Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Achieving temperature self-compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

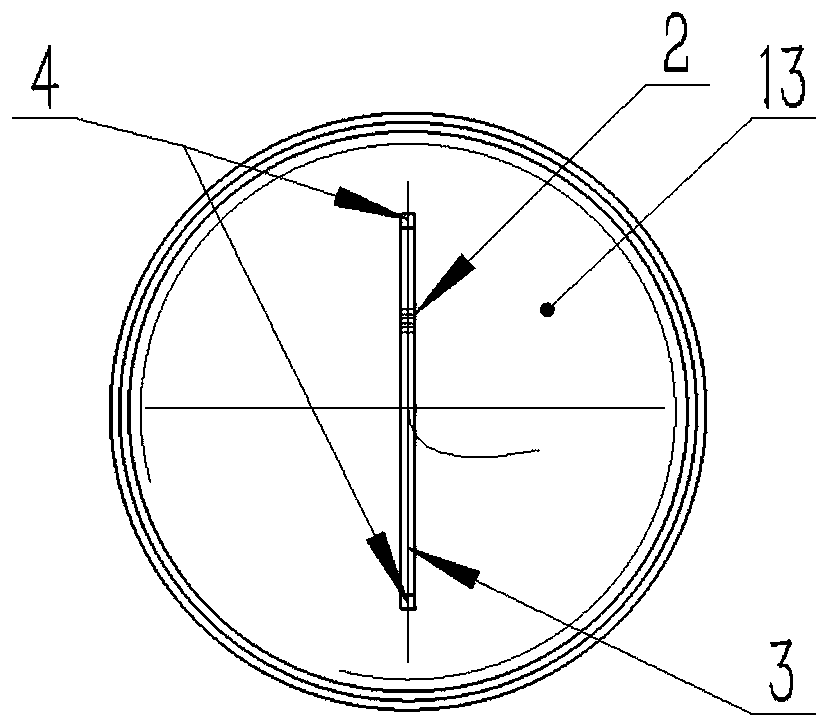

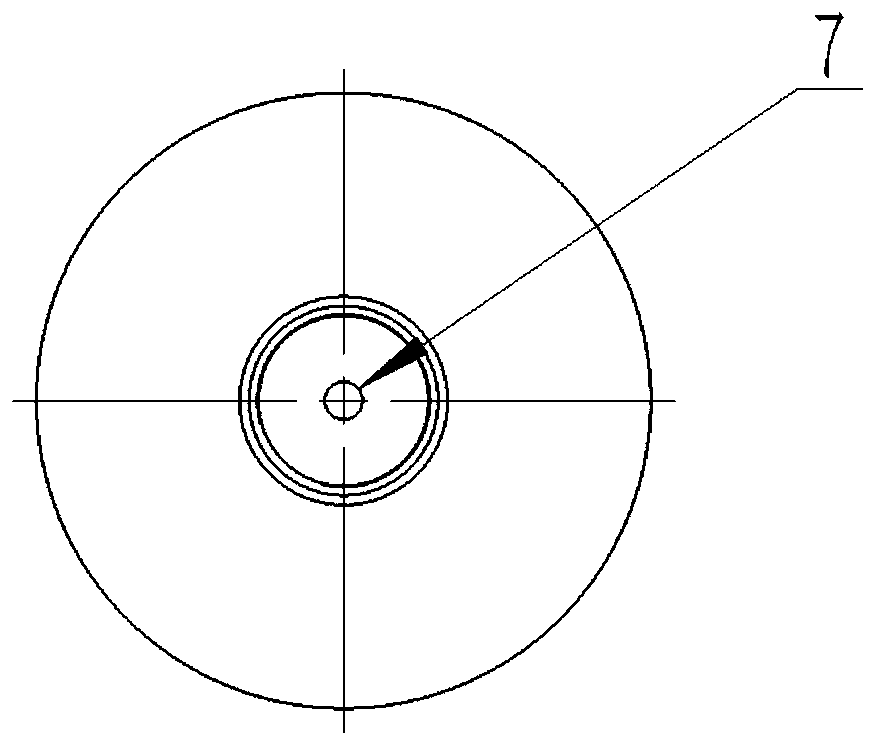

Inclination Sensor Based on Fiber Bragg Grating and Its Inclination Measurement Method

InactiveCN102288162AHigh measurement accuracyImprove machining accuracyIncline measurementGratingFiber Bragg grating

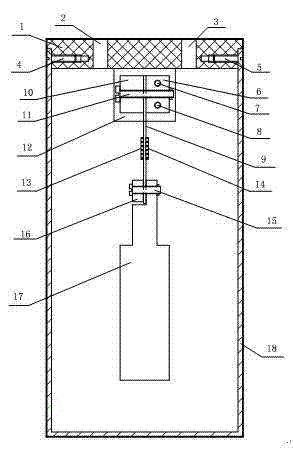

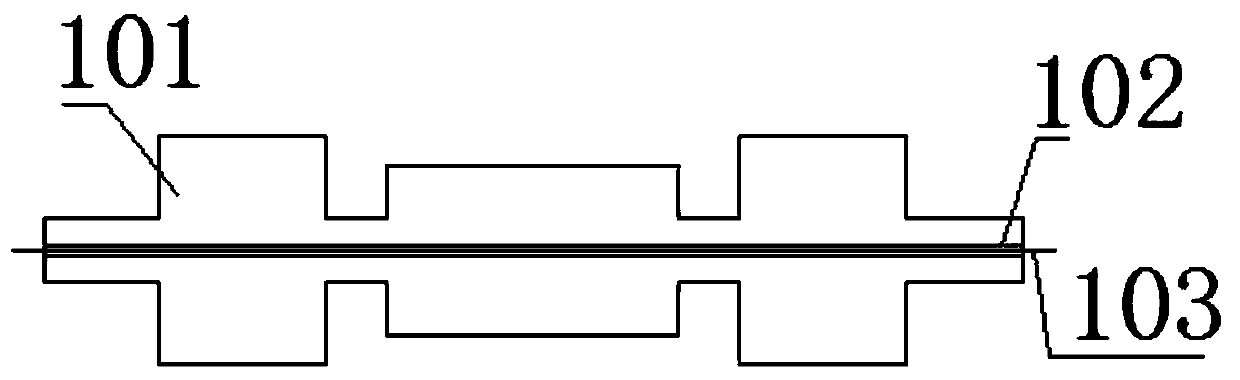

The invention relates to a tilt angle sensor based on optical fiber Bragg gratings and a method for measuring a tilt angle of the tilt angle sensor and belongs to the technical field of measurement of a structural tilt angle. The tilt angle sensor comprises a fixed base plate (12), a fixed pressing block (6), a thin-wall type uniform-section metal beam (9) and a quality block (7), wherein the upper end of the thin-wall type uniform-section metal beam (9) is arranged on the fixed base plate (12) in a mode of fitting with the fixed pressing block through a first movable pressing block (10) and a fifth screw (11); the quality block (7) is fixed at the lower end of the thin-wall type uniform-section metal beam (9) through a sixth screw (15) and a second movable pressing block (16); and a first optical fiber Bragg grating (13) and a second optical fiber Bragg grating (14) are respectively adhered to opposite positions on two sides of the thin-wall type uniform-section metal beam (9). By the method, the size and direction of the tilt angle can be detected according to a correspondence relation between the change of central wavelengths of the two optical fiber Bragg gratings and the tiltangle. The invention is high in measurement accuracy and has a temperature self-compensation function.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fiber grating cable tension transducer with temperature self-compensation function

InactiveCN102230834AWith online real-time cable force monitoringRealize online real-time cable force monitoringForce measurement by measuring optical property variationGratingSelf compensation

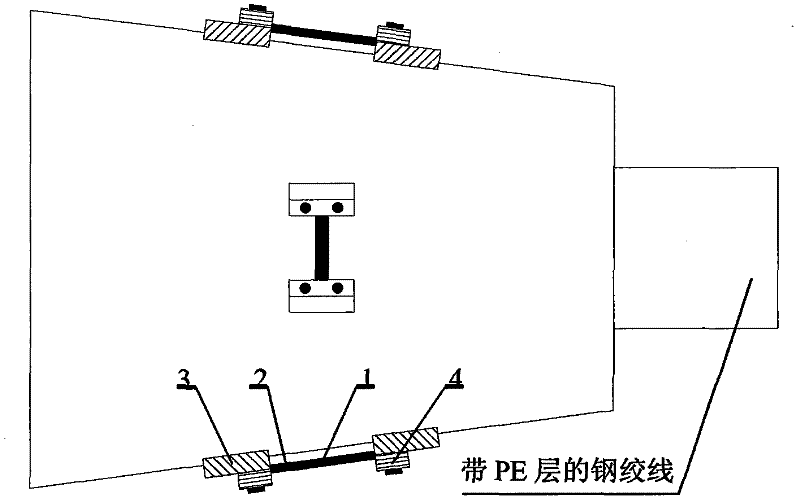

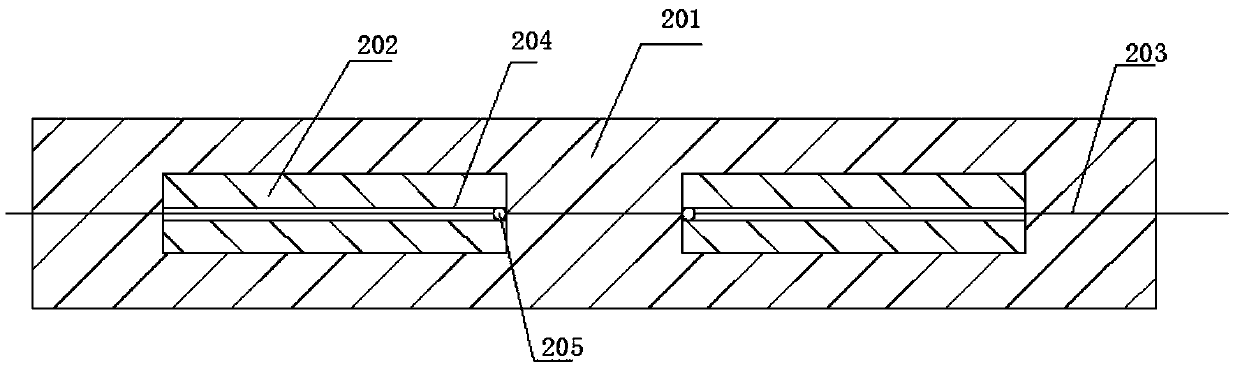

The invention provides a fiber grating cable tension transducer with a temperature self-compensation function, belonging to the field of transducer technologies. The transducer provided by the invention is characterized by comprising a metal baseplate, a clamping piece, a micro fiber grating strain transducer and a cable component of fiber transmission. The measuring sensitivity of the transducer can be adjusted by changing sizes of elements of the transducer in accordance with actual requirements, thus being suitable for monitoring cable tension of the different cables in real time. The fiber grating cable tension transducer can measure the cable tension of the cables indirectly by measuring an anchor head structure and utilize the properties of the fiber grating to improve the cable tension sensitivity coefficients of the transducer, and is not influenced by structural materials and external environments. The fiber grating cable tension transducer can eliminate influences of eccentric forces on measuring values, realize the temperature self-compensation and overcome the defects that a traditional electric transducer is subjected to electromagnetic interference easily and is poor in long-term stability, and has the advantages of high accuracy, light weight, low influences on the properties of the structure and the like.

Owner:DALIAN UNIV OF TECH

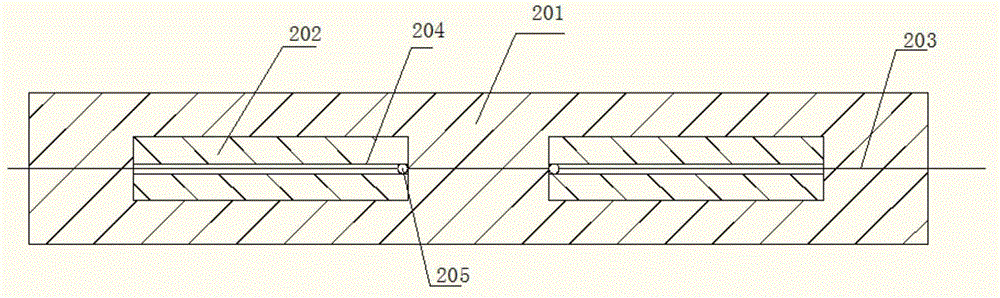

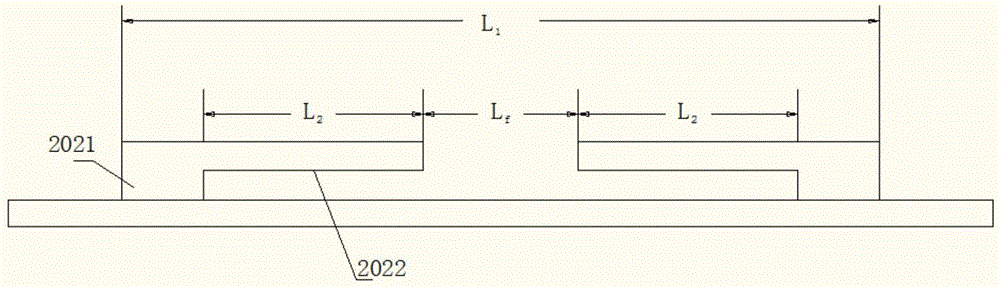

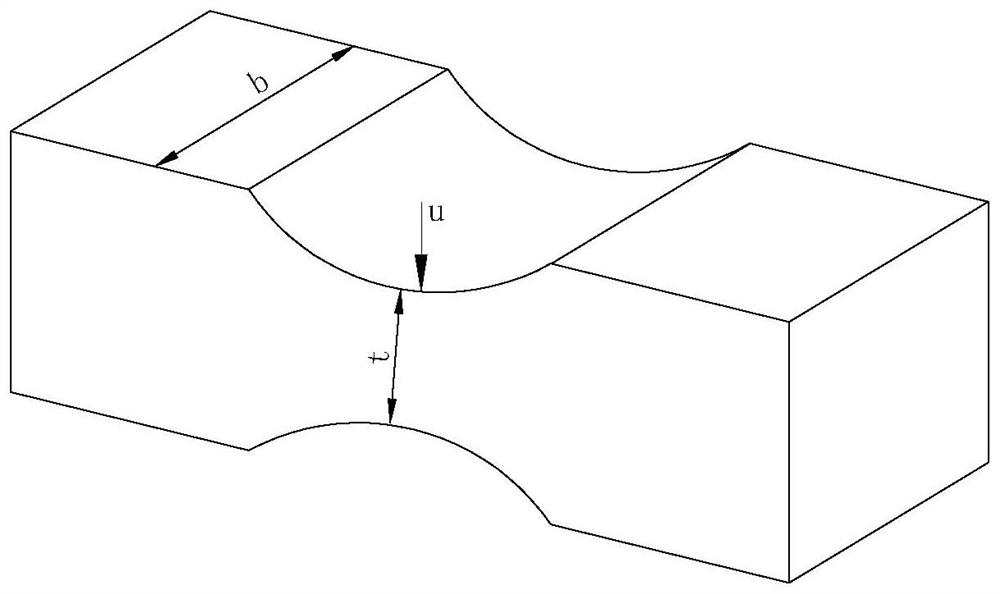

Temperature-self-compensating-integrated fiber bragg grating strain transducer and method for monitoring cable force of inhaul cable through integrated temperature self-compensating fiber bragg grating strain transducer

ActiveCN103791850AWith temperature self-compensation functionHigh sensitivityForce measurement by measuring optical property variationUsing optical meansFiberCantilevered beam

A temperature-self-compensating fiber-integrated bragg grating strain transducer comprises a fiber bragg grating transducer body composed of two bare fiber bragg gratings with the same model but different wave bands, an elastic sheet composed of high-elasticity metal thin sheets, clamping pieces, bases, a Z-shaped movable piece composed of L-shaped steel plates and a metal frame. The metal frame is provided with a frame shaft hole and a frame connecting shaft, and a connecting shaft of the Z-shaped movable piece penetrates through the frame shaft hole to be fixedly connected with the base II through the clamping piece II and can relatively move in the frame shaft hole. One end of the elastic sheet is fixedly connected with the L-shaped plates of the Z-shaped movable piece, and the other end of the elastic sheet is fixed on the metal frame. The frame connecting shaft is fixedly connected with the base I through the clamping piece I. A cantilever beam stress structure is formed by the frame, the Z-shaped movable piece, the elastic sheet, the bases and the clamping pieces. Under the working state, the two bases are fixed on the surface of a component to be tested in a bolting or welding mode, and when the component to be tested is strained, the bases and the Z-shaped movable piece are driven to drive the elastic sheet to deform, and then the fiber bragg gratings deform.

Owner:LIUZHOU OVM MASCH CO LTD

FBG (Fiber Bragg Grating) liquid level sensor and preparation method thereof

ActiveCN102865900AEliminate measurement errorsEliminate the effects of measurement accuracyLevel indicators by pressure measurementFiberGrating

The invention discloses an FBG (Fiber Bragg Grating) liquid level sensor and a preparation method thereof. The sensor comprises a metal base, pressure sensing membranes, two metal capillary tubes, optical fibers carved with two FBGs having different wavelengths, pins and a tail fiber sleeve, wherein the optical fibers penetrate into the two metal capillary tubes; an FBG is located in the first metal capillary tube; a sensing FBG is located between the two metal capillary tubes to form a structural unit; the pressure sensing membranes are fixed on the metal base, and an air cavity is formed between the pressure sensing membranes; the structural unit is located in the air cavity; the first metal capillary tube is located at the center of each pressure sensing membrane; the optical fibers are vertical to the plane where the pressure sensing membranes locate; the second tube capillary tube stretches out of the metal base and is positioned by the pins; and the tail fiber sleeve is fixed at the lower end of the metal base to be communicated with atmosphere. The metal capillary tubes are titanium tubes; and the metal base is made of stainless steel. The sensor can be applied to inflammable, explosive and strongly-corrosive liquid, and has the advantages of wide dynamic range, an FS with the precision of 0.5%, a linearity of 99.7%, electromagnetic interference resistance, easy reusability and the like.

