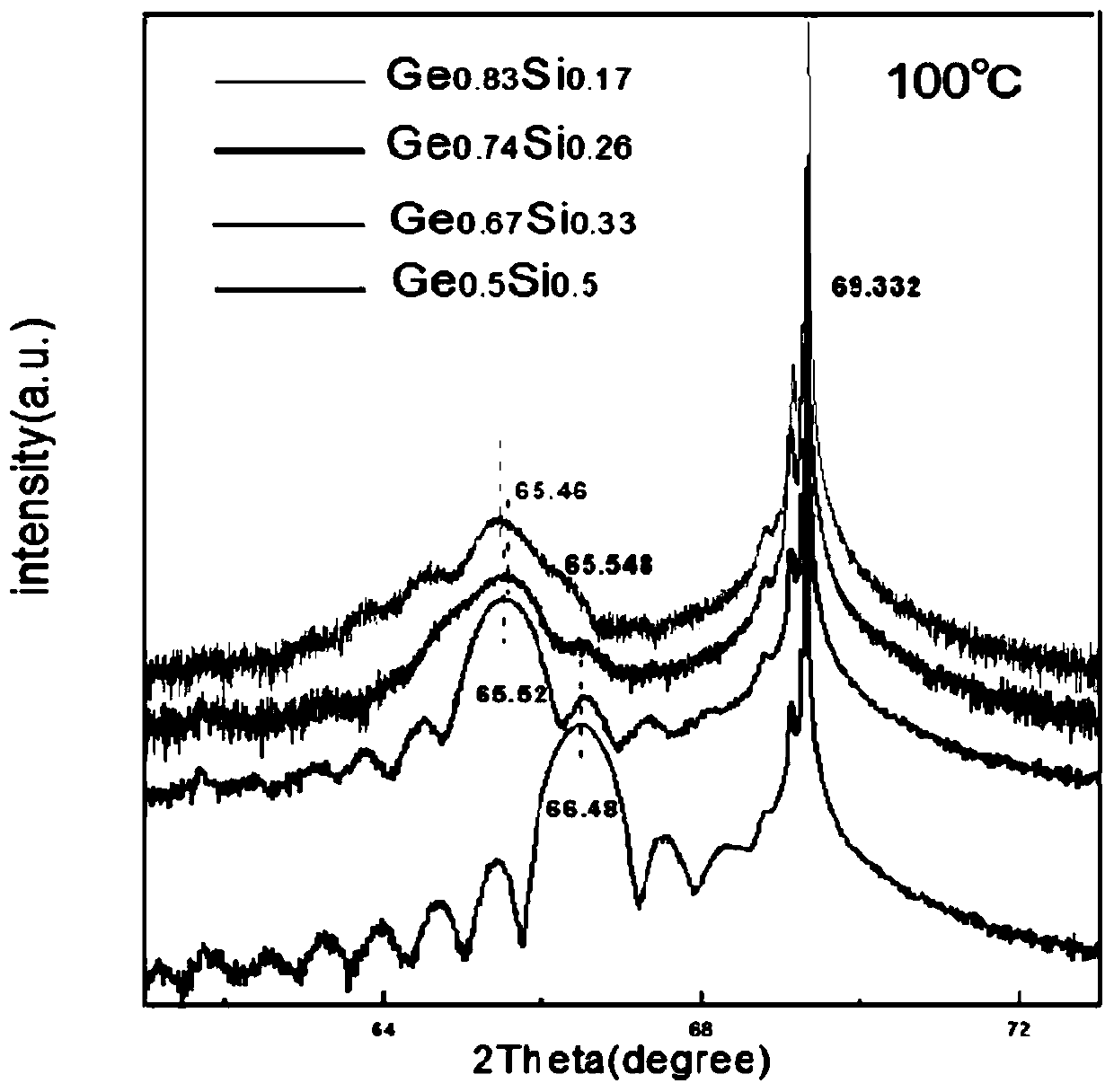

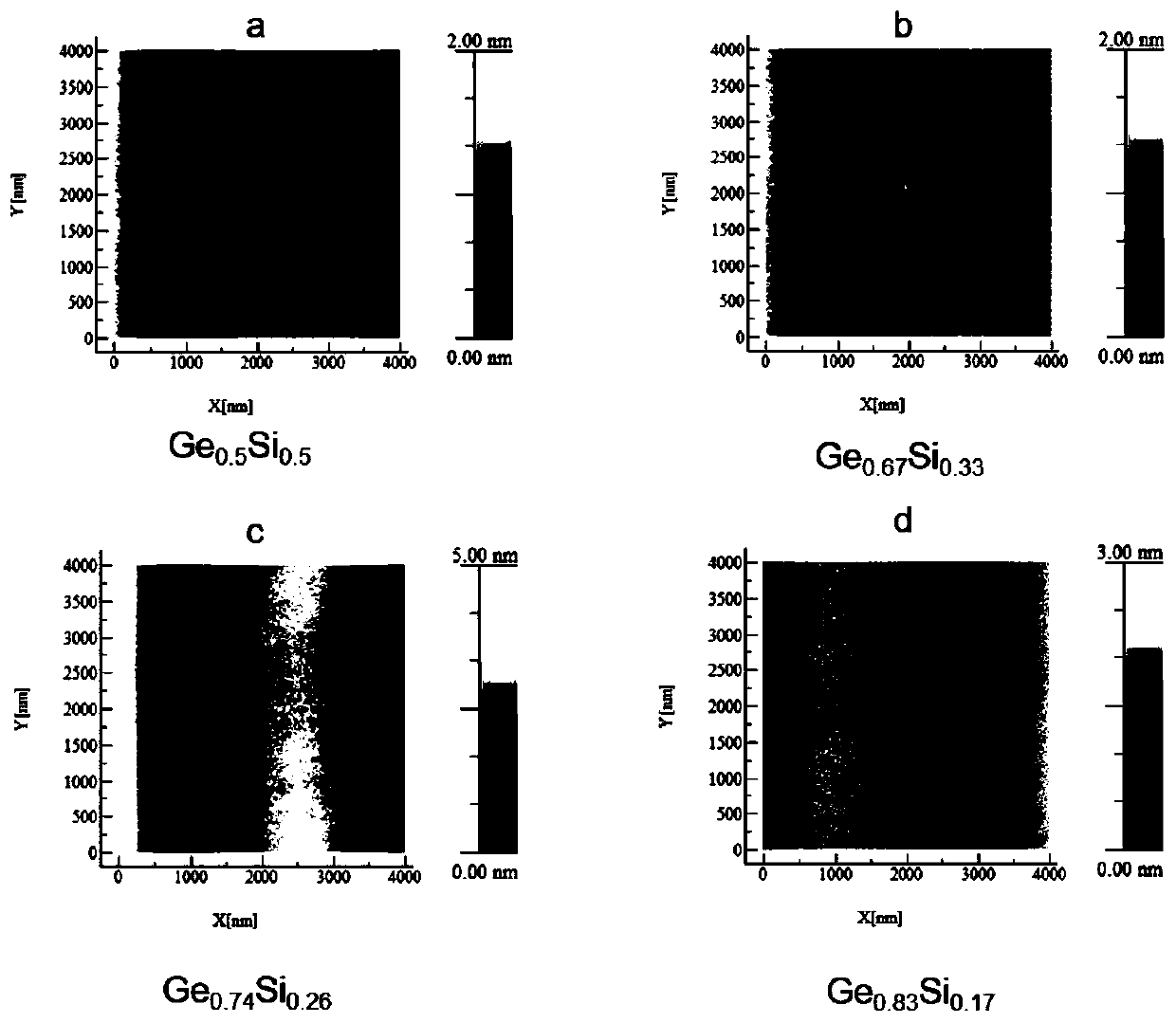

Low-temperature epitaxy preparation method of germanium-silicon film with high germanium content

ActiveCN107316802ASmall lattice mismatchAdjust the content ratio of germanium to siliconSemiconductor/solid-state device manufacturingAlloyLattice constant

The invention discloses a low-temperature epitaxy preparation method of a germanium-silicon film with high germanium content. The low-temperature epitaxy preparation method comprises the following specific steps: (1) providing a silicon substrate with a (100) crystal face; (2) carrying out deoxidation on the silicon substrate at the temperature of 1350 DEG C, wherein the deoxidation lasts for 10 minutes; (3) through a molecular beam epitaxy method, growing a silicon buffer layer with the thickness of 20 to 50 nm on the silicon substrate after deoxidation, wherein the growth temperature is 700 DEG C; and (4) cooling the silicon buffer layer to a growth temperature which is below 300 DEG C, then growing GexSi1-x alloy, and adjusting the content of Ge, namely an x value, by changing the growth rates of Ge and Si. According to the preparation method, the high-quality germanium-silicon (GexSi1-x) film material with adjustable lattice constants can be directly grown on the silicon wafer at low temperature, and the content of germanium at most can reach 83%. The method does not need to adopt a layer-by-layer growth pattern for improving the content of germanium layer by layer, so that the method is simpler in operation and lower in cost.

