Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

197 results about "Pressure sensitive film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fujifilm's Prescale Film is a single-use, pressure sensitive film that measures pressure ranging from 0.05 to 300 Mpa (about 7 to 43,500 psi) through peak pressure snapshots. It captures a pressure profile via a color scale and reveals pressure distribution.

Pressure sensor

InactiveUS7331236B2Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsAcoustic waveEngineering

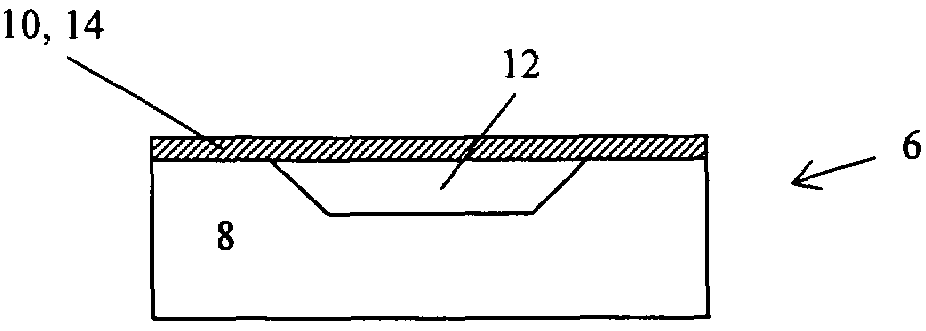

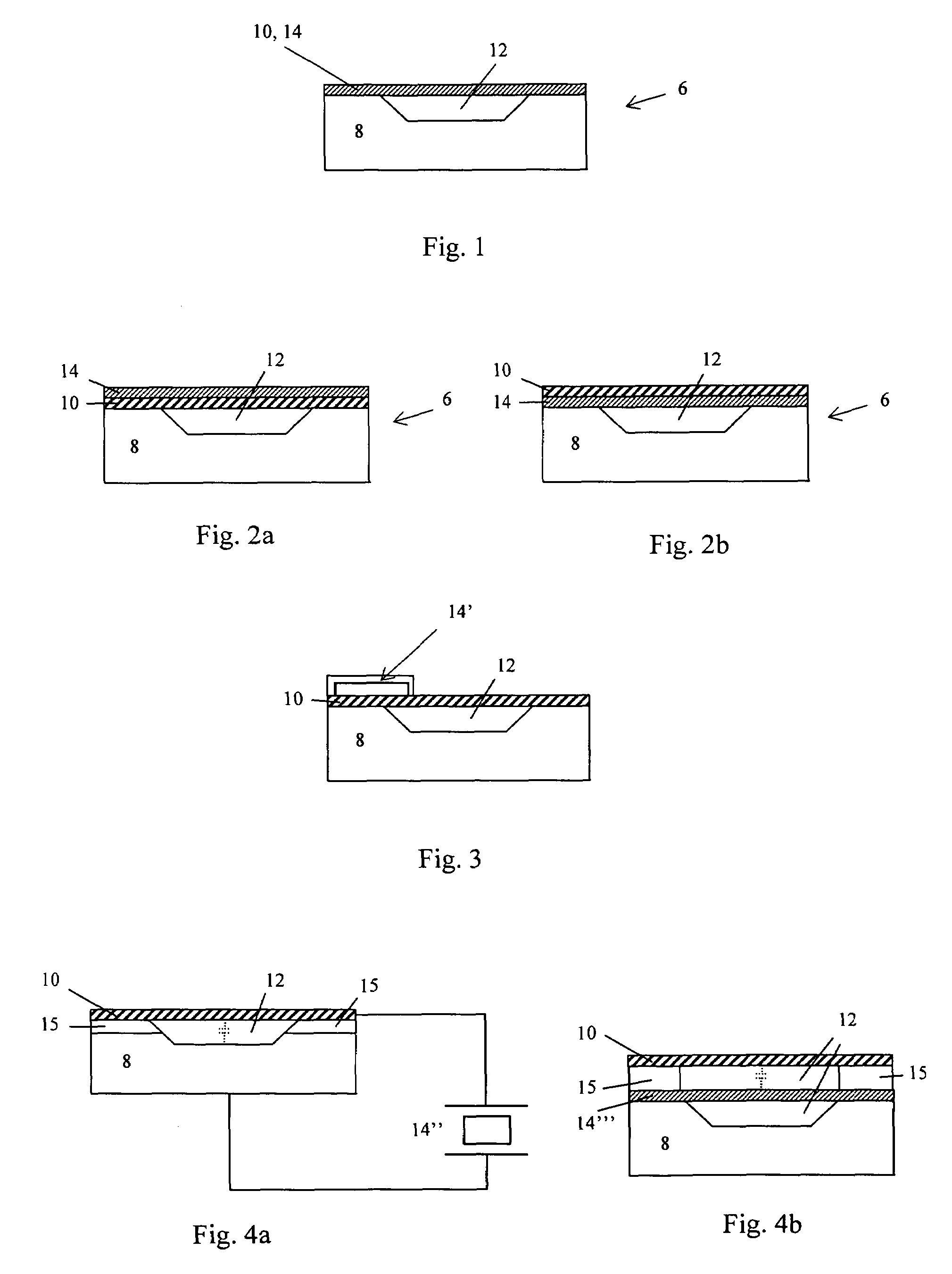

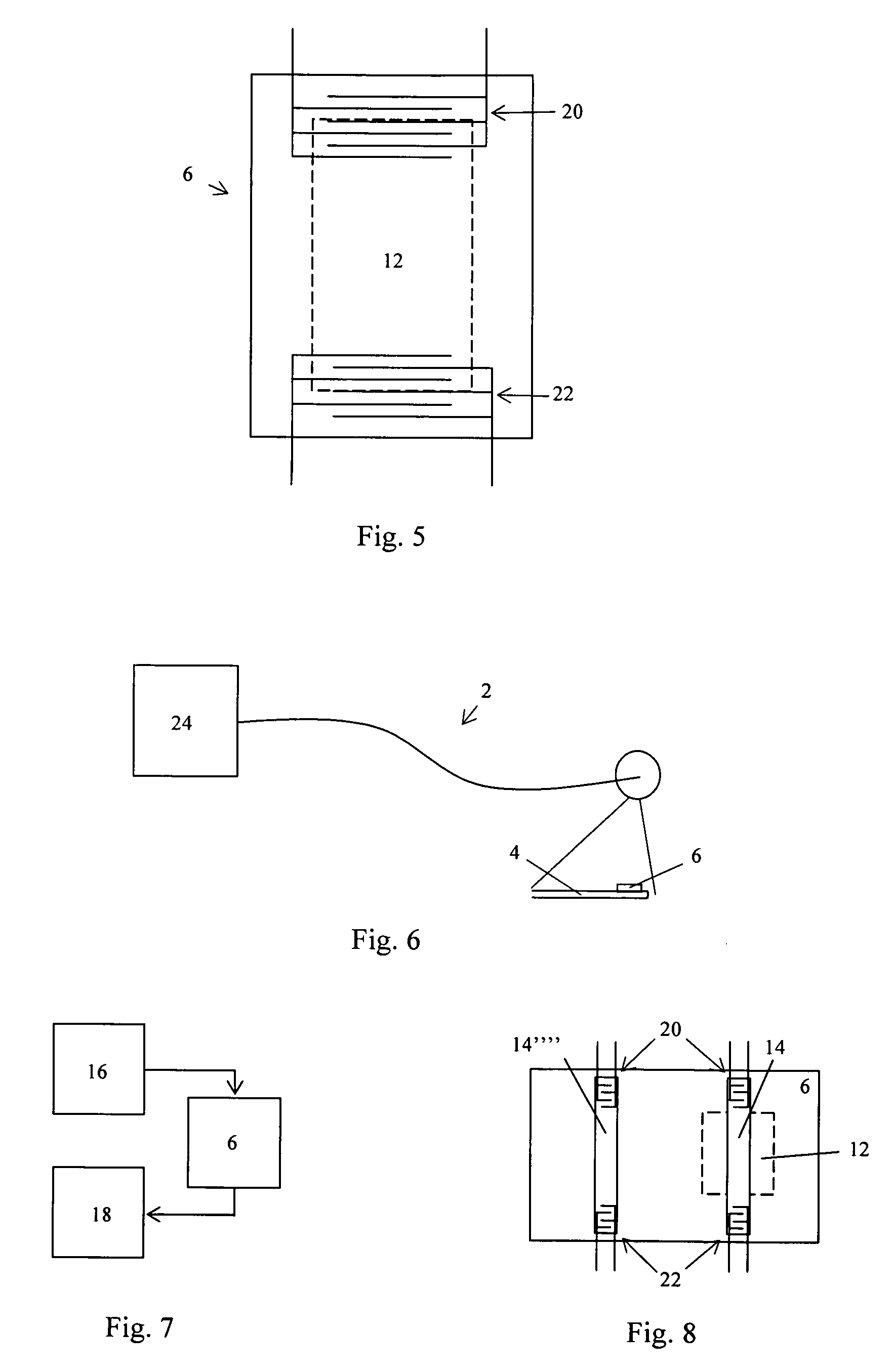

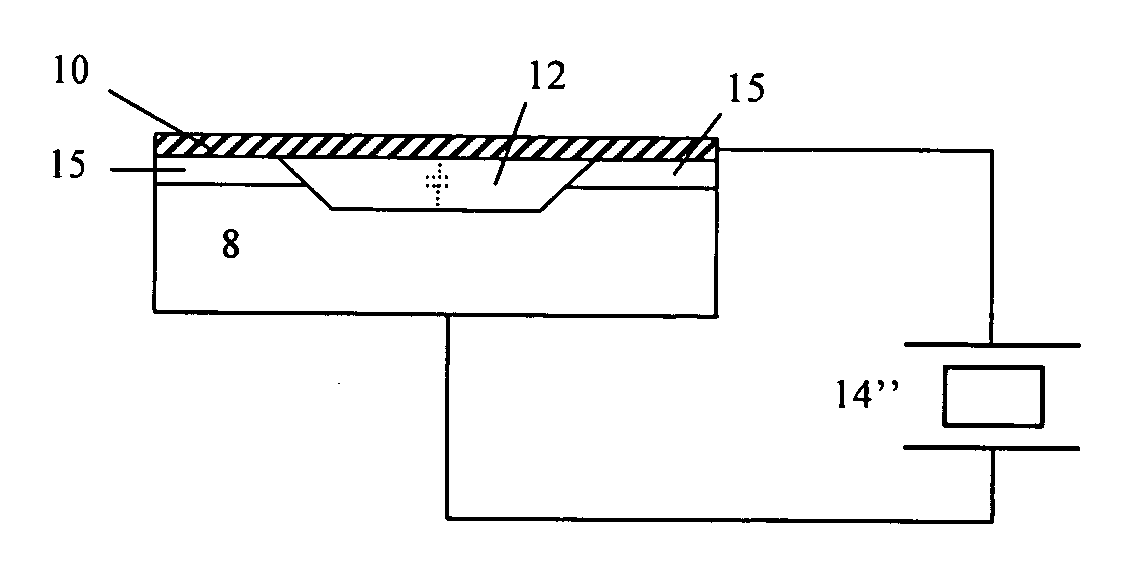

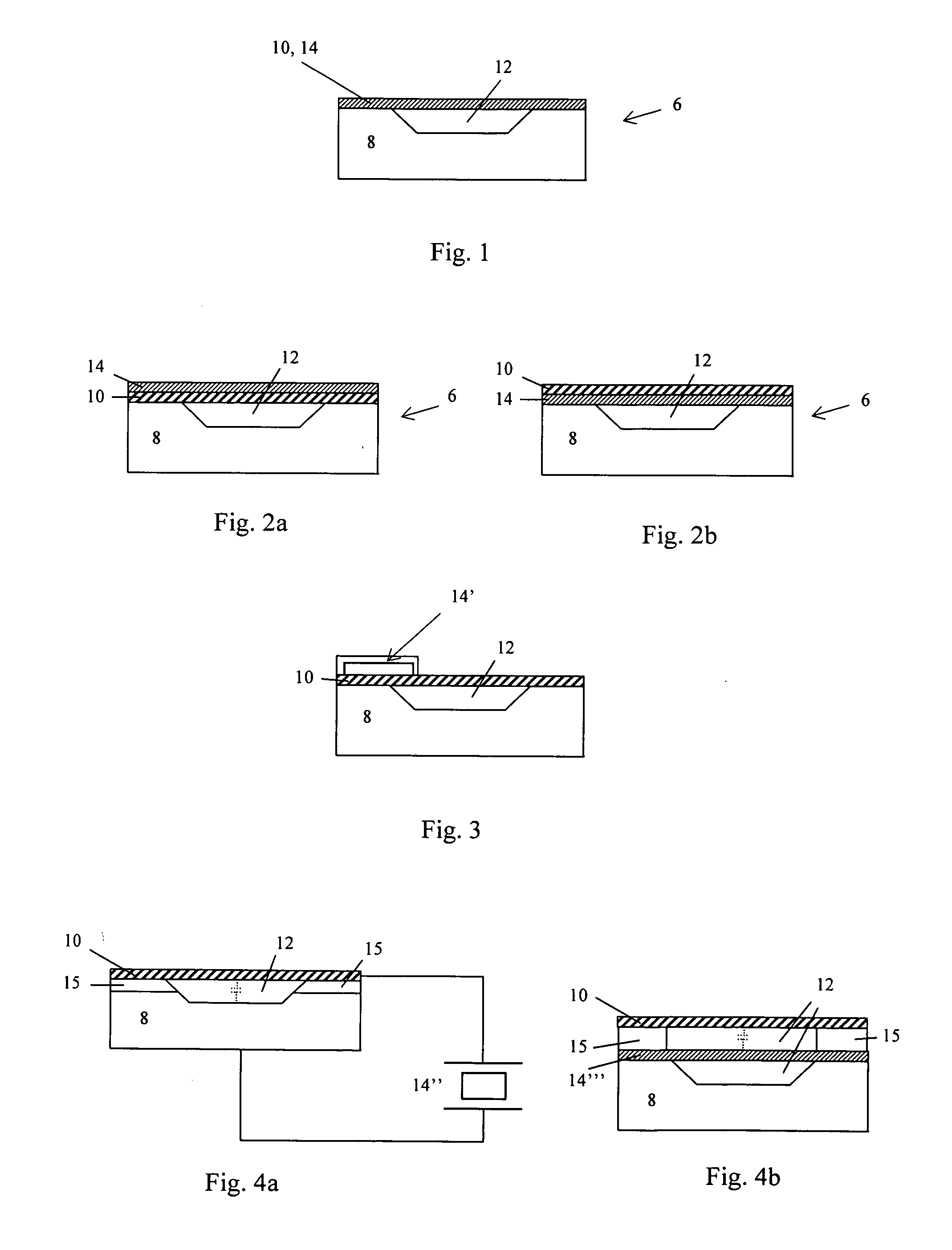

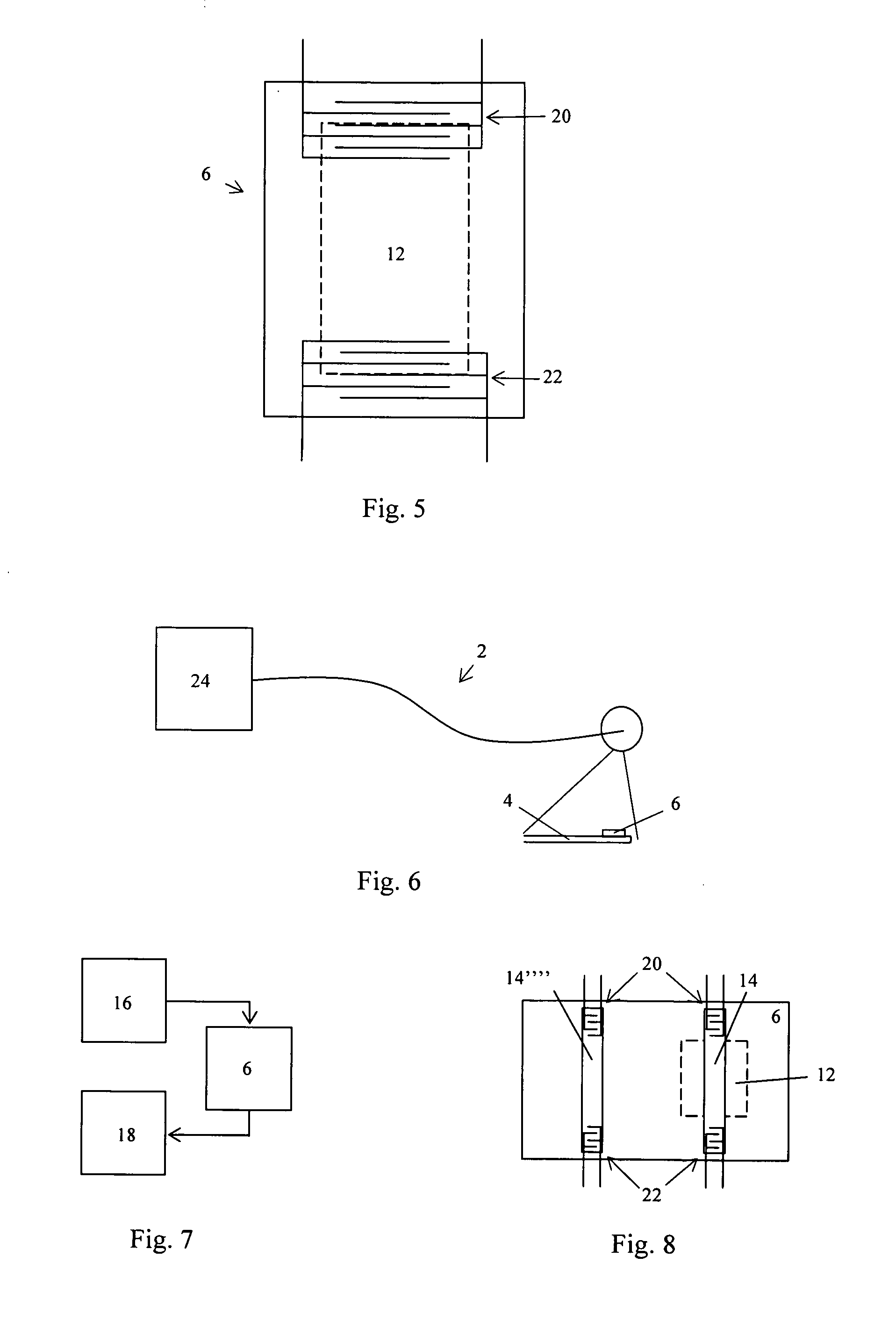

A sensor and insertion assembly 2 is used for intravascular measurement of pressure in a living body. The assembly includes, a sensor chip 6 having a substrate body 8 with a recess covered by a pressure sensitive film 10 thereby forming a cavity 12. A piezoelectric element, preferably in the form of a piezoelectric film 14, is arranged in connection with the pressure sensitive film, and energy is applied to the piezoelectric element such that acoustic waves are generated in the element. The piezoelectric element is arranged to generate an output signal, representing the pressure at the film, in dependence on the measured properties of the acoustic waves related to the deflection of the pressure sensitive film.

Owner:ST JUDE MEDICAL COORDINATION CENT

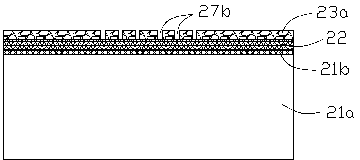

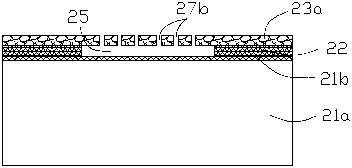

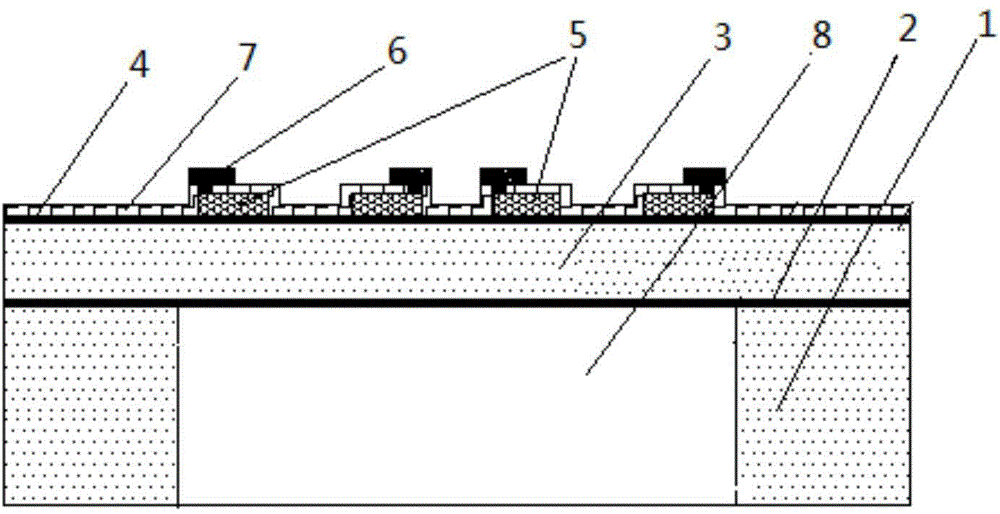

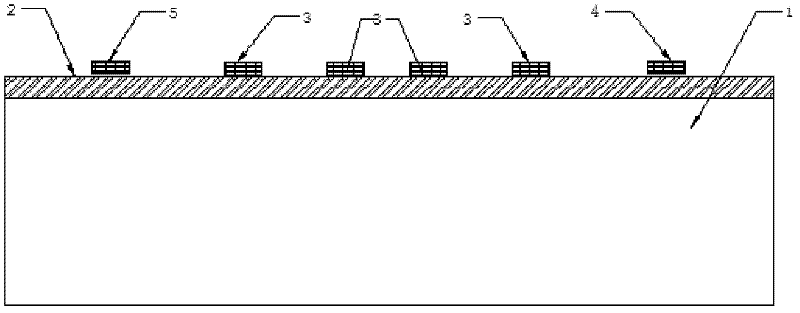

Single slice integration temperature, humidity, pressure sensor chip based on polymer material

InactiveCN1845327AReduce volumeReduce power consumptionThermometers using electric/magnetic elementsSolid-state devicesDielectricCapacitance

The single integrated sensor chip for temperature, humidity and pressure is manufactured by: on substrate, processing a parallel plate as the electrode of a capacitor for humidity and three resistances as the strain resistance and thermistor; preparing one layer of polymer on the plate and resistances as the capacitor dielectric medium and the elastic membrane respectively; arranging a grid plate on former dielectric medium as another capacitor electrode; forming a voltage-measuring bridge by resistances on pressure-sensitive membrane and substrate; vacuum sealing the cavity under the pressure-sensitive film to measure absolute pressure.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Pressure sensor

InactiveUS20070220986A1Fluid pressure measurement using ohmic-resistance variationTyre measurementsEngineeringAcoustic wave

A sensor and insertion assembly 2 is used for intravascular measurement of pressure in a living body. The assembly includes a sensor chip 6 having a substrate body 8 with a recess covered by a pressure sensitive film 10 thereby forming a cavity 12. A piezoelectric element, preferably in the form of a piezoelectric film 14, is arranged in connection with the pressure sensitive film, and energy is applied to the piezoelectric element such that acoustic waves are generated in the element. The piezoelectric element is arranged to generate an output signal, representing the pressure at the film, in dependence on the measured properties of the acoustic waves related to the deflection of the pressure sensitive film.