Owner:WUHAN UNIV OF TECH

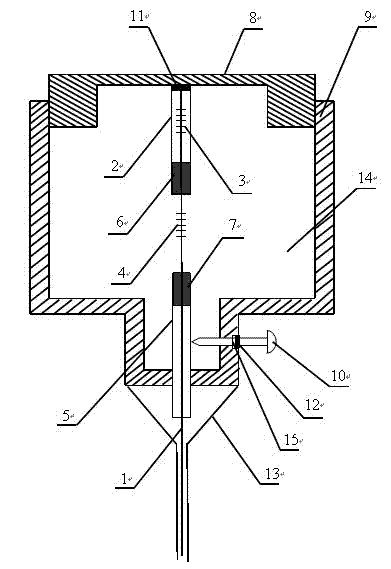

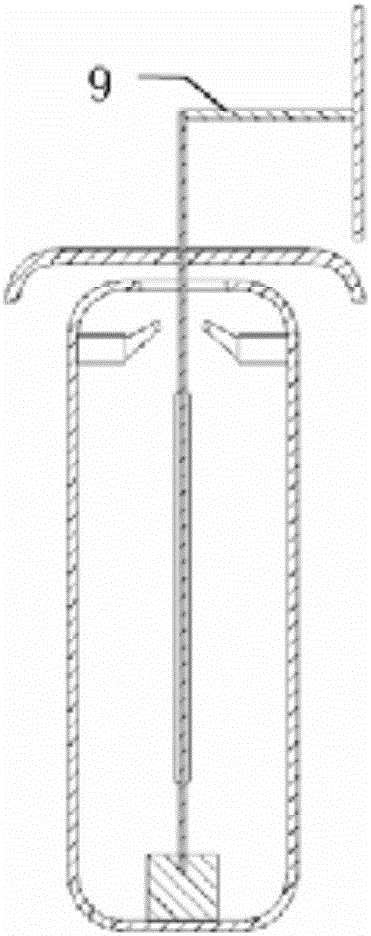

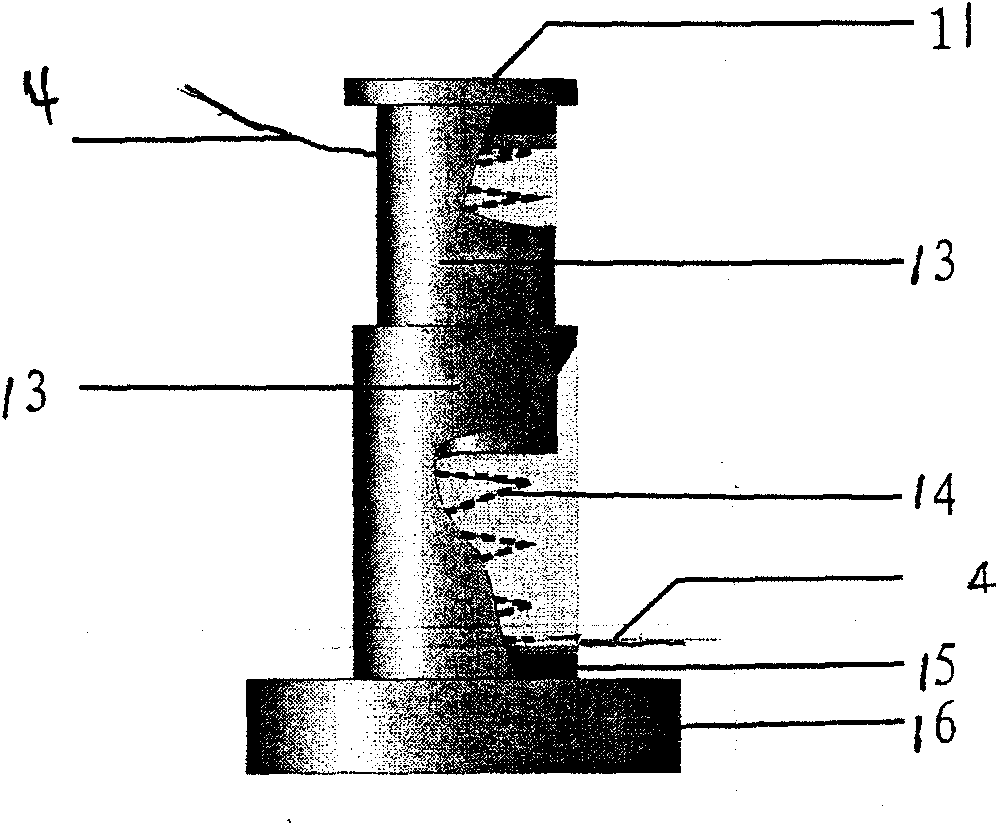

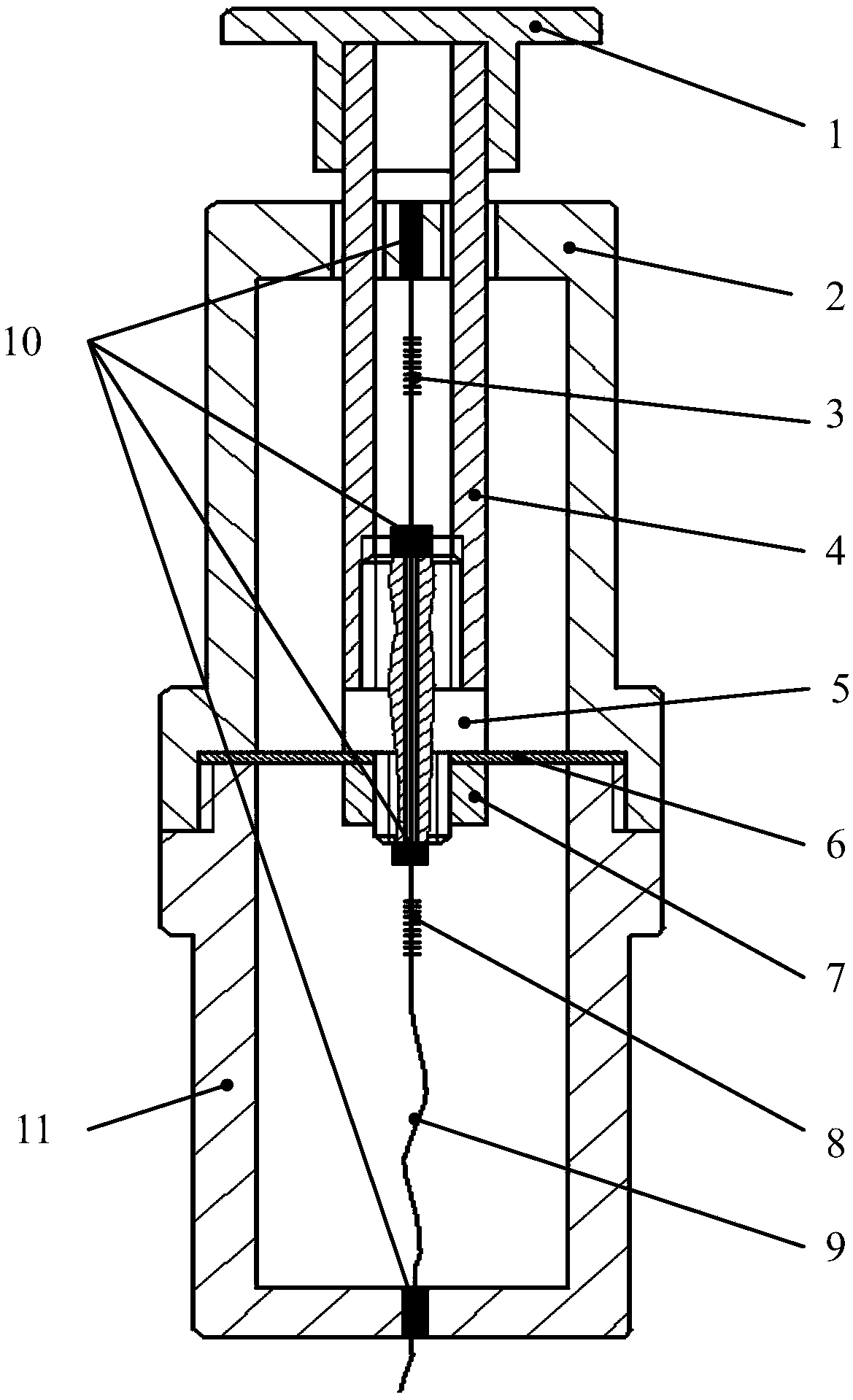

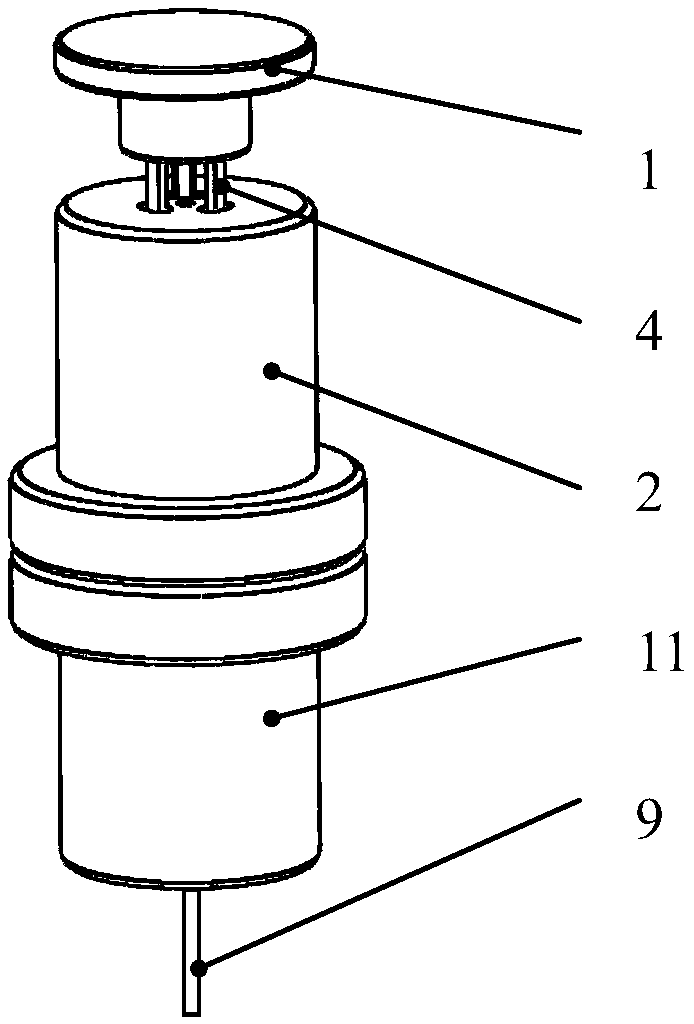

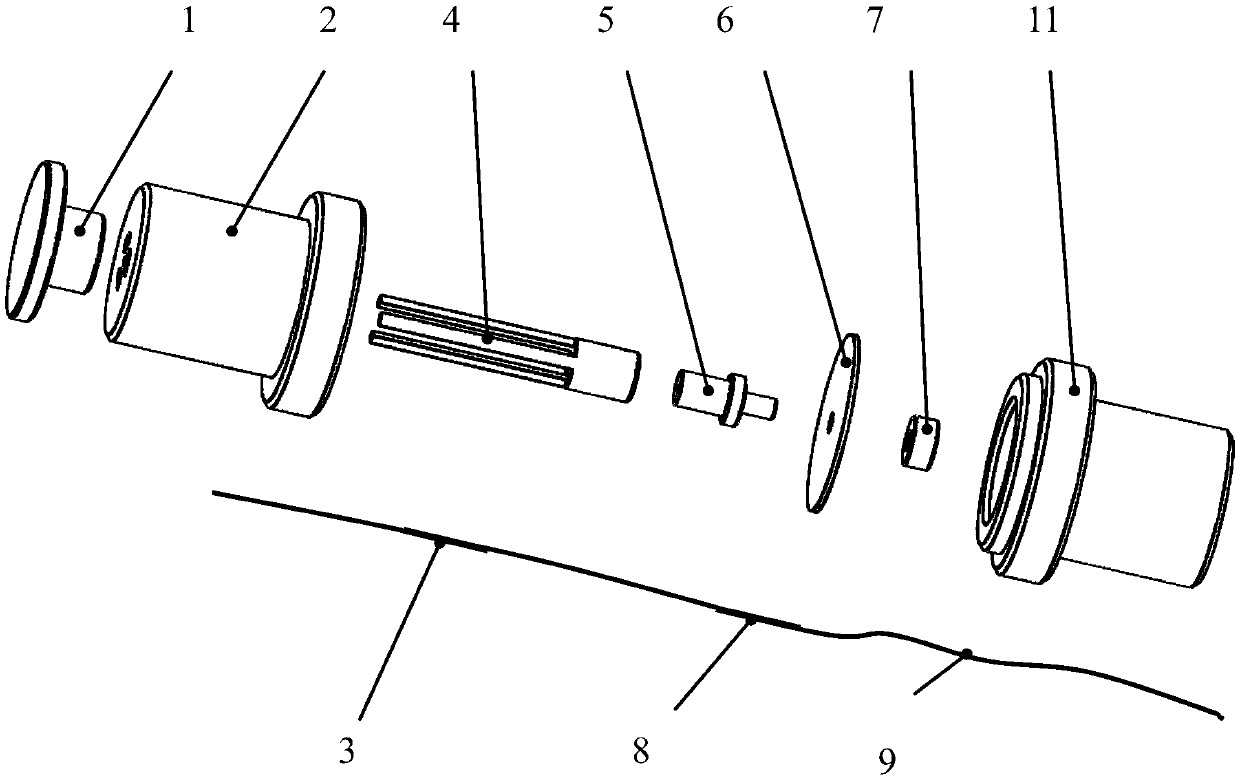

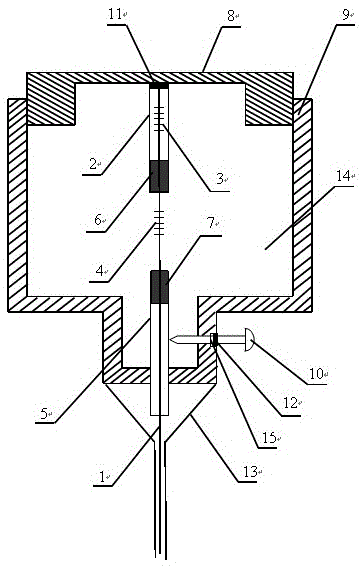

Temperature self-compensating fiber grating micro force sensor and manufacturing method thereof

ActiveCN106525299AImprove long-term reliabilityImprove long-term stabilityForce measurement by measuring optical property variationFluid pressure measurement by optical meansFiberGrating

The invention discloses a temperature self-compensating fiber grating micro force sensor and a manufacturing method thereof. The sensor comprises a force-bearing end cover, a sensor upper shell, a sensor lower shell, a hard core, a supporting cylinder and a round elastic diaphragm, wherein the hard core comprises a hard core screw and a hard core nut; the top part of the supporting cylinder passes through the sensor upper shell, and the bottom part is fixed with the hard core screw; the supporting cylinder is internally provided with a fiber, a first fiber grating and a second fiber grating are carved on the fiber, one end of the first fiber grating is fixedly connected with the top part of the upper shell and the other end is fixed with the hard core screw and is in a tensioning state, and one end of the second fiber grating is connected with the lower part of the hard core screw and the other end passes through the sensor lower shell and is in a free elastic state. The structure is simple; the force measurement sensitivity and the force measurement range of the sensor can be changed in a large range, production and manufacturing of batch sensors with multiple specifications are facilitated; temperature self compensating can be realized; and long-term and reliable effective monitoring by the sensor in a temperature-varying environment can be realized.

Owner:WUHAN UNIV OF TECH

Pendulum bob-constant section beam fiber bragg grating dip angle sensor and calibration method

InactiveCN102168956AHigh measurement accuracyFacilitates deformation monitoringUsing optical meansFiberGrating

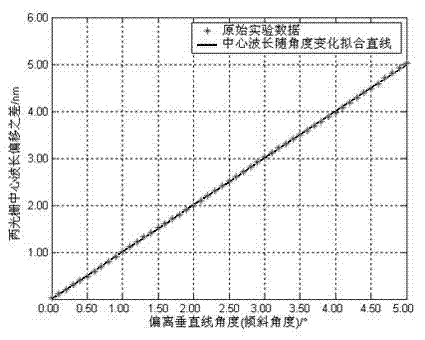

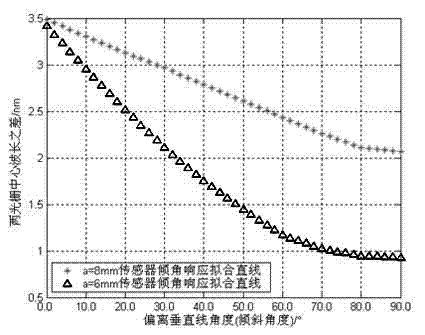

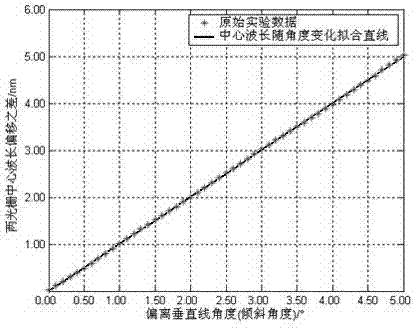

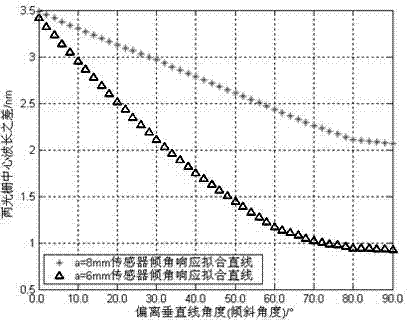

The invention relates to a pendulum bob-constant section beam fiber bragg grating dip angle sensor. In the sensor, one end of a constant section beam is fixed, and the other end of the constant section beam is connected with a pendulum bob; and two fiber bragg gratings are fixed on two opposite lateral surfaces of the constant section beam respectively. A calibration method comprises the following steps of: changing dip angle of a simply supported beam according to step length delta theta, and recording a center wavelength value lambda i of the sensor at each dip angle point theta I; setting a rectangular coordinate system by taking the dip angle theta as a horizontal coordinate and the difference delta lambda of the change of the center wavelength, which is measured at the corresponding corner actually, of the sensor as a vertical coordinate; and after a discrete distribution graph of delta lambda data points is obtained, performing linear fitting on discrete data points by using a primary polynomial, and calculating beta 1 and lambda according to the principle of a least square method, the essential condition for solving multivariate extreme values and the obtained theta i and lambda i data so as to obtain the fitted delta lambda. The pendulum bob-constant section beam fiber bragg grating dip angle sensor has high measuring accuracy, anti-electromagnetic interference capacity and stability, and is suitable for industrial production and particularly suitable for the monitoring of the structural distortion in civil engineering.