Owner:NANJING UNIV

High-power LED lighting package structure for vehicle lamp

InactiveCN106025048AHigh integration requirementsHigh light efficiencyOptical signallingSemiconductor devicesEngineeringPower flow

The invention discloses a high-power LED lighting packaging structure for vehicle lamps, which includes a high-purity aluminum plate, a diamond-like coating, a conductive layer, white silica gel, an LED chip, a packaging layer, liquid phase fusion and a fluorescent adhesive film; The aluminum plate is provided with a diamond-like coating, a conductive layer is provided on the diamond-like coating, a liquid phase fusion is provided on the conductive layer, a chip array composed of more than one LED chip is provided on the liquid phase fusion, and a package is provided on the LED chip. layer and / or fluorescent adhesive film, and a white silicone package is provided on the periphery of the chip array. The high-power LED lighting package structure for car lights of the invention can withstand high driving current, has low cost, low thermal resistance of the system, high light efficiency, and meets the high integration requirements of car lighting.

Owner:江苏鸿利国泽光电科技有限公司

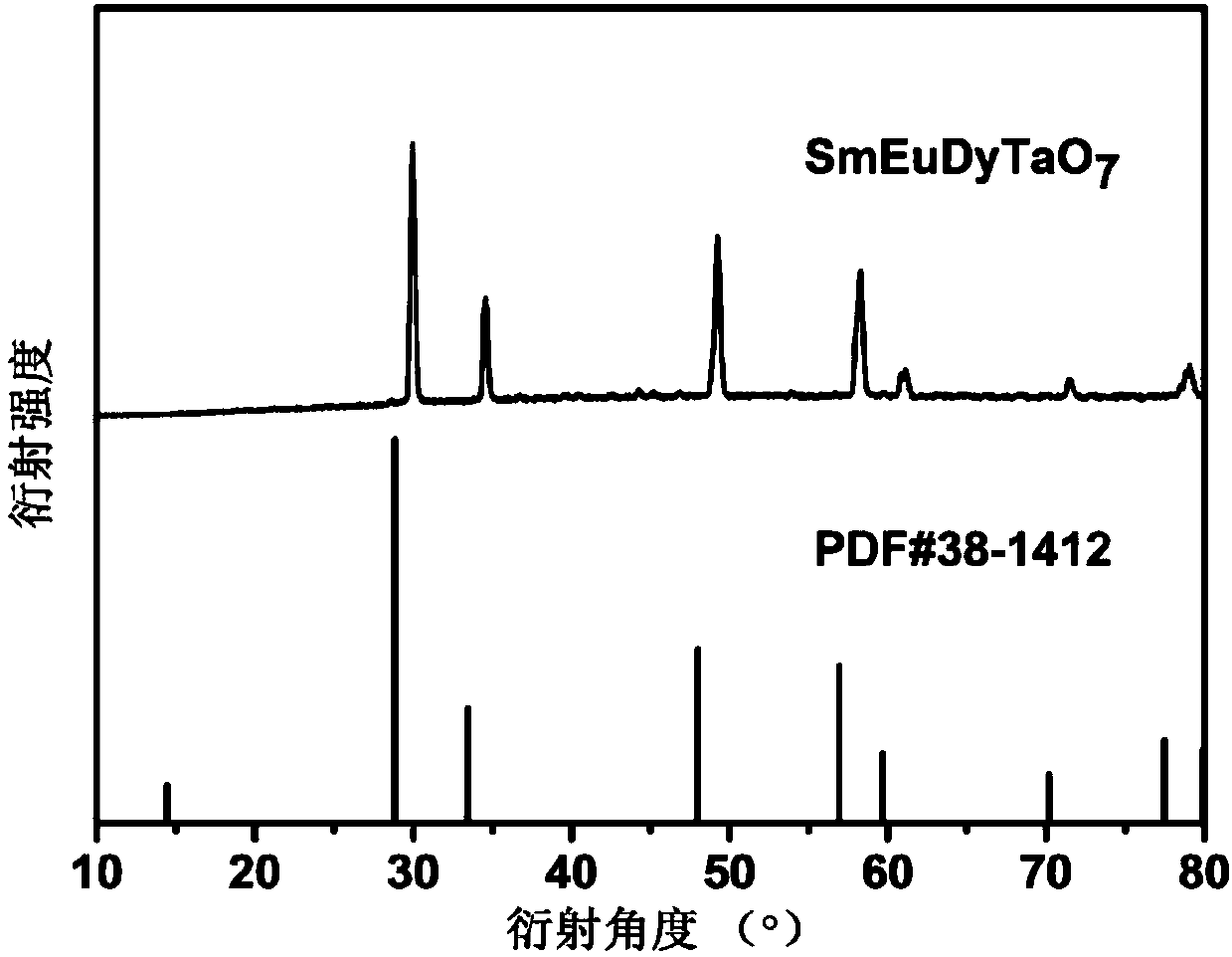

Sm-Eu-Dy tri-rare-earth ion tantalate and preparation method and application thereof

The invention discloses a Sm-Eu-Dy tri-rare-earth ion tantalate and a preparation method and application thereof. The general chemical formula of the Sm-Eu-Dy tri-rare-earth ion tantalate is SmEuDy<c>TaO<7>, wherein the a, b and c meet the relationship of a+b+c=3 and are separately in a range of 0.8-1.2. The preparation method comprises the following steps: (1) weighing europium chloride, samarium nitrate, dysprosium nitrate and tantalum oxalate according to a stoichiometric ratio, performing mechanical mixing with citric acid with a preset amount under a heat preservation condition, adding a concentrated ammonia water neutralization solution during the mixing process, and carrying out mechanical mixing to promote a chemical reaction under a heat preservation condition; and (2) drying the obtained solution, and then carrying out calcination at a high temperature to remove carbon impurities to obtain the Sm-Eu-Dy tri-rare-earth ion tantalate powder. The Sm-Eu-Dy tri-rare-earth iontantalate has good high-temperature thermal stability and low thermal conductivity, and can be used as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

