Graphene film frequency selective surface

A technology of frequency selective surface and graphene film, which is applied in the direction of synthetic resin layered products, waveguide devices, electrical components, etc., can solve problems such as thermal mismatch, weight gain, and easy-to-corrosion structures, and achieve light weight and improved adaptability Ability, the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] see Figure 7 On the other hand, the present invention also provides a preparation method comprising the steps of:

[0035]Forming: forming the graphene film layer 100 according to a preset pattern;

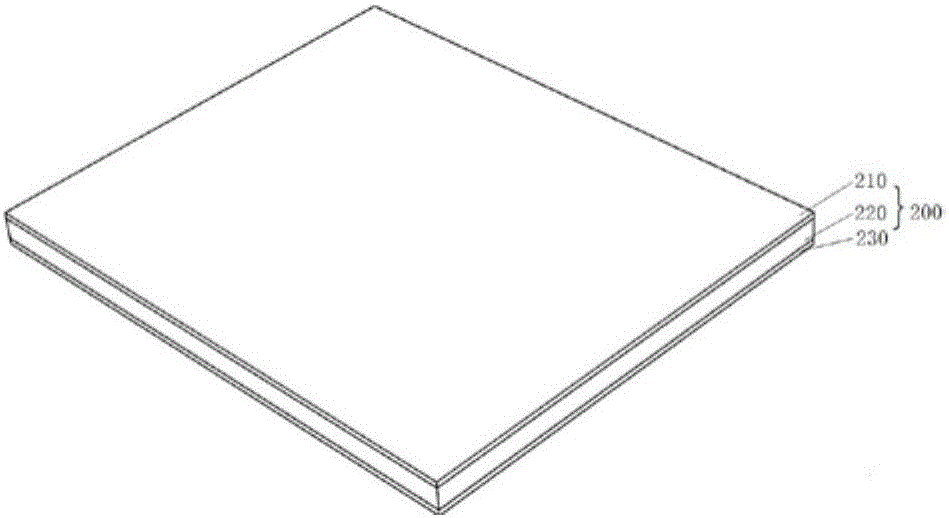

[0036] Paste: paste the graphene film layer 100 with preset graphics on the fiber-reinforced resin layer;

[0037] Press forming: the fiber-reinforced resin pasted with the graphene film layer 100 is press-cured.

[0038] FSS with high thermal stability can be obtained by adopting the above steps.

Embodiment 1

[0041] Prepare FSS sample 1 according to the following steps:

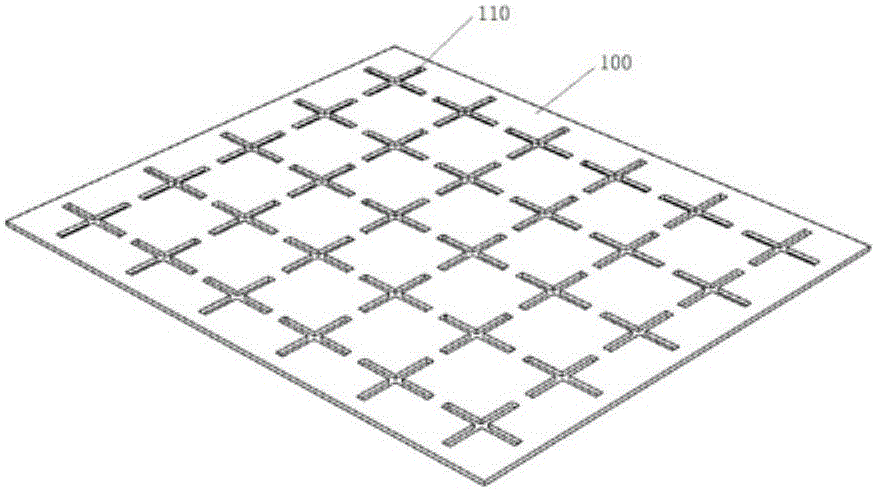

[0042] 1) The selected conductivity is about 1×10 5 A graphene film with a S / m thickness of 20 μm, engraving a plurality of cross-shaped through holes regularly arranged on the graphene film by laser engraving;

[0043] 2) Quartz fiber-reinforced epoxy resin composite honeycomb sandwich panels were prepared as substrates by vacuum infusion, and the upper and lower panels of the honeycomb sandwich panels were both quartz fiber-reinforced epoxy composite laminates with a thickness of 1.5 mm. The sandwich core is a Nomex honeycomb with a core material thickness of 8 mm and a hole side length of 4 mm. Using epoxy resin as a binder, the graphene film layer with multiple cross-shaped through holes is pasted to the quartz fiber reinforced epoxy composite honeycomb core. the surface of the board substrate;

[0044] 3) pressurized and solidified by a vacuum bag method to obtain a graphene film FSS with a band-pass shape....

Embodiment 2

[0046] Prepare FSS sample 2 according to the following steps:

[0047] 1) Select the conductivity as 2×10 5 S / m graphene film with a thickness of 100 μm, engraving a plurality of H-shaped patch units regularly arranged on the graphene film by mechanical engraving;

[0048] 2) A quartz fiber reinforced cyanate ester composite laminate with a thickness of 1mm was prepared as a substrate by a vacuum bagging method, and a graphene film layer with multiple H-shaped patch units was prepared with a cyanate resin as a binder. Bonded to the surface of a quartz fiber reinforced cyanate ester composite laminate substrate;

[0049] 3) pressurized and solidified by the vacuum bag pressure method to obtain a graphene film FSS with a band barrier shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com