Owner:CENT SOUTH UNIV

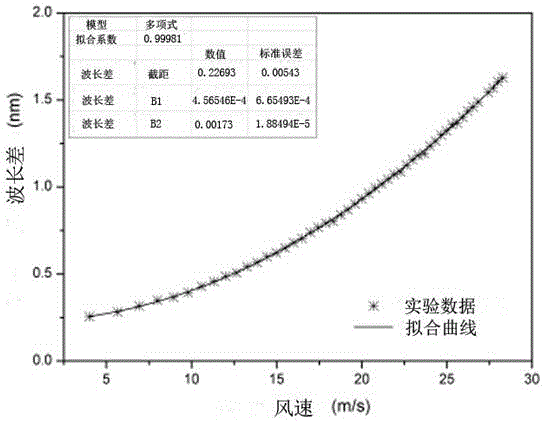

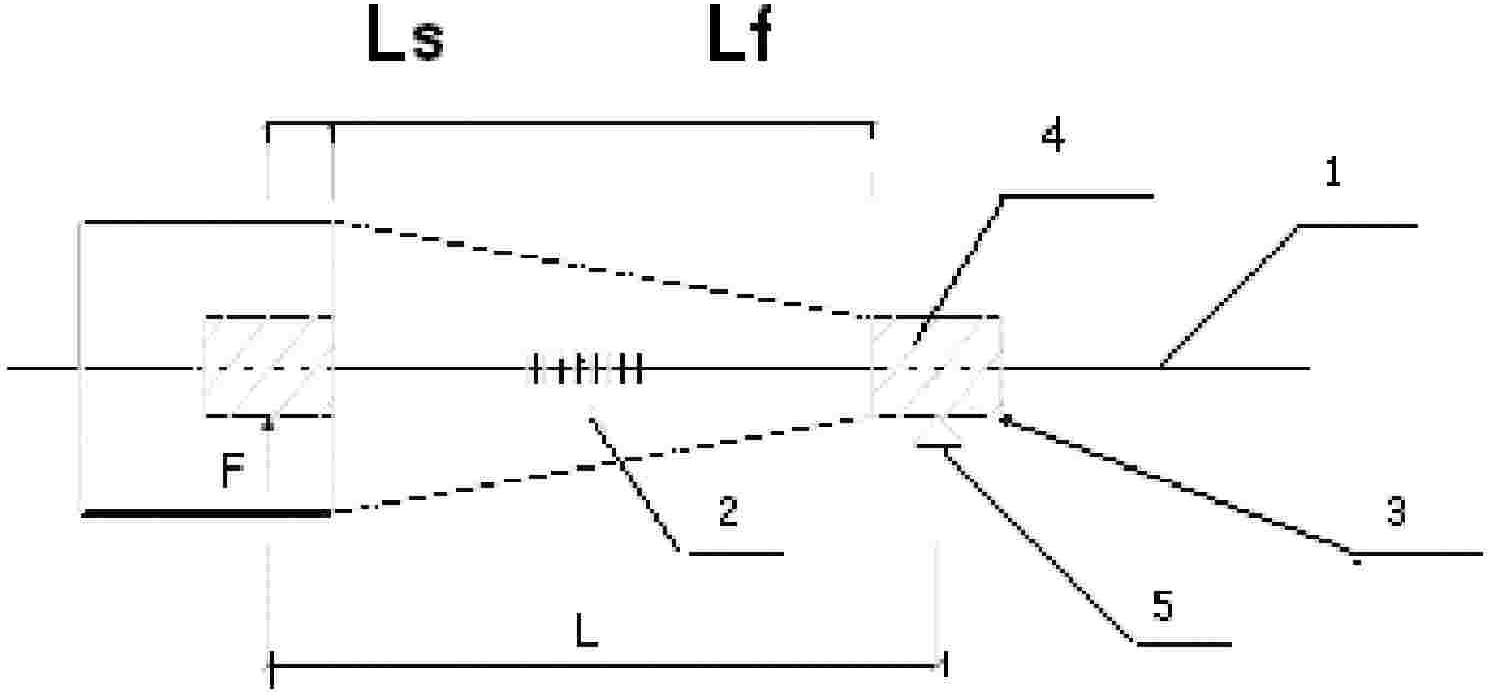

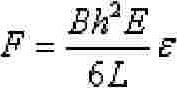

Wind speed sensing device based on fiber bragg gratings, and wind direction monitoring system

InactiveCN106124801AResolve interferenceEasy to replaceIndication/recording movementFluid speed measurementFiberCantilevered beam

The invention discloses a wind speed sensing device based on fiber bragg gratings, and a wind direction monitoring system. The device comprises a wind energy transmission mechanism, a constant strength cantilever beam, and a packaging housing. The wind energy transmission mechanism consists of a windward pressed plate and a connecting rod, wherein the connecting rod is perpendicular to the windward pressed plate. One end of the windward pressed plate is fixed at the center of the connecting rod, and the other end of the windward pressed plate is fixed at the top of the constant strength cantilever beam. The top of the packaging housing is provided with an opening, and a cantilever beam installation pedestal is fixed at the bottom of the interior of the packaging housing. The constant strength cantilever beam stretches into the opening at the top of the packaging housing, and is detachably fixed on the cantilever beam installation pedestal. The surface of the windward pressed plate is parallel to the surface of the constant strength cantilever beam. The axes of the front and back surface of the constant strength cantilever beam are respectively provided with one fiber bragg grating. The system comprises two wind speed sensing devices which are arranged in an orthogonal manner, and the measured data is transmitted to a remote terminal. The device is compact in structure, is small in size, and is resistant to electromagnetic interference.