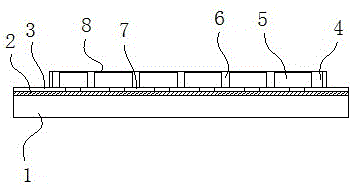

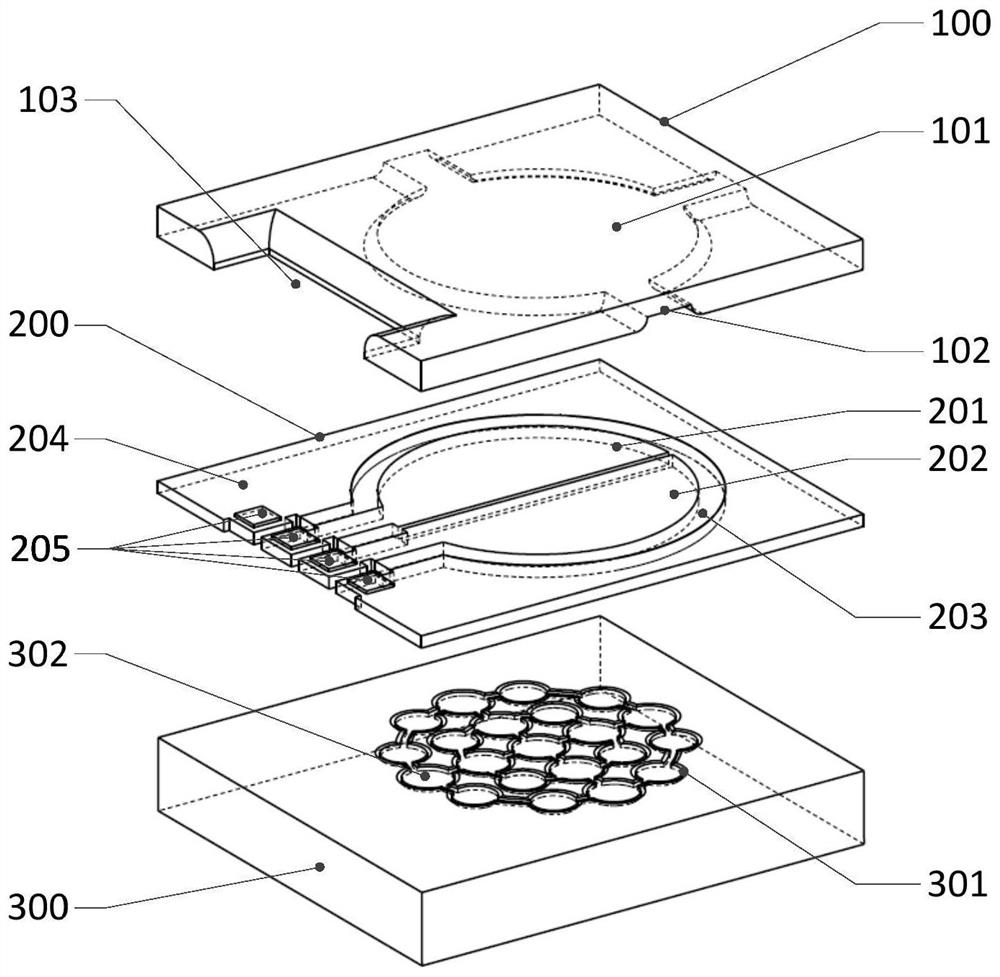

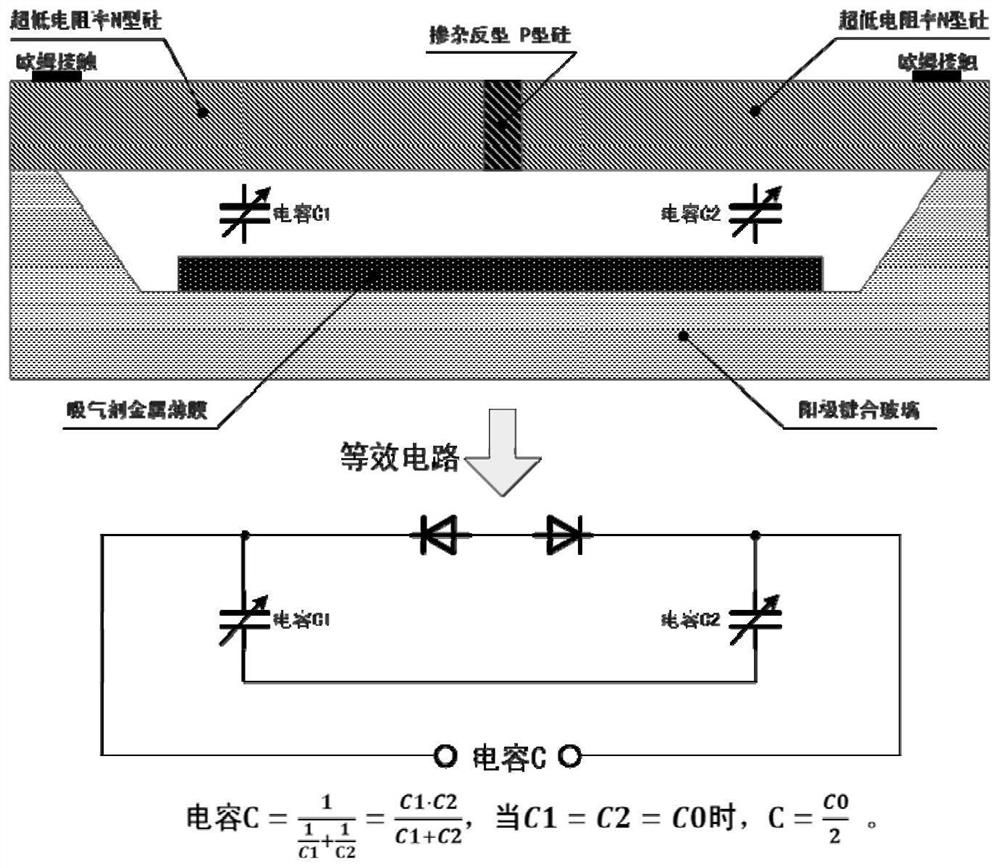

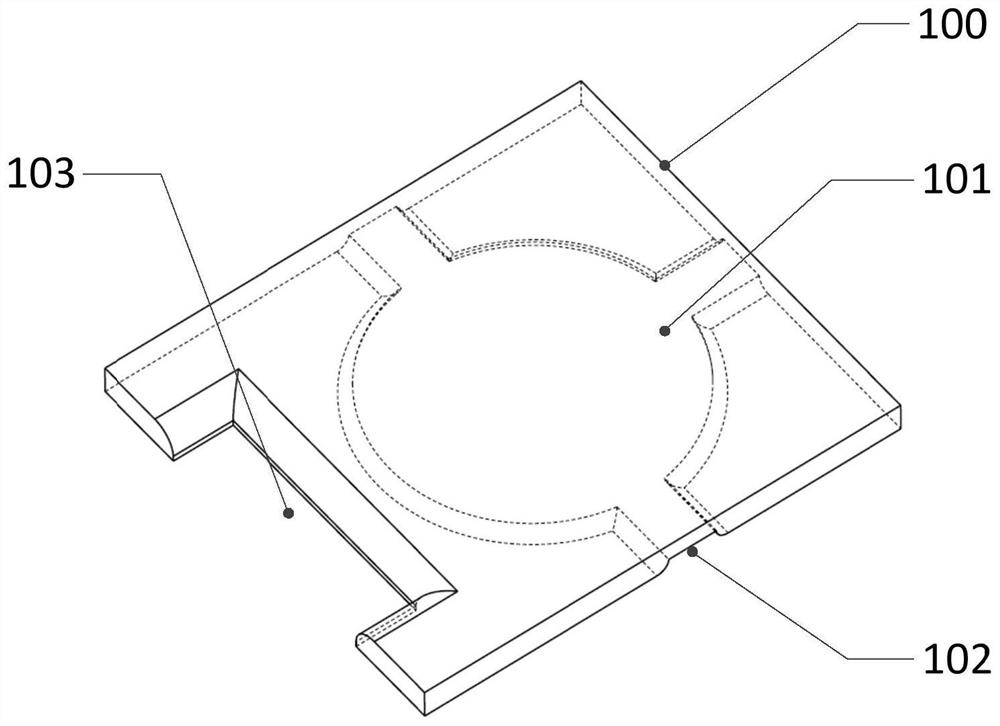

MEMS absolute pressure sensor and processing method thereof

ActiveCN112897450ALow equipment requirementsSimple processTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysicsAnodic bonding

The invention provides an MEMS absolute pressure sensor and a processing method thereof. The sensor comprises a glass cover plate, a silicon pressure sensing film and a glass substrate. One side of the silicon pressure sensing film is in anodic bonding with the glass substrate to form two communicated vacuum reference cavities, the other side of the silicon pressure sensing film is in anodic bonding with the glass cover plate to form two independent open type gas pressure sensing structures, and the two communicated vacuum reference cavities correspond to the two independent open type gas pressure sensing structures up and down, and form a series mutual inductance double-capacitor structure with a silicon pressure sensing film, and a lead electrode is processed on the silicon pressure sensing film and used for leading out an air pressure detection signal. External air pressure is applied to the silicon pressure sensing film through the open type gas pressure sensing structure, pressure difference is formed between the external air pressure and the vacuum reference cavity to enable the silicon pressure sensing film to deform, then the distance between the silicon pressure sensing film and the capacitance plate of the glass substrate is changed, and the capacitance value is changed to reflect the external air pressure. The processing technology based on the sensor is few in steps, extremely high in qualified rate, good in long-term stability of products and convenient for large-scale batch production.