Owner:ST JUDE MEDICAL COORDINATION CENT

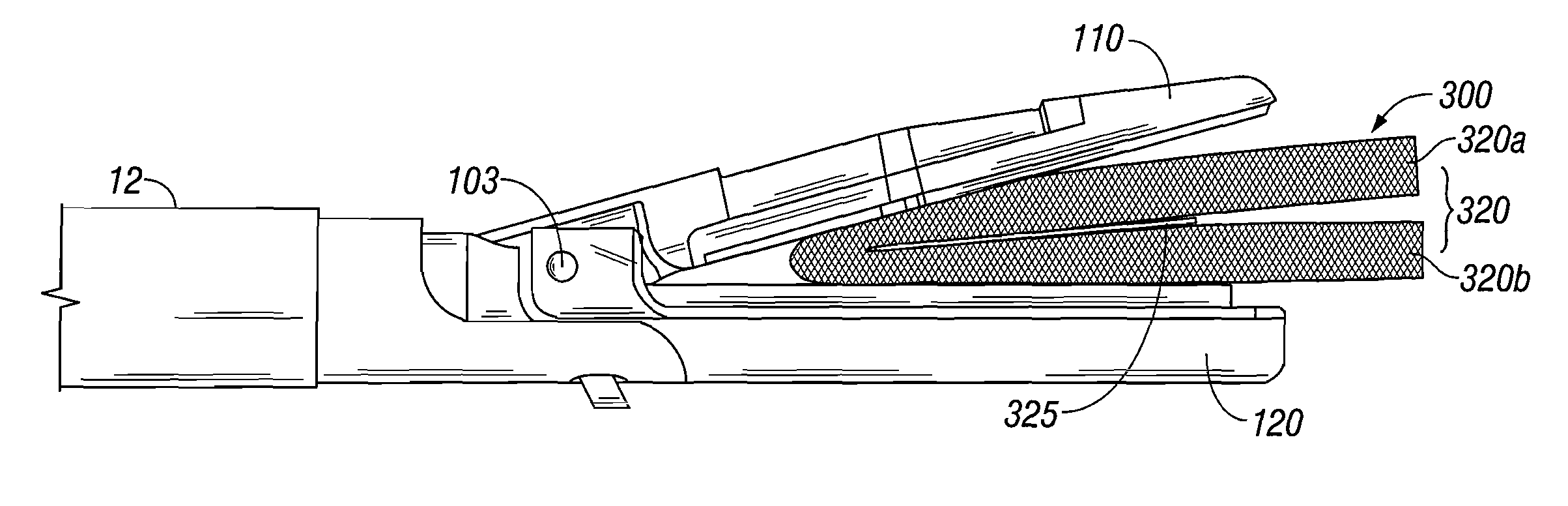

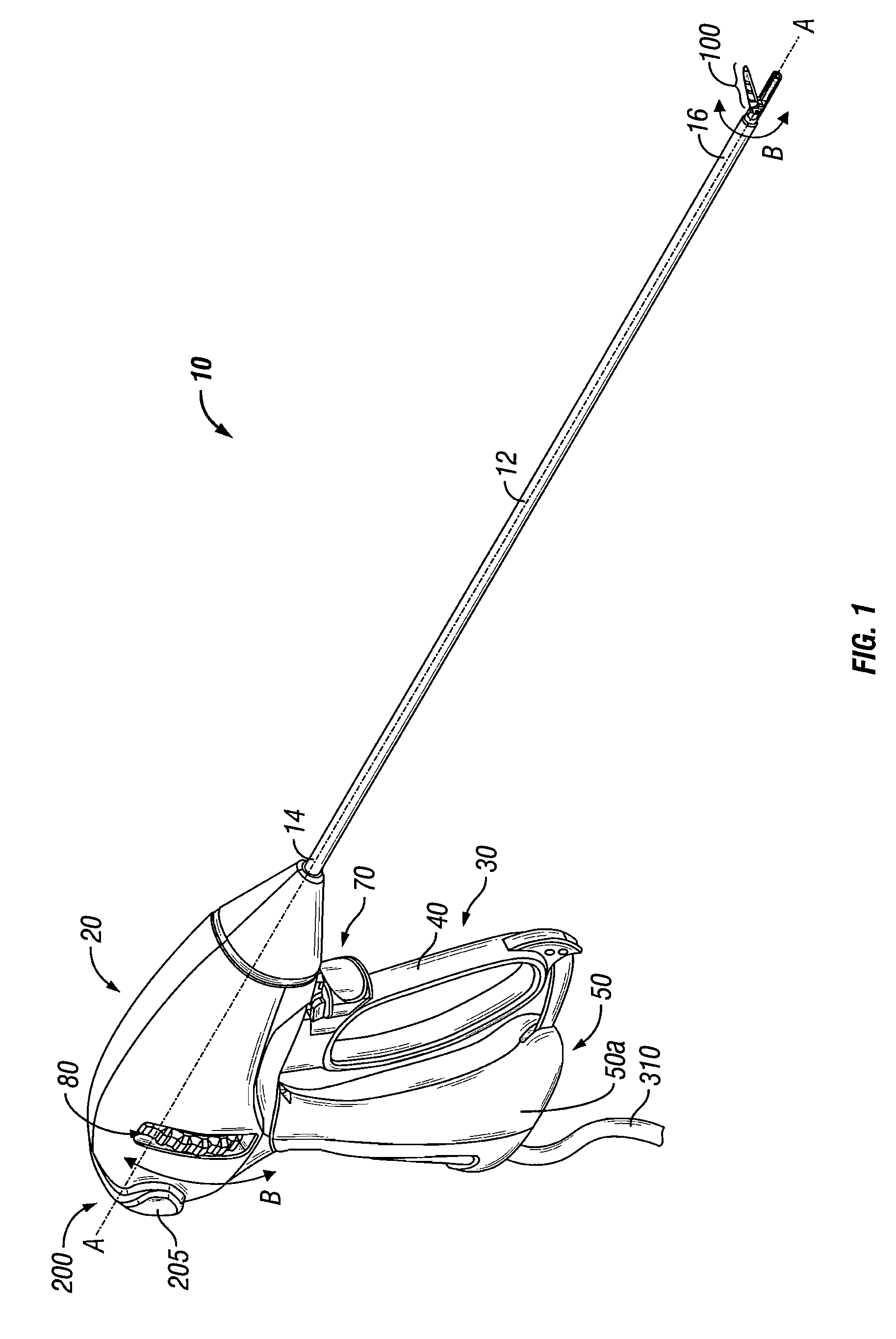

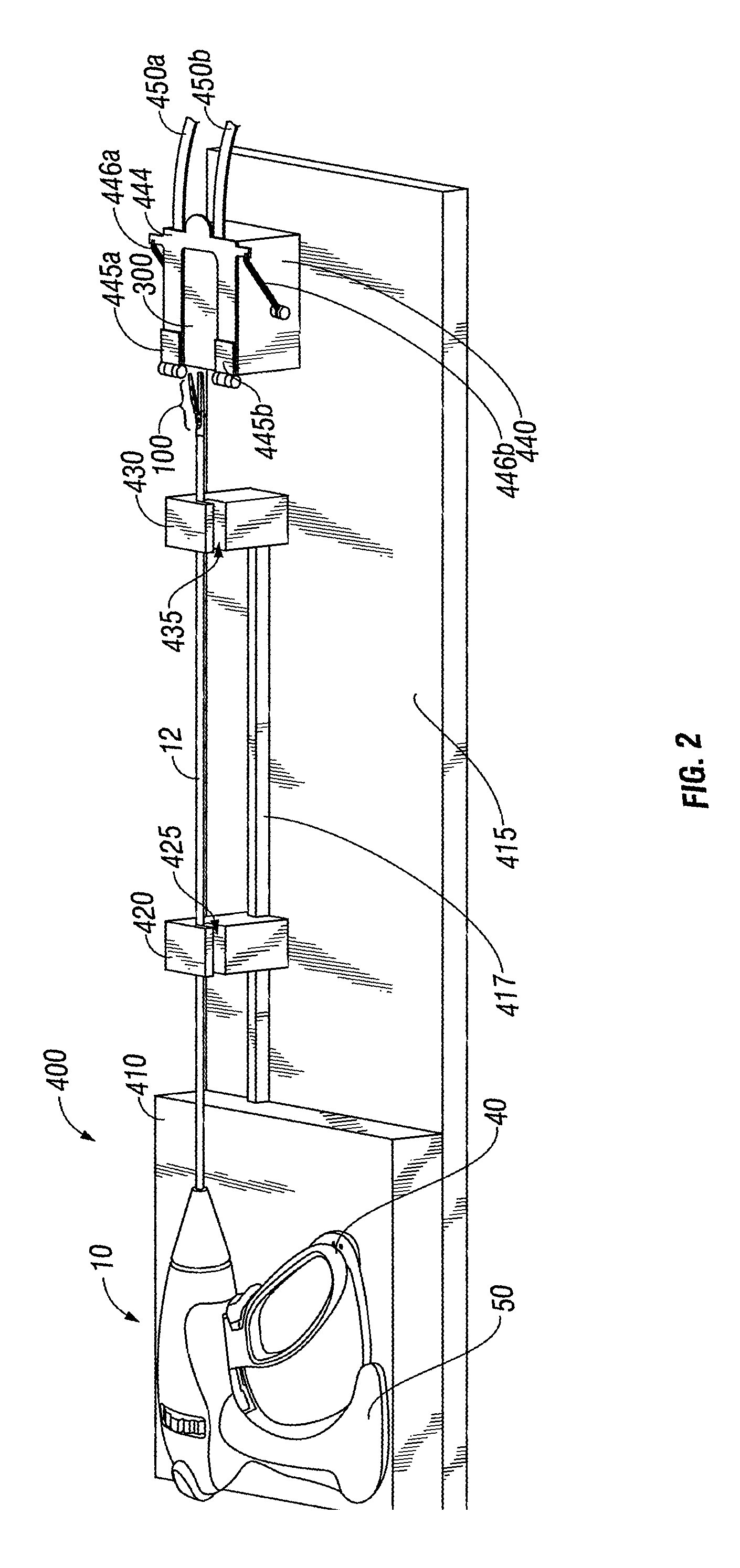

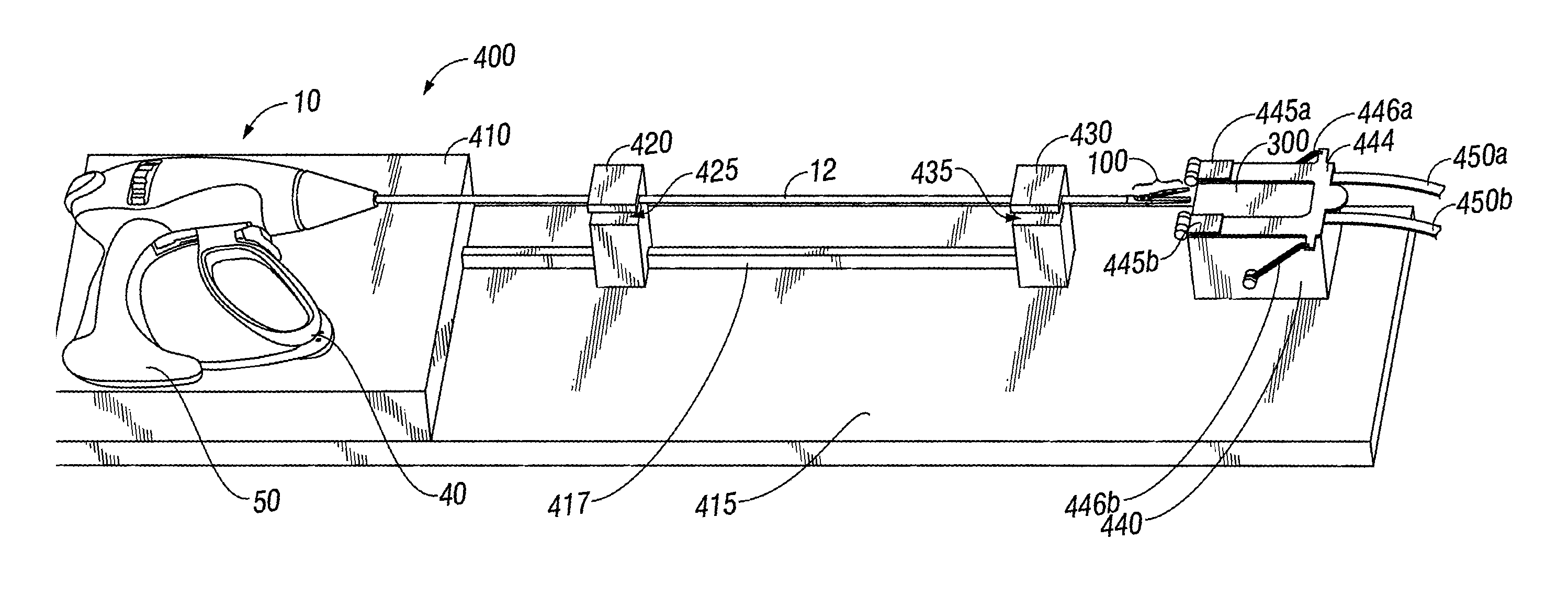

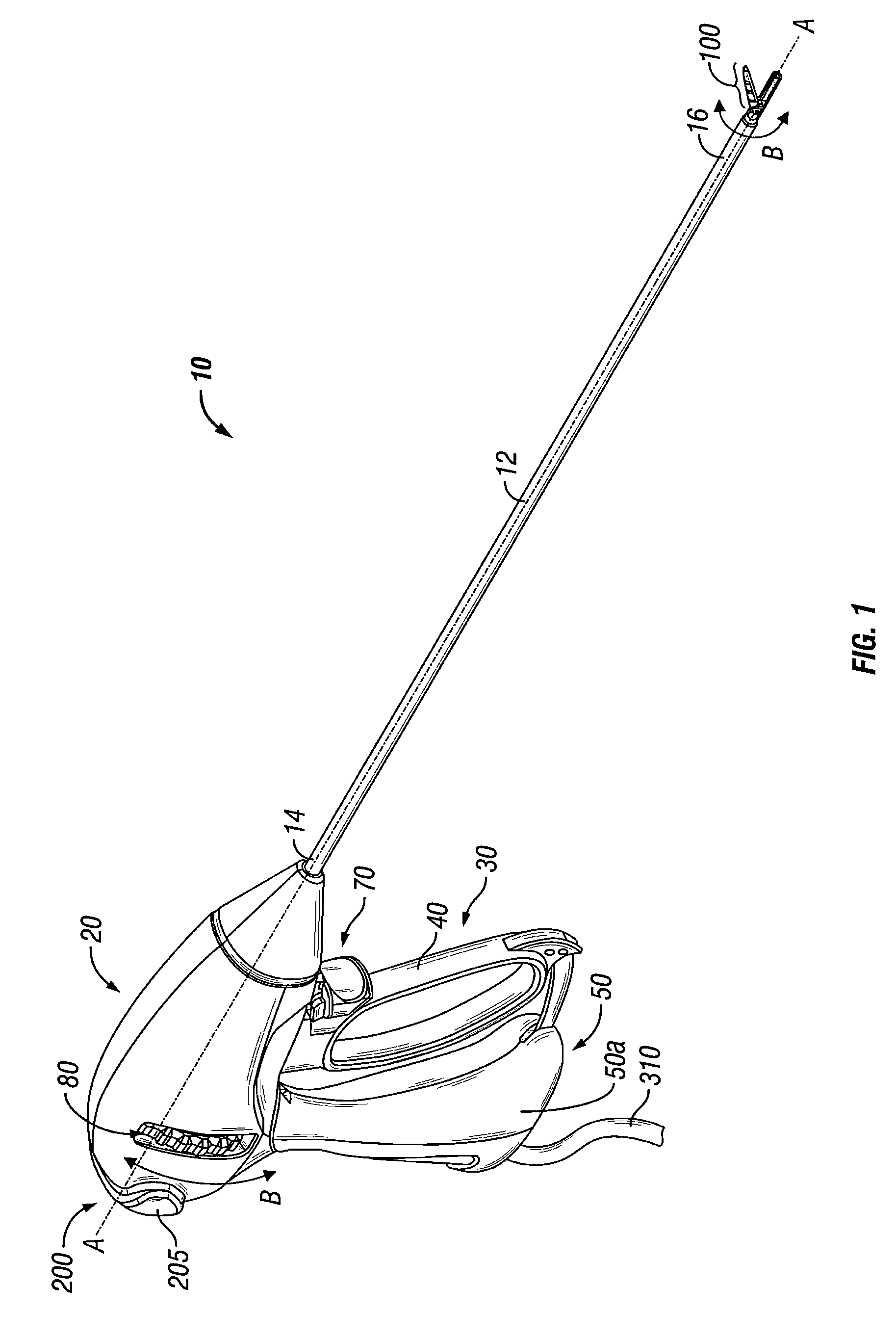

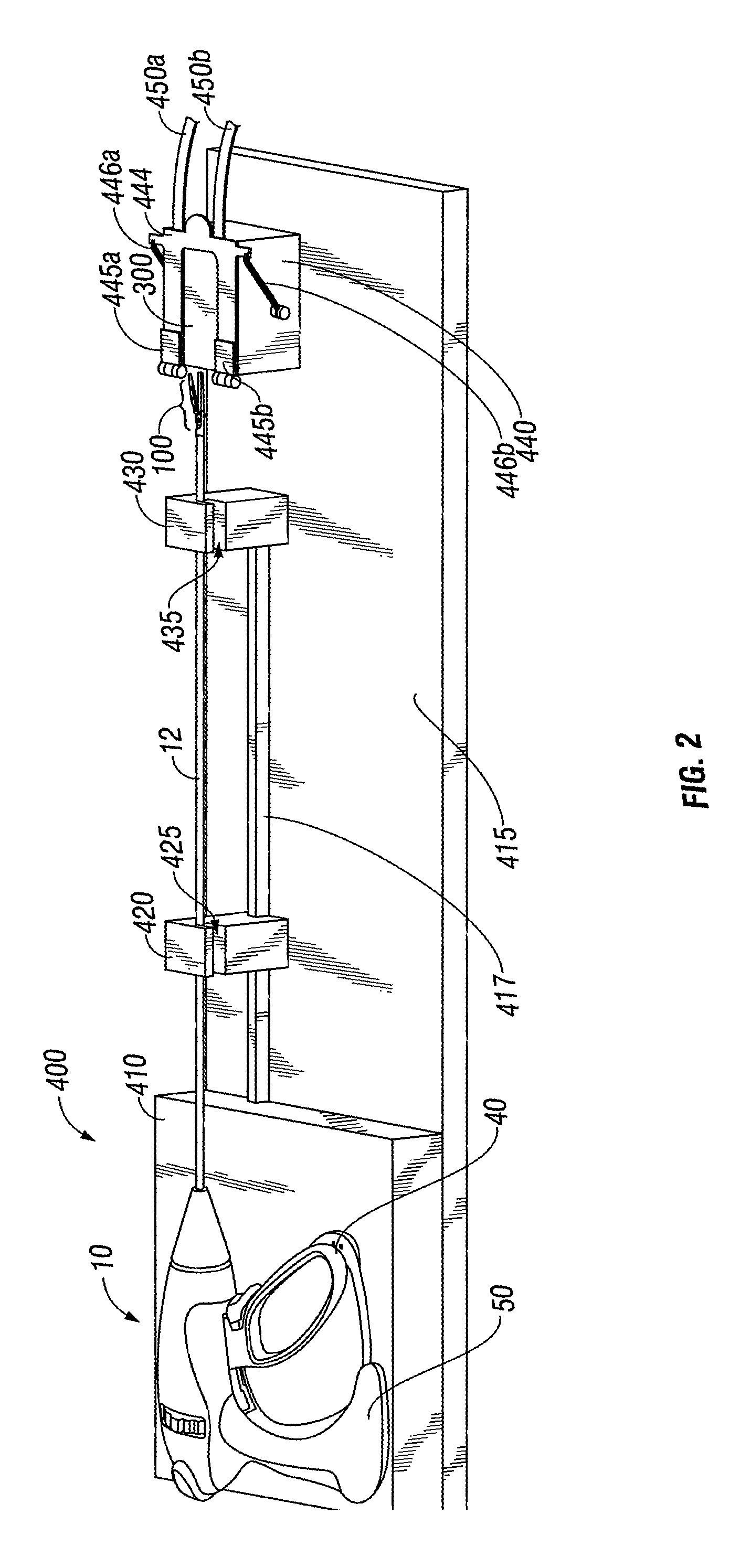

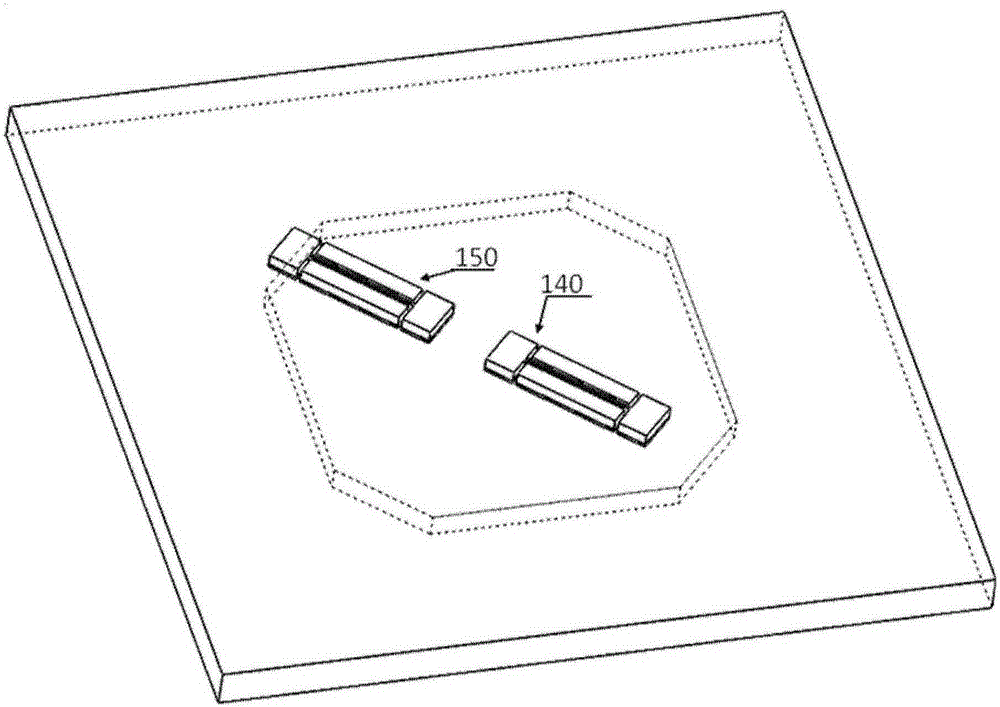

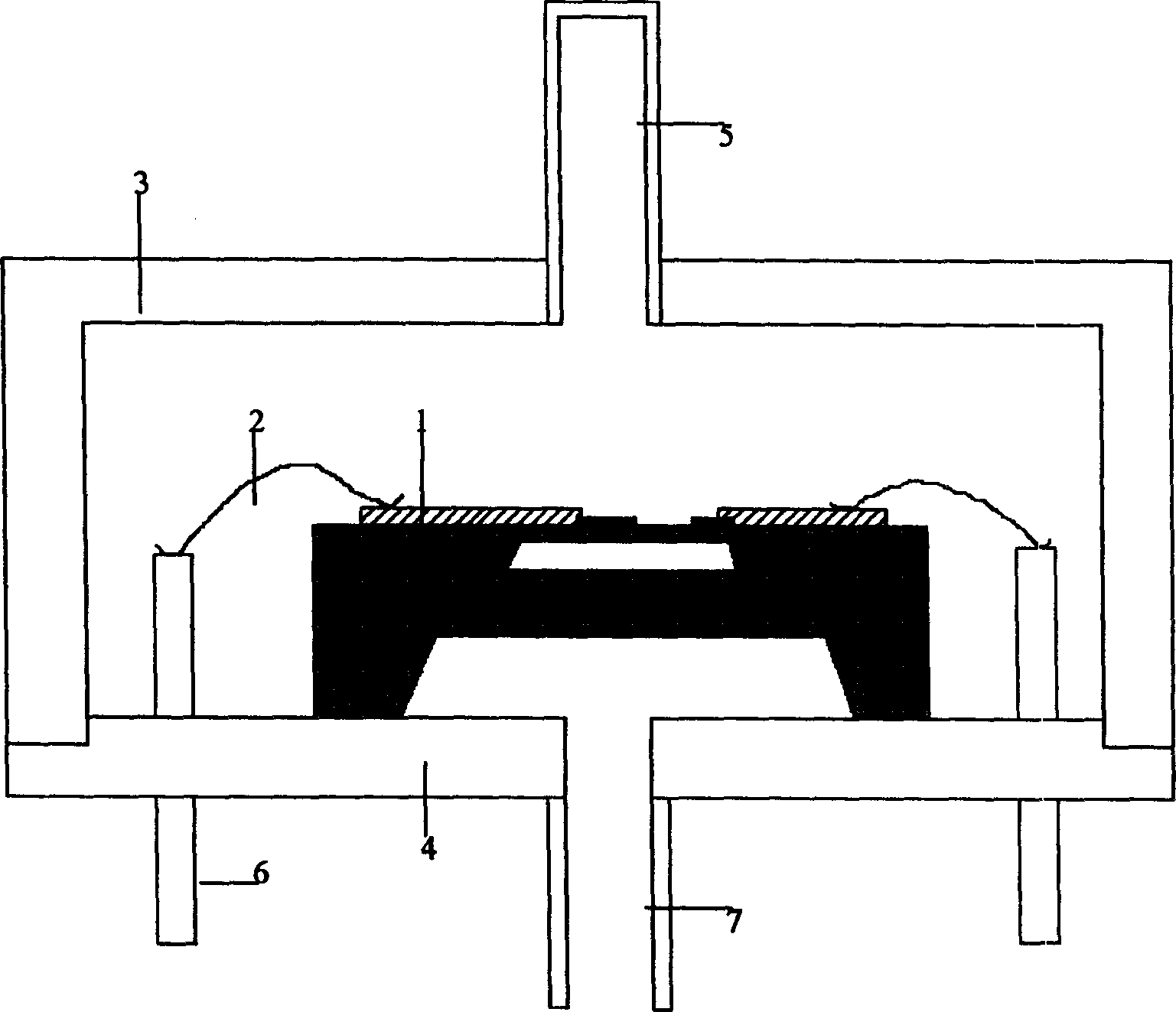

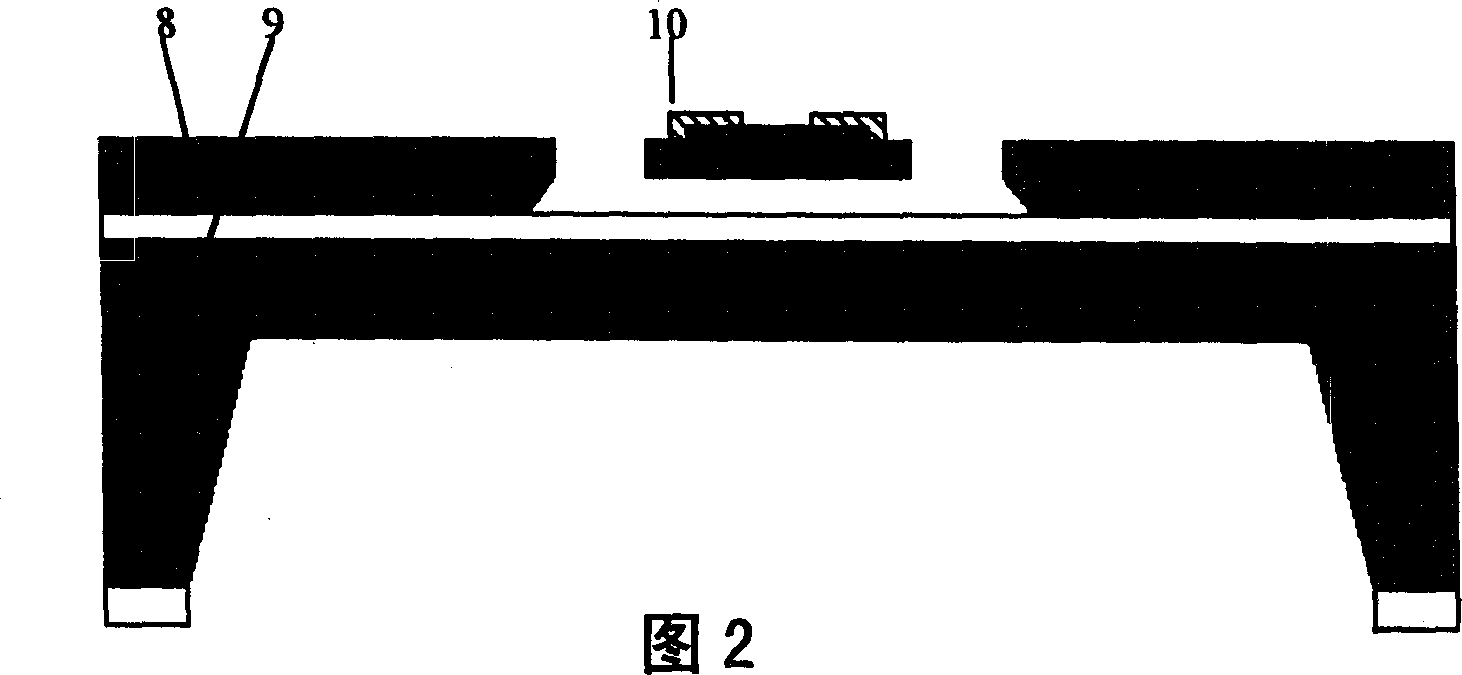

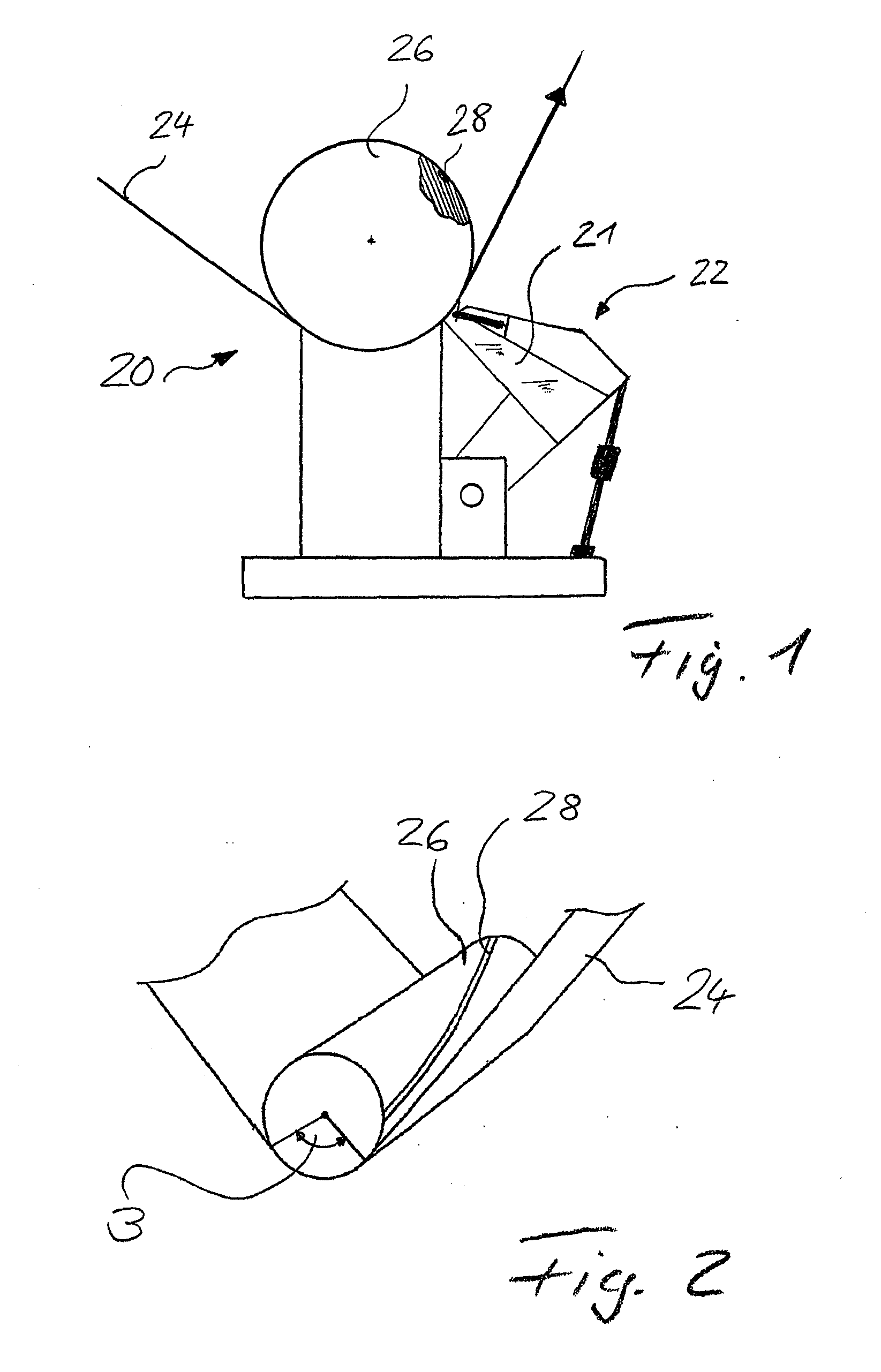

Apparatus and method for measuring pressure between jaw members

Testing system for measuring closure pressure between jaw members of electrosurgical forceps. The testing system includes a testing platform, a pair of selectively adjustable instrument supports, a testing stand. The platform has an elongated bed that supports an instrument rest, which supports the electrosurgical forceps. The pair of instrument supports are associated with the elongated bed and secure the forceps atop the elongated bed. The testing stand is disposed at a distal end of the elongated bed and supports a piece of testing material. The testing stand includes a layer of visco-elastic material and a pressure sensitive film. The layer of visco-elastic material forms a pocket. The pressure sensitive film is disposed within the pocket of the visco-elastic layer. The pressure sensitive film is adapted to electromechanically communicate with a diagnostic system to measure the closure pressure between jaw members when they are in a clamped configuration.

Owner:TYCO HEALTHCARE GRP LP

Apparatus and method for measuring pressure between jaw members

Owner:TYCO HEALTHCARE GRP LP

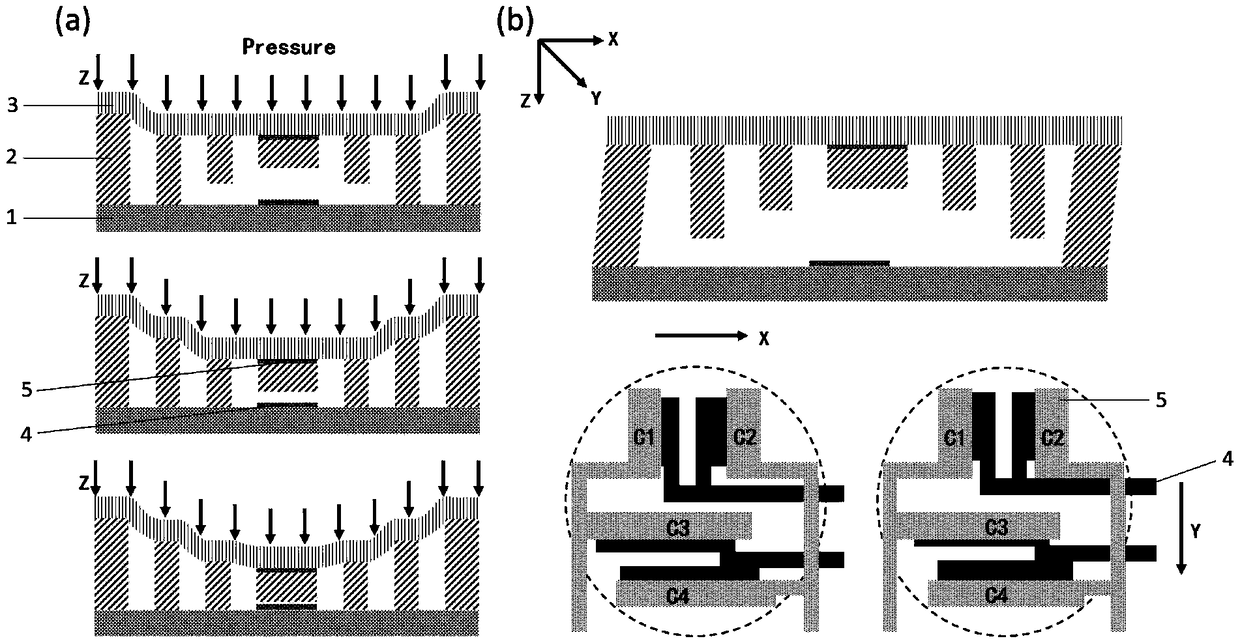

Novel flexible array pressure sensor

InactiveCN106092389AWith rectification characteristicsEliminate cross-couplingForce measurementSensor arrayEngineering

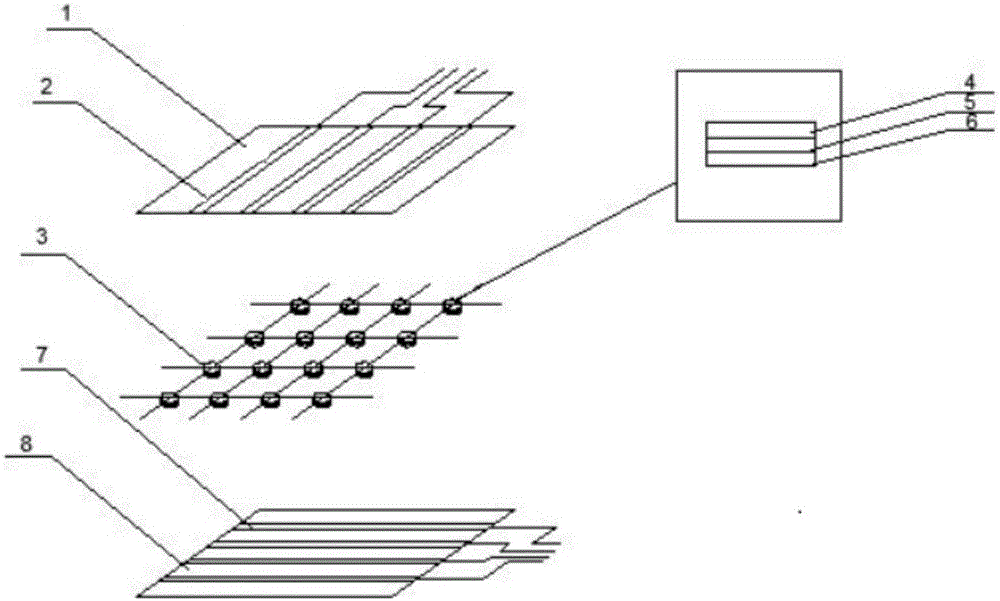

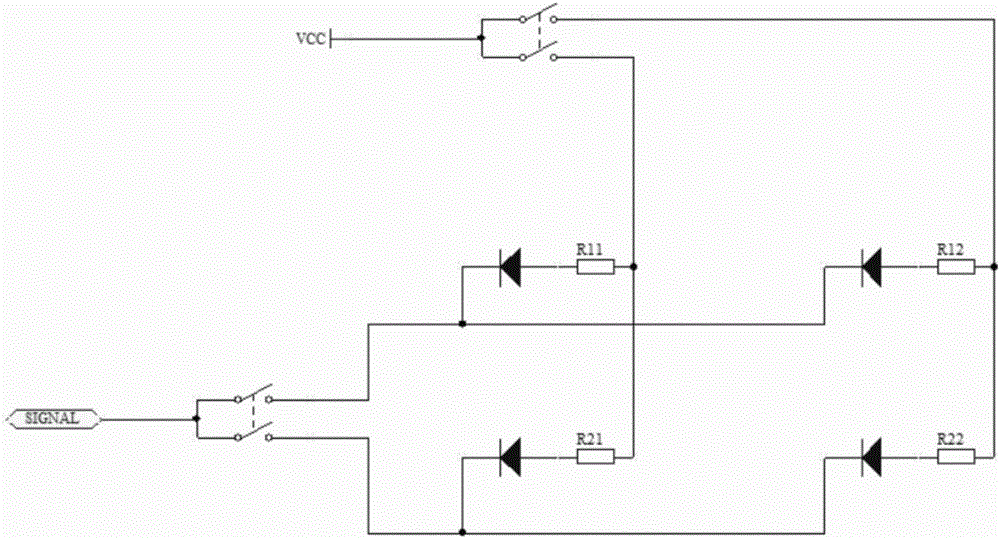

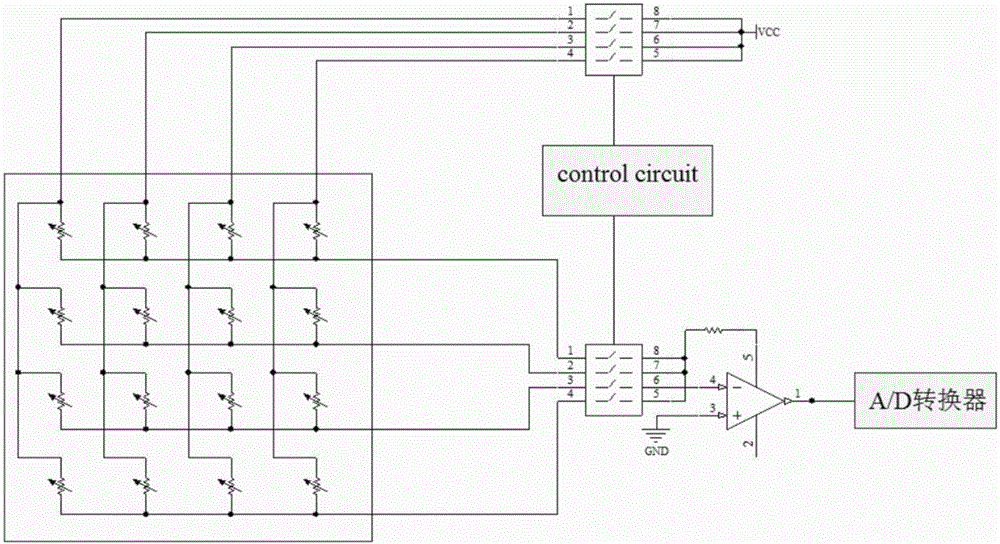

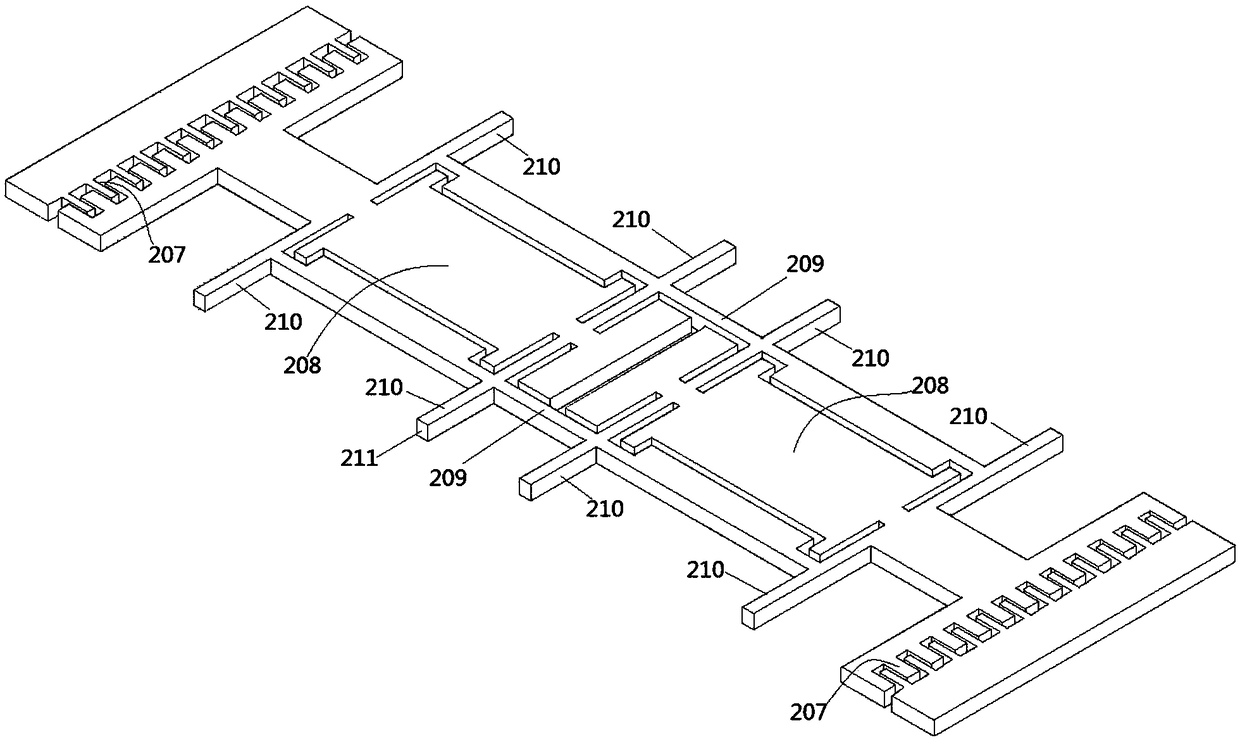

The invention provides a novel flexible array pressure sensor, including an upper flexible thin layer, an upper electrode layer, a pressure-sensitive unit array, a lower electrode layer and a lower flexible thin layer in order from top to bottom. The pressure-sensitive unit array comprises n identical pressure-sensitive units, each pressure-sensitive unit comprises a pn junction and a pressure-sensitive film, and the pn junction is composed of a p-type semiconductor film and a n-type semiconductor film. Each pressure-sensitive unit of the flexible array pressure sensor is of a serially-connected structure composed of one pressure-sensitive film and one pn junction rectification diode. During measurement of resistance change of a single sensitive point, and the unilateral conduction feature of the pn junction rectification diode enables sensitive points on a sensor array not to form a current loop, so that the cross coupling between array resistors is effectively prevented. The sensor is small in size and light in weight, and the low-cost large-scale batch production is easy to achieve.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Resonant pressure sensor and manufacturing method thereof

ActiveCN108507709AReduced external energy transferReduce the impactForce measurement using piezo-resistive materialsCouplingAcoustics

