Thinned flexible pressure sensor sensitive unit based on flatfish type electrode structure

A pressure sensor and electrode structure technology, applied in the field of sensors, can solve the problems of reducing pressure monitoring accuracy, increasing the complexity of sensor sensitive units, increasing thickness, etc., achieving the effects of reducing complexity, reducing time dependence, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

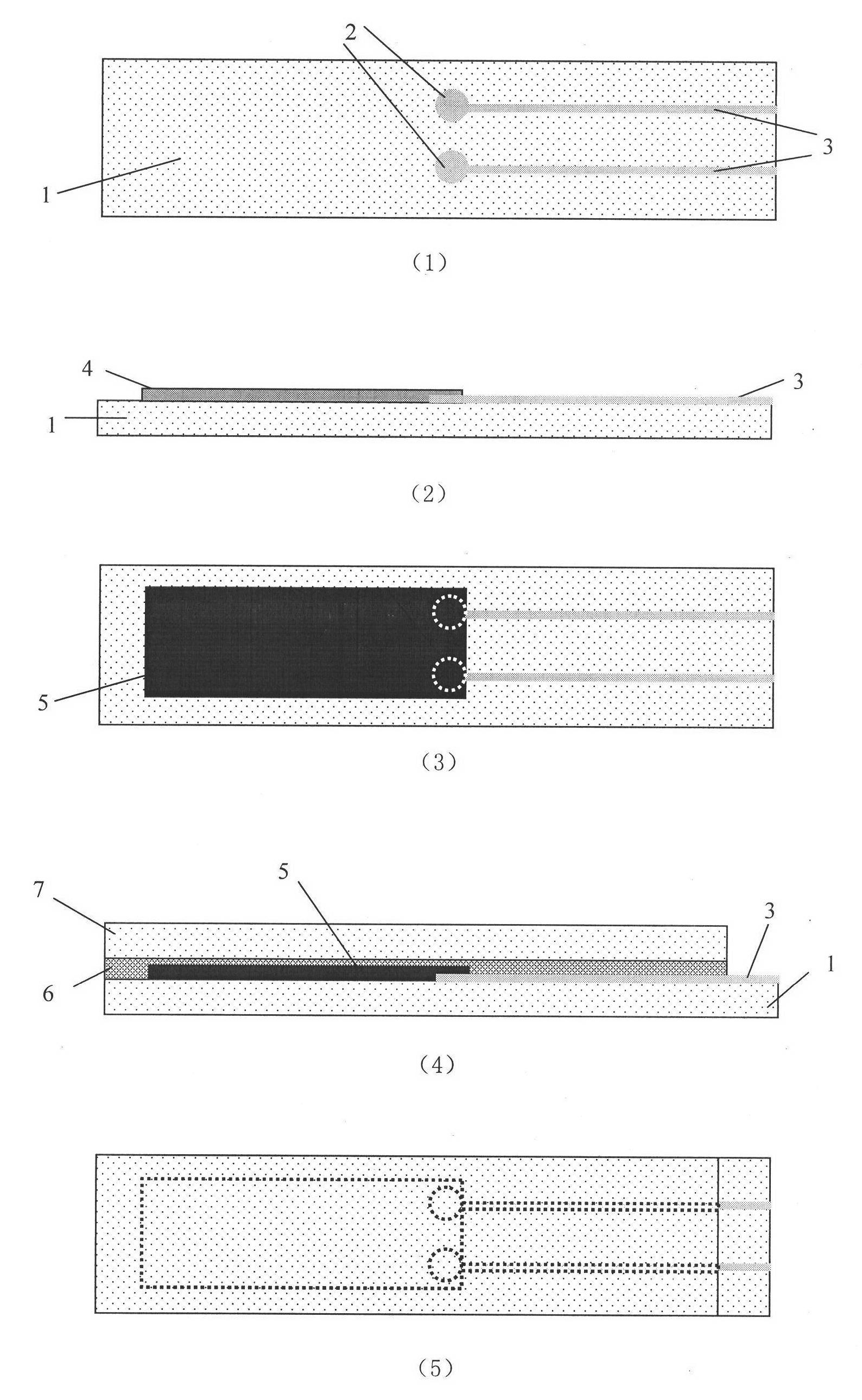

[0024] (1) Lay a circular copper foil electrode with a diameter of 5 mm and a lead wire with a length of 9 cm on the underlying polyimide film, and place it on the fixed platform of the program-controlled lifting platform.

[0025] (2) Mix multi-walled carbon nanotubes with an aspect ratio of 300, room temperature vulcanized silicone rubber and an organic solvent at a volume ratio of 1:20:800, and disperse the nano conductive powder in the mixed solution by mechanical stirring and ultrasonic oscillation , and under the action of ethyl orthosilicate and dibutyltin dilaurate, a multi-walled carbon nanotube / silicone rubber composite material colloidal sticky substance is formed.

[0026] (3) Apply the gel-like viscous evenly on the polyimide film covered with electrodes and leads prepared in step (1), and control the smooth surface fixed on the movable platform of the program-controlled lifting platform through a microcomputer. The rigid plate moves down, extruding the jelly into...

Embodiment 2

[0031] (1) Lay a circular copper foil electrode with a diameter of 6 mm and a lead wire with a length of 8 cm on the bottom polyimide film, and place it on the fixed platform of the program-controlled lifting platform for standby.

[0032] (2), carbon black, room temperature vulcanized silicone rubber and organic solvent with a particle diameter of 20 nanometers are mixed in a volume ratio of 1: 16: 960, and the nano conductive powder is dispersed in the mixed solution by mechanical stirring and ultrasonic vibration, and the Under the action of ethyl orthosilicate and dibutyltin dilaurate, a multi-walled carbon nanotube / silicone rubber composite material colloidal sticky substance is formed.

[0033] (3) Apply the gel-like viscous evenly on the polyimide film covered with electrodes and leads prepared in step (1), and control the smooth surface fixed on the movable platform of the program-controlled lifting platform through a microcomputer. The rigid plate moves down, extrudin...

Embodiment 3

[0038] (1) Lay a circular copper foil electrode with a diameter of 3 mm and a lead wire with a length of 10 cm on the underlying polyimide film, and place it on the fixed platform of the program-controlled lifting platform for standby.

[0039] (2) Mix multi-walled carbon nanotubes with an aspect ratio of 200, room temperature vulcanized silicone rubber and an organic solvent in a volume ratio of 1:12:600, and disperse the nano conductive powder in the mixed solution by mechanical stirring and ultrasonic oscillation , and under the action of ethyl orthosilicate and dibutyltin dilaurate, a multi-walled carbon nanotube / silicone rubber composite material colloidal sticky substance is formed.

[0040] (3) Apply the gel-like viscous evenly on the polyimide film covered with electrodes and leads prepared in step (1), and control the smooth surface fixed on the movable platform of the program-controlled lifting platform through a microcomputer. A rigid plate moves down, extruding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com