Owner:BEIJING RES INST OF TELEMETRY +1

sm-gd-dy triple rare earth ion tantalate and its preparation method and application

ActiveCN107585786BExtended service lifeGood thermal propertiesTantalum compoundsDysprosium nitrateCalcination

Owner:陕西天璇涂层科技有限公司

A kind of low-temperature epitaxy preparation method of germanium-silicon thin film with high germanium content

ActiveCN107316802BSmall lattice mismatchAdjust the content ratio of germanium to siliconSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention discloses a low-temperature epitaxy preparation method of a germanium-silicon film with high germanium content. The low-temperature epitaxy preparation method comprises the following specific steps: (1) providing a silicon substrate with a (100) crystal face; (2) carrying out deoxidation on the silicon substrate at the temperature of 1350 DEG C, wherein the deoxidation lasts for 10 minutes; (3) through a molecular beam epitaxy method, growing a silicon buffer layer with the thickness of 20 to 50 nm on the silicon substrate after deoxidation, wherein the growth temperature is 700 DEG C; and (4) cooling the silicon buffer layer to a growth temperature which is below 300 DEG C, then growing GexSi1-x alloy, and adjusting the content of Ge, namely an x value, by changing the growth rates of Ge and Si. According to the preparation method, the high-quality germanium-silicon (GexSi1-x) film material with adjustable lattice constants can be directly grown on the silicon wafer at low temperature, and the content of germanium at most can reach 83%. The method does not need to adopt a layer-by-layer growth pattern for improving the content of germanium layer by layer, so that the method is simpler in operation and lower in cost.

Owner:NANJING UNIV

A kind of c/c-sic-zrc-tic composite material and preparation method thereof

ActiveCN104671814BReduce thermal mismatchRelieve stress concentrationCeramic layered productsFiberInterface layer

The invention discloses a C / C-SiC-ZrC-TiC composite material and a preparation method thereof. The composite material is composed of a carbon fibre, a pyrolytic carbon, a main matrix phase ZrC-TiC and a sub matrix phase SiC. The composite material is characterized in that the SiC is used as an interface layer for separating the pyrolytic carbon from the ZrC-TiC. The preparation method comprises the following steps: melting the mixed powder of Zr, Ti and Si, permeating into the inside of the low-density C / C composite material through a capillary action, forming a ceramic phase in a hole through an in situ reaction to obtain the C / C-SiC-ZrC-TiC composite material. The preparation method is rapid and effective and low in cost; the prepared composite material has excellent super-high temperature ablation resistance performance and simultaneously has excellent strength, breaking tenacity and thermal shock resistance.

Owner:深圳金羽先进材料有限公司

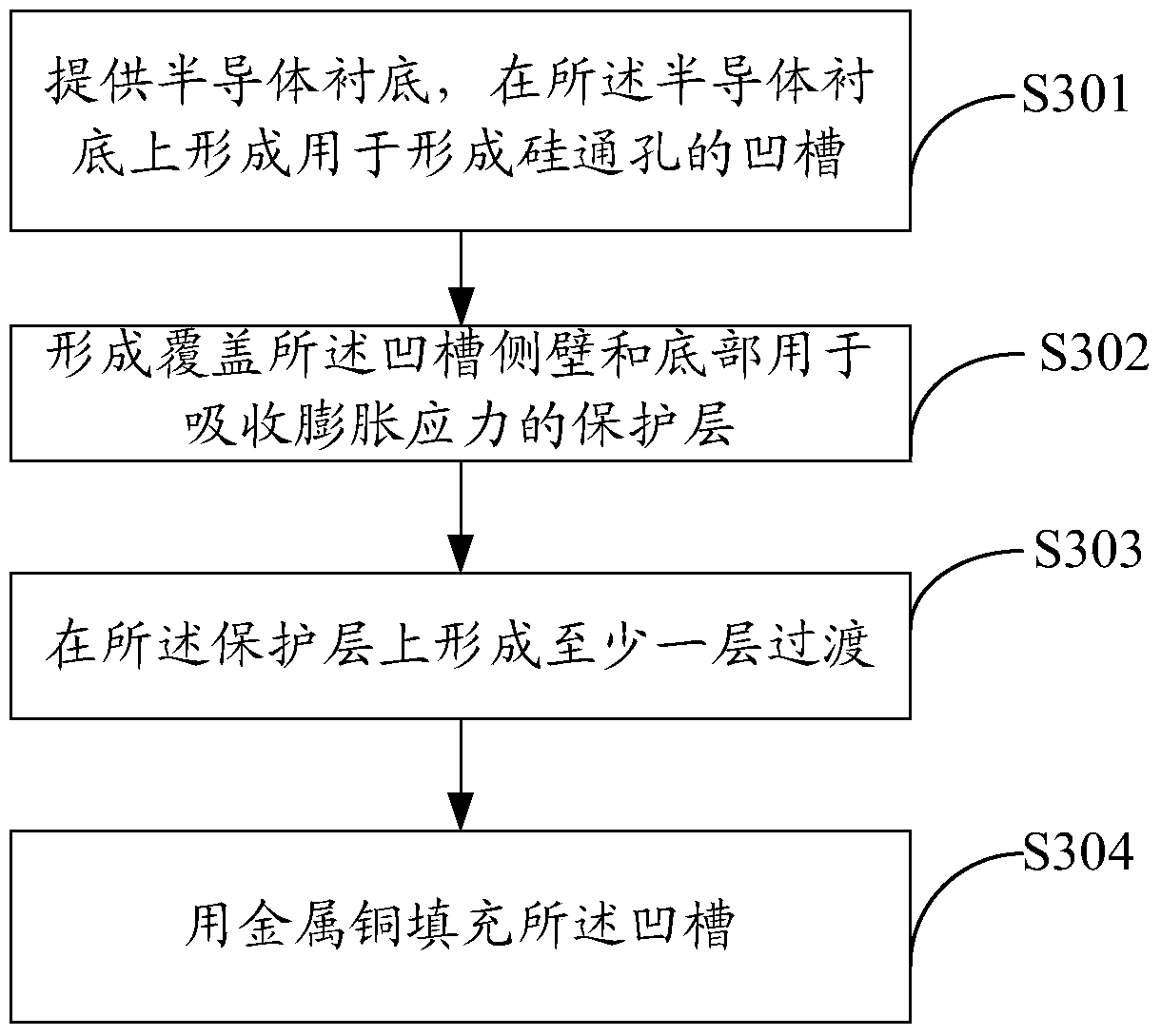

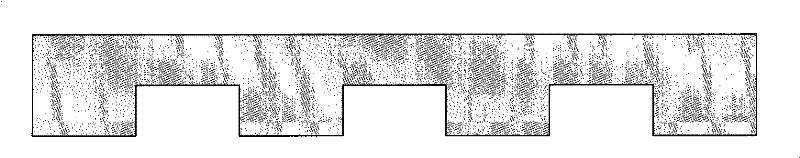

Semiconductor device manufacturing method, semiconductor device and electronic device

ActiveCN106158735BDoes not affect conductivityEnhance jumping abilitySemiconductor/solid-state device detailsSolid-state devicesMetallic materialsThermal expansion