The invention provides a resonant pressure sensor and a manufacturing method thereof. A resonator uses a resonator structure based on an SOI silicon-based silicon comb double-ended fixed tuning fork structure. A Wheatstone bridge is formed inside the resonator by two piezoresistive materials (silicon after process doping) and two equivalent resistors (undoped silicon). The resistance change of thepiezoresistive materials is changed by a pressure change to detect the change in resonant frequency. Based on the silicon island structure, the pressure sensor structure is designed to transform thedeformation on a pressure-sensitive film into the plane vibration in the direction of the resonator through the silicon island structure, which not only reduces the mechanical coupling of the sensor,but also improves a quality factor and achieves a wide measurement range and high reliability.

Owner:HEFEI UNIV OF TECH

Resonant type pressure sensor

ActiveCN105203234AHigh sensitivityImproved linearity outputForce measurement by measuring frquency variationsPressure sensitivityLinearity

The invention provides a resonant type pressure sensor. The sensor comprises a sensor body, a pressure-sensitive film is formed at the bottom of the sensor body, a first resonator and a second resonator are formed on the pressure-sensitive film, the two resonators have the same intrinsic frequency, sensitivities, to the pressure P acting on the pressure-sensitive film, of the two resonators are equal, the first resonator is located in the center of the pressure-sensitive film, and the second resonator is located on the edge of the pressure-sensitive film. According to the resonant type pressure sensor, the two resonators are adopted, pressure characteristics of the sensor are represented by means of differential frequency output, influences of temperature factors are reduced, and pressure sensitivity and linearity of the sensor are improved. Temperature characteristics of the sensor are represented by means of sum frequency output for sensor temperature compensation, and the use temperature range of the sensor is widened.

Owner:山东中科思尔科技有限公司

Sock for detection of pressure points on feet

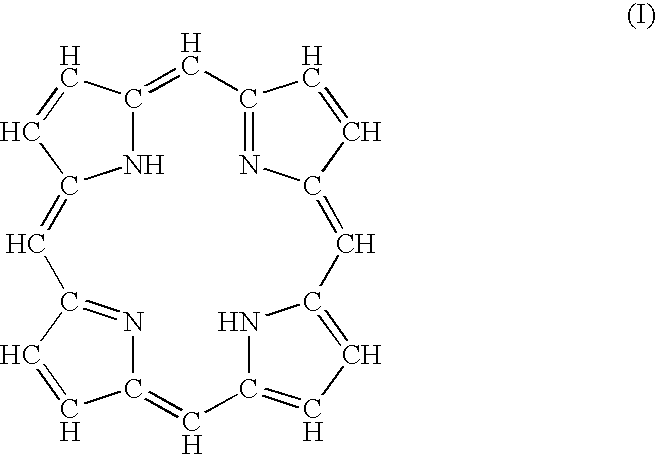

InactiveUS6918883B2Avoid developmentSlow pressurePerson identificationSensorsPhotoluminescenceOxygen

The present invention provides a sock containing a coating applied to at least a portion of a surface of the sock for sensing pressure points on a patient's foot. The coating material comprises a pressure-sensitive film comprised of oxygen-sensitive photo luminescent probe molecules dispersed within a polymer matrix, and, optionally, an inorganic pigment. Areas of increased pressure can be detected by correspondence to areas on the film of increased fluorescence intensity. The coating material can also be comprised of a coloring agent or dye such that after the sock has been worn for a period of time, in those areas of the foot susceptible to pressure points, the coating material transfers from the interior of the sock and adheres to the foot in those points. The present invention is particularly applicable to persons having diabetic neuropathic feet wherein portions of the foot may be insensitive to pressure.

