Optical fiber grating liquid level sensor and its preparation method

A liquid level sensor and fiber grating technology, applied in the field of sensing, can solve the problems of small dynamic range, poor linearity, cross-sensitivity, etc., achieve the effect of large dynamic range, improve dynamic range, and eliminate the influence of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

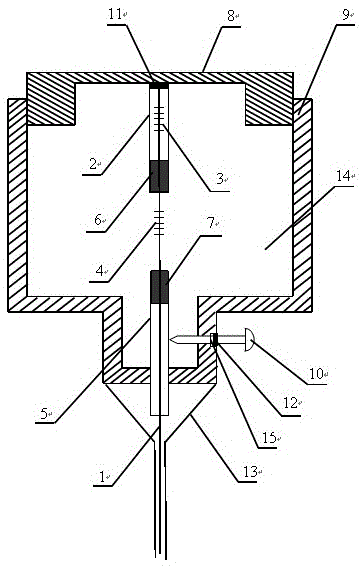

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] The preparation method step of a kind of fiber grating liquid level sensor of the present invention is:

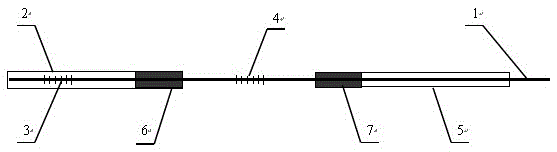

[0029] 1), such as figure 1 As shown, the optical fiber 1 engraved with the fiber grating 3 and the sensing fiber grating 4 is inserted into the first capillary metal tube 2 and the second capillary metal tube 5, the fiber grating 3 is in the first capillary metal tube 2, and the sensing The fiber grating 4 is located between the first capillary metal tube 2 and the second capillary metal tube 5, encapsulated, and the designated end 6 of the first capillary metal tube 2, and the designated end 7 of the second capillary metal tube 5 are glued to the optical fiber 1 fixed, formed as figure 1 structural units shown;

[0030] 2), then aging the packaged structural unit; the specific process of aging: put the packaged structural unit into the high and low tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com