The invention provides a manufacturing method for a semiconductor device. The manufacturing method comprises: a semiconductor substrate is provided and a groove for forming a through silicon via is formed in the semiconductor substrate; a protection layer that covers the side wall and the bottom of the groove and is used for absorbing a swelling stress is formed; at least one transition layer is formed on the protection layer; and the groove is filled by metallic copper, wherein the transition layer employs a metal material and the thermal expansion coefficient of the transition layer is smaller than that of the copper. According to the manufacturing method, the metal material having the small thermal expansion coefficient is added between the silicon and cooper during the through silicon via forming process to form the transition layer between the Si / Cu, so that the thermal mismatching between the two kinds of materials is reduced; the thermal expansion coefficient is increased gradually from the transition layer to the metallic copper layer, thereby reducing the thermal mismatching among all materials at all layers effectively and thus avoiding layering or copper layer protrusion.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Low-temperature glass solder bonding and encapsulating method based on disc level glass micro-chamber

InactiveCN101497422BGuaranteed reliabilityReduce packaging costsTelevision system detailsPrecision positioning equipmentScreen printingCMOS

The invention discloses a low-temperature glass solder bonding and packaging method based on wafer-level glass microcavities, which comprises the following steps: firstly, utilizing a silk-screen printing process to coat low-temperature glass solder on a packaging contact part of a Pyrex7740 glass substrate provided with a microcavity structure, preliminarily drying the low-temperature glass solder, and making the low-temperature glass solder be cured and cling to the Pyrex7740 glass substrate provided with the microcavity structure; secondly, aligning a Pyrex7740 glass packaging wafer which is cured with the low-temperature glass solder and a silicon substrate wafer comprising an MEMS device or a CMOS circuit, and making the microcavity structure on the Pyrex7740 glass substrate correspond to the position of the MEMS device or the CMOS circuit to be packaged of a silicon substrate; and thirdly, using a clamper to firmly clamp the two aligned wafers, applying the pressure, sintering the glass solder in a specified packaging atmosphere, and cooling the glass solder. The whole process is based on integral processing of the silicon wafer and the Pyrex7740 glass wafer, belongs to a process for manufacturing and packaging a wafer-level MEMS, and has the characteristics of simple method, adjustable packaging space and low cost.

Owner:SOUTHEAST UNIV

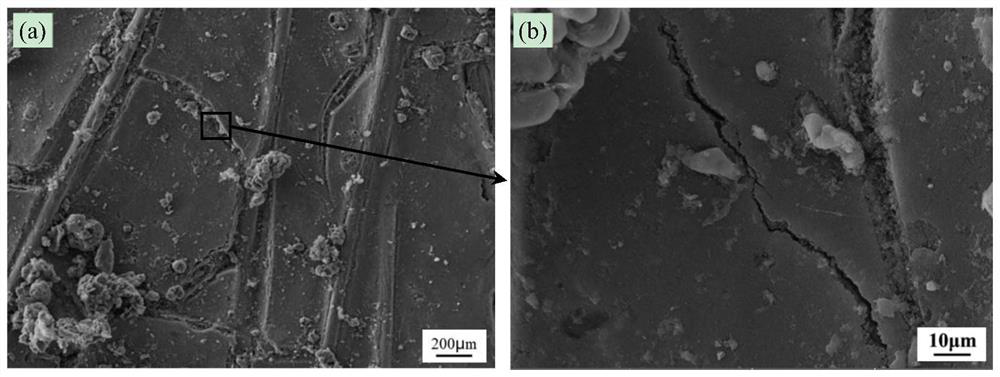

Antioxidant zrb2-sic-y2o3-sic coating on the surface of c-c composite material and preparation method thereof

The invention discloses anti-oxidation ZrB on the surface of C-C composite material 2 ‑SiC‑Y 2 O 3 ‑SiC coating and method of making the same. First, a SiC transition layer was prepared on the surface of the C-C composite matrix by embedding and infiltration technology, and ZrB was prepared on the SiC transition layer by embedding and infiltration. 2 ‑SiC‑Y 2 O 3 outer coating. in ZrB 2 ‑SiC‑Y 2 O 3 The introduction of a SiC transition layer between the coating and the substrate can alleviate the mismatch of thermal expansion coefficients, release thermal stress, and further improve the oxidation resistance of the coating. The present invention adopts two-step embedding and infiltration technology to prepare ZrB 2 ‑SiC‑Y 2 O 3 ‑SiC composite coating has little thermal damage to the C‑C substrate, strong bonding force of the coating, and dense coating. The SiC transition layer effectively relieves the mismatch between the thermal expansion coefficients of the outer coating and the substrate, reduces the cracking of the outer coating due to thermal stress, improves the bonding force of the coating, and effectively improves the oxidation resistance of the coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

mems capacitive air pressure sensor based on pn junction electrical isolation and anodic bonding technology

ActiveCN111044206BControl thicknessTo meet the needs of different detection rangePrecision positioning equipmentSoldering apparatusCapacitanceGlass cover

The invention discloses a MEMS capacitive air pressure sensor based on PN junction electrical isolation and anodic bonding technology, comprising an air pressure sensitive film, a glass substrate and a glass cover plate; one side of the air pressure sensitive film is anodically bonded with the glass substrate to form a vacuum reference chamber , the other side of the air pressure sensitive film is anodically bonded with the glass cover to form an open gas pressure sensitive film, the external air pressure is applied to the air pressure sensitive film, and the pressure difference with the vacuum reference chamber forms a pressure difference to deform the air pressure sensitive film, and then changes the air pressure sensitive film The distance between the capacitive plate and the glass substrate changes the capacitance value to reflect the external air pressure. The invention also discloses the processing technology of the MEMS capacitive air pressure sensor. The capacitive air pressure sensor of the invention has simple processing technology, high yield rate and good commercialization effect.

