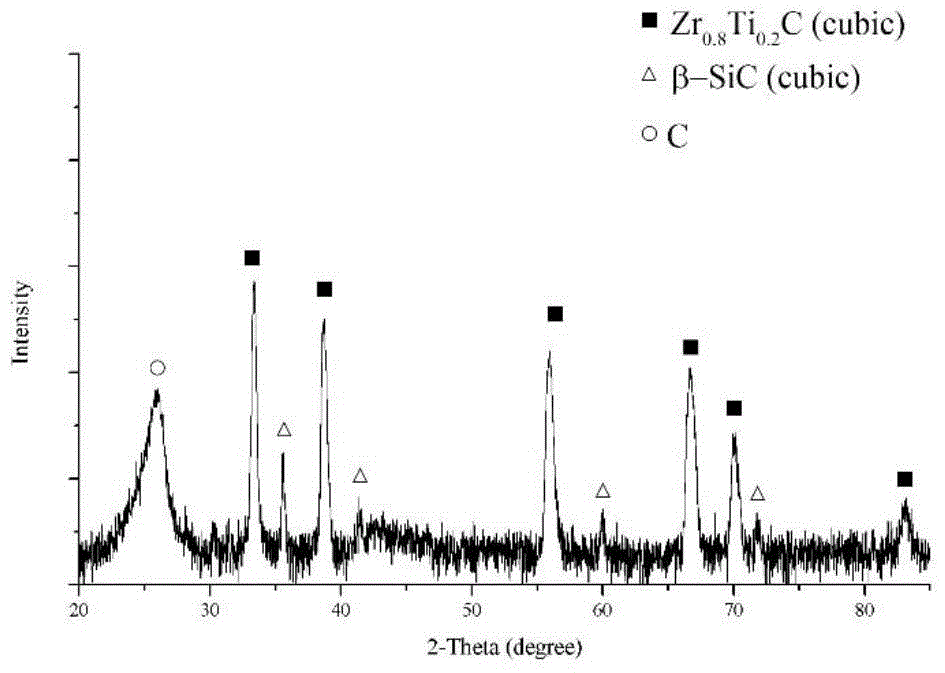

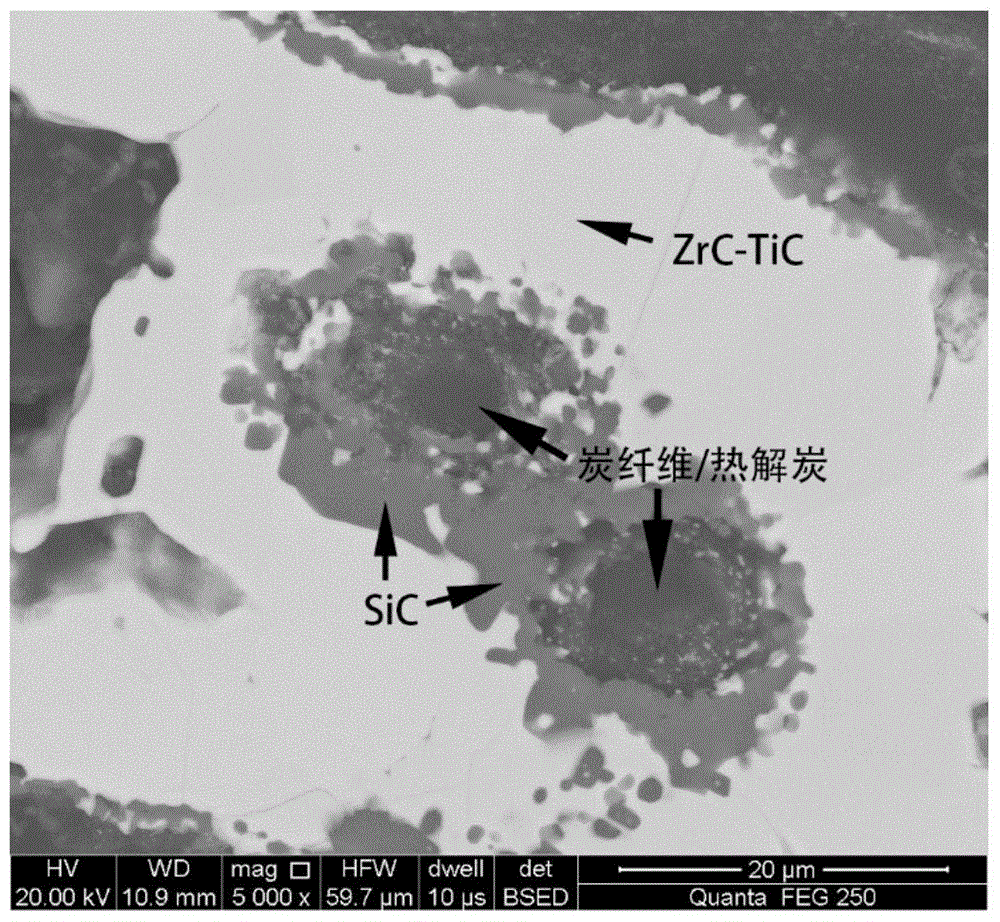

A kind of c/c-sic-zrc-tic composite material and preparation method thereof

A c-sic-zrc-tic, composite material technology, applied in chemical instruments and methods, layered products, ceramic layered products, etc., to achieve the effect of shortening the preparation cycle, fast and efficient process, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Put zirconium powder, titanium powder and silicon powder with a purity greater than 99% in the ball mill tank at an atomic ratio of 50%, 10%, and 39%, respectively, and at the same time add aluminum powder at an atomic ratio of 1%, and fill it with argon before ball milling , the mixed powder was prepared by a planetary ball mill, and the ball milling medium was ZrO 2 , the ball-to-material ratio is 4:1, the milling speed is 400r / min, and the milling time is 10h. After the mixed powder is vacuum-dried at low temperature, it will be used in the next step.

[0055] Set the density to 0.7g / cm 3 The finely woven needle felt fiber preform was densified to 1.4 g / cm by chemical vapor deposition 3 C / C composite material, then cut the composite material into 60*55*15mm 3 The blocks were dried in vacuum at low temperature and prepared for use in subsequent steps.

[0056] 100 g of the mixed powder was weighed, placed in a graphite jar with a diameter of 80 mm, and spread flat...

Embodiment 2

[0059]Put zirconium powder, titanium powder and silicon powder with a purity of more than 99% in the ball mill tank at an atomic ratio of 59.5%, 30%, and 10%, respectively, and add iron powder at an atomic ratio of 0.5%, and fill it with argon before ball milling , the mixed powder was obtained through