Owner:NORTH CAROLINA STATE UNIV +1

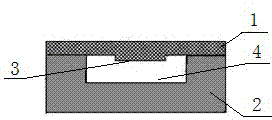

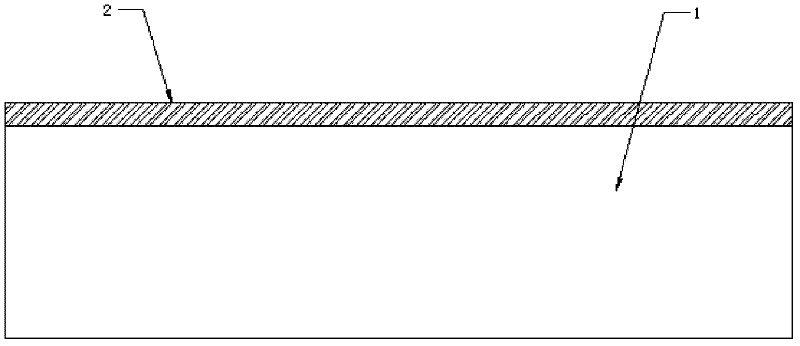

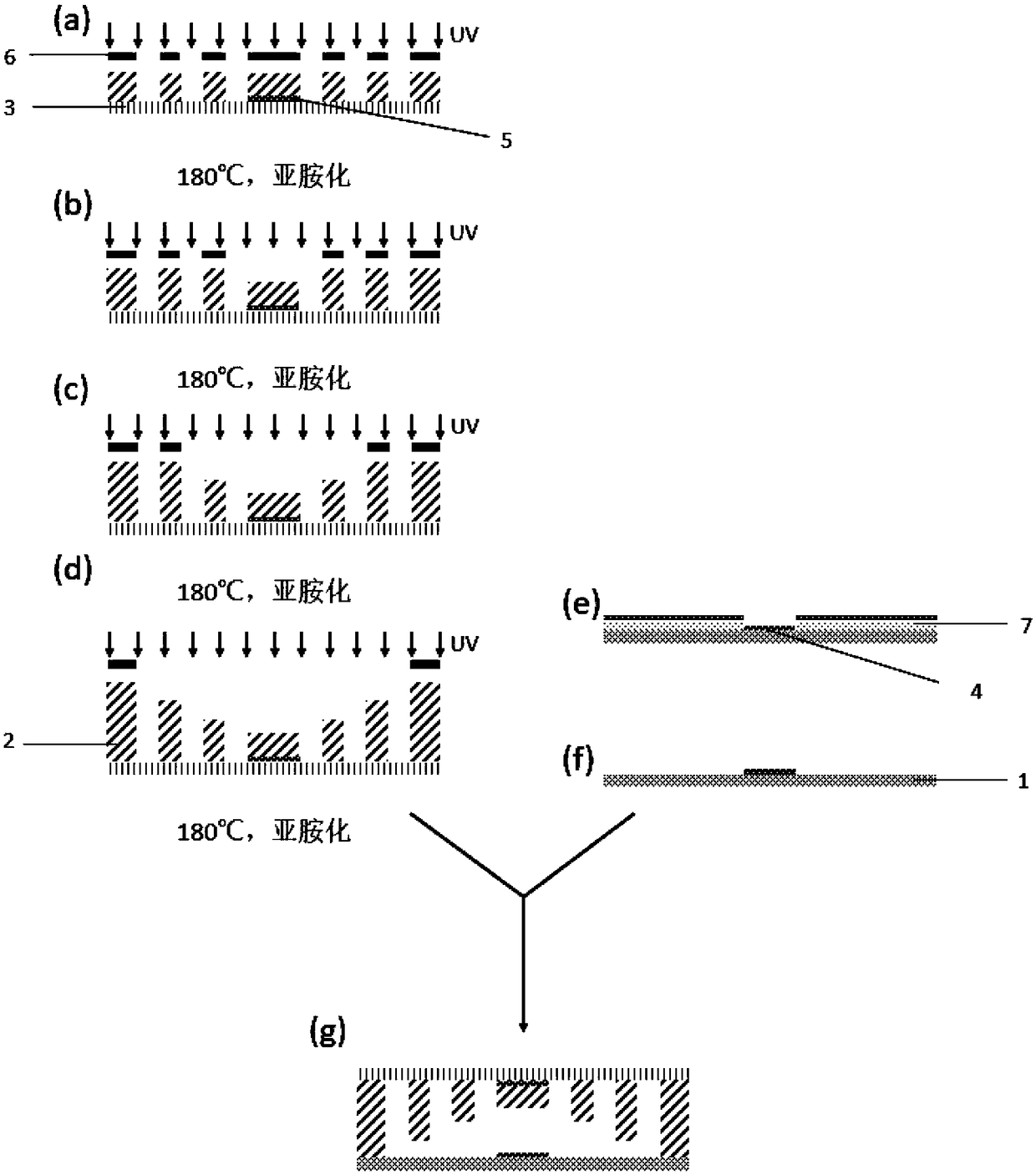

Capacitive pressure sensor and manufacturing method thereof

InactiveCN103257005AResolution timeSolve process problemsForce measurementFluid pressure measurement using capacitance variationCapacitive pressure sensorGas phase

The invention discloses a capacitive pressure sensor used for measuring pressure and a manufacturing method of the capacitive pressure sensor. According to the manufacturing method, by utilization of a surface silicon micro-machining technology, a silicon oxide sacrificial layer is deposited on a silicon substrate, and then a polycrystalline silicon film is deposited on the sacrificial layer to serve as a pressure sensitive film. The sacrificial layer is partially corroded to form a capacitance gap through sacrificial layer release holes formed in the polycrystalline silicon sensitive film. The sacrificial layer release holes in the polycrystalline silicon sensitive film are further filled through another deposition of a polycrystalline silicon film, and thus a sealed cavity is formed. At last, a gas vent hole is corroded in the polycrystalline silicon sensitive film again and sealed through metal with a physical vapor deposition (PVD) method, and thus a vacuum is formed in the sealed cavity.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

Method for mfg. microstructure resonance beam pressure sensor using SiNx as beam

InactiveCN1401980ARealize integrationAchieve integrationFluid pressure measurement by mechanical elementsConverting sensor output mechanicallyResonanceNitrogen

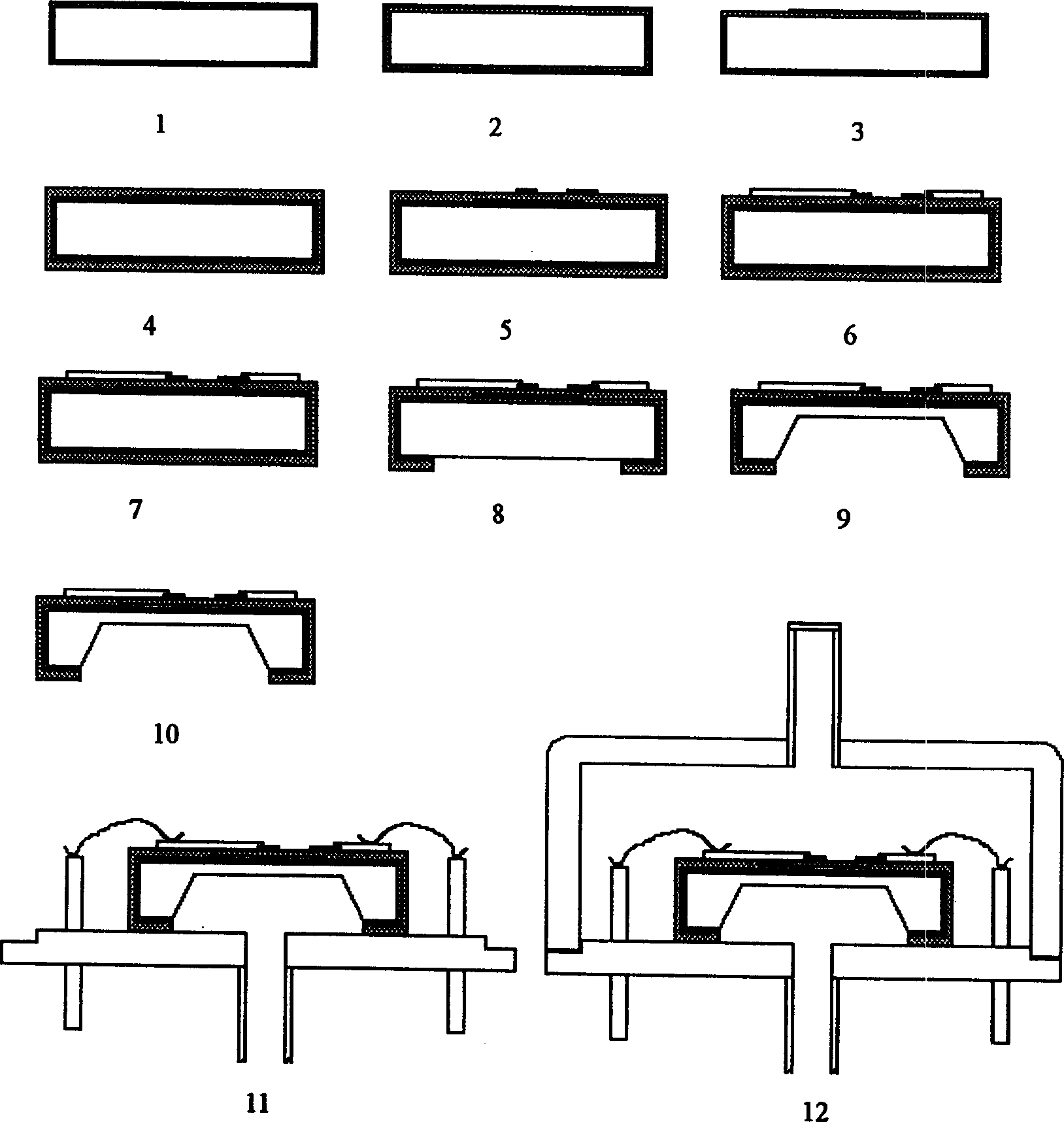

A process for preparing the pressure sensor using SiNx as micro resonant beam includes depositing SiN film on polished silicon substrate, depositing sacrificial layer, etching, depositing SiNx film, preparing vibration exciting and picking up resistors, preparing metal leading wires, etching beam slot, preparing resonant beam, etching low-stress nitrogen silicide film on the back of Si substrate to form corrosion windows, corrosion, preparing pressure-sensitive film, corrosiding out sacrificial layer, releasing SiNx beam, welding leading wire and vacuum packaging.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

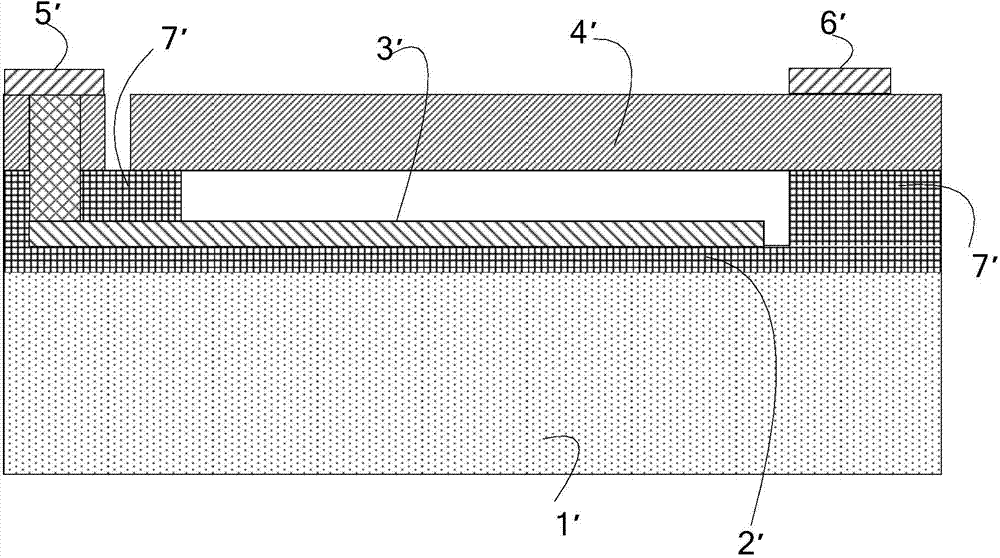

Silicon-glass-silicon structure surface acoustic wave temperature and pressure integrated sensor and preparation thereof

ActiveCN105784189AAvoid disturbanceImprove reliabilityForce measurementThermometers using physical/chemical changesBond interfaceOptoelectronics

The invention provides a silicon-glass-silicon structure surface acoustic wave temperature and pressure integrated sensor and preparation thereof, and relates to a sensor. The sensor has a silicon-glass-silicon sandwich structure. A pressure sensor is integrated on a silicon-based pressure-sensitive film of the upper layer. A temperature sensor is integrated on a silicon substrate of the bottom part. The silicon substrate and the upper layer are isolated by a glass framework. The manufacturing method comprises the steps that the silicon substrate is prepared; the silicon-based pressure-sensitive film is prepared; a sandwich structure cavity is formed by the silicon substrate, the silicon-based pressure-sensitive film and the glass framework through bonding; the substrate layer of an SOI wafer is etched with the buried silicon oxide layer in the SOI wafer acting as a corrosion auto-stop layer so that the device layer of the SOI wafer is remained to act as the silicon-based pressure-sensitive film of the pressure sensor; four electrode regions are formed on the silicon-based pressure-sensitive film through etching, and the etching regions are arranged above the electrode regions of the temperature sensor and the pressure sensor with the bonding interface of the glass framework and the silicon-based pressure-sensitive film and the inlaid electrodes in the silicon-based pressure-sensitive film acting as the etching stop layer respectively; and array devices are split and then single devices are obtained.

Owner:厦门纵能电子科技有限公司

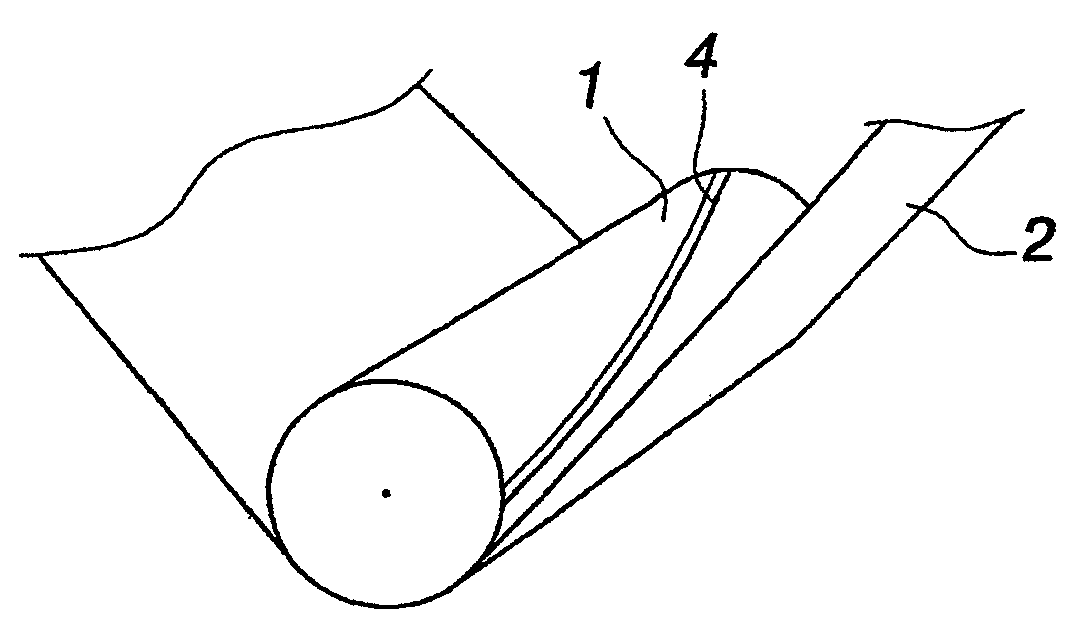

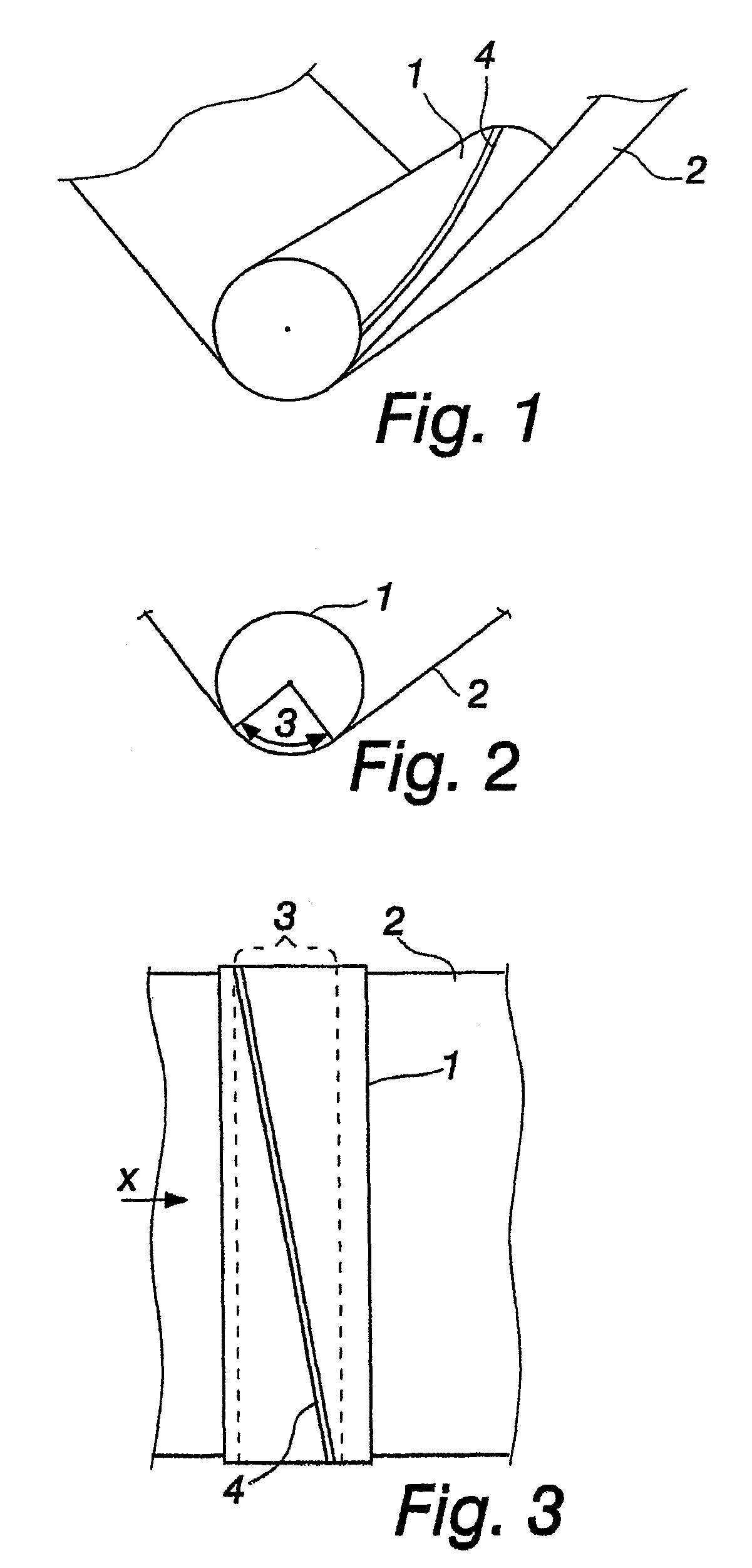

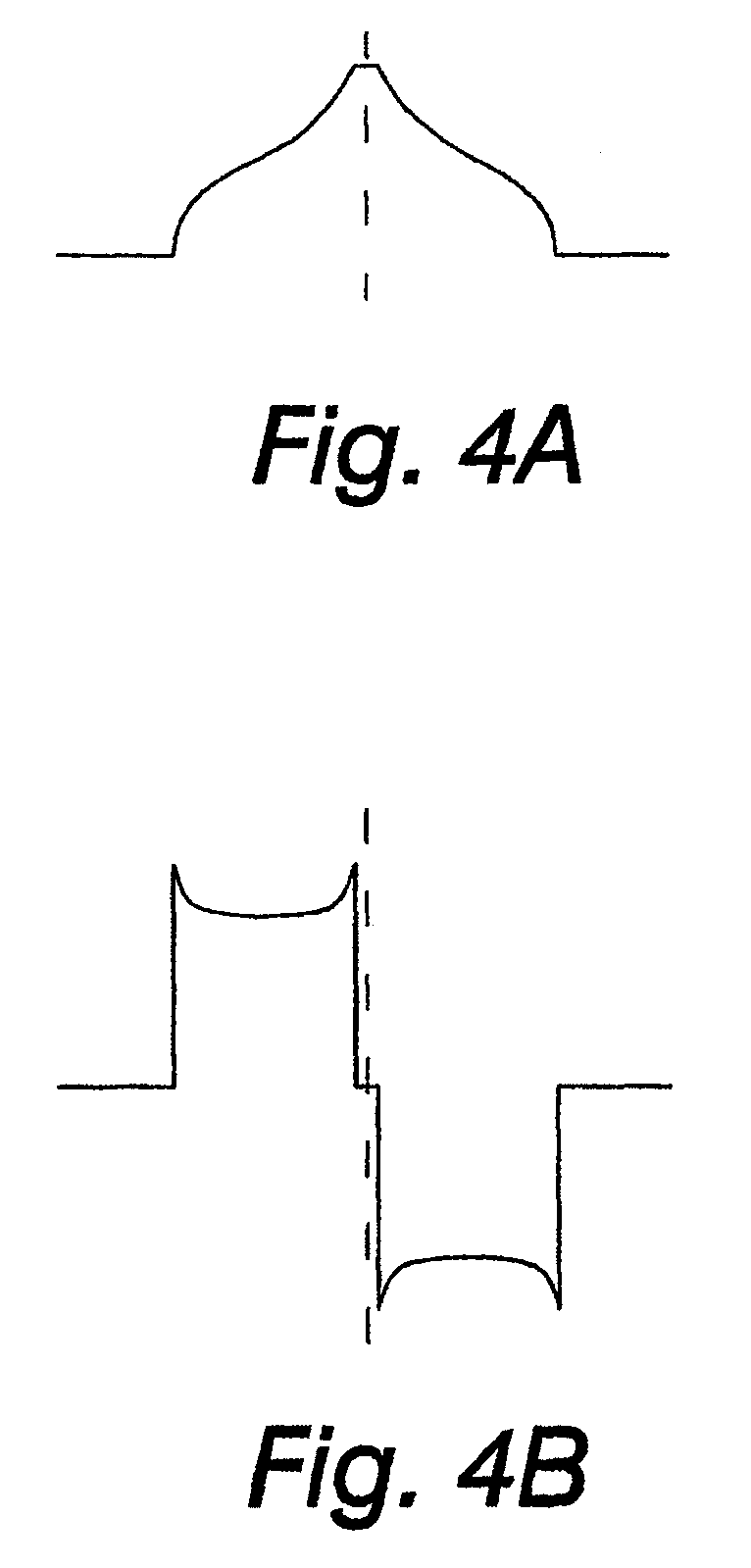

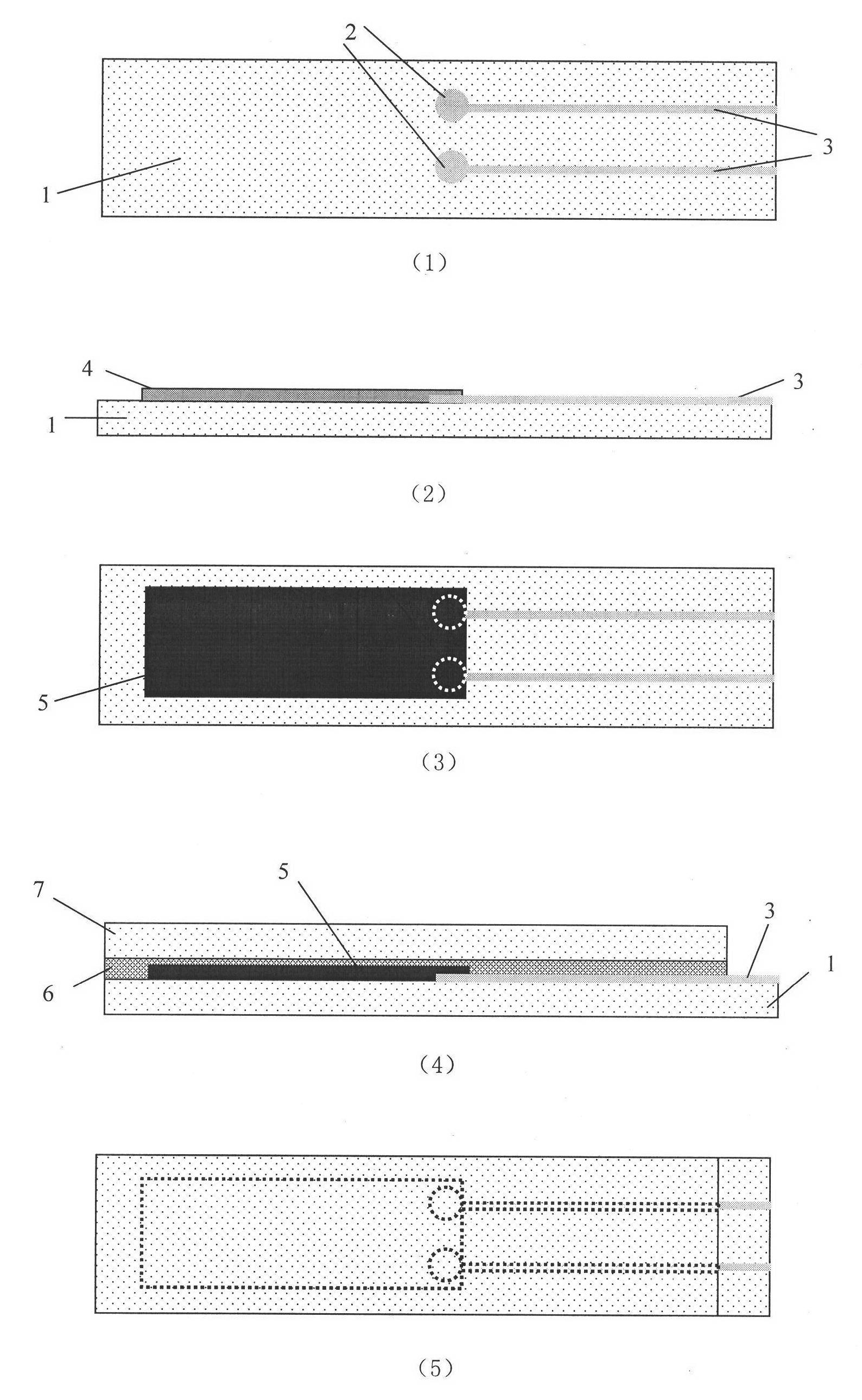

Web tension profile measuring method and roll applying the same

InactiveUS7444862B2Sufficiently precise measurementHigh measurement accuracyTesting/calibration apparatusForce measurementThin film sensorEngineering

A method and a roll for measuring a tension profile is provided. The roll has planted on its surface a spirally helical pressure-sensitive film sensor, such as an EMFi pressure-sensitive film sensor, which makes contact with a web obliquely and which, co-directionally with the web, has a measuring range which is substantially equal to or shorter than a web overlap angle when the roll is used for measuring a lateral tension profile of the web.