Owner:BEIJING RES INST OF TELEMETRY +1

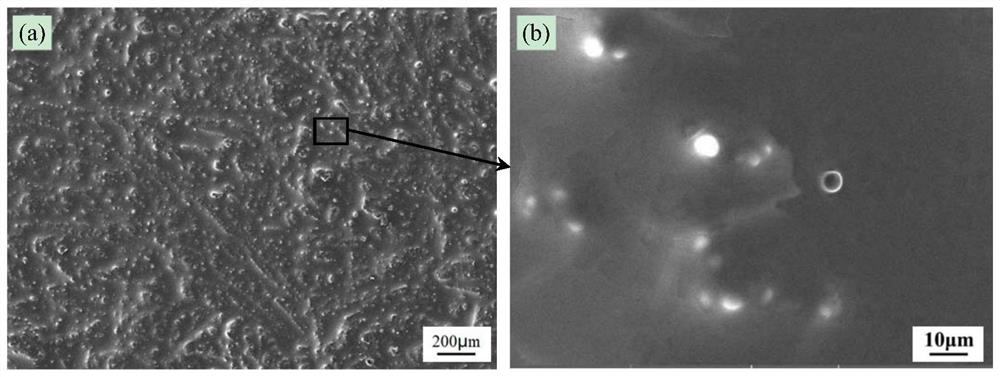

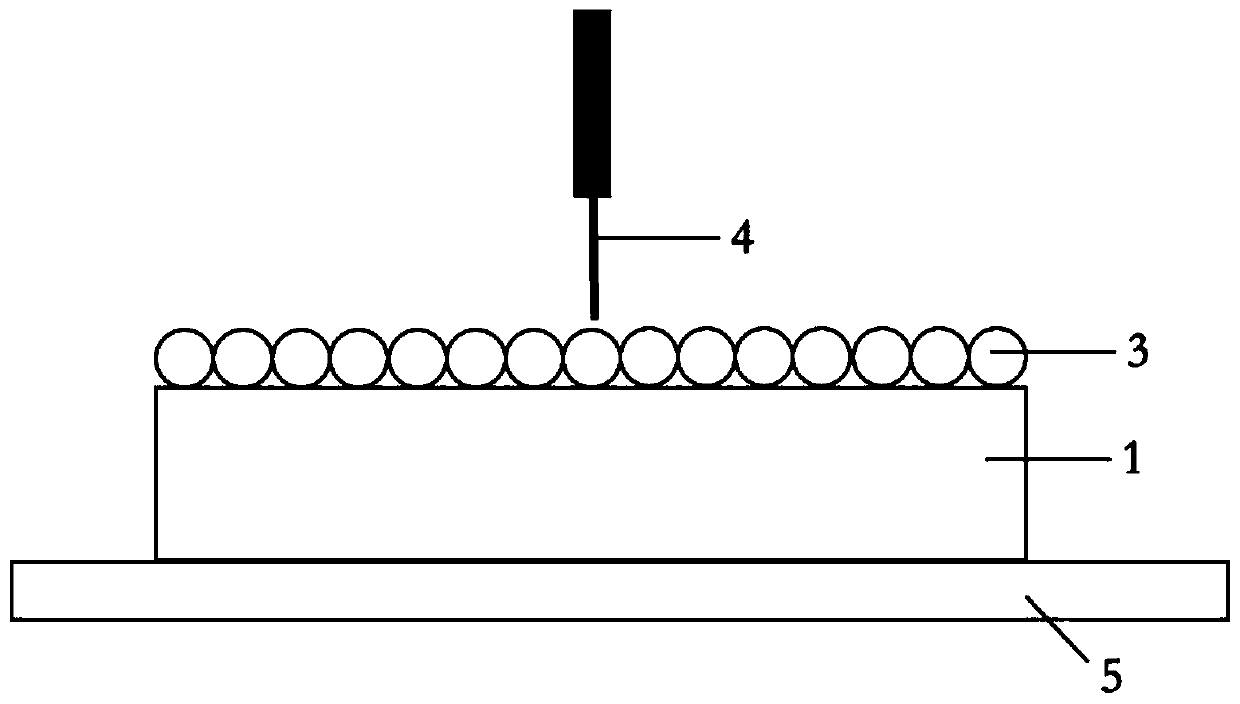

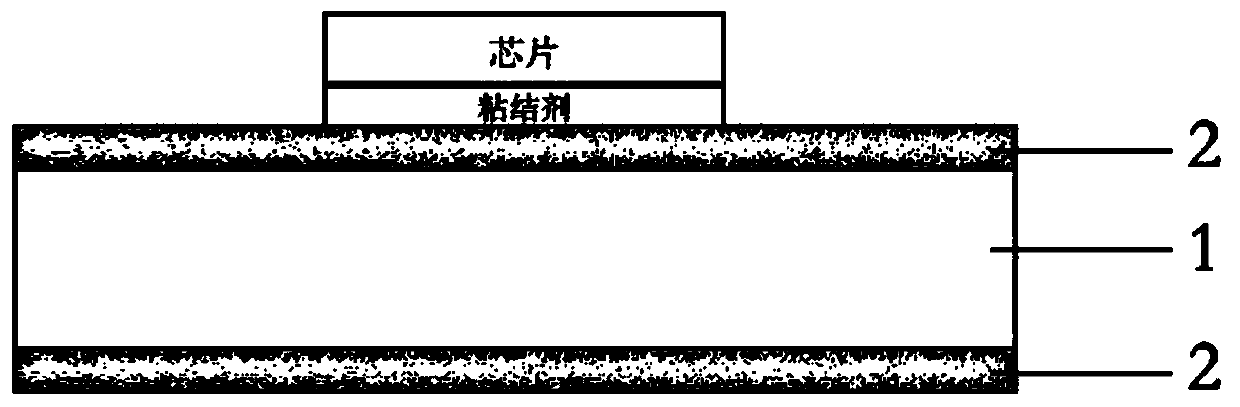

Silicon carbide surface-enhanced aluminum heat dissipation substrate and manufacturing method thereof

InactiveCN110957228AUniform deformationIncrease stiffnessSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationDevice material

The invention belongs to the technical field of electronic packaging, and particularly relates to a silicon carbide surface-enhanced aluminum heat dissipation substrate and a manufacturing method. Nanometer silicon carbide ceramic particles are evenly spread on the surface of an aluminum substrate, the nanometer silicon carbide ceramic particles are sintered through laser beams or electron beams,and the surface of the aluminum substrate is evenly covered with a formed silicon carbide layer; and the nanometer silicon carbide particles at the interface permeate into the surface layer of the aluminum material to form firm interface connection. The overall thermal expansion coefficient of the aluminum heat dissipation substrate is reduced, the hardness and strength are improved, warping is reduced, thermal fatigue failure and crack generation and expansion are reduced, the thermal mechanical property of the aluminum heat dissipation substrate is improved, the aluminum heat dissipation substrate is applied to the field of electronic packaging, and the reliability of a semiconductor device can be improved.