a planetary ball mill, the ball milling medium was stainless steel, the ball-to-material ratio was 10:1, the ball milling speed was 150r / min, and the milling time was 20h. After the mixed powder is vacuum-dried at low temperature, it will be used in the next step.

[0060] Set the density to 0.1g / cm 3 The short-fiber laminated needle-punched preform was densified to 0.8g / cm by chemical vapor deposition 3 C / C composite material, then cut the composite material into 60*55*15mm 3 The blocks were dried in vacuum at low temperature and prepared for use in subsequent steps.

[0061] Weigh 100 g of the mixed powder, place it in a graphite jar with a diameter of 80 mm, and spread it ...

Embodiment 3

[0064] Put zirconium powder, titanium powder and silicon powder with a purity of more than 99% in the ball mill tank at an atomic ratio of 59%, 20%, and 20%, respectively, and add copper powder at an atomic ratio of 1%, and fill it with argon before ball milling , the mixed powder was prepared by a planetary ball mill, and the ball milling medium was ZrO 2 , the ball-to-material ratio is 6:1, the milling speed is 250r / min, and the milling time is 15h. After the mixed powder is vacuum-dried at low temperature, it will be used in the next step.

[0065] Set the density to 0.6g / cm 3 The needle-punched integral felt fiber preform is densified to 1.2g / cm by chemical vapor deposition 3 C / C composite material, then cut the composite material into 60*55*15mm 3 The blocks were dried in vacuum at low temperature and prepared for use in subsequent steps.

[0066] Weigh 100 g of the mixed powder, place it in a graphite jar with a diameter of 80 mm, and spread it flat; then, place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com