Owner:CHANGSHU ZJU INST FOR OPTO ELECTRONICS TECH COMMLIZATION IOTEC

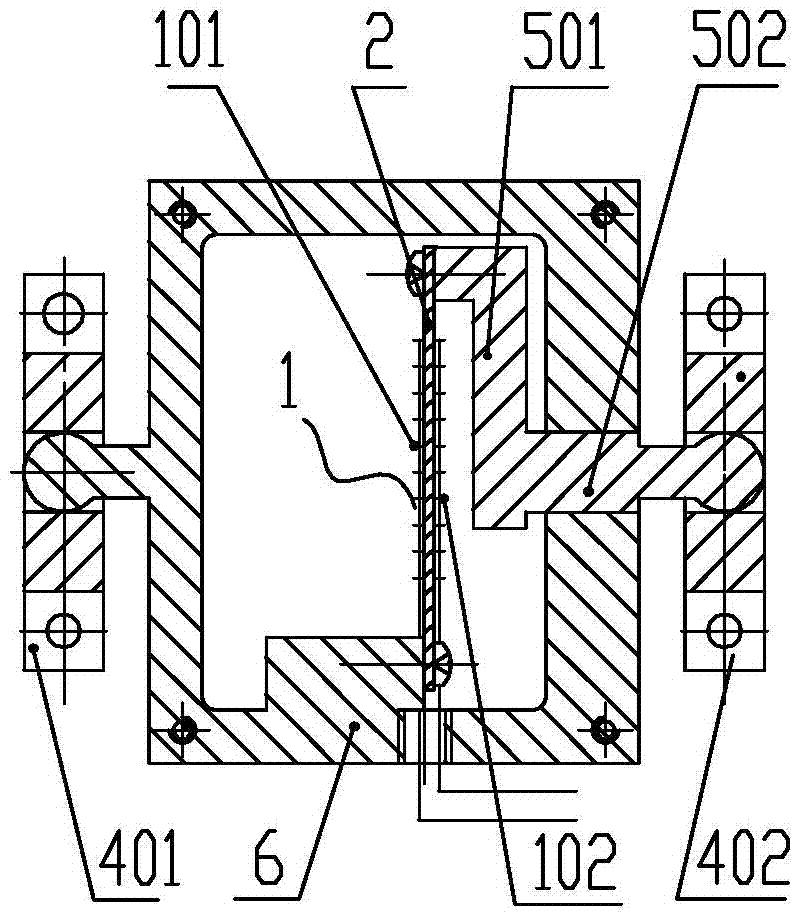

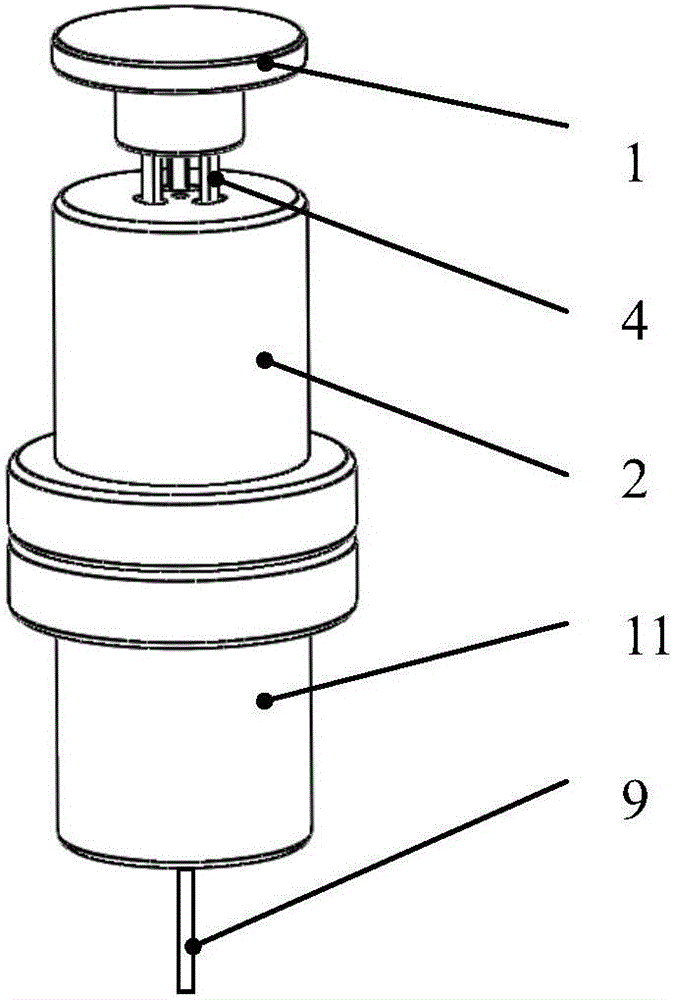

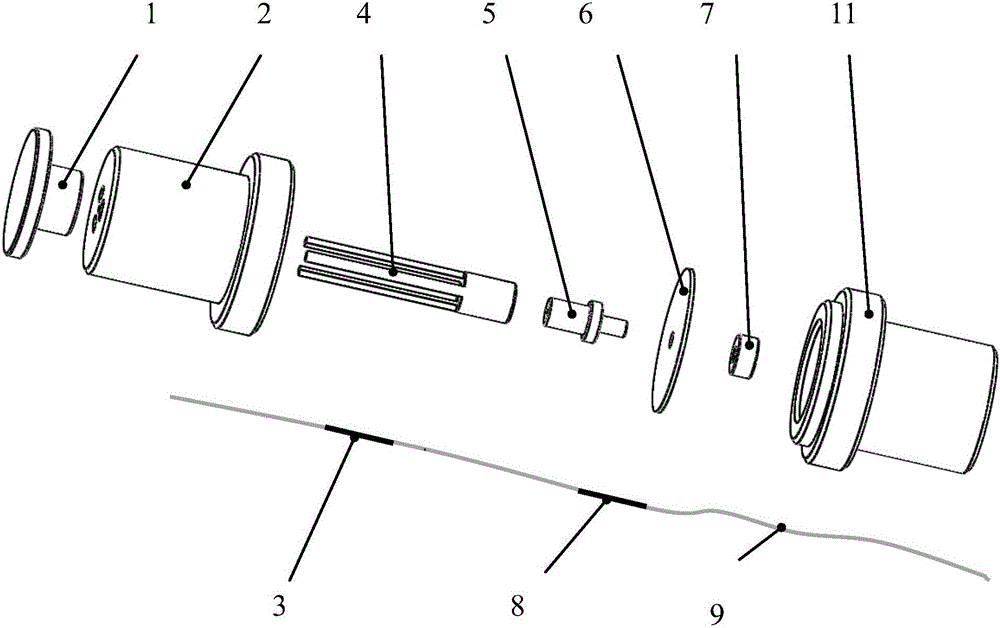

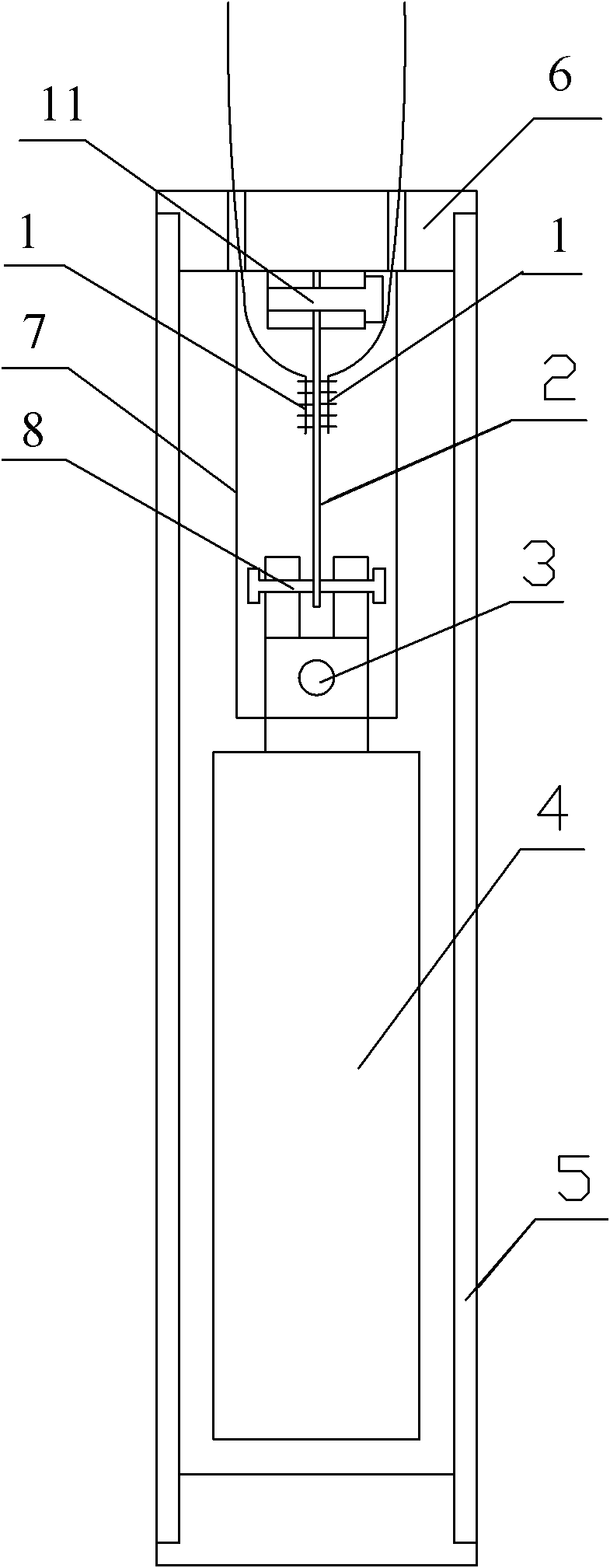

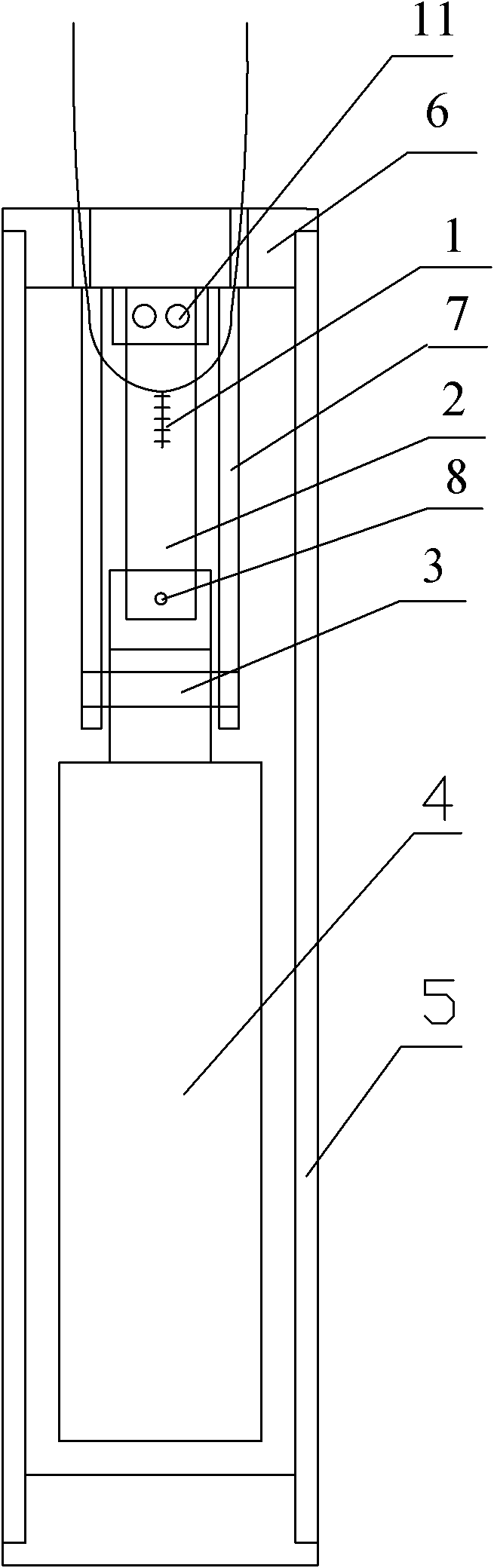

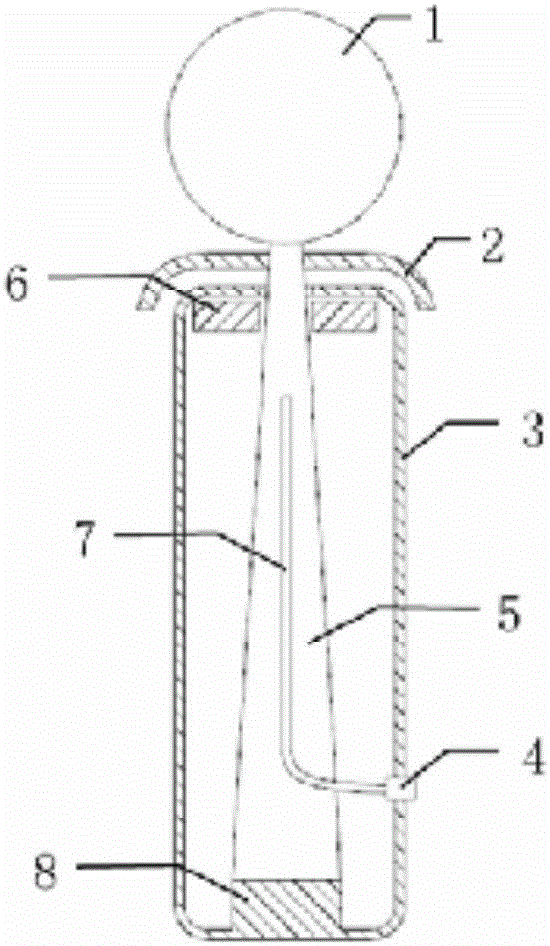

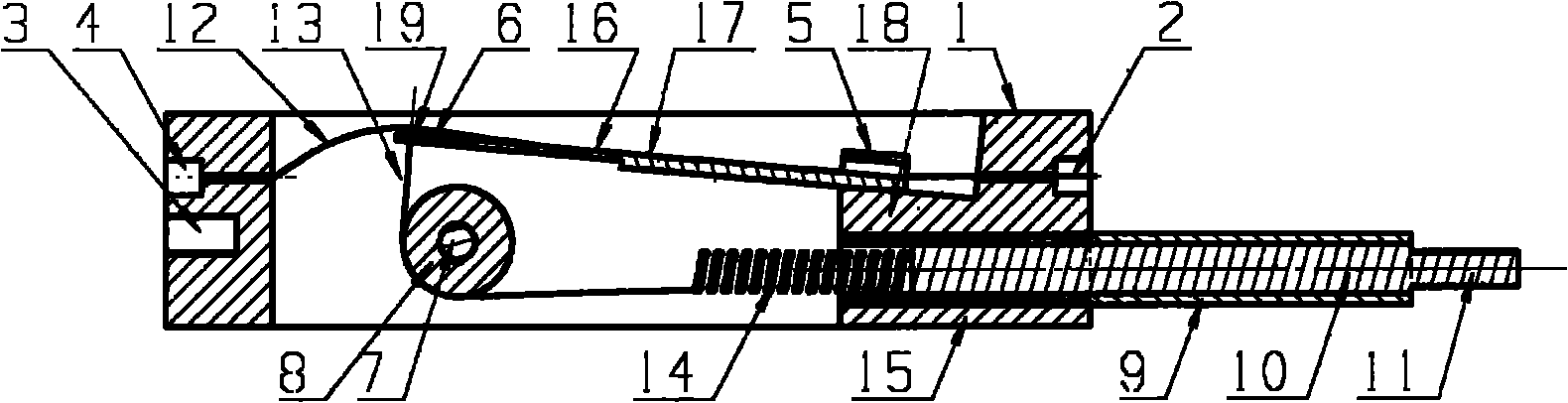

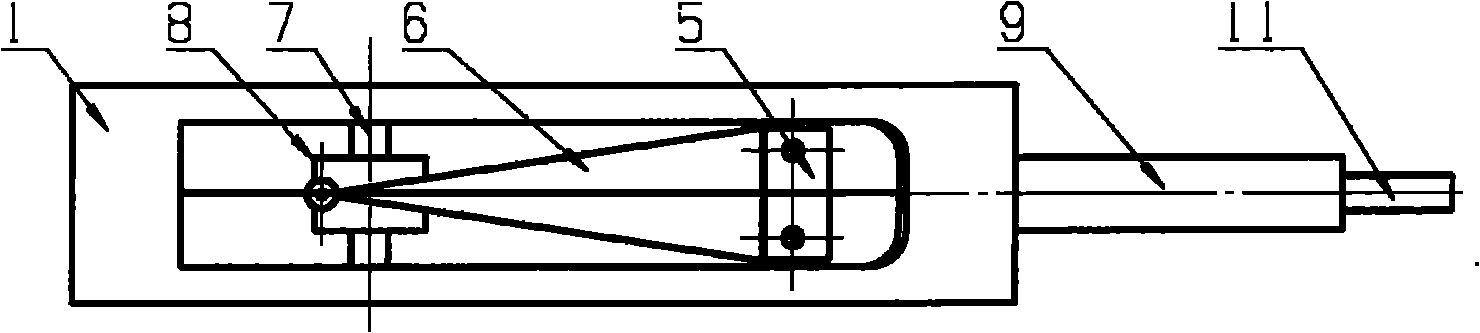

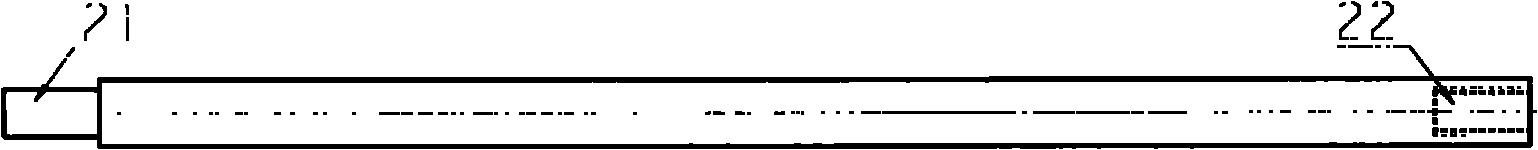

Temperature self-compensated fiber grating tension sensor

InactiveCN102072787AAccurate measurementAchieving temperature self-compensationForce measurement by measuring optical property variationFiberCantilevered beam

The invention relates to a temperature self-compensated fiber grating tension sensor comprising a base, wherein a cantilever is arranged on a cantilever mounting station of an inner cavity of the base through a fixed briquetting; a wire rope mounting hole is arranged at a position symmetric with the top end of the cantilever; a bearing is fixed through a cross shaft in the inner cavity of the base below a free end of the cantilever; a wire rope rounds the bearing from the wire rope mounting hole and is fixed at one end of a spring; the other end of the spring is fixed on an extension rod which is arranged in a sleeve of the extension rod; the external thread end of the extension rod is stretched out of the base; an optical fiber etched with a first fiber grating and a second fiber grating is arranged through an entrance of the optical fiber, the cantilever and an exit of the optical fiber; and the first fiber grating and the second fiber grating are arranged along the symmetric positions on the cantilever closely. The temperature self-compensating fiber grating tension sensor can realize a comprehensive test of tension and pressure in a static state and a dynamic state, in the meantime can resist electromagnetic interference and has a temperature self-compensating function.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

High-sensitivity fiber bragg grating pressure sensor based on square diaphragm

InactiveCN110702280AHigh sensitivitySensitivity adjustableForce measurement by measuring optical property variationFluid pressure measurement by optical meansFiberGrating

The invention provides a high-sensitivity fiber bragg grating pressure sensor based on a square diaphragm. The high-sensitivity fiber bragg grating pressure sensor comprises a protection top cover which is provided with a lead-out hole for an optical fiber pigtail at the center of the top, a middle component which is provided with a square pressure bearing diaphragm for directly sensing an external oil gas pressure signal at a top surface, a stress transfer rod installed at the center of the square pressure bearing diaphragm, two vertical beams installed on the surface of a disc, cross beams installed at the free ends of the vertical beams, temperature measurement fiber bragg gratings installed on the upper surfaces of the cross beams, a pressure measurement fiber bragg grating installed between the stress transfer rod and the cross beams for applying certain prestress during packaging, a pressure port which is provided with a pressure conducting channel at the inner center and two clamping grooves formed in the bottom of the pressure port. The high-sensitivity fiber bragg grating pressure sensor provided by the invention has the characteristics of high sensitivity, the simple structure, small size, low cost and so on.

Owner:XI'AN PETROLEUM UNIVERSITY

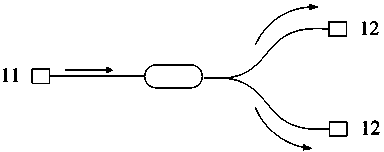

Gross-volume monitoring sensing device for corrosion states and temperature field states of reinforcing steel bars in concrete

InactiveCN103512850AAvoid influenceEnables full volume monitoringThermometers using physical/chemical changesColor/spectral properties measurementsFiberLong-period fiber grating

The invention discloses a gross-volume monitoring sensing device for the corrosion states and the temperature field states of reinforcing steel bars in concrete, and a monitoring device with the gross-volume monitoring sensing device. The gross-volume monitoring sensing device comprises a broadband light source, a Y-shaped optical fiber coupler, a coupler connector, a sensing optical fiber, an LPFG (Long Period Fiber Grating) reinforcing steel bar corrosion sensing probe, an LPFG temperature sensing probe, an optical switch, a spectrograph and a computer, wherein the broadband light source enters the input end of the Y-shaped optical fiber coupler, is transmitted to the output end of the Y-shaped optical fiber coupler, is further transmitted to the LPFG reinforcing steel bar corrosion sensing probe and the LPFG temperature sensing probe respectively through the coupler connector and the sensing optical fiber, passes the optical switch, enters the spectrograph through the outgoing end of the optical switch, and is finally processed by the computer; then a curve of relationship between a transmitted spectrum and the corrosion states is output. By utilizing the device, the gross-volume monitoring on the corrosion states and the temperature field states of the reinforcing steel bars in the concrete can be realized.

Owner:SOUTHEAST UNIV

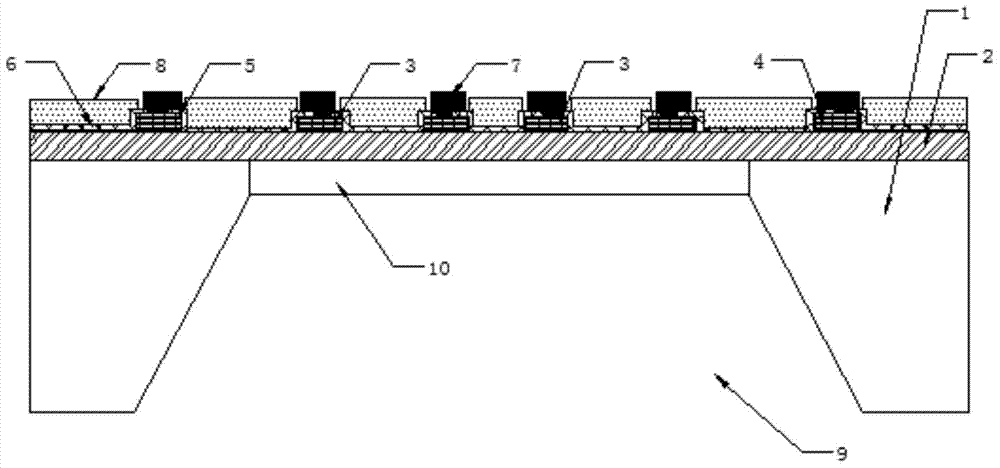

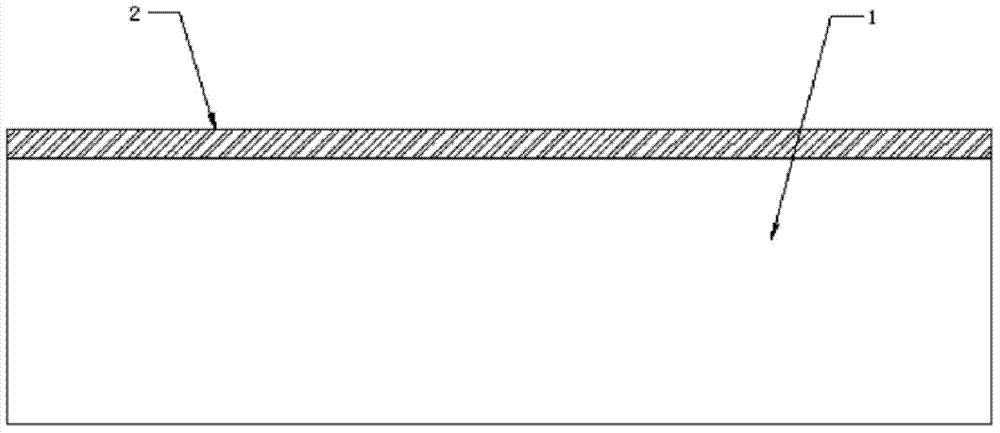

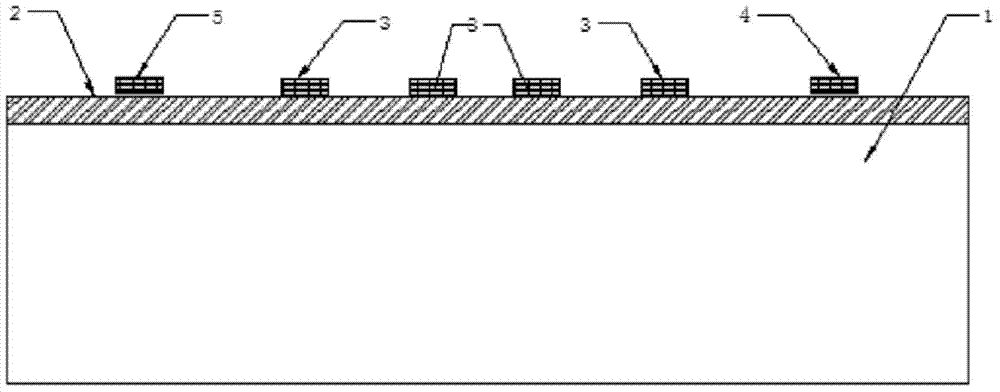

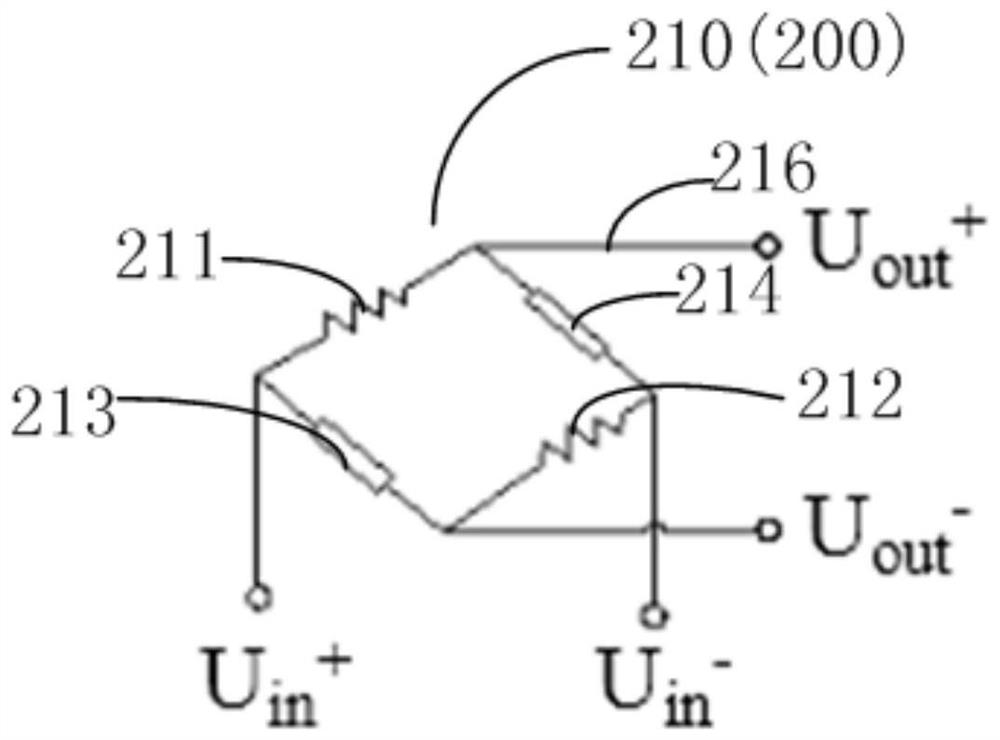

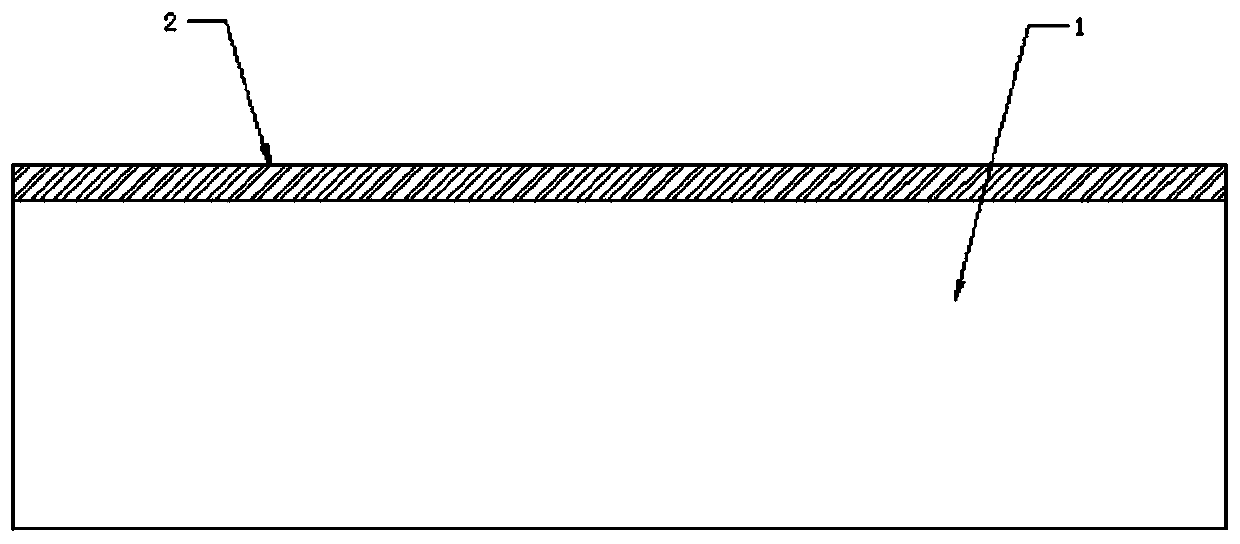

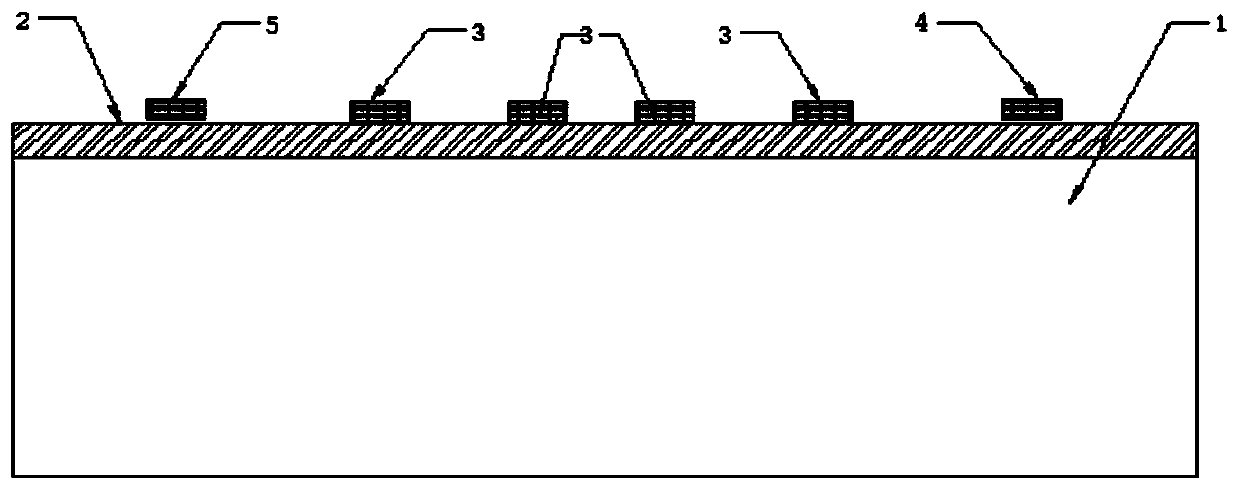

Preparing and compensating method for temperature drift self-compensating SOI pressure sensor

ActiveCN104280186AAchieving temperature self-compensationImprove stabilityFluid pressure measurement using ohmic-resistance variationEngineeringSoi substrate

The invention relates to a preparing and compensating method for a temperature drift self-compensating SOI pressure sensor. The temperature drift self-compensating SOI pressure sensor comprises an SOI substrate, a bridge circuit resistor used for being configured into a wheatstone bridge is arranged on the SOI substrate, a compensating resistor used for conducting temperature compensation on the wheatstone bridge is arranged on the part, corresponding to the surface provided with the bridge circuit resistor, of the SOI substrate, and interconnection leads electrically connected are arranged on the compensation resistor and the bridge circuit resistor. The compensation resistor and the bridge circuit resistor are isolated through an insulation isolating layer and a passivation layer, the insulation isolating layer covers the SOI substrate, and the passivation layer covers the insulation isolating layer. The part, corresponding to the other side provided with the bridge circuit resistor, of the SOI substrate is etched to form a pressure cavity and a pressure sensitive membrane, and the pressure cavity and the pressure sensitive membrane are located under the bridge circuit resistor. The temperature drift self-compensating SOI pressure sensor is compact in structure, capable of achieving temperature drift self-compensation and reducing cost, high in stability, good in consistency, suitable for mass production, wide in application range, safe and reliable.