Owner:FUDAN UNIV

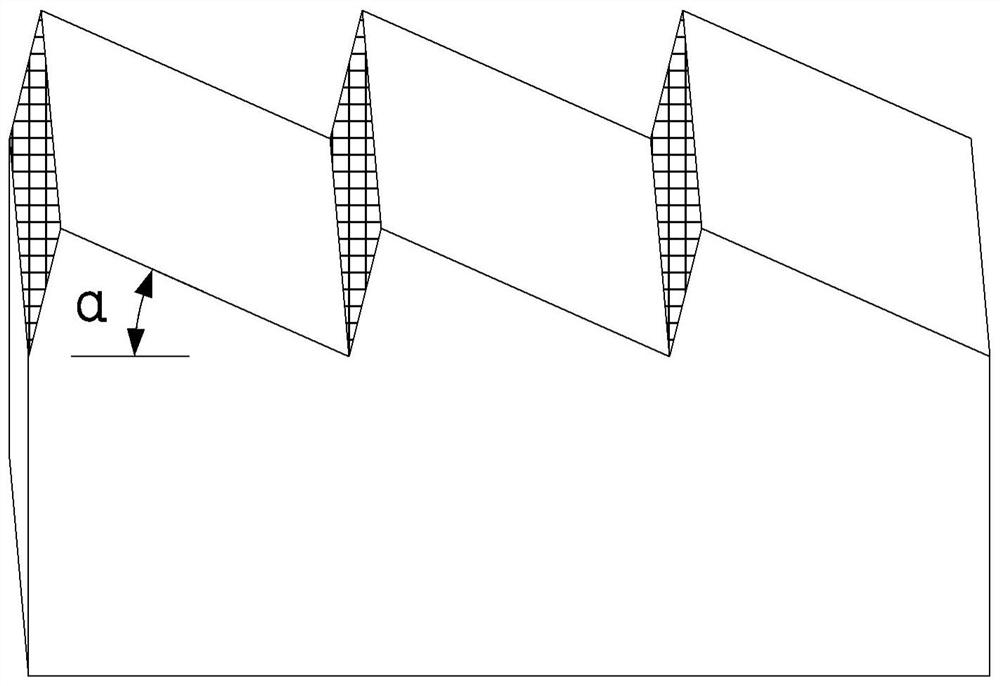

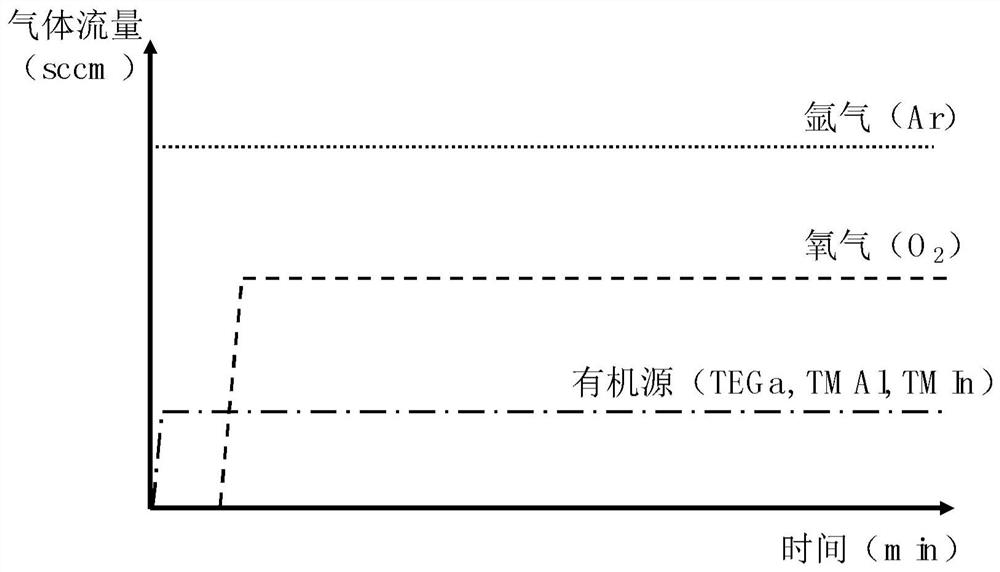

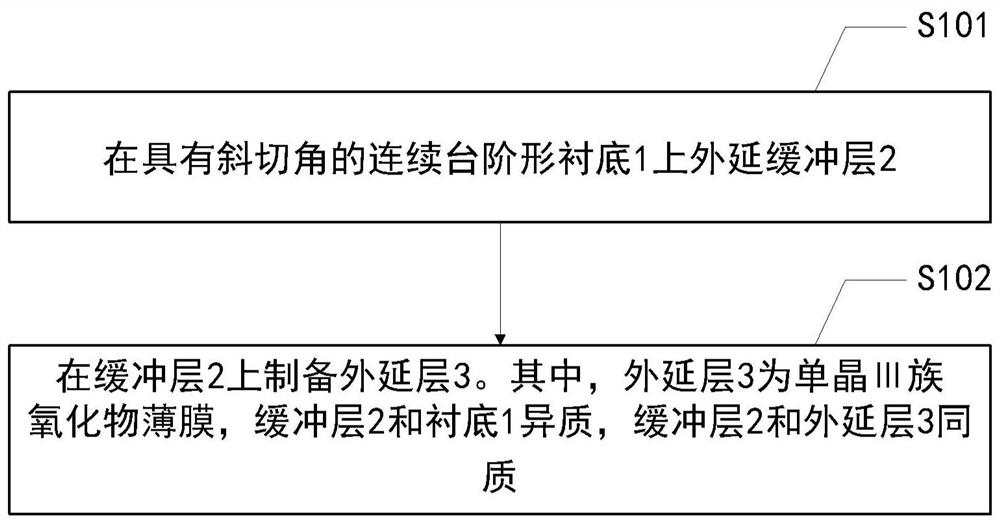

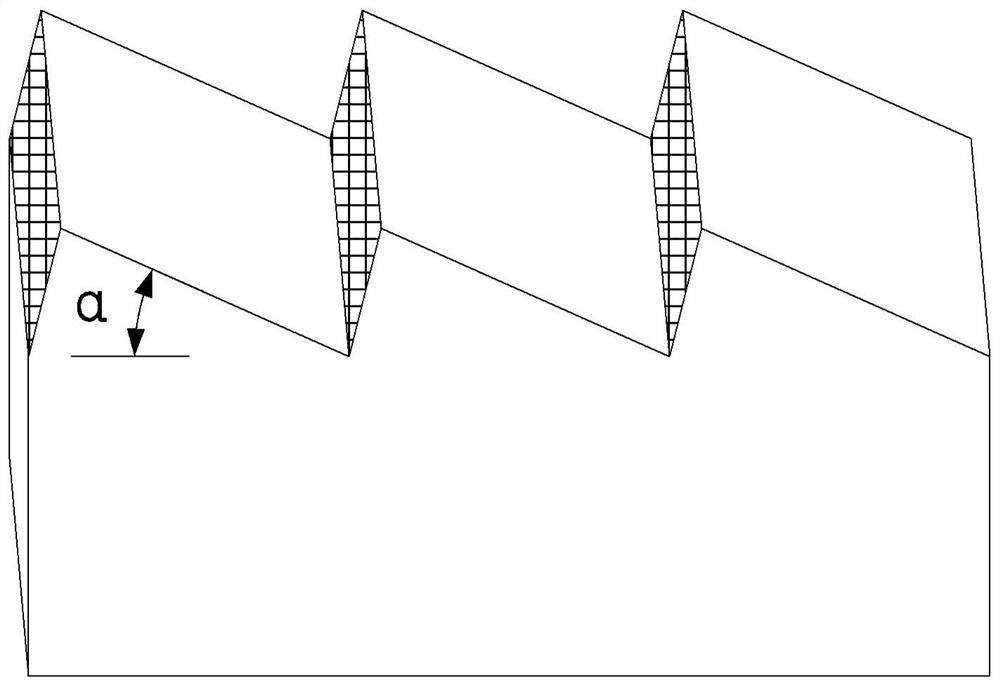

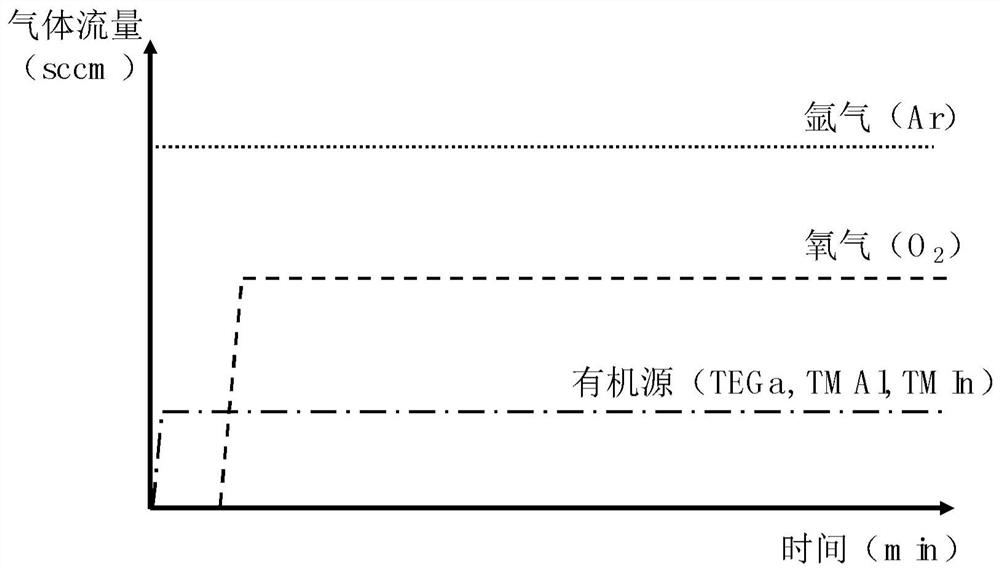

Preparation method of group Ⅲ oxide thin film based on chamfered corner substrate and its epitaxial wafer

ActiveCN113471064BLow costStrong process compatibilitySemiconductor/solid-state device manufacturingSemiconductor devicesFilm basePhysical chemistry

The present disclosure provides a method for preparing a group III oxide thin film based on a chamfered corner substrate and an epitaxial wafer thereof, the preparation method comprising: epitaxial buffer layer (2) on a continuous stepped substrate (1) with chamfered corners; An epitaxial layer (3) is prepared on the buffer layer (2); wherein, the epitaxial layer (3) is a single crystal Group III oxide thin film, the buffer layer (2) and the substrate (1) are heterogeneous, and the buffer layer (2) and The epitaxial layer (3) is homogeneous. By epitaxial buffer layer on a continuous atomic-level stepped substrate with chamfered corners, the adatoms of the reaction source can be promoted to grow at the edge of the step to form a growth pattern with consistent orientation, and a complete single-crystal buffer layer film can be obtained. A high-quality single-crystal epitaxial layer film is homoepitaxially grown on the single-crystal buffer layer film. The method has strong process compatibility, reduces the cost of producing high-quality single crystal group III oxide thin films, and facilitates its popularization and use.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of III-group oxide film based on beveled corner substrate and epitaxial wafer thereof

ActiveCN113471064ALow costStrong process compatibilitySemiconductor/solid-state device manufacturingSemiconductor devicesFilm basePhysical chemistry

The invention provides a preparation method of a III-group oxide film based on a beveled corner substrate and an epitaxial wafer thereof. The preparation method comprises the following steps of extending a buffer layer (2) on a continuous step-shaped substrate (1) with a beveled corner, preparing an epitaxial layer (3) on the buffer layer (2), wherein the epitaxial layer (3) is a monocrystalline III-group oxide film, the buffer layer (2) and the substrate (1) are heterogeneous, and the buffer layer (2) and the epitaxial layer (3) are homogeneous. By extending the buffer layer on the continuous atomic-scale step-shaped substrate with the beveled corner, adsorption atoms of a reaction source can be promoted to grow at the edge of the step, a consistent-orientation growth mode is formed, a complete monocrystalline buffer layer film is obtained, and then a high-quality monocrystalline epitaxial layer film is formed on the monocrystalline buffer layer film in a homoepitaxial mode. According to the method, the process compatibility is high, the cost for producing the high-quality monocrystalline III-group oxide film is reduced, and the method is convenient to popularize and use.

