SOI (silicon on insulator) pressure sensor with self- temperature drift compensation

A pressure sensor and self-compensation technology, applied in the field of MEMS sensors, can solve the problems of limiting the development of the sensor industry, affecting the accuracy of the sensor, poor consistency, etc., to achieve the effect of improving stability and operating temperature range, good product consistency, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

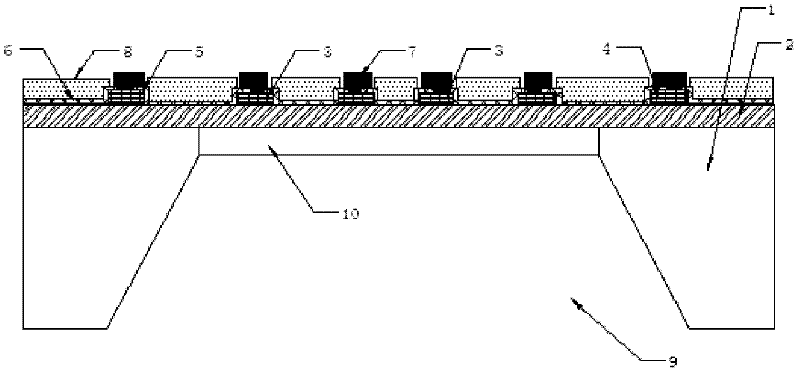

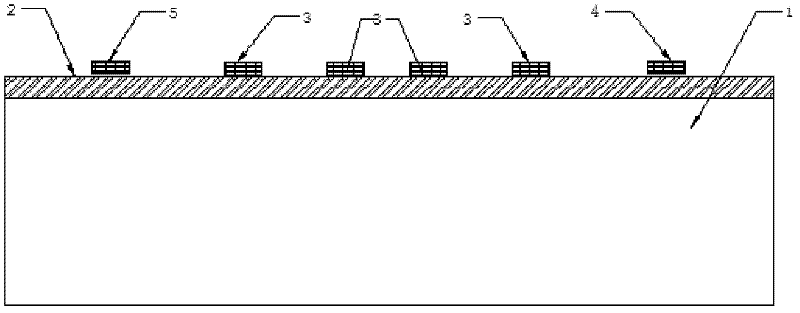

[0026] Such as figure 1 Shown: In order to improve the measurement accuracy and temperature adaptation range of the pressure sensor, the pressure sensor includes an SOI substrate on which conductive materials are deposited to obtain a bridge resistance 3 configured as a Wheatstone bridge, And in order to reduce the influence of temperature drift, a compensation resistor is provided on the SOI substrate, the compensation resistor includes a constant voltage power supply compensation resistor 4 or a constant current power supply compensation resistor 5, and a constant voltage power supply compensation resistor 4 is also provided on the SOI substrate. And the constant current power supply compensation resistor 5, the constant voltage power supply compensation resistor 4 or the constant current power supply compensation resistor 5 can be selected as needed, which can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com