Owner:无锡芯感智半导体有限公司

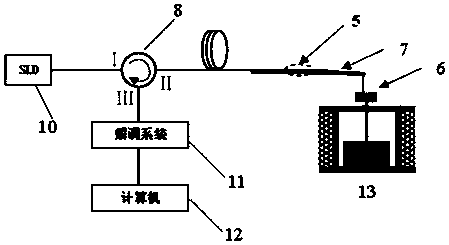

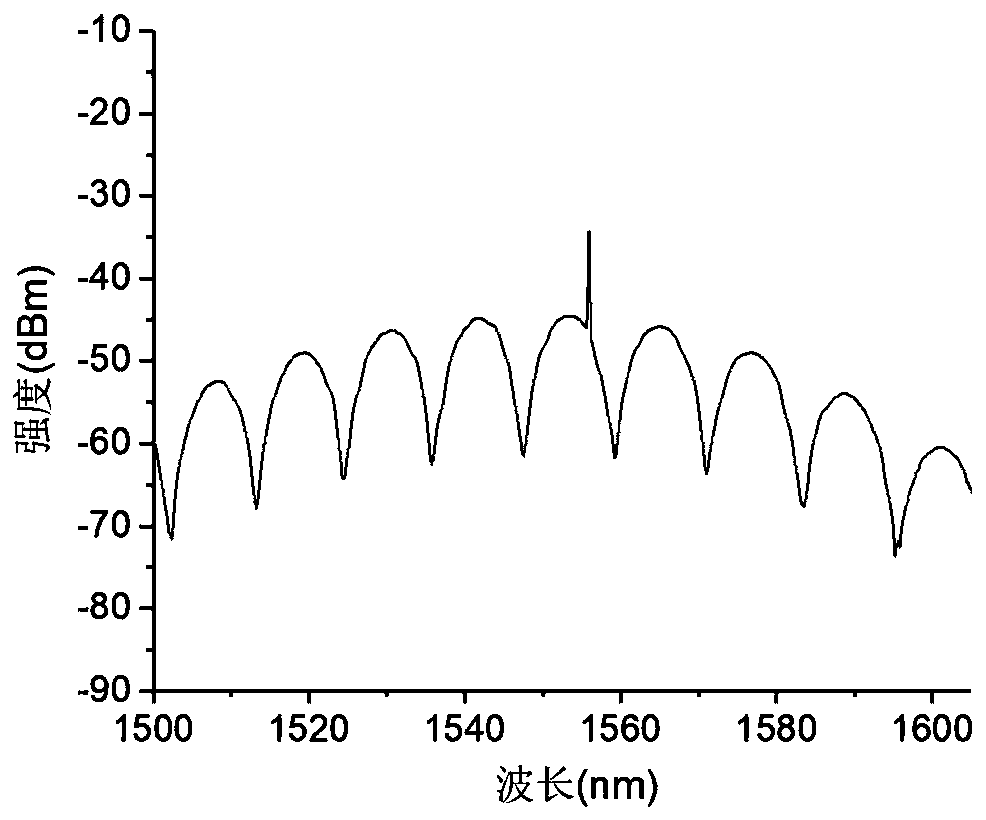

Optical fiber F-P/FBG composite cavity current and temperature synchronous measurement system

InactiveCN111473811AEliminate measurement errorsAchieving temperature self-compensationConverting sensor output opticallyStrain gaugeTemperature measurement

The invention relates to an optical fiber F-P / FBG composite cavity current and temperature synchronous measurement system. An optical fiber F-P / FBG composite cavity is used as a sensing element; a magnetic field generating device generates a magnetic field under the action of current; the magnet suspended at one end of the strain gauge bonded with the optical fiber F-P / FBG composite cavity is attracted by the magnetic field, the cavity length of the optical fiber F-P / FBG composite cavity changes under the action of the magnet, and the relation between the measured current and the cavity lengthis established by measuring the cavity length change of the optical fiber F-P / FBG composite cavity. Besides, the optical fiber F-P / FBG composite cavity also has a temperature measurement function, the whole system not only can synchronously measure the temperature of the working environment, but also can utilize the temperature measurement data of the optical fiber F-P / FBG composite cavity to eliminate the measurement error caused by temperature change in the F-P cavity, i.e., eliminate the measurement error caused by expansion of the strain gauge due to temperature change, and realize the temperature self-compensation function.

Owner:WUHAN UNIV OF TECH

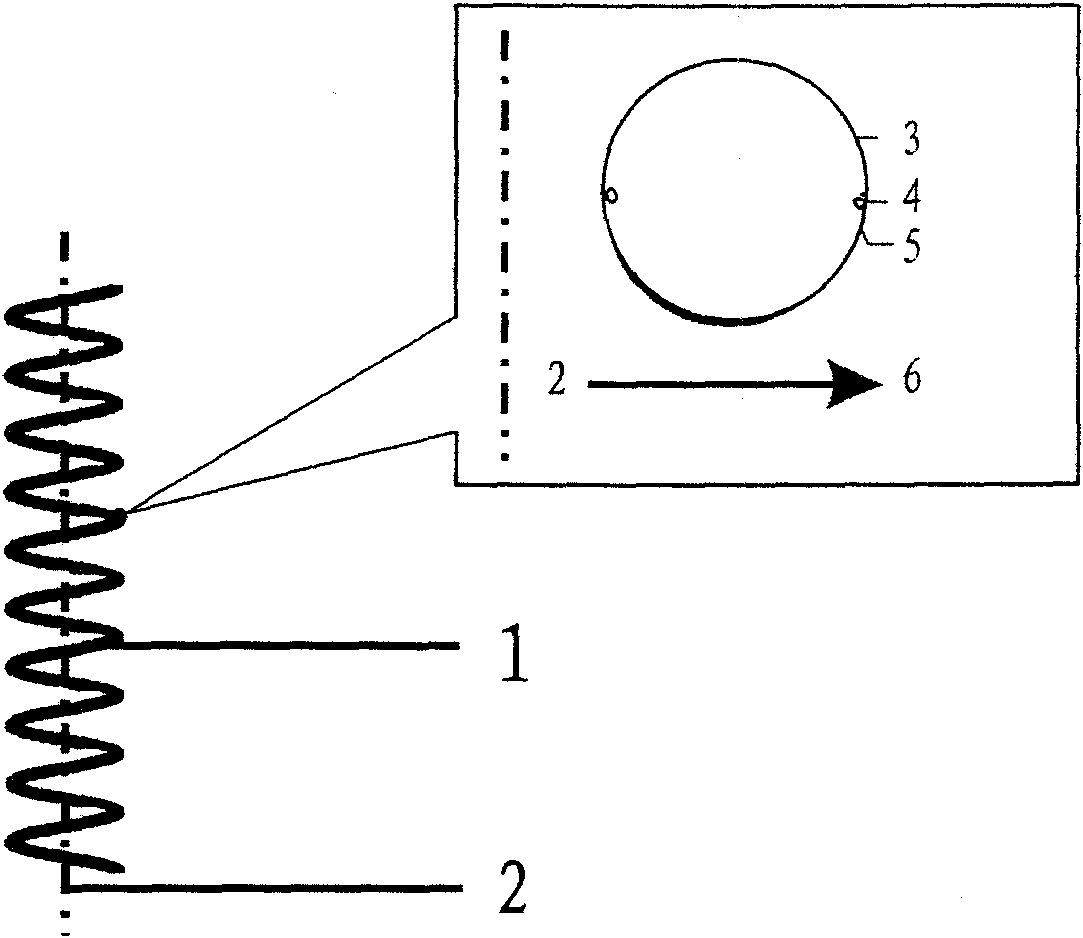

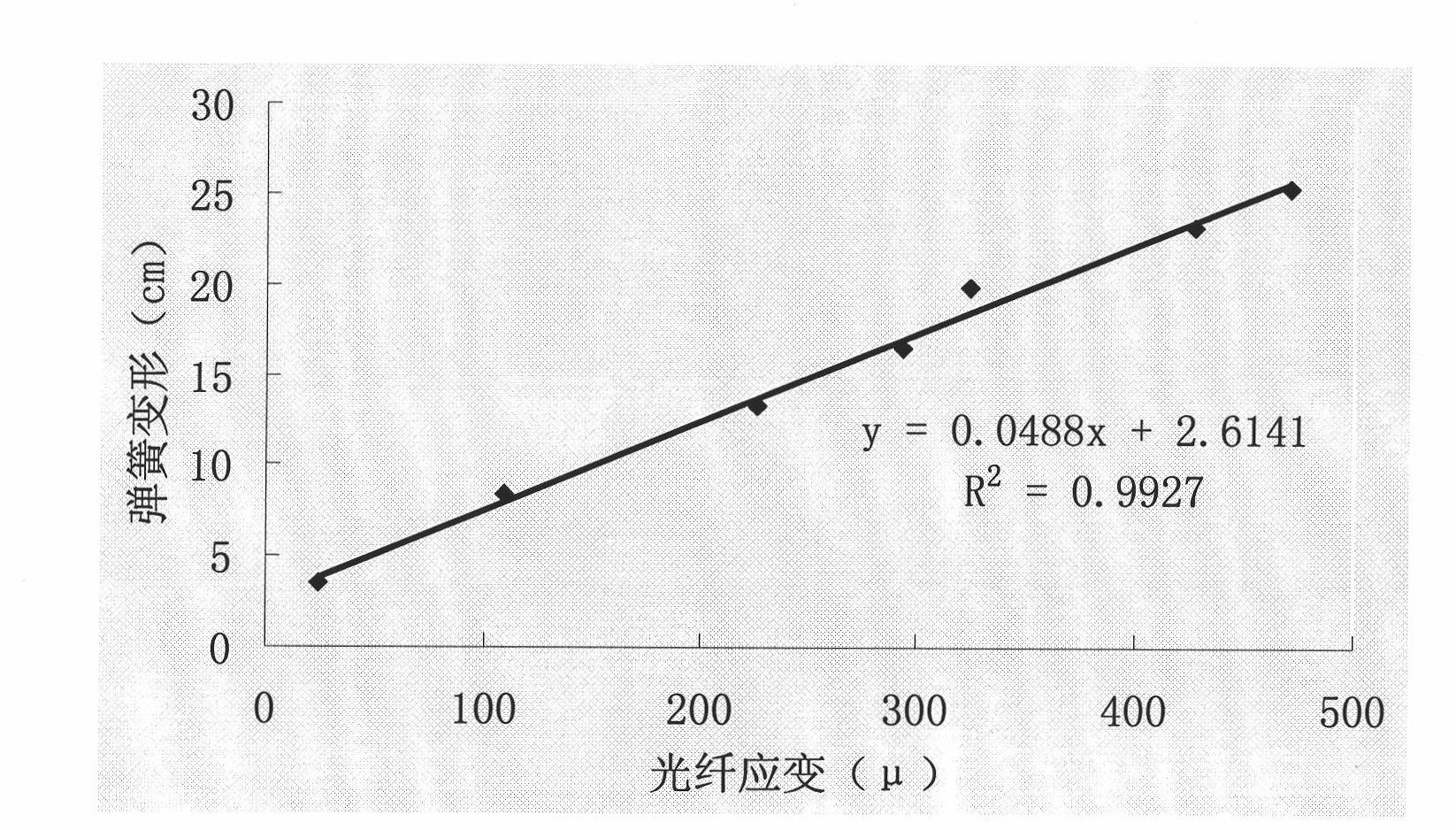

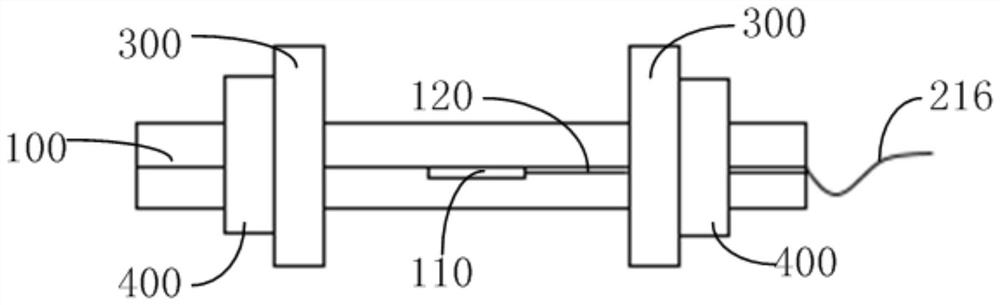

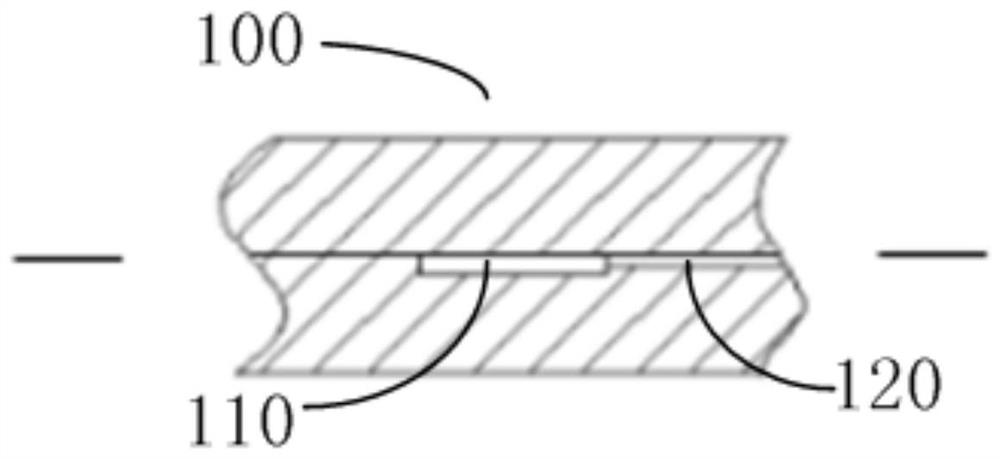

Distributed optical fiber large-deformation measuring sensor

ActiveCN101625230BHigh precisionImprove survival rateUsing optical meansMechanical solid deformation measurementsMeasuring instrumentSelf compensation

The invention discloses a distributed optical fiber large-deformation measuring sensor which is characterized in that a stain sensing optical fiber is embedded into a large-deformation measured spring, particularly embedded into or fixed on a spring rod interlocked with the spring; one end of the large-deformation measuring sensor is fixed with the spring rod so that when the spring expands to become deformed, the deformation quantity of the spring is corresponding to that of the spring rod and has the corresponding relation with the deformation quantity of the stain sensing optical fiber; the deformation quantity of the spring can be obtained by measuring strain of the optical fiber, thus realizing the conversion from the large-deformation of the spring to the little strain of the optical fiber; and the stain sensing optical fiber is connected with the optical fiber of a Brillouin back scattering luminous power measuring instrument. The sensor is characterized by large measuring range, variable measuring range, stably, reliability, corrosion resisting, temperature self-compensation, realization of a plurality of series connections, easy to industrial production, convenient installation, etc.

Owner:SUZHOU NANZEE SENSING TECH

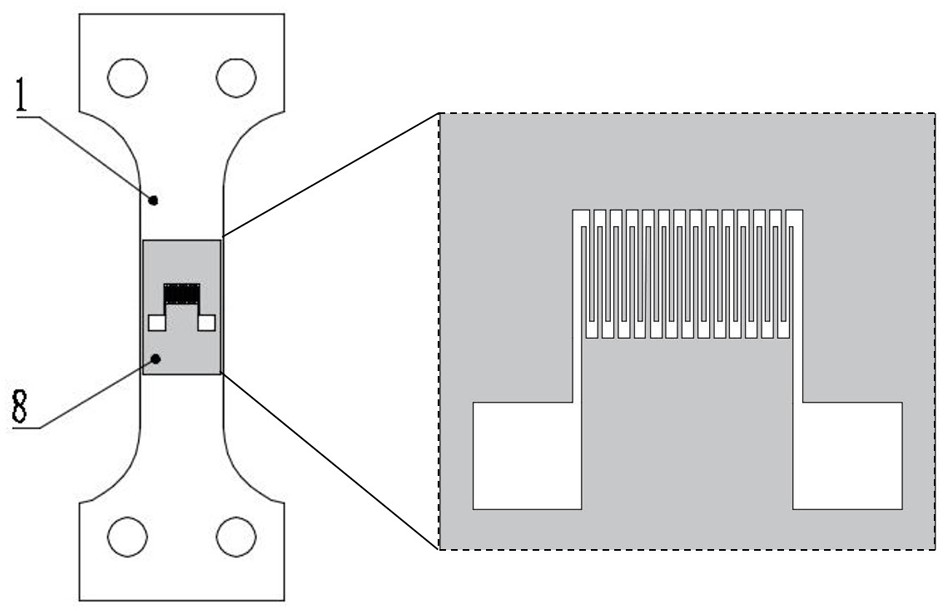

Strain sensor and application thereof

PendingCN114111561APlay a protective effectSimple structureElectrical/magnetic solid deformation measurementFilm resistanceElectrical resistance and conductance

The invention relates to the technical field of sensors, in particular to a strain sensor and application thereof. The strain sensor comprises an elastic piece provided with a mounting cavity and a wire passing hole, the wire passing hole is communicated with the mounting cavity, and the elastic piece can deform along with strain; the detection module comprises a Wheatstone half-bridge circuit unit, the Wheatstone half-bridge circuit unit is arranged in the mounting cavity, the Wheatstone half-bridge circuit unit comprises a first thin-film resistor, a second thin-film resistor, a third thin-film resistor and a fourth thin-film resistor, and the length directions of the first thin-film resistor and the second thin-film resistor are the same; the third thin-film resistor and the fourth thin-film resistor are perpendicular to the first thin-film resistor and the second thin-film resistor; leads of the first thin-film resistor, the second thin-film resistor, the third thin-film resistor and the fourth thin-film resistor are exposed out of the elastic piece through the wire passing holes; and the fixing piece is connected with the elastic piece and is used for fixing the elastic piece. The sensor is high in measurement precision.