Owner:UNIV OF SCI & TECH OF CHINA

A temperature-resistant 1650°C fiber-reinforced ceramic matrix composite material surface oxidation resistance/infrared stealth coating and its preparation method

ActiveCN111732457BImprove antioxidant capacityImprove high temperature stabilityLiquid surface applicatorsMolten spray coatingEmissivityMullite

The invention relates to the technical field of high-temperature infrared stealth materials, and specifically discloses an anti-oxidation / infrared stealth coating on the surface of a fiber-reinforced ceramic matrix composite material with a temperature resistance of 1650°C. The infrared stealth coating has a layered structure, which consists of A ceramic inner layer, a ceramic middle layer, a ceramic outer layer and a low infrared emissivity functional layer, the ceramic inner layer is a mullite layer, the ceramic middle layer is a rare earth silicate layer, and the ceramic outer layer is an 8YSZ layer , the low infrared emissivity functional layer is based on Pt as the conductive phase, Bi 2 o 3 coating for the binder phase. The invention also provides a preparation method for the anti-oxidation / infrared stealth coating on the surface of the fiber-reinforced ceramic matrix composite material with a temperature resistance of 1650°C. The infrared stealth coating of the invention improves the oxidation resistance and high temperature stability of the composite material, can significantly reduce the infrared radiation intensity of the base material, and has excellent oxidation resistance and infrared stealth function.

Owner:NAT UNIV OF DEFENSE TECH

A kind of preparation method of low heat dissipation motorcycle engine

ActiveCN107034429BReduce bond strengthImprove cohesionMolten spray coatingSand blastingCylinder head

Owner:GUANGDONG INST OF NEW MATERIALS

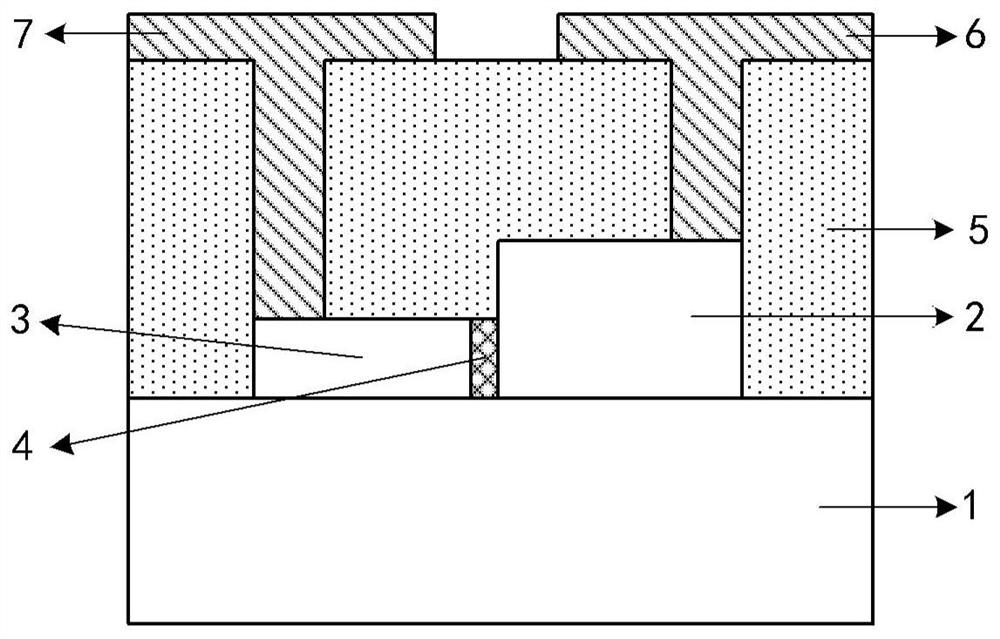

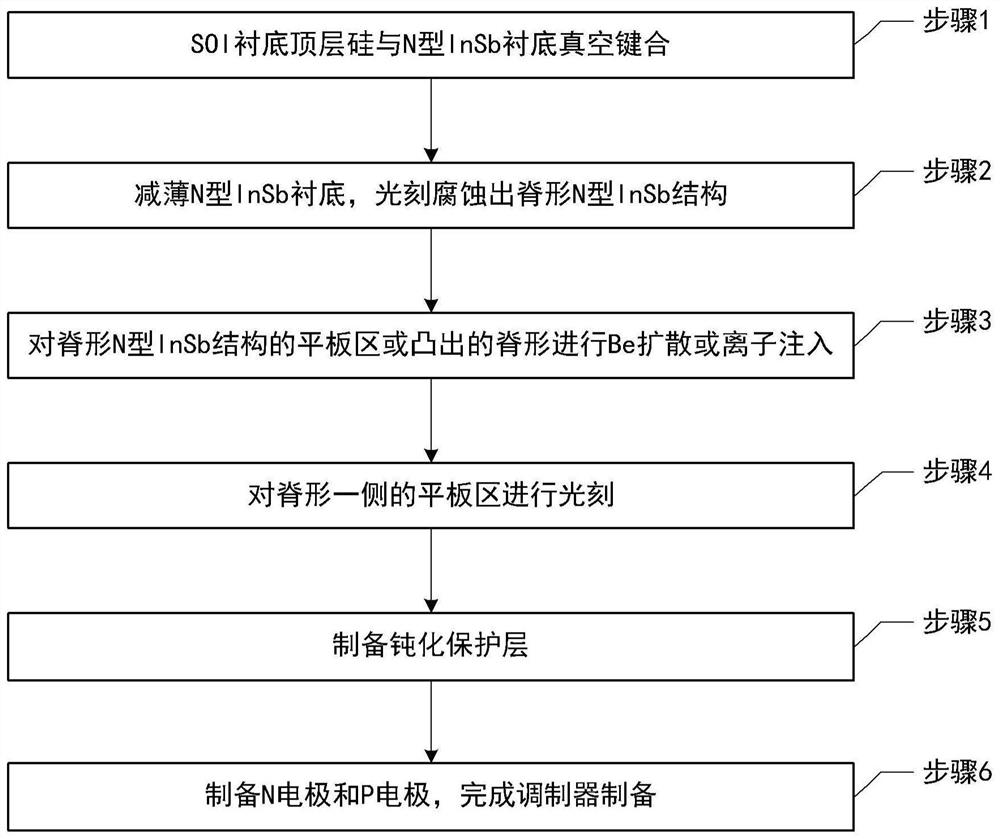

A mid-infrared band modulator and its preparation method

ActiveCN109683354BAchieve integrationSmooth connectionNon-linear opticsSoi substrateProtection layer

The invention provides a mid-infrared band modulator preparation method. The method comprises the steps that 1, vacuum bonding is conducted on an SOI substrate top silicon (1) and an N-type InSb substrate (20); 2, the N-type InSb substrate (20) is thinned and then etched to obtain a ridge N-type InSb structure (2) which includes the ridge in the middle and flat areas on the two sides; 3, the flatareas are transformed into a P-type InSb structure (3), or the ridge protruding out of the flat areas is transformed into the P-type InSb structure (3), and meanwhile a neutral area I (4) is formed between the N-type InSb structure (2) and P-type InSb structure (3); 4, photoetching corrosion is conducted on the flat area on one side of the ridge, and the flat area on the other side of the ridge isretained; 5, a passive protective layer (5) is prepared; 6, an N electrode (6) and a P electrode (7) are prepared. The invention further provides a mid-infrared band modulator.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com