Owner:VALMET TECH INC

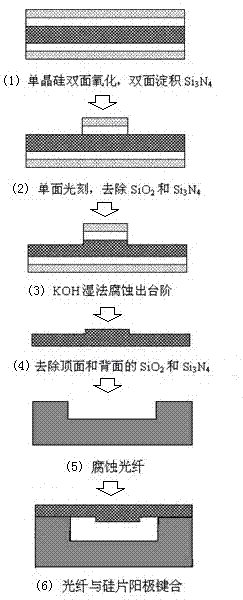

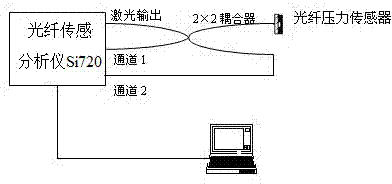

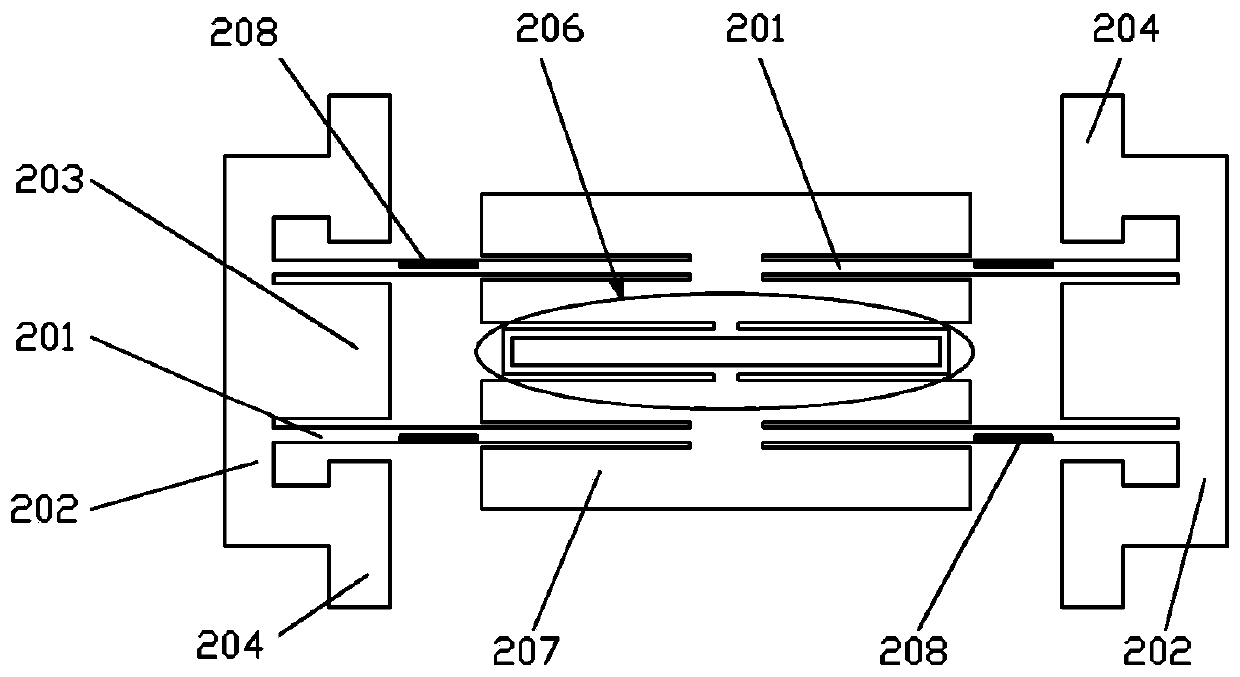

Miniature optical fiber Fabry-Perot pressure sensor and manufacturing method thereof

ActiveCN103528735AHigh measurement accuracyHigh precisionForce measurement by measuring optical property variationFluid pressure measurement by optical meansLight energyEngineering

The invention discloses a novel miniature optical fiber Fabry-Perot pressure sensor and a manufacturing method thereof. According to the sensor, the defects that large light energy loss is caused because a traditional optical fiber Fabry-Perot sensor generates non-planar movement when a pressure sensitive film is pressed can be effectively overcome, and higher measurement accuracy can be obtained. The provided miniature optical fiber Fabry-Perot pressure sensor comprises a monocrystalline silicon film and a borosilicate optical fiber which are connected through an anodic bonding process, wherein the monocrystalline silicon film comprises a boss; the borosilicate optical fiber comprises a concave cavity; one side of the monocrystalline silicon film with the boss and the concave cavity of the borosilicate optical fiber relatively form a Fabry-Perot cavity; a reflecting surface is formed on the top of the boss. The sensor has the advantages that two reflecting surfaces of the Fabry-Perot cavity are always kept to be parallel to each other in the compressive deformation of the sensitive film, and the measurement accuracy is greatly improved.

Owner:广州烽鼎医疗科技有限公司

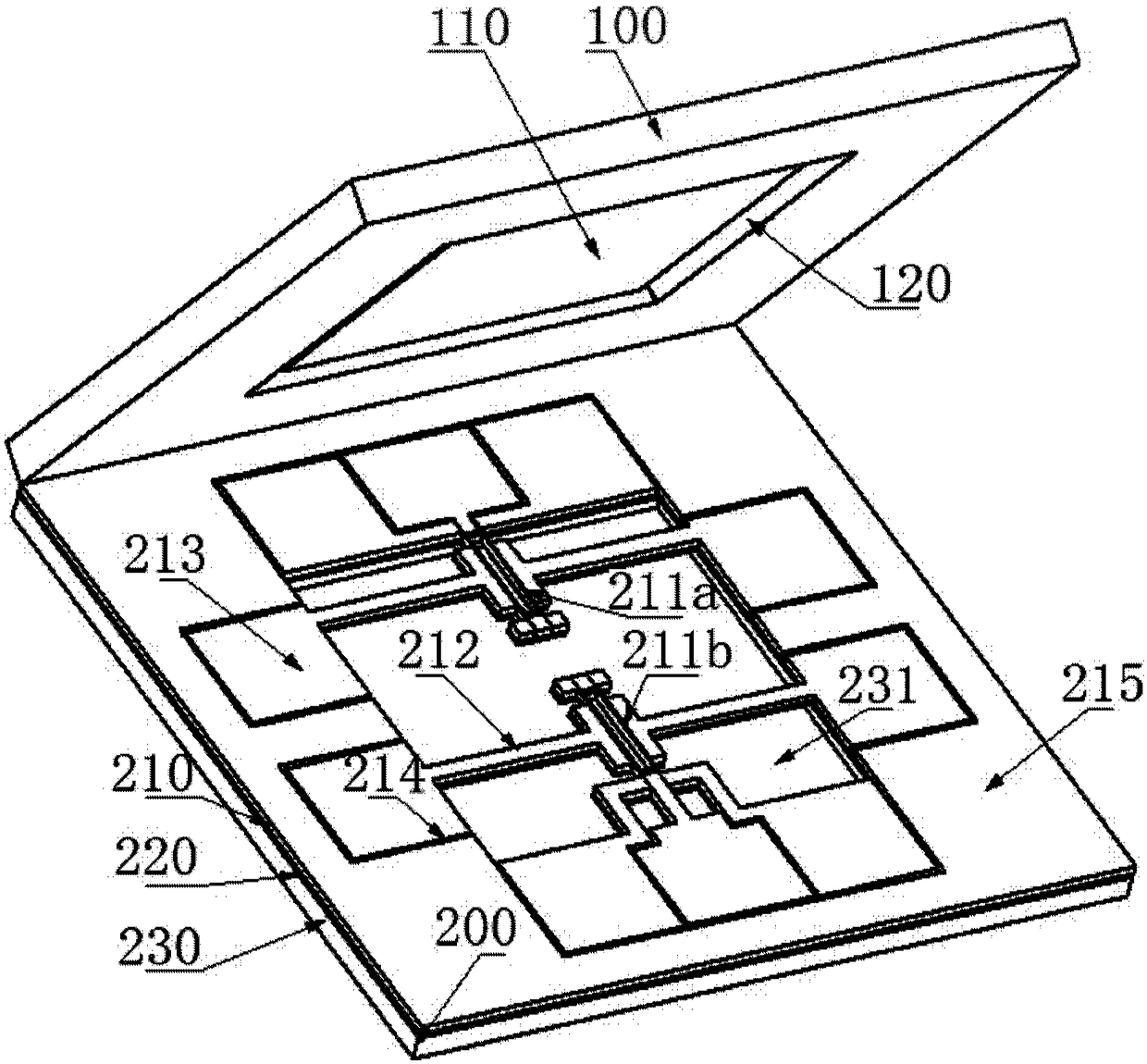

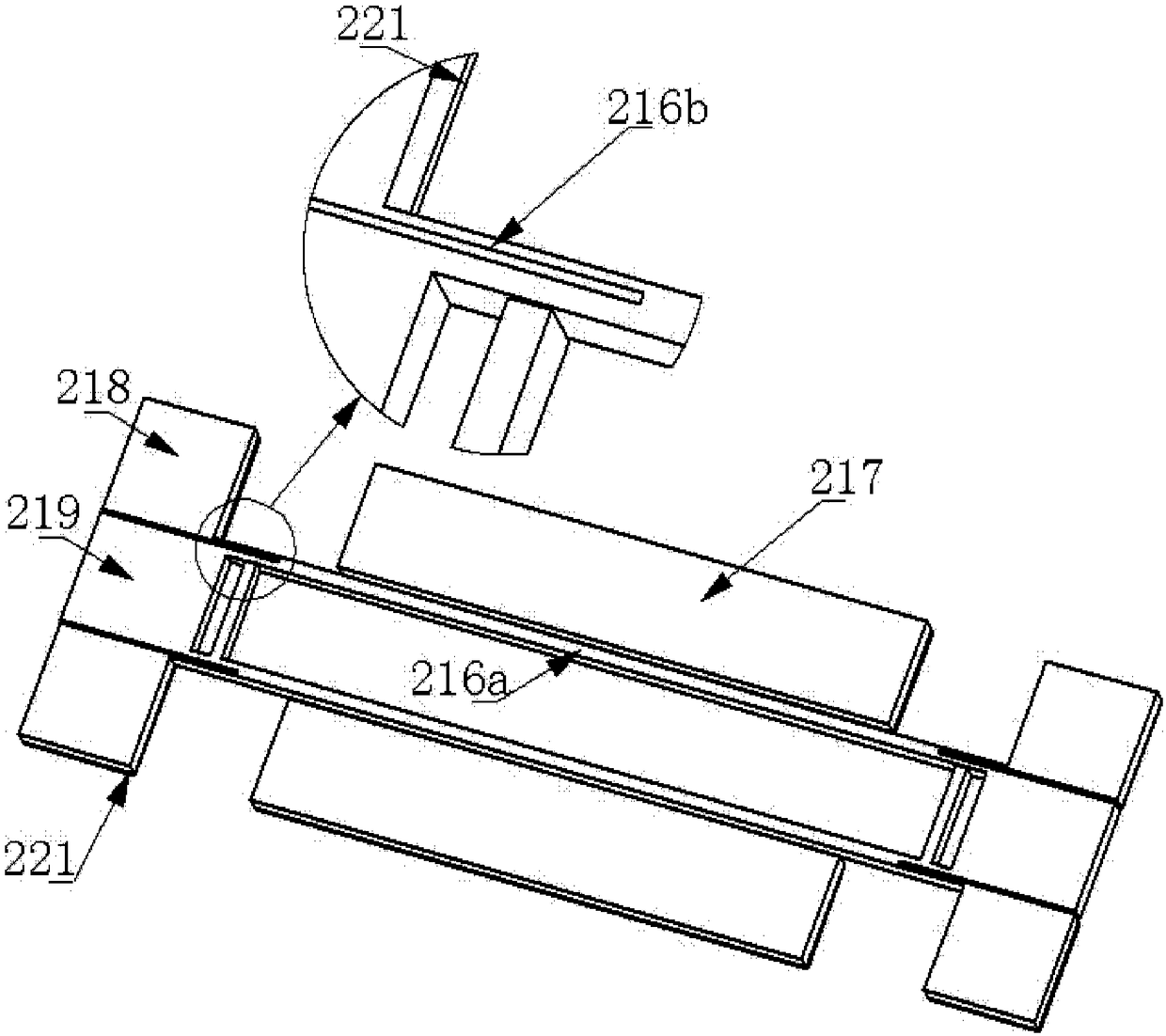

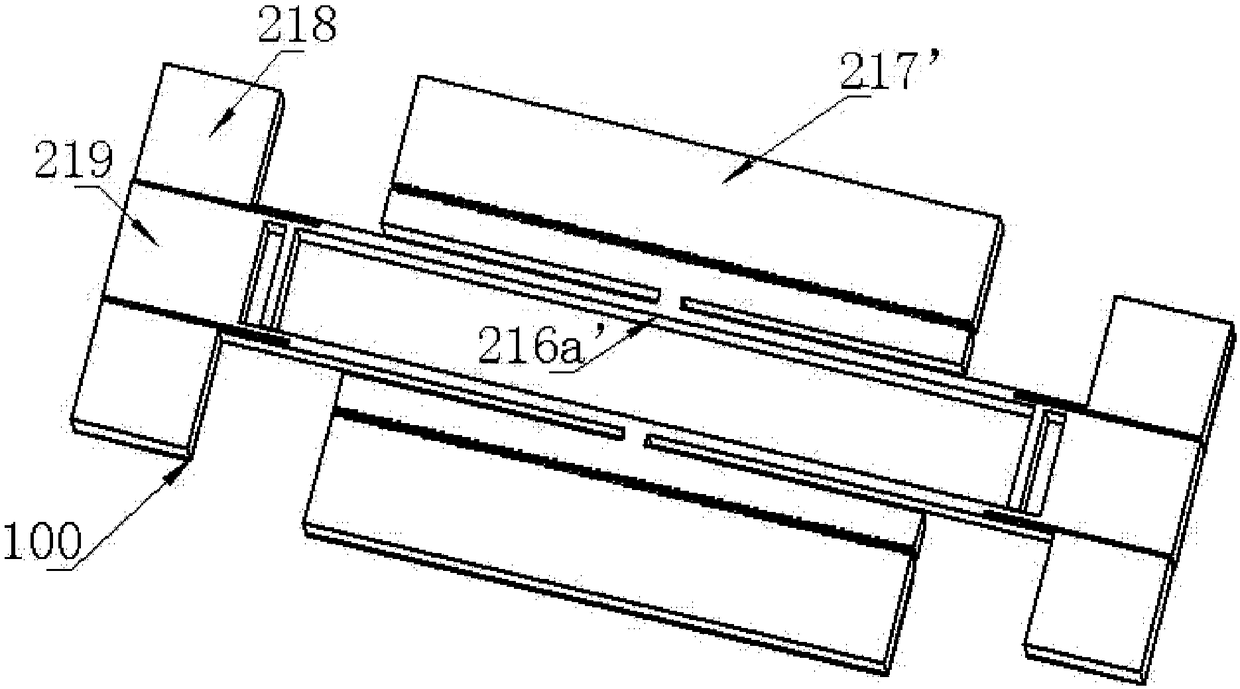

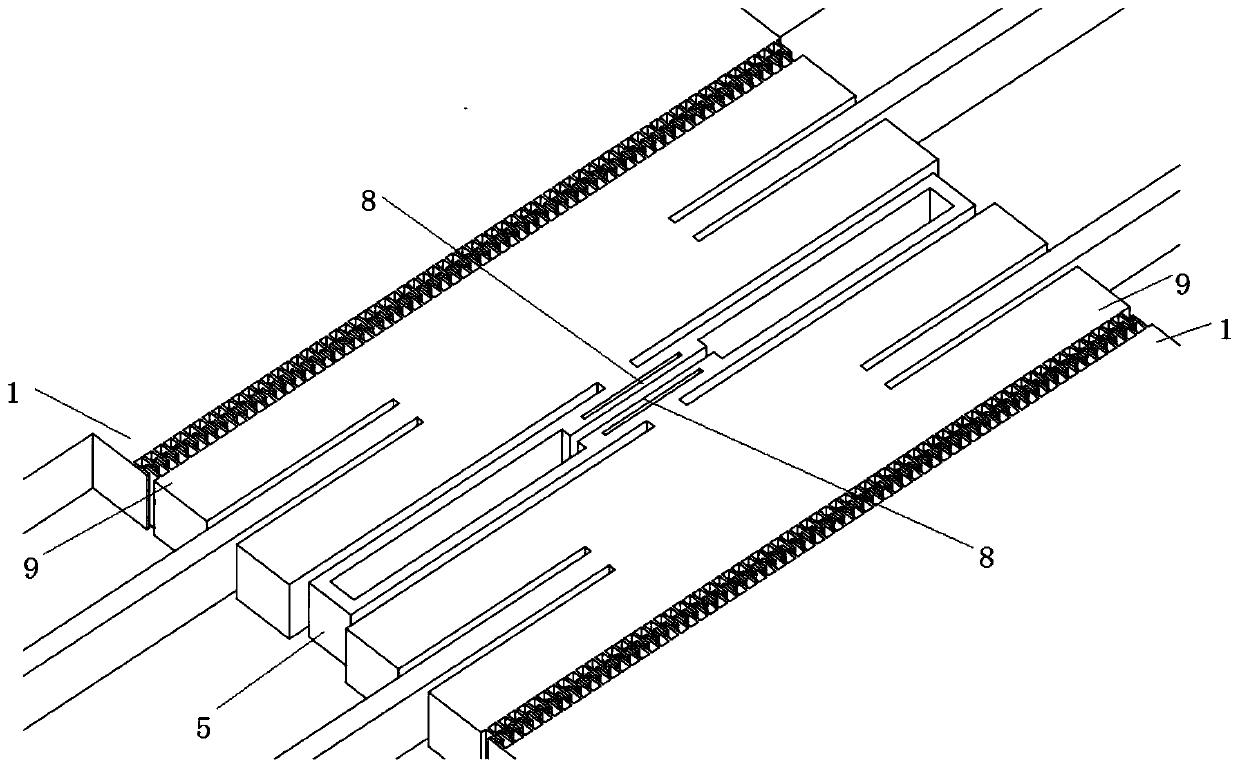

Piezoelectric excitation pulled silicon micro-resonant pressure sensor chip and preparation method thereof

ActiveCN109786422AHigh sensitivityHigh quality factorPiezoelectric/electrostrictive device manufacture/assemblySolid-state devicesGlass coverPiezoelectric actuators

The invention provides a piezoelectric excitation pulled silicon micro-resonant pressure sensor chip and a preparation method thereof. The pressure sensor chip mainly comprises a sealed glass cover, aresonator layer, a pressure sensitive film layer, a stress isolation pad, a piezoelectric excitation element and a resistance vibration pick-up element. A composite structure of a pressure sensitivediaphragm and a resonator is adopted. For a second sensitive mode, the resonator layer comprises a resonant beam and a torsion beam. An extension part at one end of two adjacent resonant beams is connected to the same suspended torsion beam, and the other end is connected to a mass block. A coupling beam is arranged in the middle of the mass block. The resonator is connected to an anchor point through a connection point. A pressure guide hole is formed in the stress isolation pad, and the pressure is delivered to the rectangular pressure sensitive diaphragm under the guidance of the pressure guide hole to cause deformation. The deformation is amplified by the anchor point, and delivered to the resonator layer. Piezoelectric actuators and resistive vibration pick-up elements are respectively arranged on the outer surface of the resonant beam and the coupling beam. The piezoelectric actuators and the resistive vibration pick-up elements are connected with an external circuit through leads respectively.