Owner:北京石墨烯技术研究院有限公司

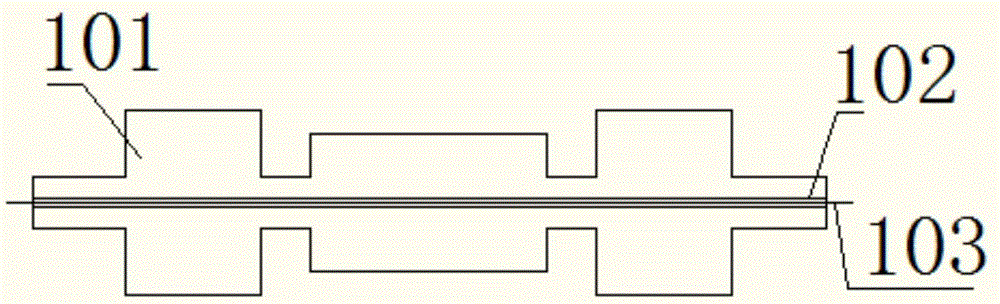

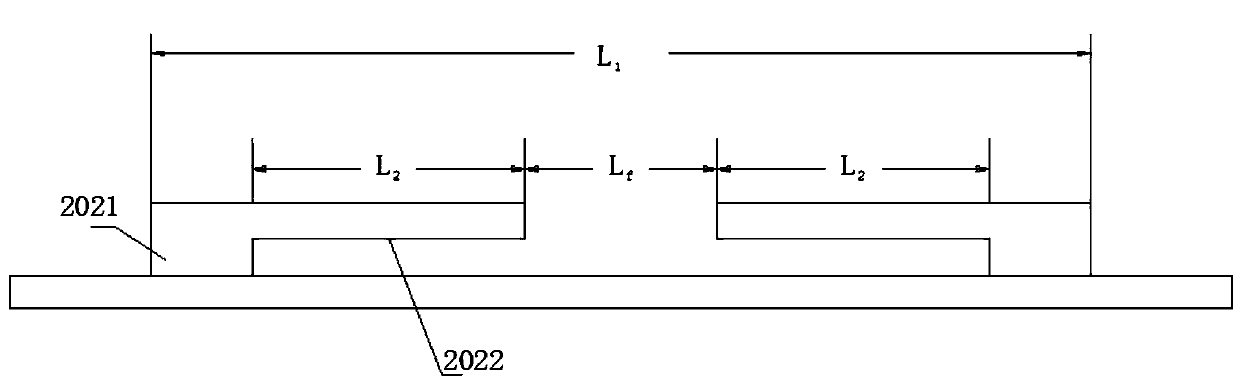

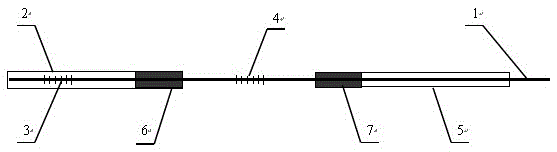

Fiber bragg grating strain device

ActiveCN106524937ACompensation for expansionAchieving temperature self-compensationUsing optical meansStrain sensorEngineering

The invention provides a fiber bragg grating strain sensor. The sensor comprises a substrate, two compensation arms and fiber bragg gratings, wherein the two compensation arms are symmetrically arranged on two sides of the substrate; one side of an upper end of each compensation arm, which is close to a substrate center, is provided with an optical fiber fixing point; one side of a lower end of the each compensation arm, which is far away from the optical fiber fixing point, is fixed to the substrate; and the fiber bragg gratings are arranged on the two compensation arms through the optical fiber fixing points. In the invention, an expansion direction of the compensation arms is opposite to an expansion direction of the substrate so that expansion quantities and the expansion directions of the substrate and the compensation arms are different, expansion quantities of the fiber bragg gratings are compensated and a temperature cross interference is eliminated.

Owner:BEIJING UNIV OF POSTS & TELECOMM

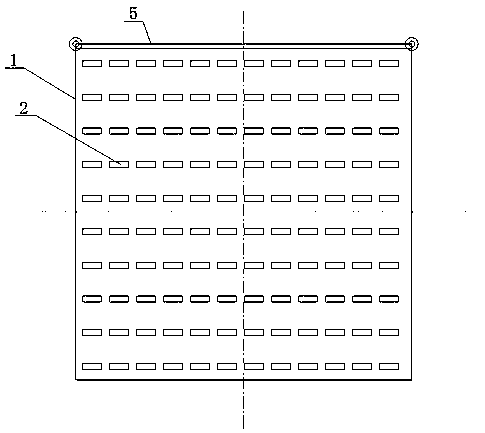

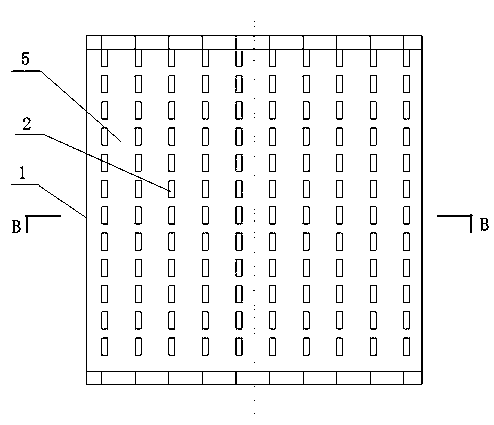

Engineering soil frost heaving force testing device

PendingCN111189992AGood durabilityGuaranteed complianceEarth material testingApparatus for force/torque/work measurementSoil frostStrain gauge

The invention belongs to an engineering soil frost heaving amount testing device, in particular to an engineering soil frost heaving force testing device. A cubic copper box body is formed by a pure copper plate; a copper box cover formed by a pure copper plate is hinged on the upper opening of the copper box body through an arranged hinge base; long-strip-shaped water permeable holes are evenly distributed in the four walls, the bottom face and the copper box cover of the copper box body respectively and formed in the inner walls of the six faces of the closed copper box body. Crisscrossed patterns are respectively arranged along the center line of the inner wall of each surface; the resistance strain gauge is positioned in the center of the inner wall; the axes of the resistance strain gauges arranged on the corresponding inner walls of the closed copper box body are perpendicular to each other, the copper box body is filled with a soil material which is the same as an engineering soil body, two-layer filling and layered tamping are carried out, an electric thermometer is buried in the copper box body, and cables of the resistance strain gauges are led out of the water permeableholes to be connected with the reading instrument. The device is reasonable in structure, reliable in performance, capable of measuring the frost heaving force of engineering soil in the three-dimensional direction, high in measurement precision, good in durability, free of influences of low temperature and water and soil environment corrosion and convenient to install and use.

Owner:XINJIANG INST OF WATER RESOURCES & HYDRAULIC POWER +1

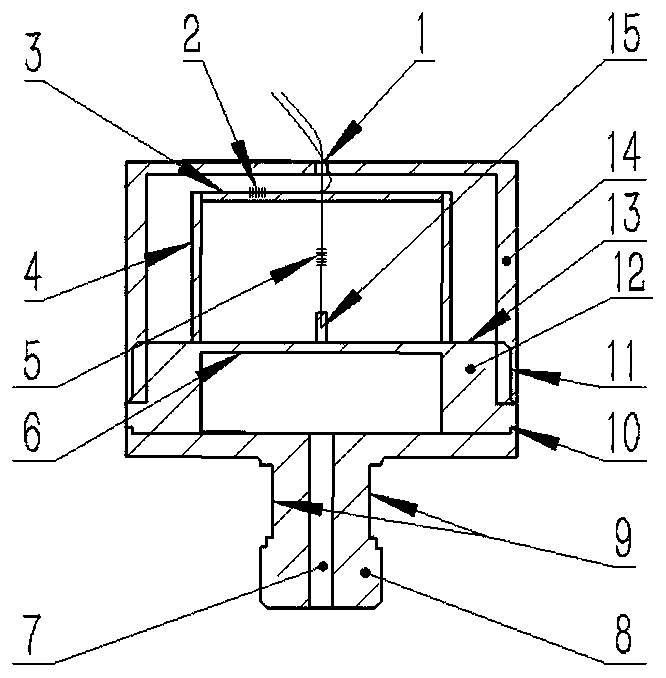

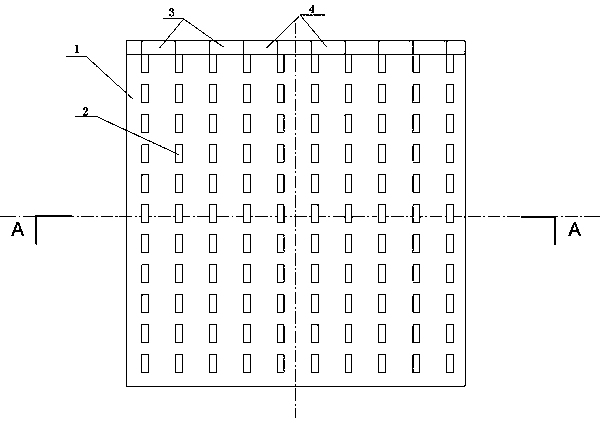

Optical fiber grating ice-pressure sensor

InactiveCN101701860BLow costImprove stabilityCladded optical fibreForce measurement by measuring optical property variationGratingSelf compensation

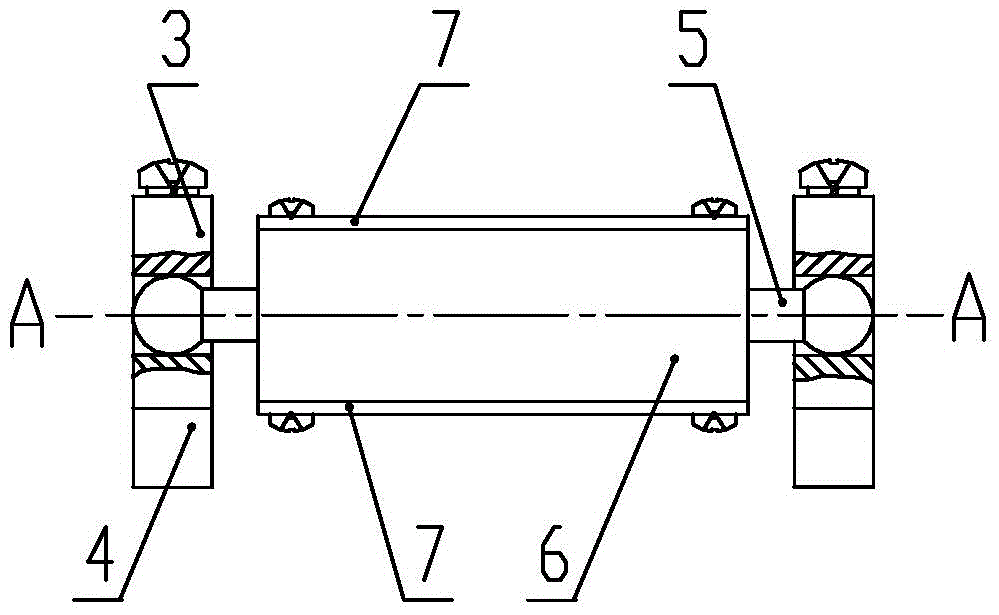

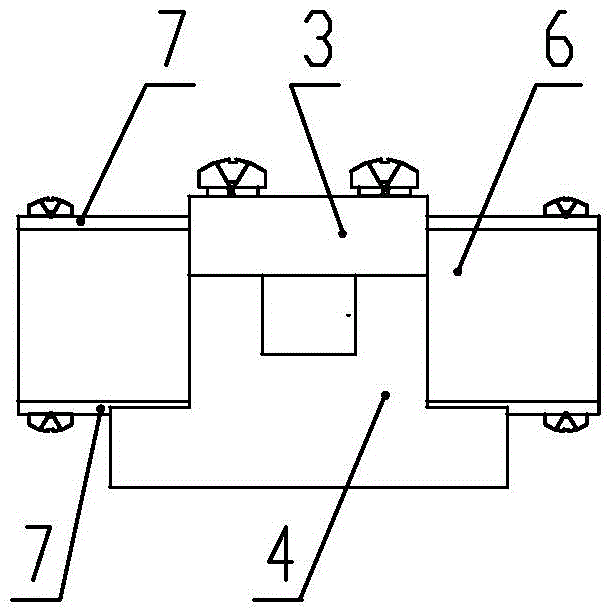

The invention discloses a contact type optical fiber grating ice-pressure sensor with better stability, which belongs to the field of sensing technologies. The sensor is characterized in that the contact type optical fiber grating ice-pressure sensor consists of a metal bottom plate, a metal protective case, a metal force-bearing panel, a clamping piece, a uniform strength beam, a micro-optical fiber grating strain sensor and a transmission optical cable component. The sensor is mounted on the structure through the metal bottom plate, the clamping piece fixes the micro-optical fiber grating strain sensor on the uniform strength beam through a screw, and the different shapes of the metal force-bearing panel can be changed according to the different force application structures; in addition, the measurement sensitivity of the sensor can be adjusted by changing the dimensions of devices according to actual demands, thereby being applicable to different types of model tests. The ice-pressure sensor can indirectly measure the ice-pressure by measuring the strain, and the pressure sensitivity coefficient of the sensor is improved by utilizing the natures of an optical fiber grating, which is not affected by materials. The ice-pressure sensor can well eliminate the affects of eccentric force on the measured value and realize the temperature self-compensation; and the ice-pressure sensor can simultaneously overcome the shortcomings that the traditional electric sensor is vulnerable to electromagnetic interferences, the long-term stability is poor and the like, and has the advantages of high precision, small volume, light weight, small affects on the natures of the structure and the like.

Owner:DALIAN UNIV OF TECH

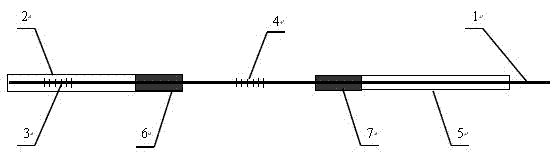

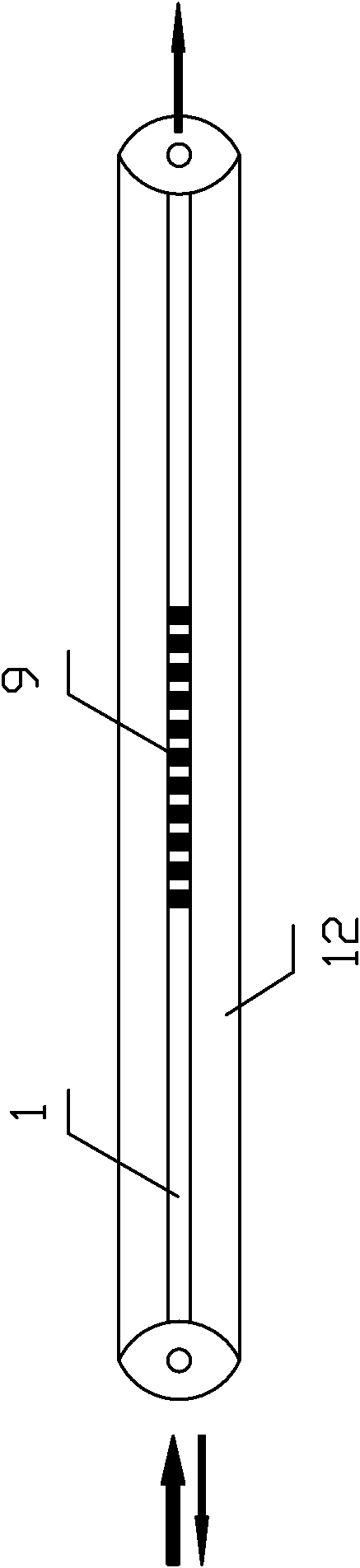

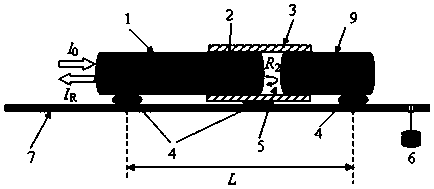

Tilt angle sensor based on optical fiber Bragg gratings and method for measuring tilt angle of tilt angle sensor

InactiveCN102288162BHigh measurement accuracyImprove machining accuracyIncline measurementGratingFiber Bragg grating

The invention relates to a tilt angle sensor based on optical fiber Bragg gratings and a method for measuring a tilt angle of the tilt angle sensor and belongs to the technical field of measurement of a structural tilt angle. The tilt angle sensor comprises a fixed base plate (12), a fixed pressing block (6), a thin-wall type uniform-section metal beam (9) and a quality block (7), wherein the upper end of the thin-wall type uniform-section metal beam (9) is arranged on the fixed base plate (12) in a mode of fitting with the fixed pressing block through a first movable pressing block (10) and a fifth screw (11); the quality block (7) is fixed at the lower end of the thin-wall type uniform-section metal beam (9) through a sixth screw (15) and a second movable pressing block (16); and a first optical fiber Bragg grating (13) and a second optical fiber Bragg grating (14) are respectively adhered to opposite positions on two sides of the thin-wall type uniform-section metal beam (9). By the method, the size and direction of the tilt angle can be detected according to a correspondence relation between the change of central wavelengths of the two optical fiber Bragg gratings and the tiltangle. The invention is high in measurement accuracy and has a temperature self-compensation function.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A Fiber Bragg Grating Strainer

ActiveCN106524937BCompensation for expansionAchieving temperature self-compensationUsing optical meansFiberGrating

The invention provides a fiber bragg grating strain sensor. The sensor comprises a substrate, two compensation arms and fiber bragg gratings, wherein the two compensation arms are symmetrically arranged on two sides of the substrate; one side of an upper end of each compensation arm, which is close to a substrate center, is provided with an optical fiber fixing point; one side of a lower end of the each compensation arm, which is far away from the optical fiber fixing point, is fixed to the substrate; and the fiber bragg gratings are arranged on the two compensation arms through the optical fiber fixing points. In the invention, an expansion direction of the compensation arms is opposite to an expansion direction of the substrate so that expansion quantities and the expansion directions of the substrate and the compensation arms are different, expansion quantities of the fiber bragg gratings are compensated and a temperature cross interference is eliminated.

Owner:BEIJING UNIV OF POSTS & TELECOMM

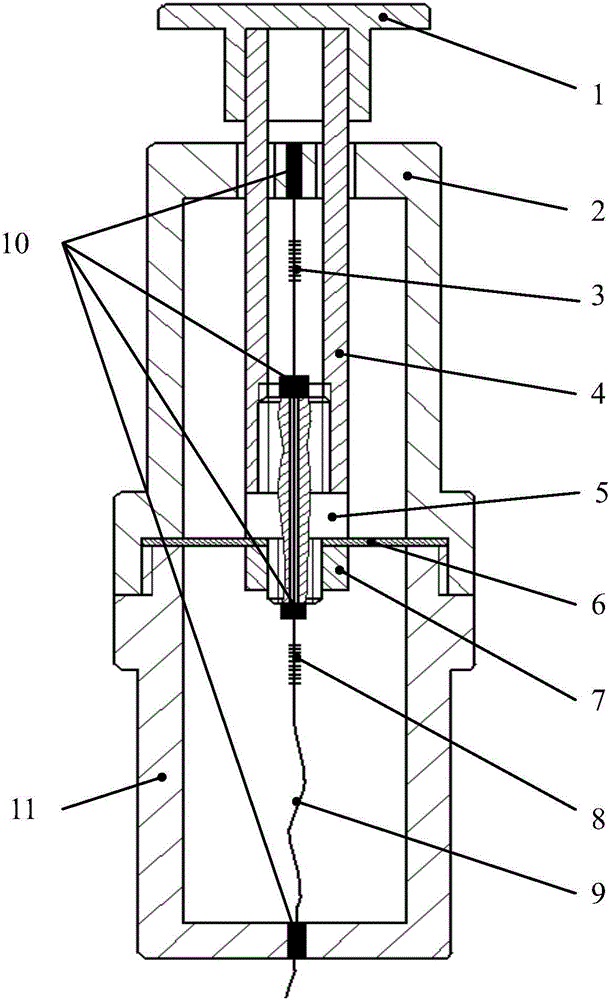

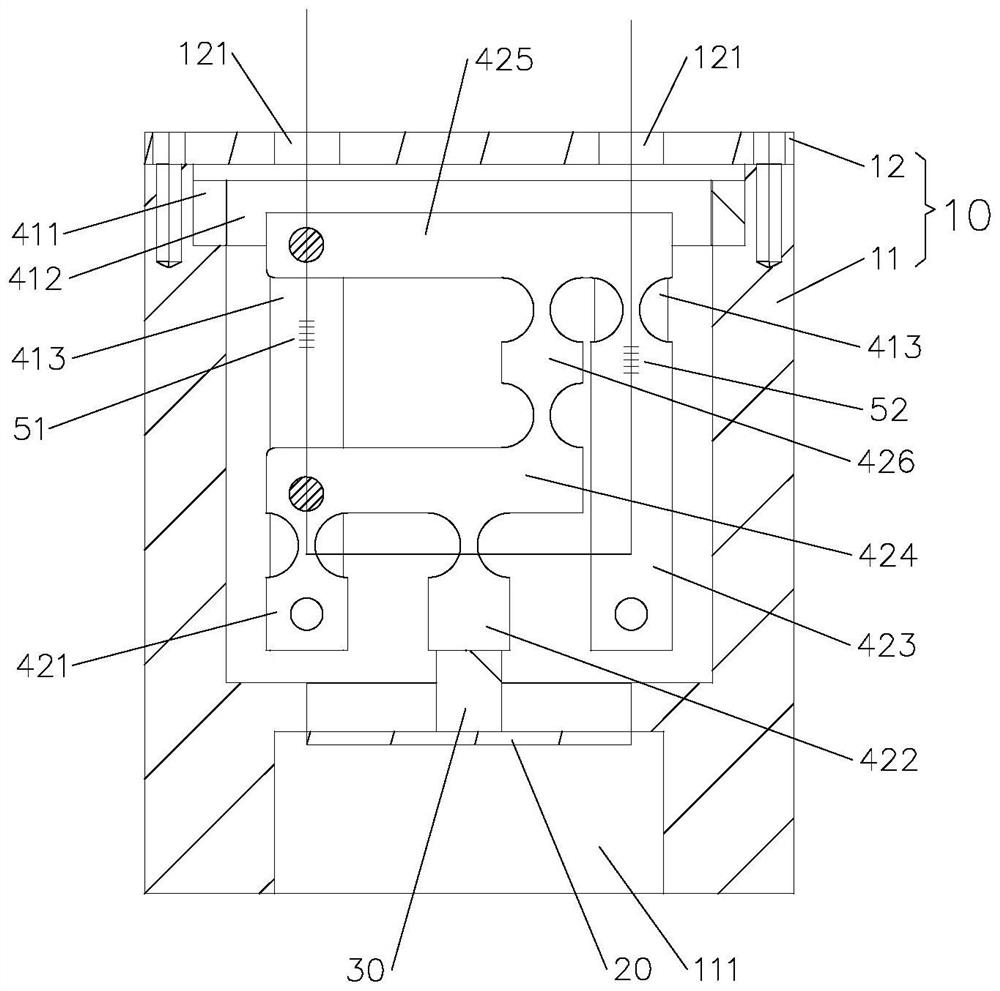

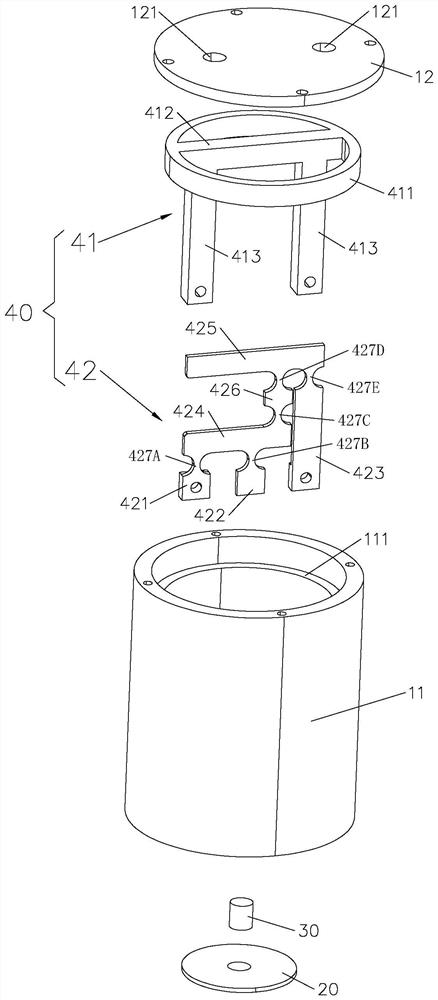

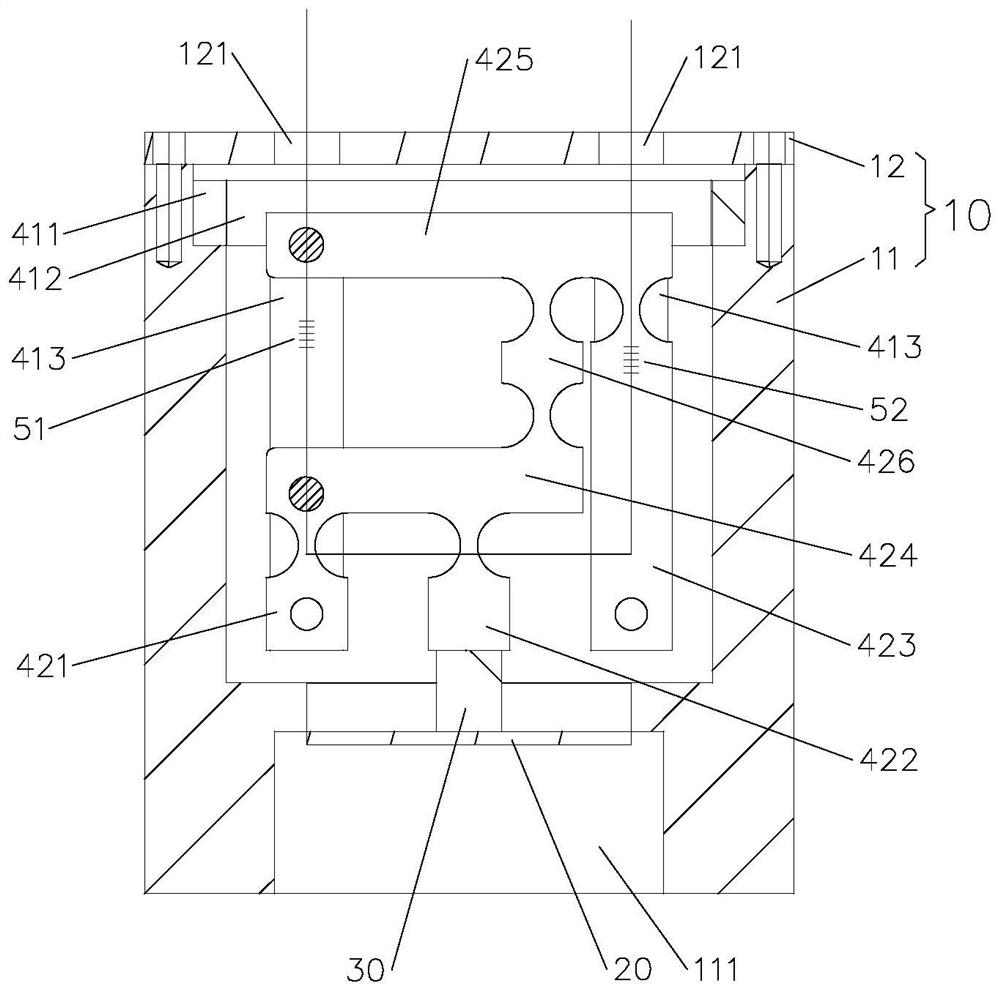

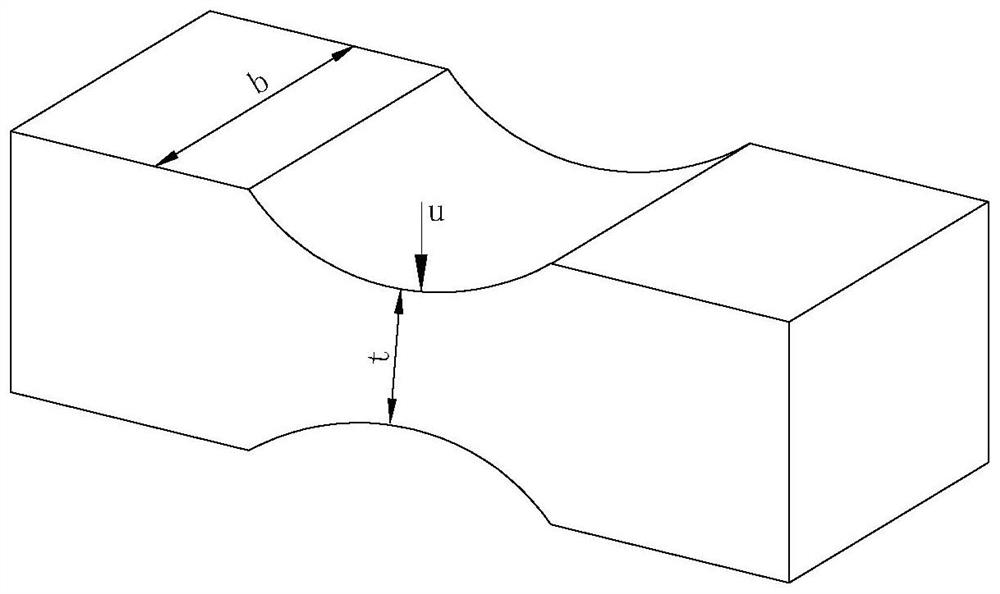

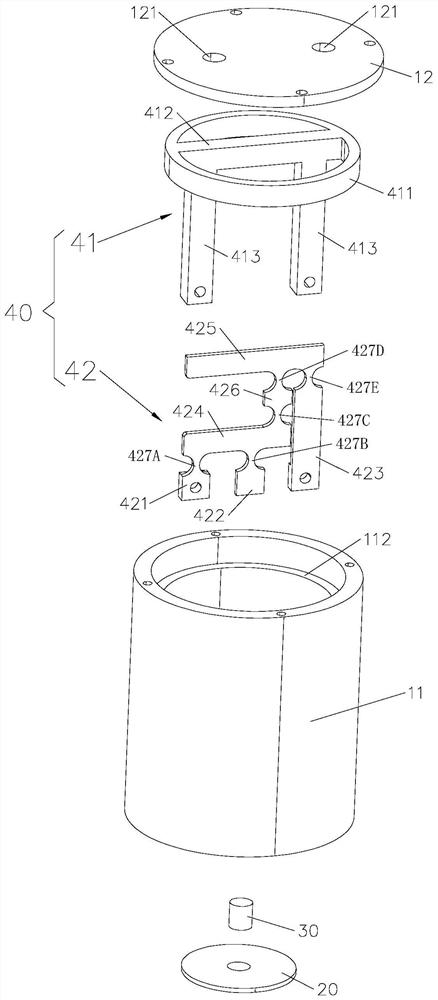

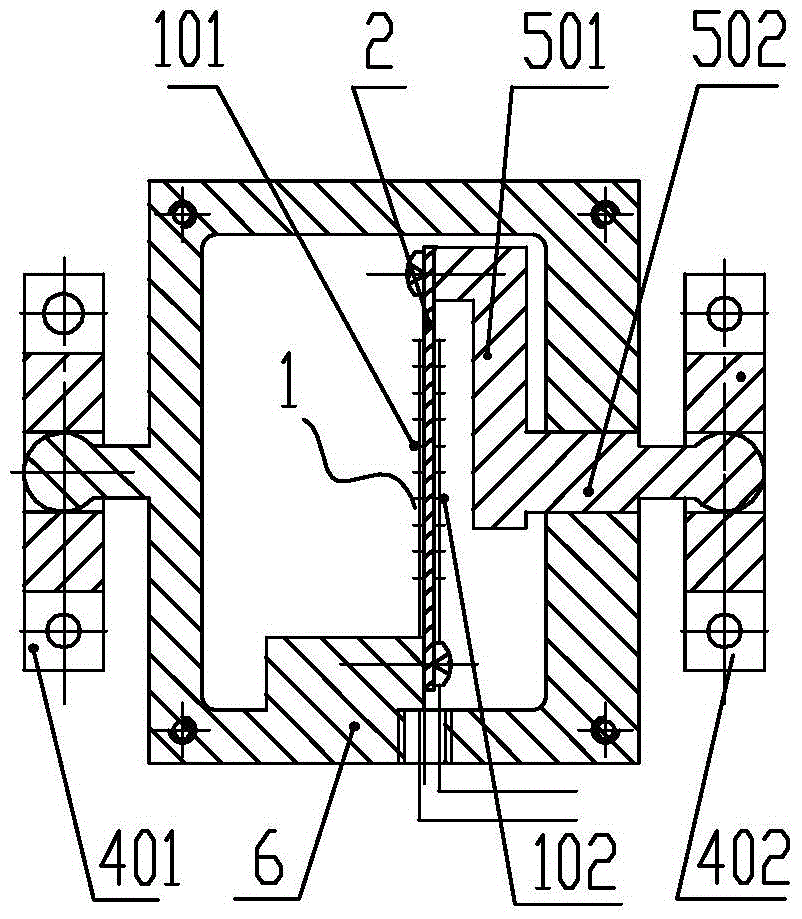

FBG pressure sensor based on diaphragm and flexible hinge lever mechanism

ActiveCN113280957AAchieving temperature self-compensationAchieve pressure sensitizationForce measurement by measuring optical property variationThermometers using physical/chemical changesEngineeringStress sensors

The invention discloses an FBG pressure sensor based on a diaphragm and a flexible hinge lever mechanism. The sensor comprises a shell assembly, a diaphragm, a dowel bar, a lever mechanism, a pressure measuring fiber bragg grating and a temperature measuring fiber bragg grating, wherein the shell assemblyis provided with two optical fiber outlets at the top and a pressure measuring channel at the bottom; the diaphragm is arranged in the pressure measuring channel; the dowel bar is positioned above the diaphragm and is connected with the middle part of the diaphragm; the lever mechanism is arranged in the inner cavity of the shell assembly and comprises a supporting frame and a flexible hinge lever arranged on the supporting frame, and the flexible hinge lever is located above the dowel bar; the pressure measuring fiber bragg grating and the temperature measuring fiber bragg grating are arranged on the flexible hinge lever and are arranged at intervals, and tail fibers of the pressure measuring fiber bragg grating and the temperature measuring fiber bragg grating penetrate through the fiber outlets respectively. Through the above structure, pressure sensitization can be realized, temperature self-compensation can be carried out, and the measurement precision and sensitivity are improved.

Owner:中山市精量光电子科技有限公司

A fbg pressure sensor based on diaphragm and flexible hinge lever mechanism

ActiveCN113280957BAchieving temperature self-compensationAccurate pressureForce measurement by measuring optical property variationThermometers using physical/chemical changesFiberEngineering

The invention discloses a FBG pressure sensor based on a diaphragm and a flexible hinge lever mechanism, which comprises: a casing assembly, which has two optical fiber outlets at the top and a pressure measurement channel at the bottom; the diaphragm is arranged in the pressure measurement channel; The force rod is located above the diaphragm and is connected to the middle of the diaphragm; the lever mechanism is located in the inner cavity of the housing assembly, including a support frame and a flexible hinge lever arranged on the support frame, and the flexible hinge lever is located on the force transmission rod. Above; the pressure measuring fiber grating and the temperature measuring fiber grating are arranged on the flexible hinge lever and arranged at intervals, and the pigtails of the pressure measuring fiber grating and the temperature measuring fiber grating are respectively passed through an optical fiber outlet. Through the above structure, pressure sensitization can be achieved, and temperature self-compensation can be performed, thereby improving measurement accuracy and sensitivity.

Owner:中山市精量光电子科技有限公司

A kind of temperature self-compensating fiber grating micro-force sensor and preparation method thereof

ActiveCN106525299BImprove long-term reliabilityImprove long-term stabilityForce measurement by measuring optical property variationFluid pressure measurement by optical meansFiberGrating

The invention discloses a temperature self-compensating fiber grating micro force sensor and a manufacturing method thereof. The sensor comprises a force-bearing end cover, a sensor upper shell, a sensor lower shell, a hard core, a supporting cylinder and a round elastic diaphragm, wherein the hard core comprises a hard core screw and a hard core nut; the top part of the supporting cylinder passes through the sensor upper shell, and the bottom part is fixed with the hard core screw; the supporting cylinder is internally provided with a fiber, a first fiber grating and a second fiber grating are carved on the fiber, one end of the first fiber grating is fixedly connected with the top part of the upper shell and the other end is fixed with the hard core screw and is in a tensioning state, and one end of the second fiber grating is connected with the lower part of the hard core screw and the other end passes through the sensor lower shell and is in a free elastic state. The structure is simple; the force measurement sensitivity and the force measurement range of the sensor can be changed in a large range, production and manufacturing of batch sensors with multiple specifications are facilitated; temperature self compensating can be realized; and long-term and reliable effective monitoring by the sensor in a temperature-varying environment can be realized.