Owner:XI AN JIAOTONG UNIV

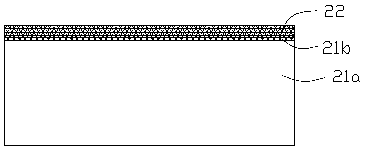

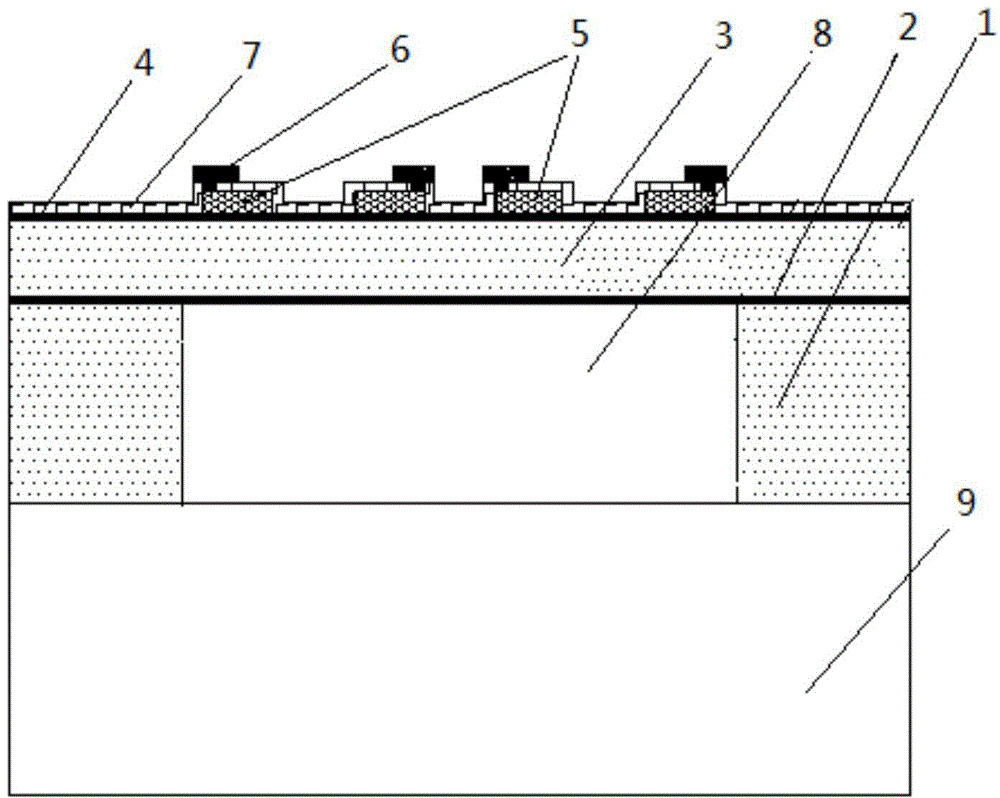

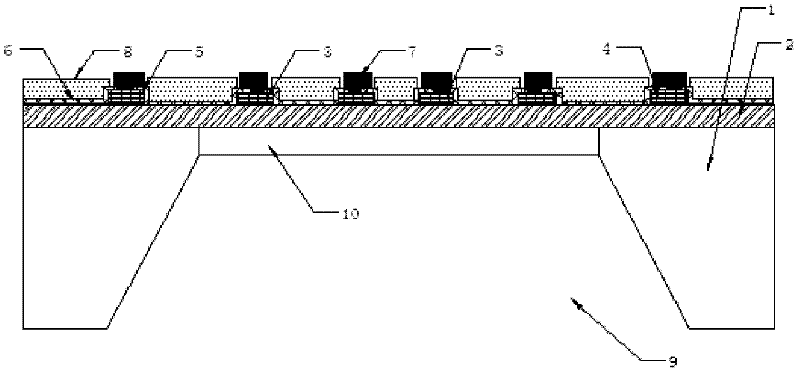

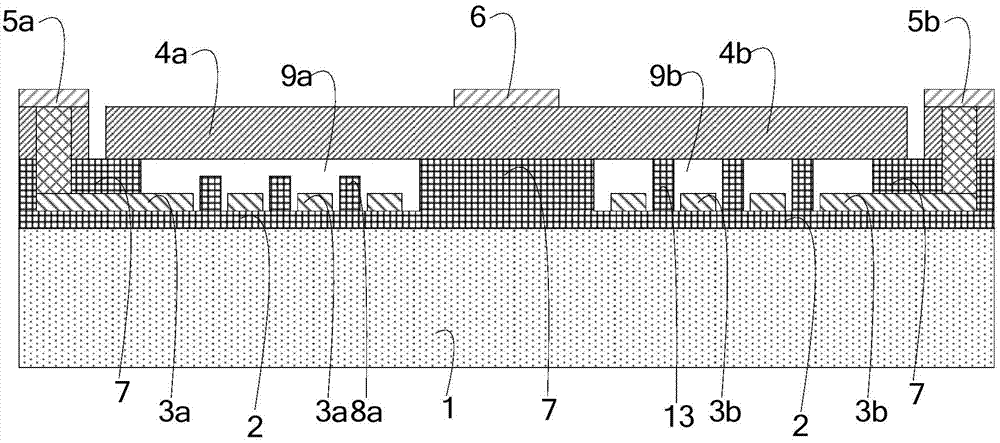

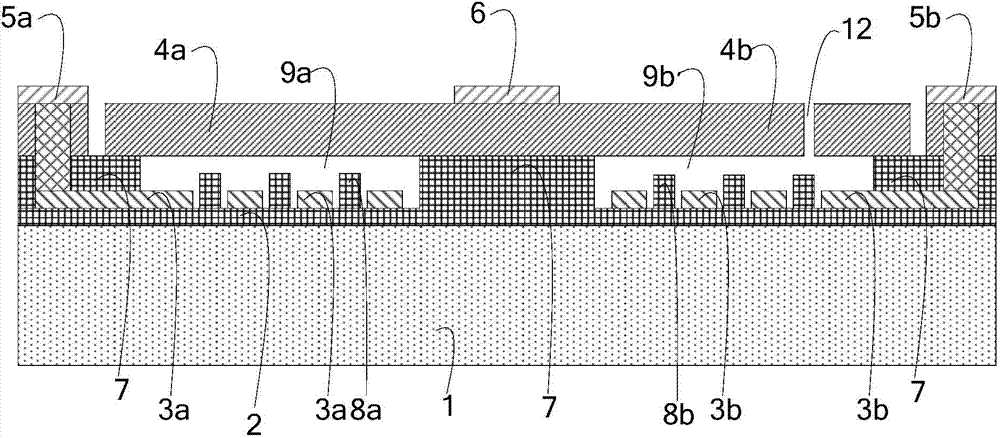

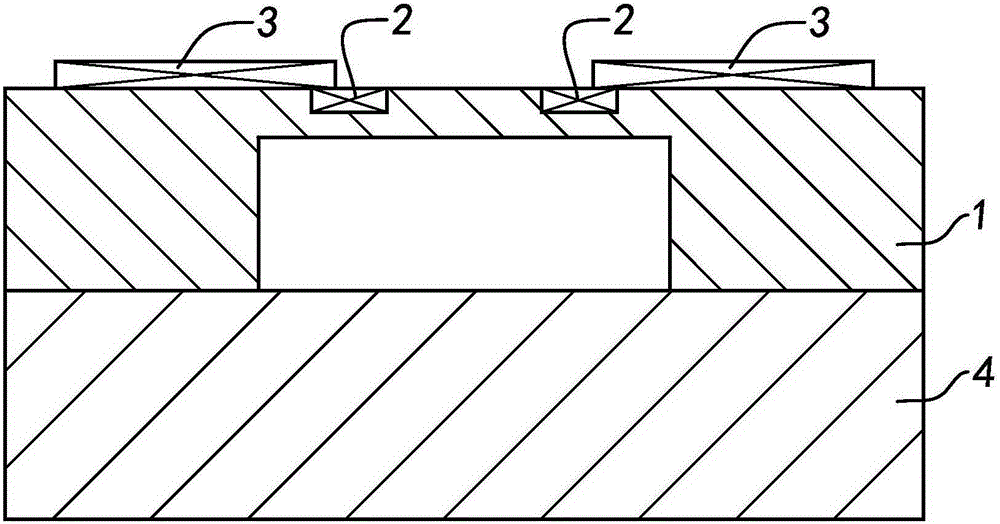

Dual-SOI-structured MEMS pressure sensor chip and manufacturing method thereof

ActiveCN104931163AExtended operating temperature rangeImprove stabilityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsEngineeringOperating temperature range

The invention proposes a dual-SOI-structured MEMS pressure sensor chip and a manufacturing method thereof. The dual-SOI-structured MEMS pressure sensor chip comprises a first SOI structure and a second SOI structure, wherein the first SOI structure comprises a substrate and a pressure sensitive film of a pressure sensor, the second SOI structure is a surface-layer SOI structure and comprises a piezoresistor material which is formed by growing insulation isolation medium and depositing and doping alpha-silicon on the insulation medium, a Wheatstone bridge structure is formed through etching, and the second SOI structure replaces the conventional PN junction isolating mode and increases the operating temperature range of the sensor chip. The dual-SOI-structured high-temperature MEMS pressure sensor chip related by the invention is suitable for mass production, and has good consistency, precise measuring range, small chip size, high temperature resistance, high reliability and low cost.

Owner:无锡芯感智半导体有限公司

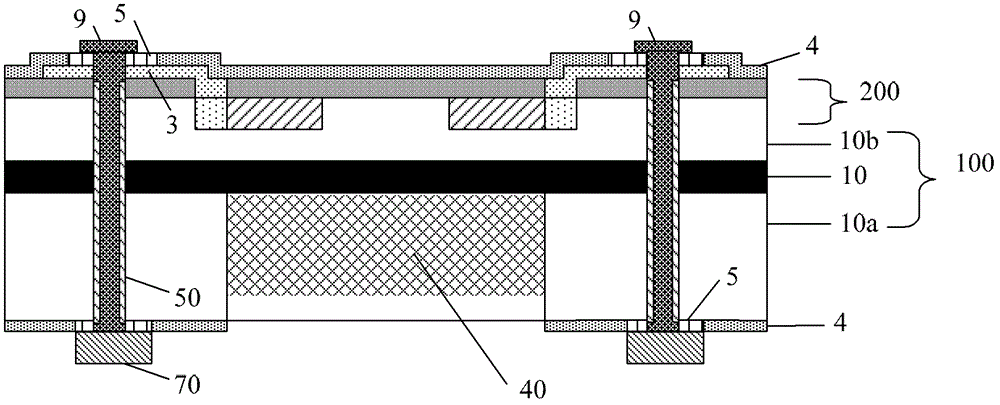

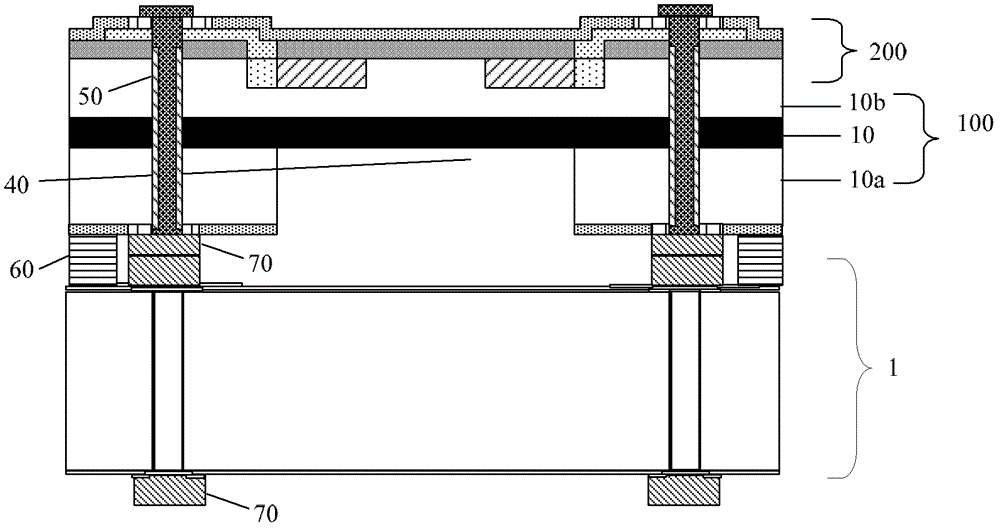

Pressure sensor and preparation method thereof

ActiveCN102798489ASmall sizeDecorative surface effectsForce measurement using piezo-resistive materialsEngineeringPressure sensitive film

The invention provides a pressure sensor which can reduce the size and facilitate packaging and a preparation method of the pressure sensor, aiming at the defects of a pressure sensor structure in size and packaging technology in the prior art. The pressure sensor comprises a substrate (100), a pressure sensitive element (200) and an extraction electrode thereof, and a silicon through hole (50), wherein the pressure sensitive element (200) and the extraction electrode thereof are positioned on one side of the substrate (100), the silicon through hole (50) penetrates through the substrate (100), one end of the silicon through hole (50) is interconnected with the extraction electrode of the pressure sensitive element (200), the other end of the silicon through hole (50) is used as an output terminal of the pressure sensor, the pressure sensor also comprises a sealing cavity (40) positioned below the pressure sensitive element (200), and a pressure sensitive film is formed between the pressure sensitive element (200) and the sealing cavity (40).

Owner:厦门清芯集成科技有限公司

SOI (silicon on insulator) pressure sensor with self- temperature drift compensation

PendingCN102445301AAchieving temperature self-compensationImprove stabilityFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceElectricity

The invention relates to an SOI (silicon on insulator) pressure sensor with self- temperature drift compensation, which comprises an SOI substrate, wherein the SOI substrate is provided with a bridge resistance configured into a wheatstone bridge; the surface of the bridge resistance, corresponding to the SOI substrate, is provided with a compensating resistance for carrying out temperature compensation on the wheatstone bridge; leads electrically connected mutually are arranged on the compensating resistance and the bridge resistance; the bridge resistance is separated from the compensating resistance through an isolation layer and a passivation layer; the isolation layer is covered on the SOI substrate; the passivation layer is covered on the isolation layer; the other side of the SOI substrate, corresponding to the side on which the bridge resistance is arranged, is etched to form a pressure cavity and a pressure sensitive film; and the pressure cavity and the pressure sensitive film are located right below the bridge resistance. The SOI pressure sensor with self- temperature drift compensation has a compact structure, realizes self- temperature drift compensation, has reduced cost, high stability, good consistency, wide application range, is suitable for batch production, and is safe and reliable.

Owner:无锡芯感智半导体有限公司

Quasi-differential-capacitor type MEMS pressure sensor and manufacturing method thereof

ActiveCN104848982AImprove stabilityHigh resolutionPressure difference measurement between multiple valvesFluid pressure measurement using capacitance variationMems pressure sensorElectric capacity

Owner:GOERTEK MICROELECTRONICS CO LTD

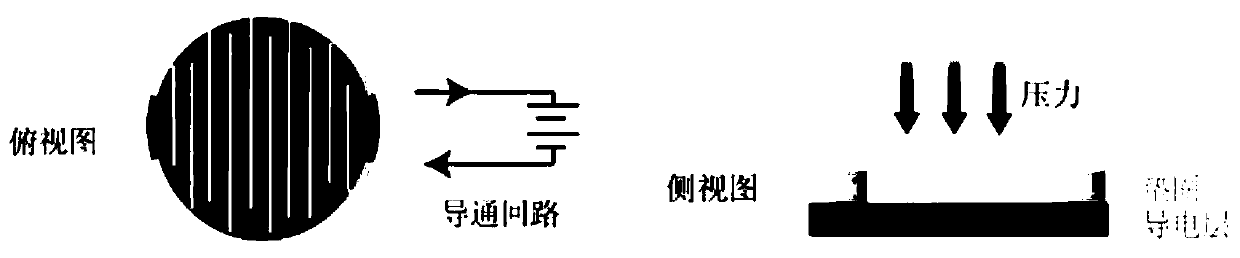

Thinned flexible pressure sensor sensitive unit based on flatfish type electrode structure

InactiveCN102419226AReduce time dependenceReduce adverse effectsForce measurement using piezo-resistive materialsConductive polymer compositeIndustrial equipment

The invention relates to a thinned flexible pressure sensor sensitive unit based on a flatfish type electrode structure, belonging to the technical field of sensors. The sensitive unit comprises a top packaging film, a bottom packaging film and a pressure-sensitive film arranged in the middle, wherein the top packaging film is made of polyimide material, the pressure-sensitive film is made of nano conductive polymer composite material, the bottom packaging film is a polyimide film with a pair of electrodes / leads, the two electrodes / leads are both arranged at the same side of the pressure-sensitive film so as to form a flatfish type electrode structure. The pressure-sensitive unit developed by using the method provided by the invention has the advantages of slight thickness, simple structure, low cost and the like; moreover, since signals are led out from the same side of a sensitive material, time dependence of the pressure-sensitive unit during signal output is reduced, and adverse effect of time dependence on the measurement accuracy is reduced further; therefore, the sensitive unit is especially applicable to the fields of interlayer pressure monitoring of narrow and small curved surfaces of national defense and industrial equipment, artificial electronic skin research and development and the like.

Owner:NORTHEASTERN UNIV

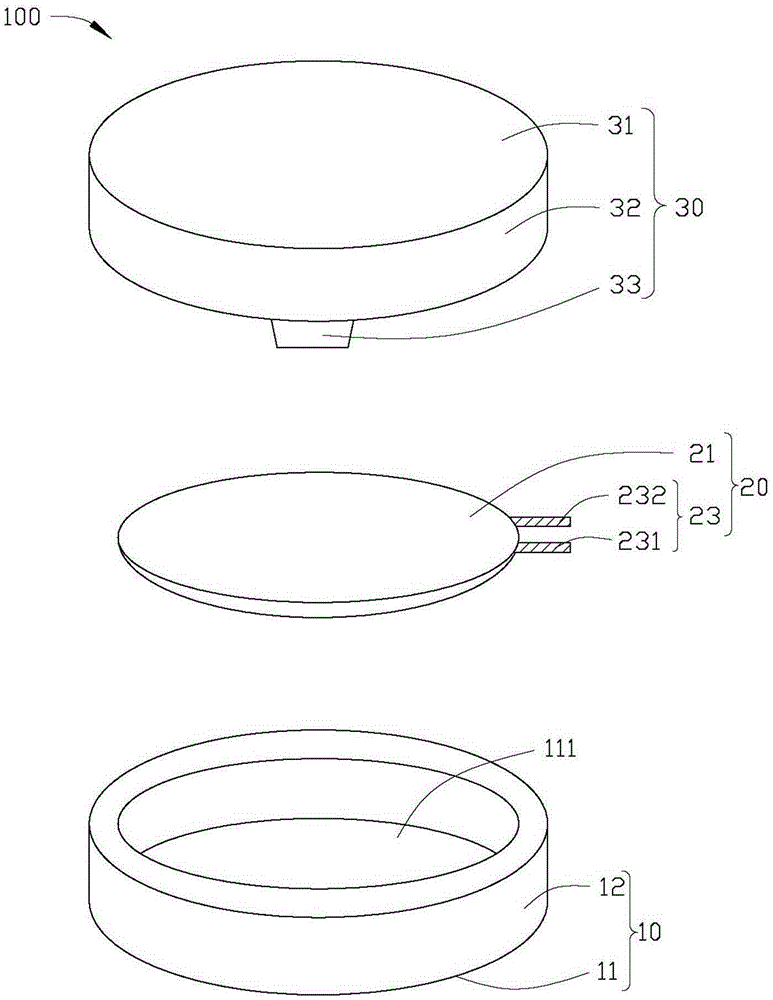

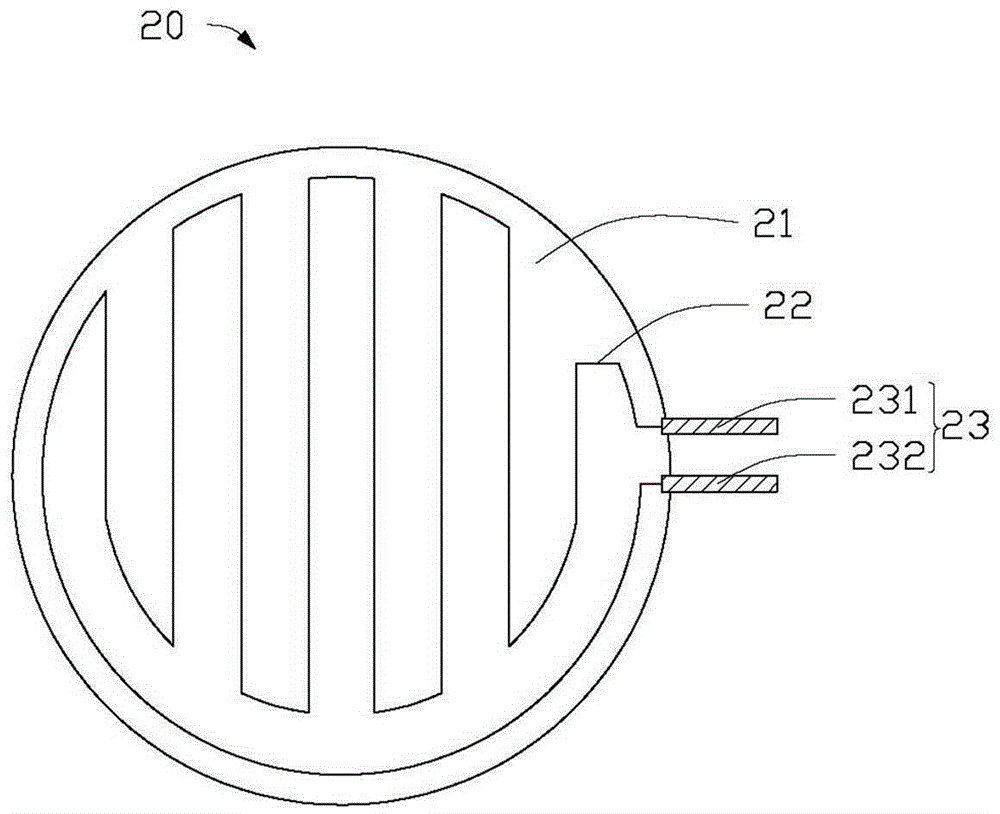

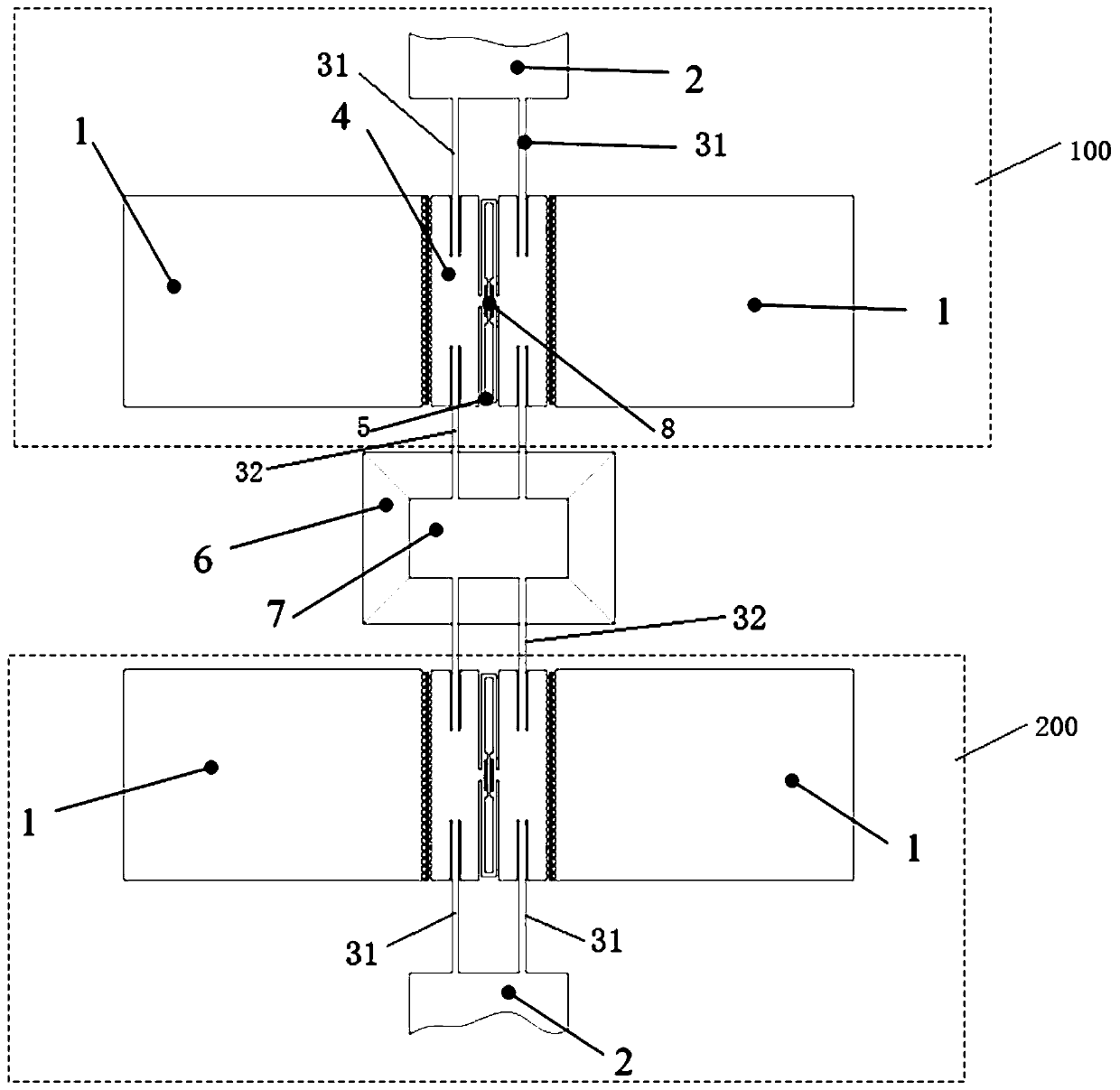

Built-in high-temperature wireless pressure sensor

InactiveCN103926026AIncreasing the thicknessLower the resistance valueForce measurement by measuring frquency variationsFluid pressure measurement using capacitance variationCapacitanceChinese characters

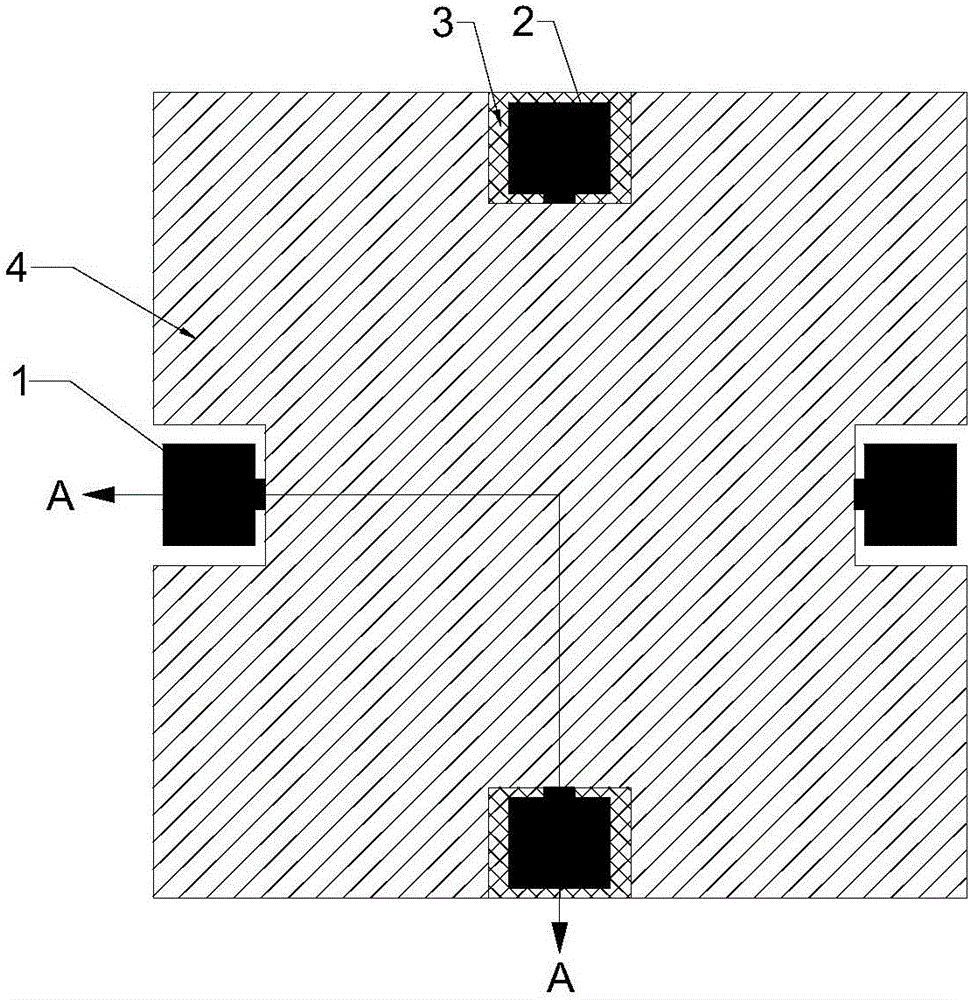

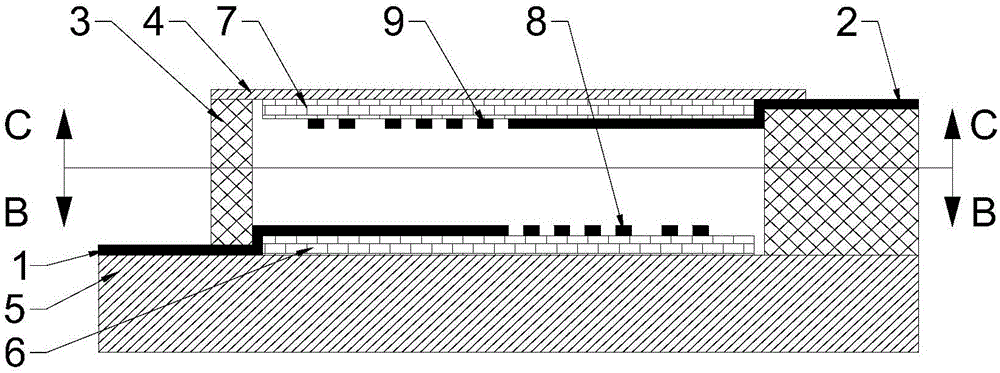

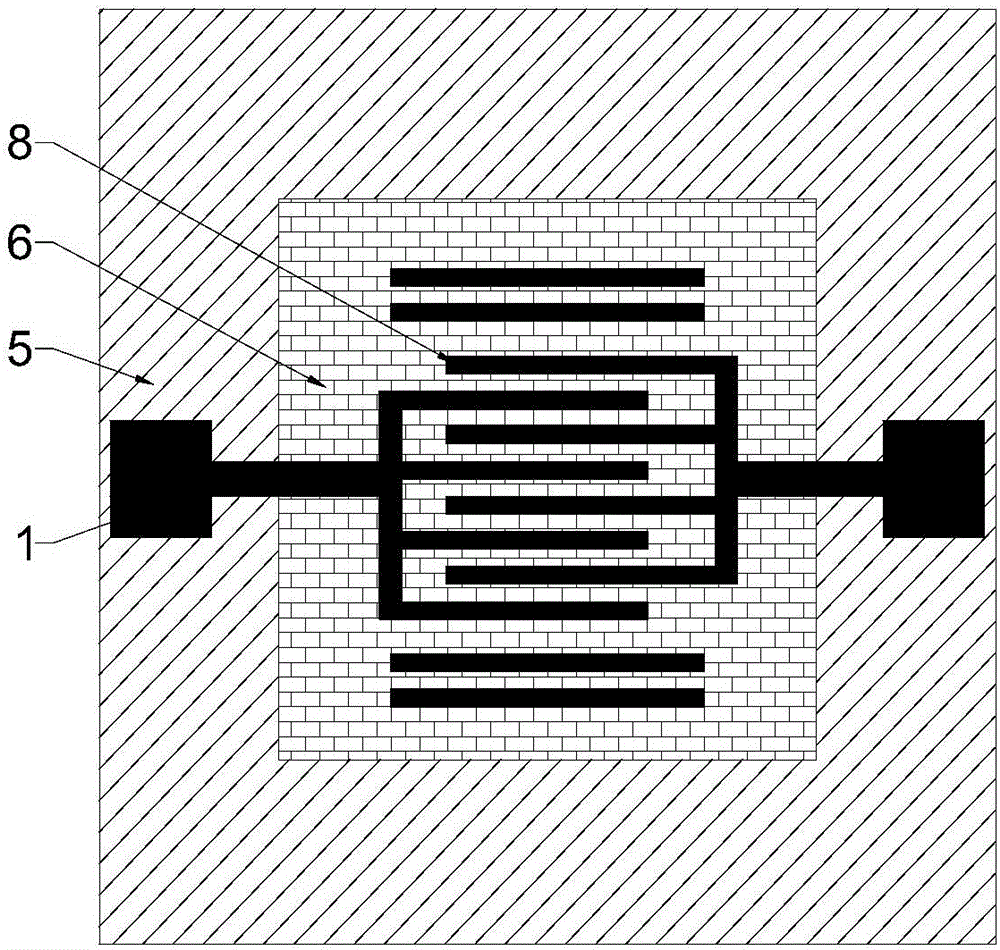

The invention relates to a pressure sensor, in particular to a built-in high-temperature wireless pressure sensor. The built-in high-temperature wireless pressure sensor is provided with a pressure sensitive film, a sensor upper covering plate, a capacitor upper counter electrode, a capacitor lower counter electrode, an inductance coil, a sensor base and a pressure reference cavity, wherein a square groove is formed in the sensor upper covering plate to form the pressure sensitive film, the capacitor upper counter electrode is manufactured on the back surface of the sensor upper covering plate, a groove shaped like a Chinese character 'hui' is formed in the sensor base, the capacitor lower counter electrode and the inductance coil are manufactured on the sensor base, the upper surface of the capacitor lower counter electrode is flush with the upper surface of the inductance coil, and the inductance coil is manufactured in the groove shaped like the Chinese character 'hui'. The capacitor upper counter electrode, the capacitor lower counter electrode and the inductance coil are all made of silicon doped with metal, the capacitor upper counter electrode and the capacitor lower counter electrode form a parallel plate capacitor, the capacitor upper counter electrode and the inductance coil lead out wires at the upper layer and wires at the lower layer respectively, the sensor upper covering plate and the sensor base are bonded, the wires at the upper layer make tight contact with the wires at the lower layer, the capacitor upper counter electrode, the inductance coil and the capacitor lower counter electrode are connected in series to form a standard RLC loop, and the pressure reference cavity is formed.

Owner:XIAMEN UNIV

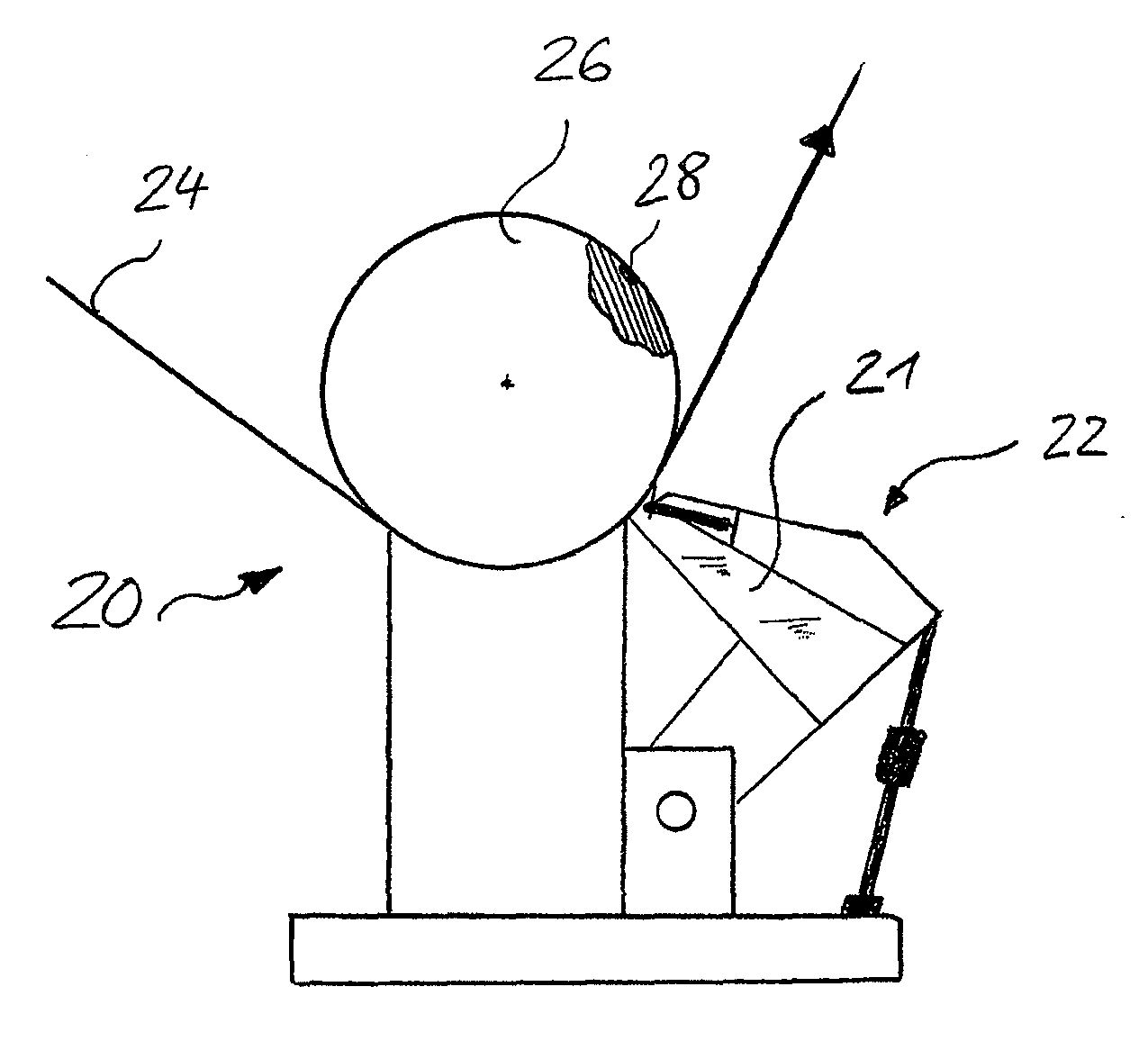

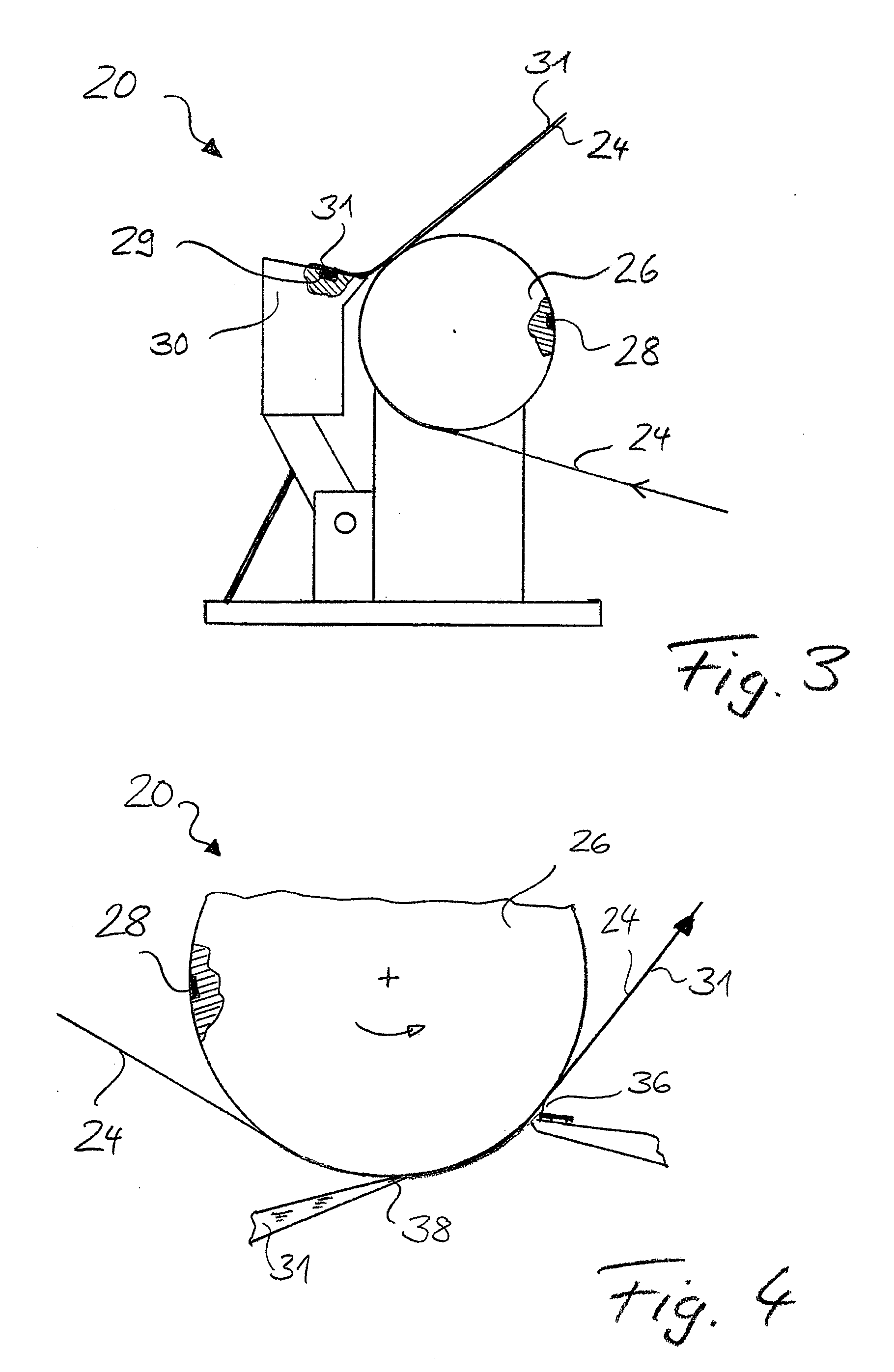

Papermaking coating station with pressure-sensitive film roll

ActiveUS20110020532A1Quality measurement is accurately and quickly possibleEasy to installPretreated surfacesApparatus for force/torque/work measurementCardboardEngineering

A counter roll (26) is positioned to engage a paper or board web (24) in a paper or board making machine along a contact line. A pressure-sensitive EMFi film (28) is disposed on the counter roll to measure the pressure profile of the web along the contact line. A coating apparatus (22) applies a coating to the web passing over the counter roll (26), and a pressure profile of the applied coating is measured by the pressure-sensitive film (28) on the counter roll (26). The pressure-sensitive film (28) may also be disposed to detect details of coating application in a curtain coater (30). Moreover, the film may be driven to provide adjustable vibration for cleaning the coater, or conditioning or controlling the coating flow.

Owner:VALMET TECH INC

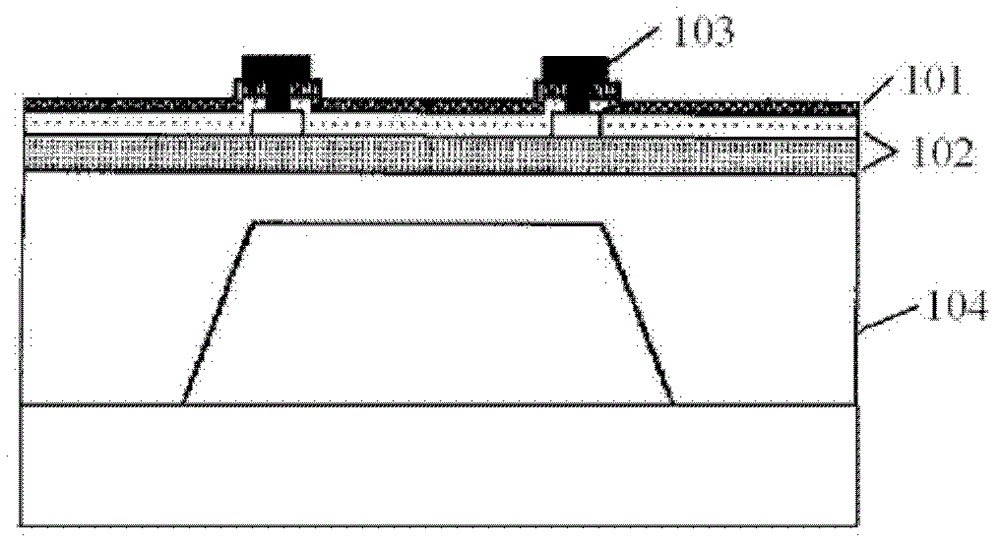

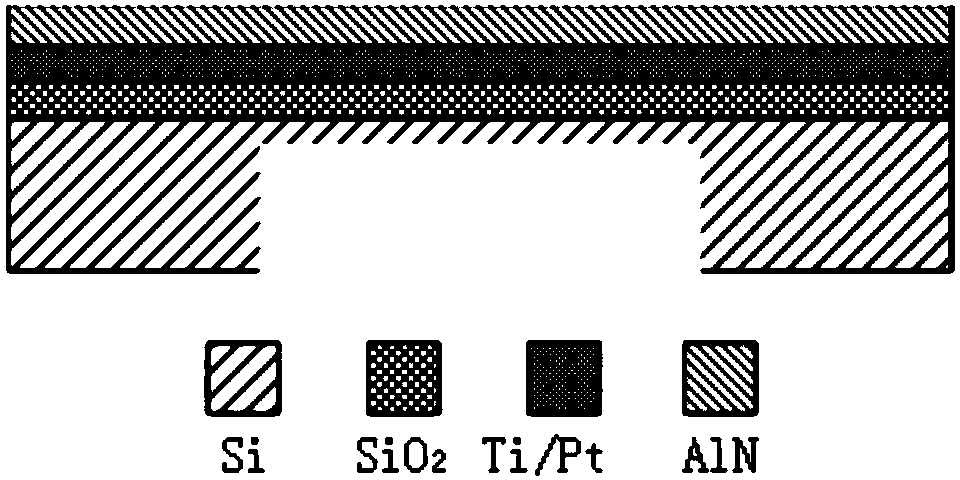

Surface acoustic wave high-temperature pressure sensor chip based on silicon wafer and piezoelectric thin film and preparation method of surface acoustic wave high-temperature pressure sensor chip

PendingCN107631827AReduce volumeRealize wireless transmission and receptionFluid pressure measurement using piezo-electric devicesRadio frequencyForce sensor

The present invention provides a surface acoustic wave high-temperature pressure sensor chip based on a silicon wafer and a piezoelectric thin film and a preparation method of the surface acoustic wave high-temperature pressure sensor chip. The surface acoustic wave high-temperature pressure sensor chip comprises a silicon wafer chip substrate; the silicon wafer chip substrate includes a first surface and a second surface; a chamber is disposed inside the silicon wafer chip substrate; an opening at the second surface of the silicon wafer chip substrate is formed in the chamber, or the chamberis sealed by a second chip substrate bonded on the silicon wafer chip substrate so as to form a sealed chamber; the silicon wafer chip substrate above the chamber is a pressure-sensitive film; the piezoelectric thin film is formed on the pressure-sensitive film; and an interdigital transducer and a reflection grid are formed on the piezoelectric thin film. The surface acoustic wave high-temperature pressure sensor chip based on the silicon wafer and the piezoelectric thin film is small in size, can realize wireless receiving and transmitting when working at a radio frequency band, is flexiblein measurement mode and has a great potential application in the high-temperature pressure measurement field.

Owner:CHONGQING UNIV

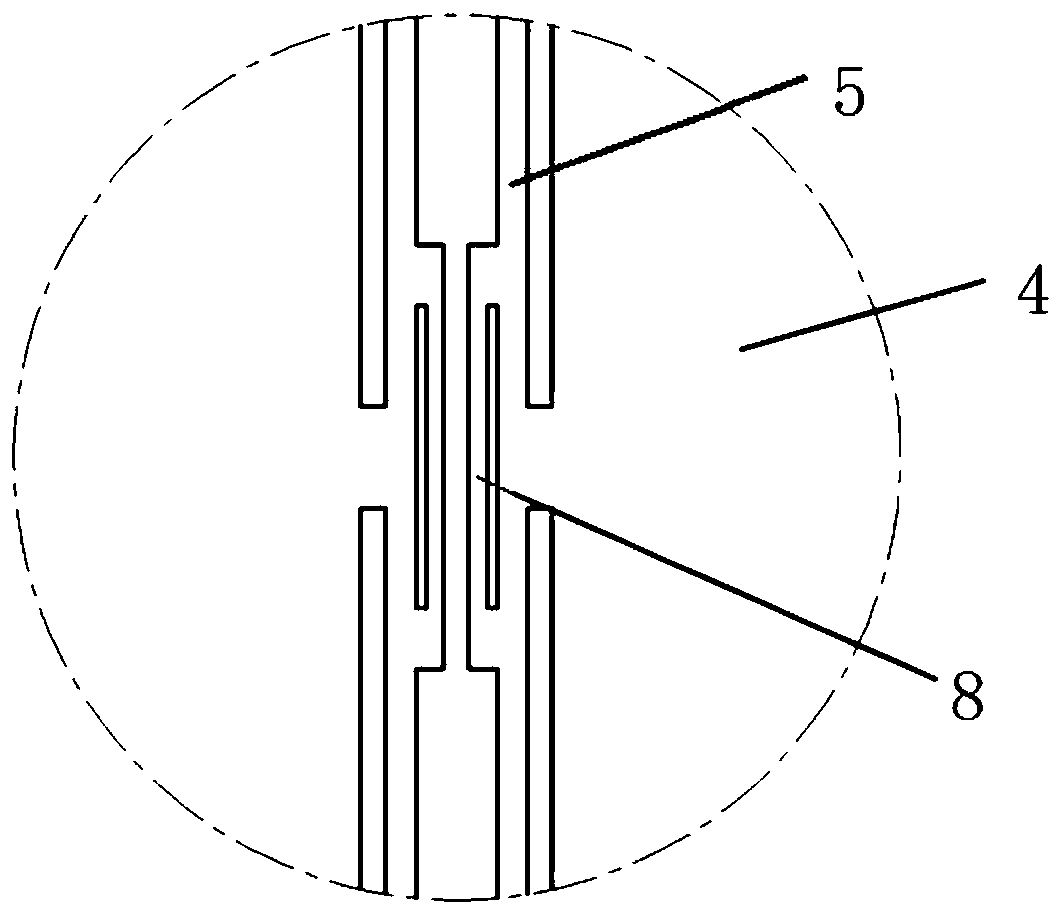

Resonant pressure sensor based on piezoresistive detection and preparation method thereof

ActiveCN108516518AIncrease output signal strengthImprove anti-interference abilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsAnchor pointSingle beam

The invention relates to a resonant pressure sensor based on piezoresistive detection and a preparation method thereof. The resonant pressure sensor comprises a pressure sensitive film, a resonator located on the pressure sensitive film and six anchor points, wherein the resonator comprises a double-end fixed support beam and two driving electrodes arranged on the two sides of the double-end fixedsupport beam, wherein the double-end fixed support beam comprises two end parts and two single beams connected to the two end parts; etching is carried out on root regions of the two single beams symmetrically; body pressure resistance is formed at the root parts of the two single beams; the same three-electrode structures are arranged at the two end parts, one three-electrode structure is suspended, and the other three-electrode structure takes an electrode in the middle position as a grounding end and the electrodes at the two sides as detection electrodes; the six anchor points are arranged under the two three-electrode structures respectively; and the double-end fixed support beam is fixedly supported on the pressure sensitive film. According to the resonant pressure sensor and the preparation method, a piezoresistive detection and resonator tuning fork vibration mode is adopted, so that the output signal strength is improved, and the anti-interference capability and the stabilityare enhanced.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

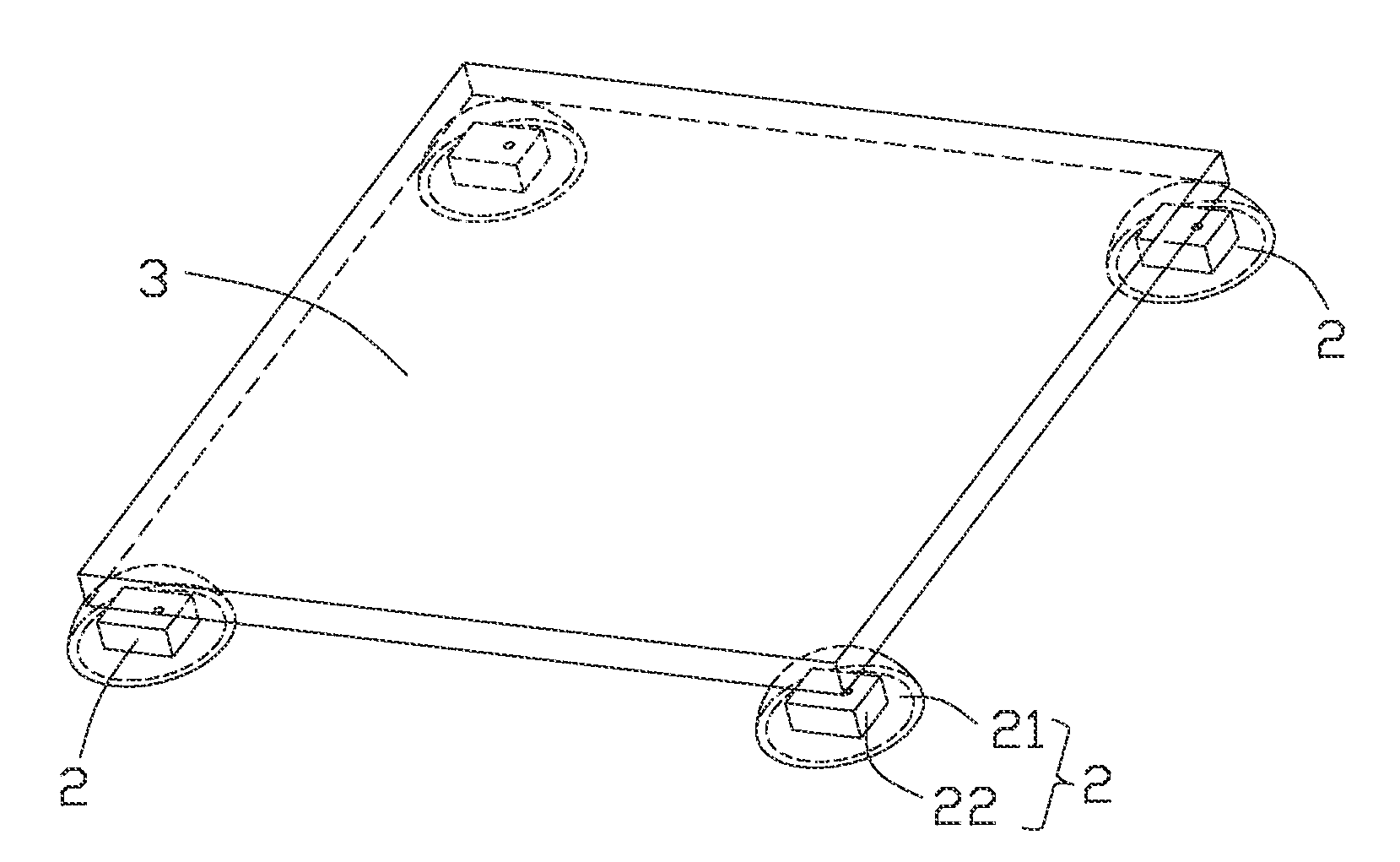

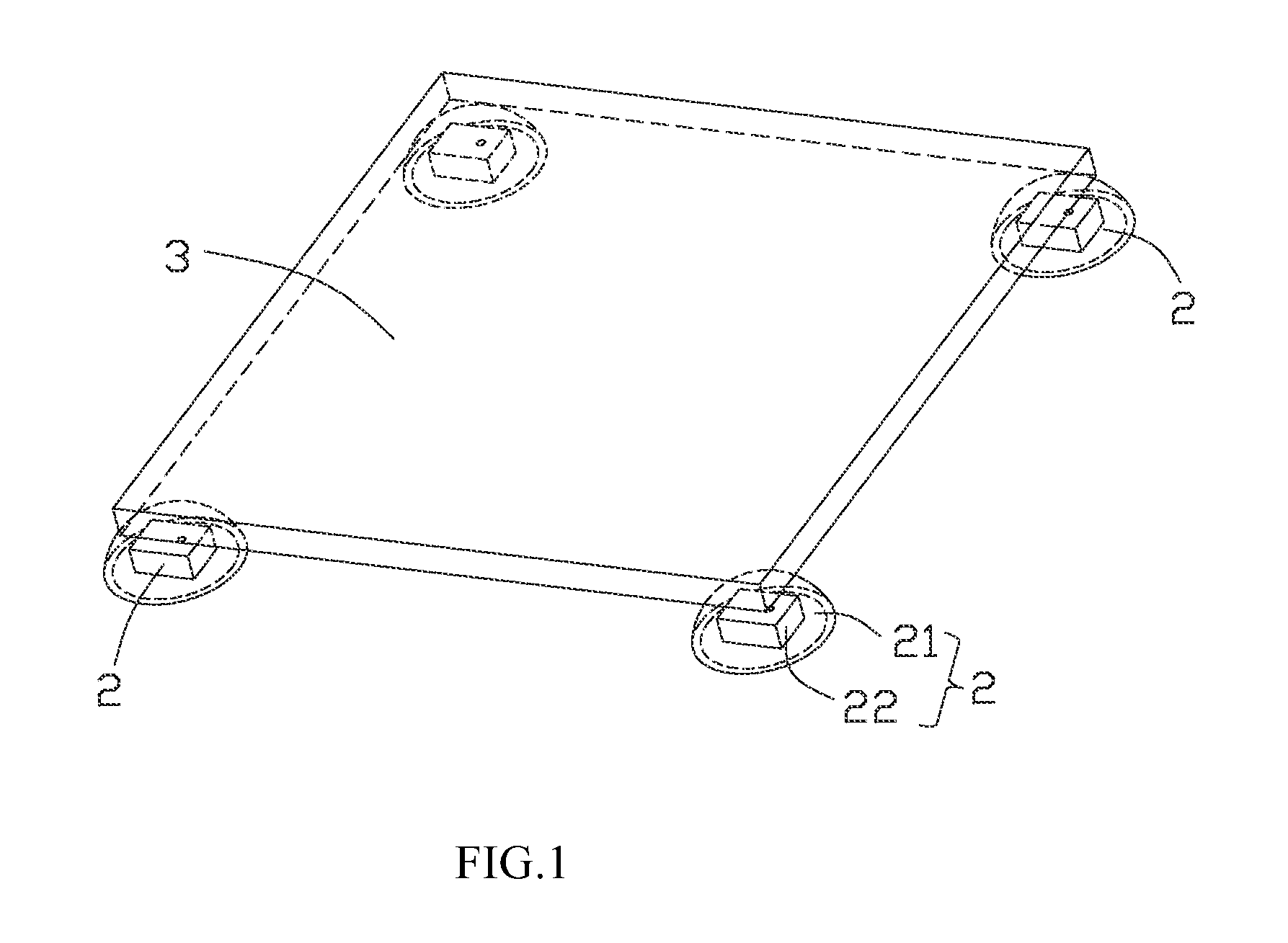

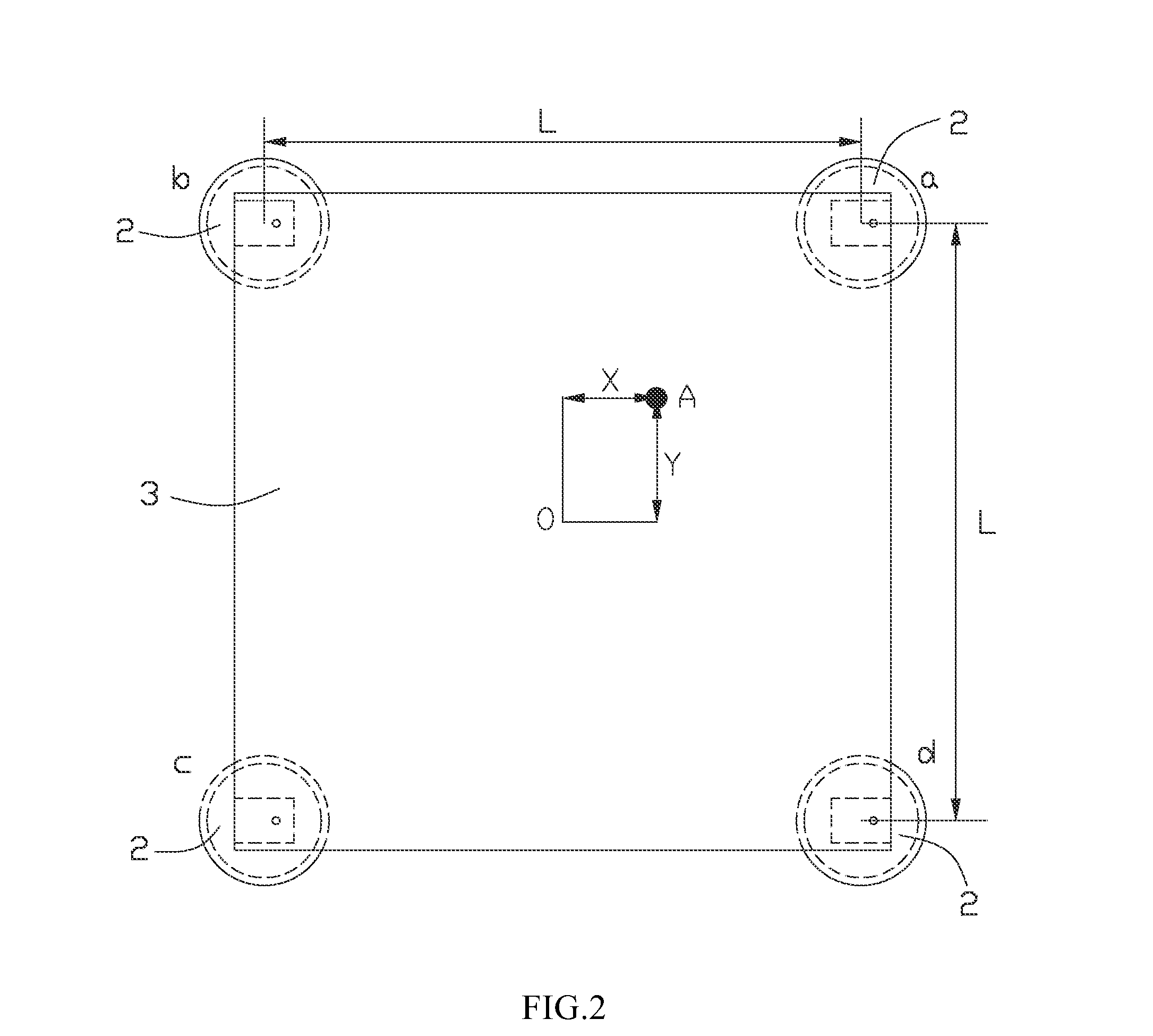

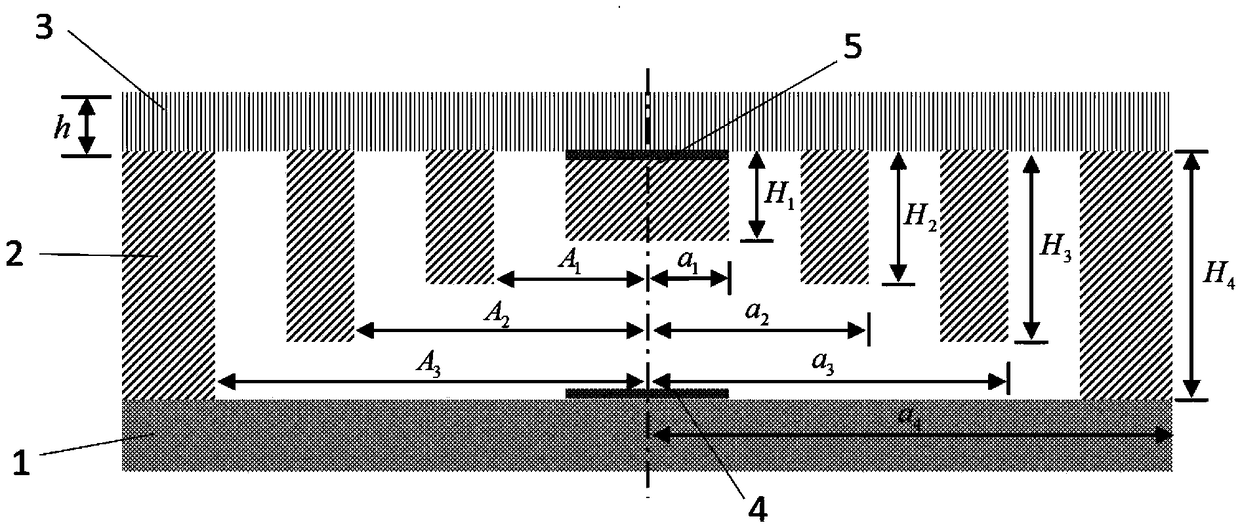

Feedback System for Identifying Movement and Intensity of External Force

ActiveUS20120042735A1Solid-state devicesApparatus for force/torque/work measurementPressure senseEngineering

A feedback system for identifying an external force, includes an operation plate and a pressure-sensing unit. The pressure-sensing unit includes an elastic member supporting the operation plate and a pressure sensor inside the elastic member. The pressure sensor includes a pressure sensitive film. An inner side of the elastic member is filled with fluid material which acts on the pressure sensitive film. The operation plate is driven by the external force to be slant which extrudes the elastic member to deform so as to change fluid pressure of the fluid material limited in the elastic member, and such change of the fluid pressure can be sensed by the pressure sensitive film of the pressure sensor so as to identify the movement and the intensity of the external force.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

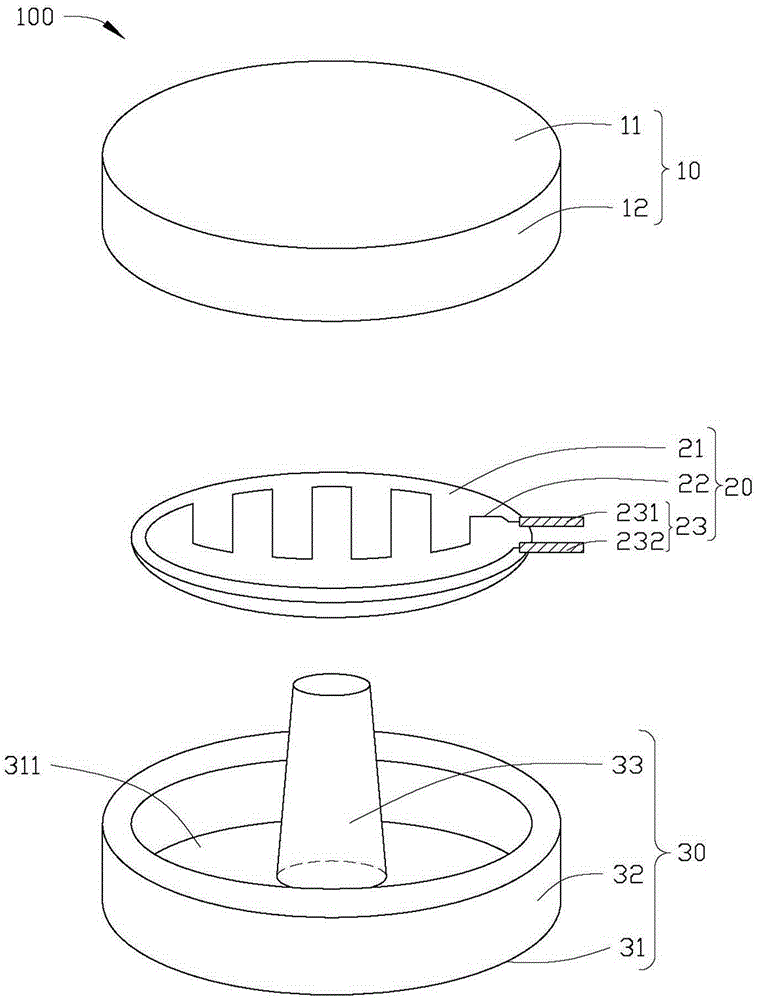

Flexible multi-range capacitive-type pressure sensor and preparation method and application thereof

ActiveCN109387348AIncrease rangeHigh sensitivityAerodynamic testingFluid pressure measurement using capacitance variationCapacitive pressure sensorEngineering

The invention belongs to the field of pressure sensor design and manufacturing, and specifically discloses a flexible multi-range capacitive-type pressure sensor and a preparation method and an application thereof. The sensor comprises a flexible substrate, a multi-stage support island and a pressure sensitive film, which are sequentially arranged from bottom to top. The multi-stage support islandis composed of a central circular boss located at the middle of the pressure sensitive film, and n-stage annular bosses which are disposed on the pressure sensitive film and are concentrically arranged with the central circular boss. A top electrode is disposed between the central circular boss and the pressure sensitive film, and the heights of the n-stage annular bosses sequentially increase from the inside to the outside, wherein the outermost annular boss is attached to the flexible substrate. The bottom portion of the flexible substrate is provided with a bottom electrode directly belowthe central circular boss. The sensor provided by the invention has a wide range of pressure measurement while maintaining high sensitivity, and solves the contradiction between the range and sensitivity of the pressure sensor, and can meet the requirements of the pressure range and sensitivity of different wind tunnel tests.

Owner:HUAZHONG UNIV OF SCI & TECH

Pressure Sensor

InactiveCN106482889AImprove accuracyFluid pressure measurement using ohmic-resistance variationEngineeringPressure sensitive film

The invention relates to a pressure sensor. The pressure sensor includes a base, a pressure sensitive film and an elastic cover. The pressure sensitive film is located in the base and teh elastic cover, and is fixed on the base. The protruding column presses against the pressure sensitive film, the resistance of the pressure sensitive film reaches a bias point, and when an external pressure acts on the elastic cover, and the resistance of the pressure sensitive film is virtually linear corresponding to the external pressure.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

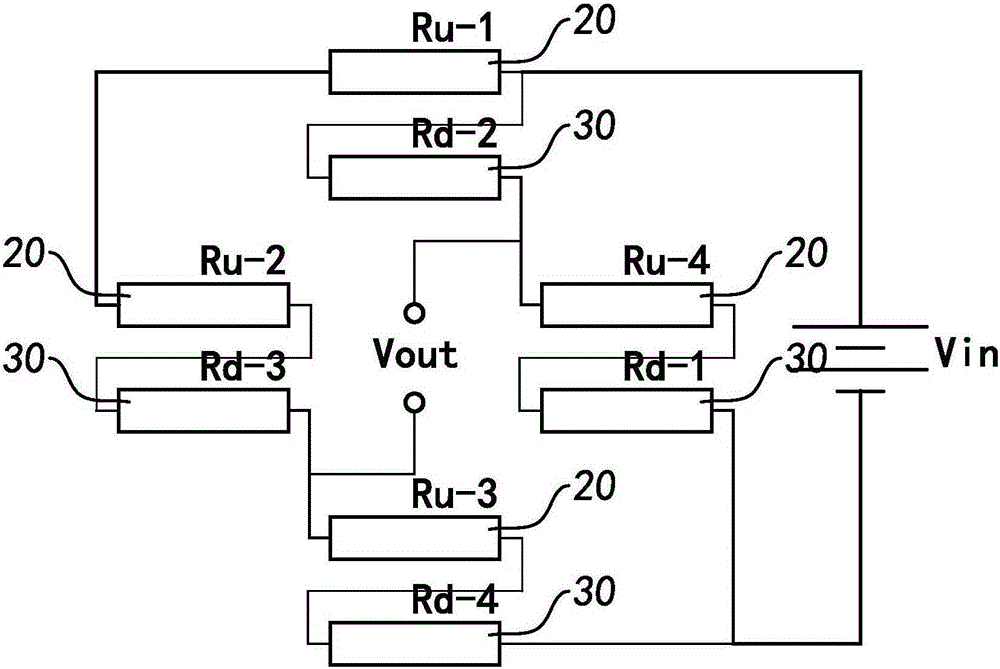

Differential silicon micro-resonant pressure sensor based on electrostatic excitation piezoresistance detection

ActiveCN111289156AImprove output sensitivityHigh precisionForce measurement using piezo-resistive materialsEngineeringMechanical engineering

The invention discloses a differential silicon micro-resonance type pressure sensor based on electrostatic excitation piezoresistance detection. The differential silicon micro-resonance type pressuresensor comprises a resonance beam, a coupling beam, a vibration pickup beam, a fixed electrode, a movable electrode, a mass block, a movable anchor point, a fixed anchor point and a silicon island, wherein the movable anchor point is fixedly connected with the pressure sensitive film through using the silicon island; when the pressure sensitive film is deformed by a load, the movable anchor pointconnected with the pressure sensitive film is driven, then the movable anchor point drives the resonance beam to deform, such that the internal stress of the resonance beam is changed, the vibration frequency of the resonator is changed, the vibration frequency of the resonance beam is measured by means of a piezoresistor on the vibration pickup beam, and the vibration pickup beam and the couplingbeam adopt a special design method, so that the vibration pickup beam generates straight pulling and straight pressing acting force when the resonator is in a working mode, and the amplitude of the resonance beam can be linearly output through using a Wheatstone bridge.

Owner:XI AN JIAOTONG UNIV

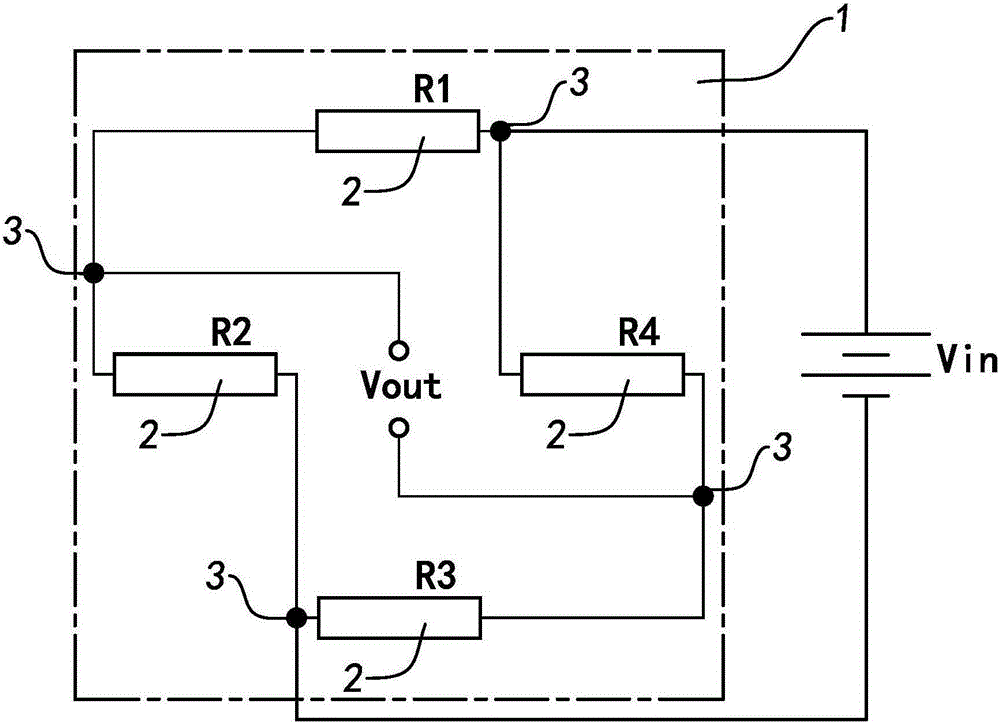

MEMS pressure sensor and preparation method thereof

ActiveCN105181217AOffset errorExtended service lifeFluid pressure measurement using ohmic-resistance variationMems pressure sensorEngineering

The invention relates to an MEMS pressure sensor and a preparation method thereof. The MEMS pressure sensor comprises a pressure sensitive film, at least four front-side voltage dependent resistors and at least four back-side voltage dependent resistors, the pressure sensitive film includes a front side and a back side, each front-side voltage dependent resistor is arranged at the front side of the pressure sensitive film, each back-side voltage dependent resistor is arranged at the back side of the pressure sensitive film, and the front-side voltage dependent resistors and the back-side voltage dependent resistors are electrically connected to form a Wheatstone bridge. The change direction of the resistance, along with the pressure, of the front-side voltage dependent resistor is opposite to that of the resistance, along with the pressure, of the back-side voltage dependent resistor at the corresponding position, so that errors caused by technical conditions and / or external factors of the voltage dependent resistors are offset, and the output stability and precision of the MEMS pressure sensor are improved.

Owner:苏州曼普拉斯传感科技有限公司

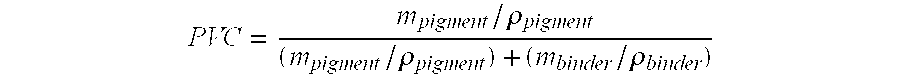

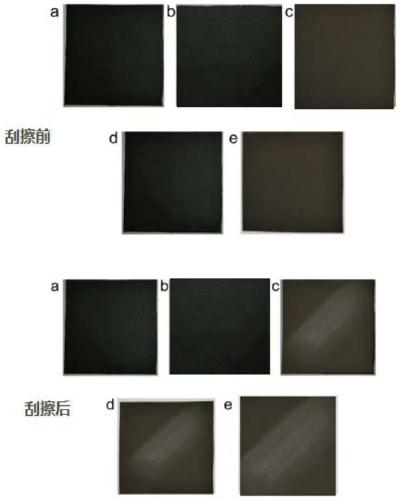

Preparation method of pressure-sensitive film, pressure-sensitive film and pressure sensor

PendingCN110330675AExcellent peelabilityEvenly dispersedForce measurement using piezo-resistive materialsOrganic solventSemiconductor materials

The invention discloses a preparation method of a pressure-sensitive film, the pressure-sensitive film and a pressure sensor, wherein the preparation method of the pressure-sensitive film mainly comprises (1) grinding and extruding a layered material; (2) dissolving out a two-dimensional material with an organic solvent; (3) blending the two-dimensional material with an organic solution containinga polymer; and (4) making the film. The invention also discloses the pressure sensitive film prepared by the preparation method and the pressure sensor based on the pressure sensitive film. In addition, the invention also discloses the pressure sensitive film mainly composed of a two-dimensional conductive material, a two-dimensional semiconductor material and a flexible high molecular polymer. The pressure-sensitive film has the advantages of simple preparation method, industrial large-scale production, controllable product performance, uniform quality and the like.

Owner:TIANJIN VOCATIONAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com