Owner:WUHAN UNIV OF TECH

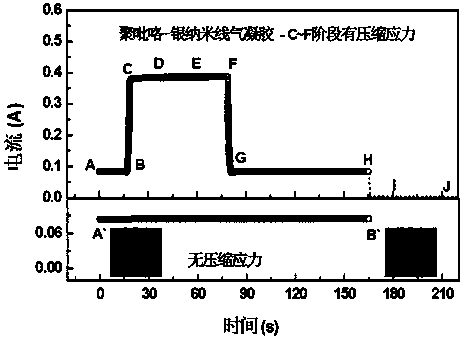

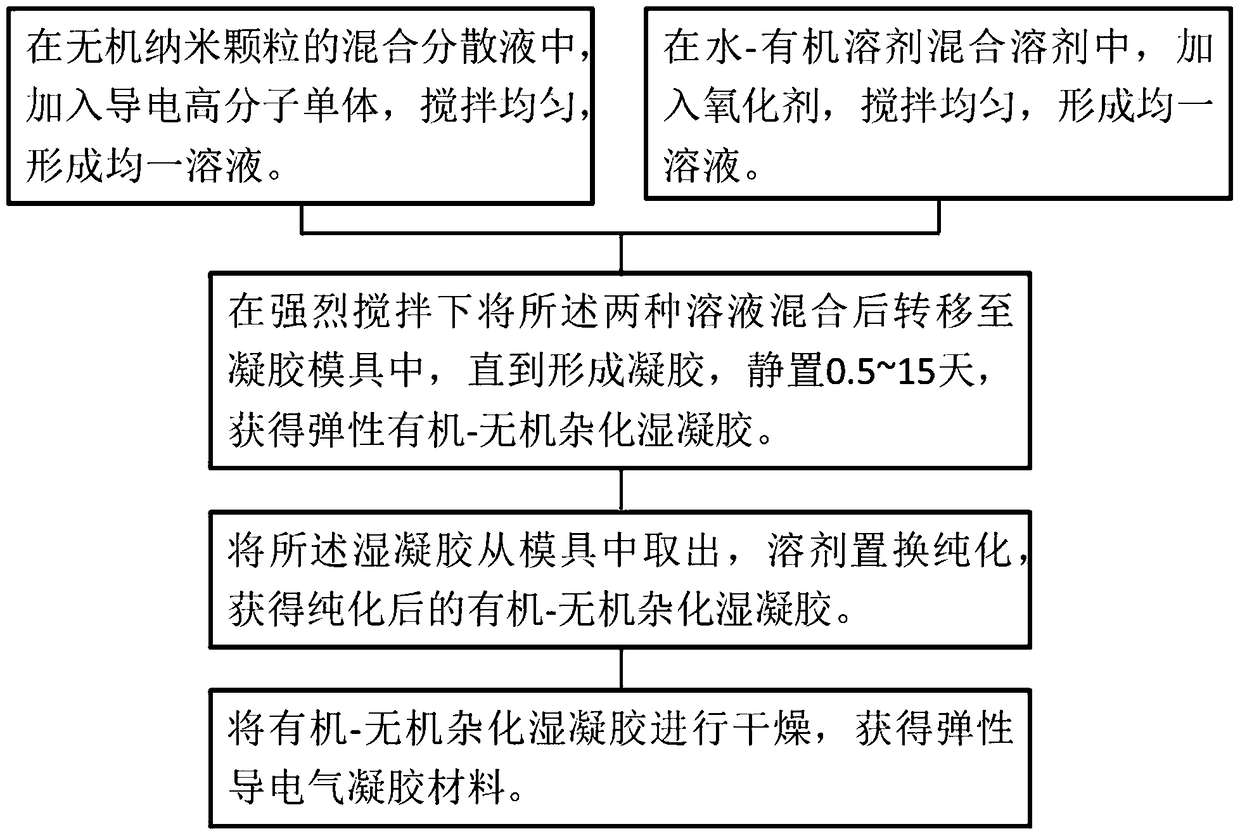

Elastic conductive organic-inorganic hybrid airgel and its preparation method and application

The invention discloses an elastic conductive organic-inorganic hybrid airgel, a preparation method and application thereof. The airgel comprises a continuous three-dimensional network structure, the continuous three-dimensional network structure is mainly formed by the interconnection of the core-shell basic skeleton composed of a primary network and a conformal covering layer, and the primary network is mainly composed of a suspension of low-dimensional inorganic nanoparticles The conformal covering layer is mainly formed by in-situ polymerization of intrinsically conductive polymers. The airgel has good structure and performance controllability, the maximum compression ratio can reach 95%, and it will return to its original shape within 10s to 5 minutes after compression. The electrical conductivity is 0.001 to 1000S / m, and the electrical conductivity increases with the compression It can be widely used in the fields of temperature self-compensating stress sensing, intelligent heaters, etc., and the airgel preparation process of the present invention is simple and easy to operate, has high controllability, and is suitable for large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Integrated temperature self-compensation fiber grating strain sensor and its method for monitoring cable force

ActiveCN103791850BWith temperature self-compensation functionHigh sensitivityForce measurement by measuring optical property variationUsing optical meansFiberGrating

A temperature-self-compensating fiber-integrated bragg grating strain transducer comprises a fiber bragg grating transducer body composed of two bare fiber bragg gratings with the same model but different wave bands, an elastic sheet composed of high-elasticity metal thin sheets, clamping pieces, bases, a Z-shaped movable piece composed of L-shaped steel plates and a metal frame. The metal frame is provided with a frame shaft hole and a frame connecting shaft, and a connecting shaft of the Z-shaped movable piece penetrates through the frame shaft hole to be fixedly connected with the base II through the clamping piece II and can relatively move in the frame shaft hole. One end of the elastic sheet is fixedly connected with the L-shaped plates of the Z-shaped movable piece, and the other end of the elastic sheet is fixed on the metal frame. The frame connecting shaft is fixedly connected with the base I through the clamping piece I. A cantilever beam stress structure is formed by the frame, the Z-shaped movable piece, the elastic sheet, the bases and the clamping pieces. Under the working state, the two bases are fixed on the surface of a component to be tested in a bolting or welding mode, and when the component to be tested is strained, the bases and the Z-shaped movable piece are driven to drive the elastic sheet to deform, and then the fiber bragg gratings deform.

Owner:LIUZHOU OVM MASCH CO LTD

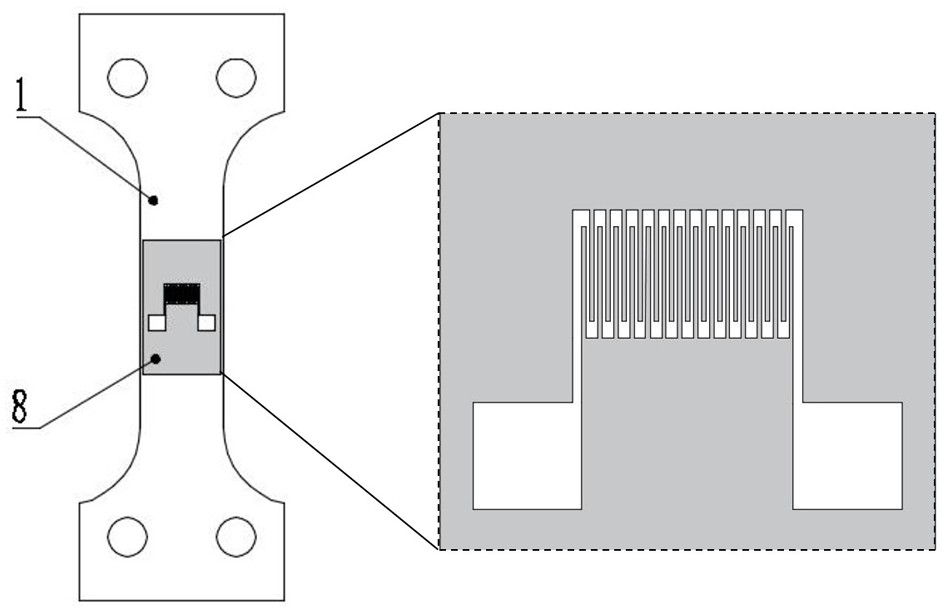

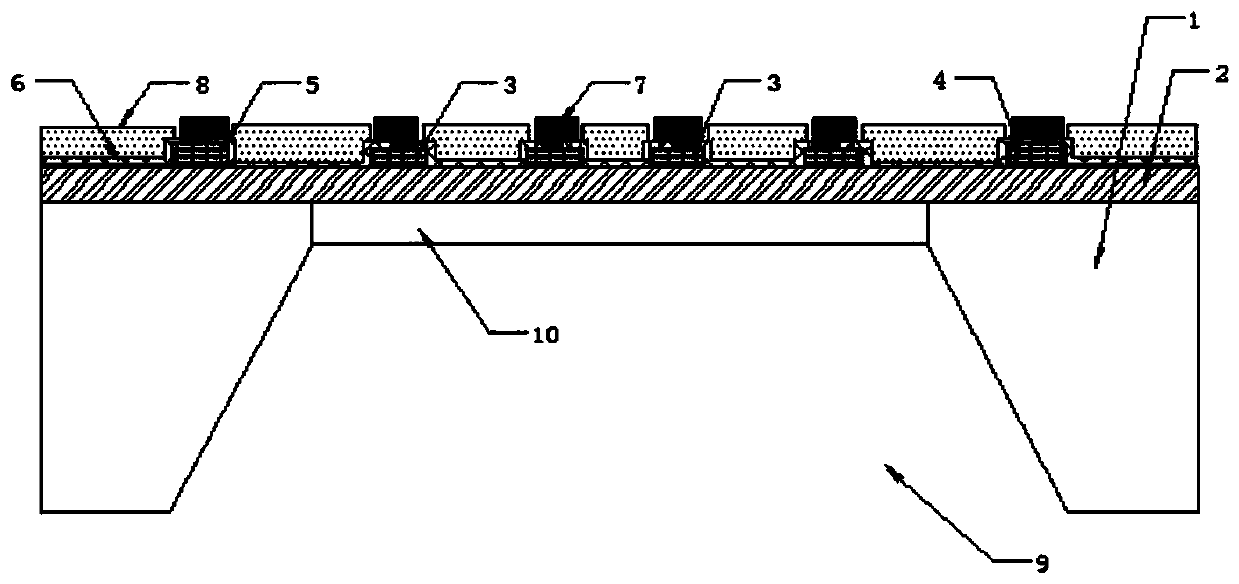

Load Cell Elements for Use in Wet Water Environments

ActiveCN112432720BAvoid errorsRelieve stressVacuum evaporation coatingForce measurementSS - Stainless steelAlloy

Owner:ZHEJIANG UNIV OF TECH

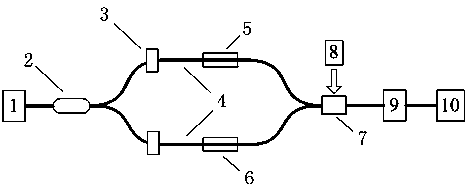

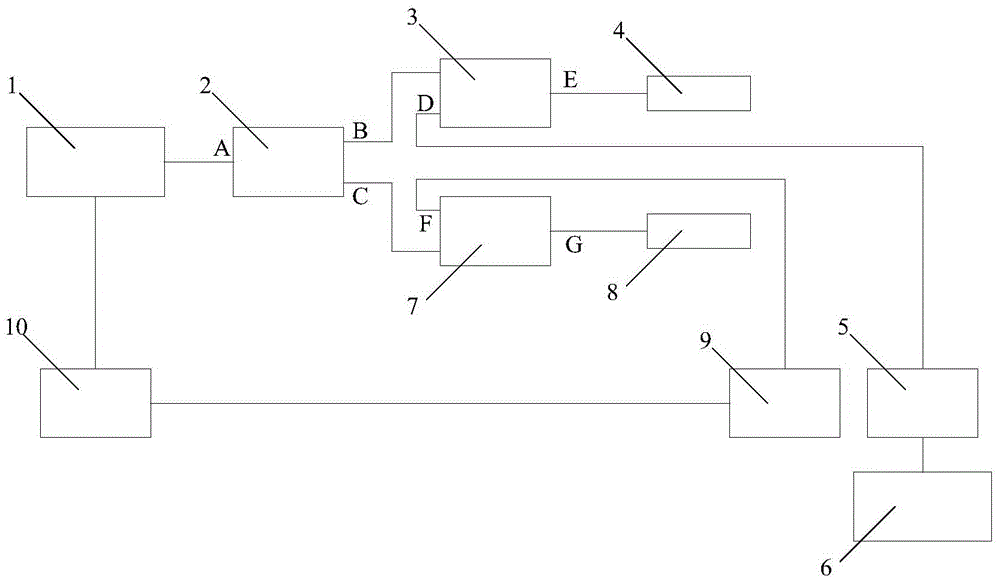

A temperature self-compensation method for a temperature self-compensation high-resolution high-frequency fiber grating demodulation system

The invention discloses a temperature self-compensation high-resolution high-frequency demodulation system and method for a fiber bragg grating. According the optical path transmission process, a tunable narrow-band laser device emits narrow-band light which is divided into two light beams through an optical fiber splitter, the two light beams are output through two output ports of the optical fiber splitter respectively, one light beam is transmitted to a sensing grating through the input end of a first optical fiber coupler and returns to the other input end of the first optical fiber coupler after passing through the sensing grating to be transmitted to a first photoelectric detector and be converted into a voltage signal, and then the voltage signal is transmitted to a data colleting and processing device; the other light beam is transmitted to a temperature compensation grating through a second optical fiber coupler and returns to the other input end of the second optical fiber coupler after passing through the temperature compensation grating to be transmitted to a second photoelectric detector and be converted into a voltage signal, and then temperature compensation is performed on the voltage signal through a temperature self-compensation device, so that the variable quantity of the output center wavelength of the tunable narrow-band laser device is obtained. The temperature self-compensation high-resolution high-frequency demodulation system and method have the advantages that temperature self-compensation is achieved, and the resolution is high.

Owner:SHANDONG UNIV +1

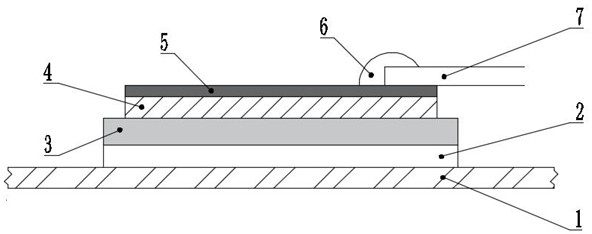

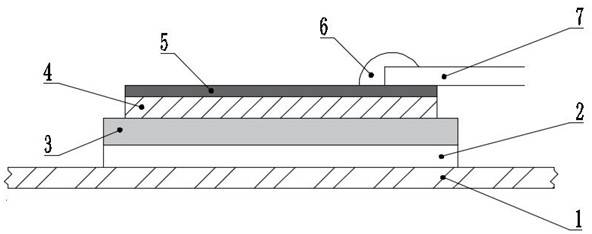

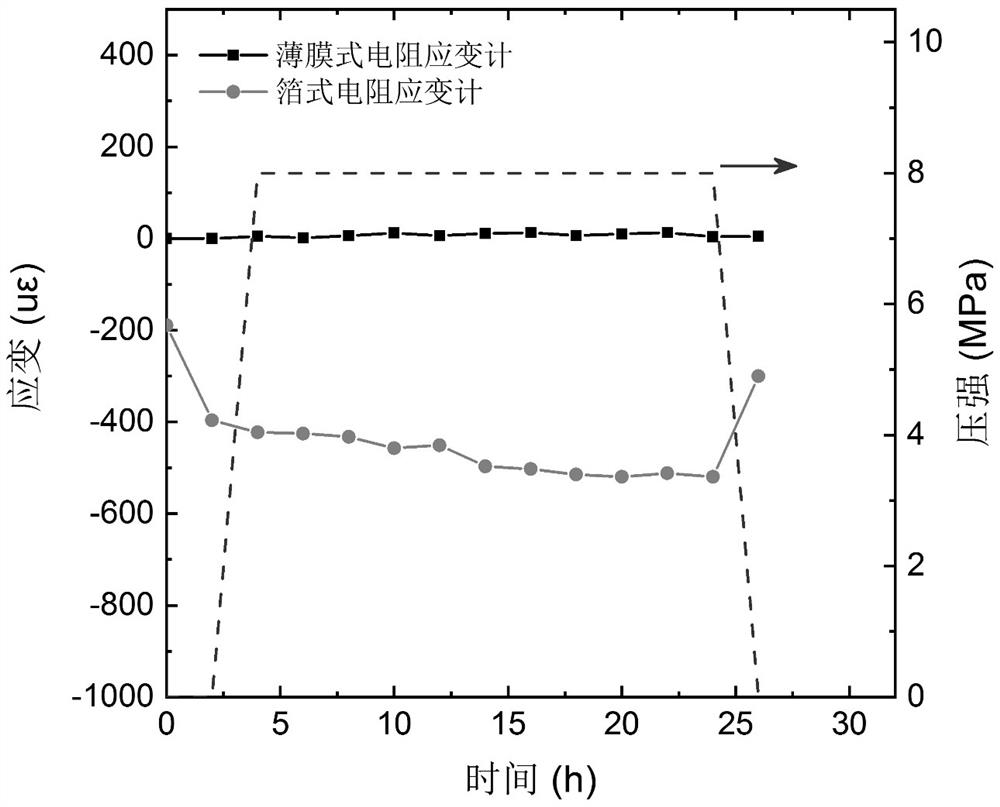

Film type resistance strain gauge used in high-pressure hydrogen sulfide environment

PendingCN112525062AAvoid errorsRelieve stressForce measurementVacuum evaporation coatingTest sampleThin membrane

The invention discloses a film type resistance strain gauge used in a high-pressure hydrogen sulfide environment. The film type resistance strain gauge comprises a substrate, a transition buffer layerarranged on the upper surface of the substrate, an insulating layer arranged on the upper surface of the transition buffer layer, a functional layer arranged on the upper surface of the insulating layer, and a protective layer arranged on the upper surface of the functional layer, wherein the substrate is made of a 316L stainless steel material, the transition buffer layer is a Cr film, the insulating layer is an AlN film, the functional layer is a FeNi alloy film, and the protective layer is a CrOx film. In a high-pressure hydrogen sulfide environment, the film type resistance strain gauge can be firmly fixed on a test sample, and the connection between the film type resistance strain gauge and the test sample is inorganic so that zero drift and creep deformation are eliminated, temperature self-compensation is realized, and the sensitivity of the film type resistance strain gauge and the accuracy of a measurement result are improved.

Owner:ZHEJIANG UNIV OF TECH

Temperature drift self-compensating SOI pressure sensor

ActiveCN111076856AAchieving temperature self-compensationImprove stabilityFluid pressure measurement by electric/magnetic elementsElectrical connectionEngineering

The invention relates to a temperature drift self-compensating SOI pressure sensor. The sensor comprises an SOI substrate, the SOI substrate is provided with a bridge circuit resistor used for being configured into a Wheatstone bridge, a surface, corresponding to the bridge circuit resistor, of the SOI substrate is provided with a compensation resistor used for conducting temperature compensationon the Wheatstone bridge, and the compensation resistor and the bridge circuit resistor are provided with interconnection leads which are electrically connected. The bridge circuit resistor and the compensation resistor are isolated through an insulation isolation layer and a passivation layer, the insulation isolation layer covers the SOI substrate, and the passivation layer covers the insulationisolation layer. The SOI substrate corresponding to the other side of the bridge circuit resistor is etched to form a pressure cavity and a pressure sensitive film, wherein the pressure cavity and the pressure sensitive film are located right below the bridge circuit resistor. The sensor is compact in structure, capable of achieving temperature drift self-compensation and reducing cost, high in stability, good in consistency, suitable for batch production, wide in application range, safe and reliable.

Owner:无锡芯感智半导体有限公司

Optical fiber grating liquid level sensor and its preparation method

ActiveCN102865900BWorking frequency bandwidthLarge dynamic rangeLevel indicators by pressure measurementFiberGrating

The invention discloses an FBG (Fiber Bragg Grating) liquid level sensor and a preparation method thereof. The sensor comprises a metal base, pressure sensing membranes, two metal capillary tubes, optical fibers carved with two FBGs having different wavelengths, pins and a tail fiber sleeve, wherein the optical fibers penetrate into the two metal capillary tubes; an FBG is located in the first metal capillary tube; a sensing FBG is located between the two metal capillary tubes to form a structural unit; the pressure sensing membranes are fixed on the metal base, and an air cavity is formed between the pressure sensing membranes; the structural unit is located in the air cavity; the first metal capillary tube is located at the center of each pressure sensing membrane; the optical fibers are vertical to the plane where the pressure sensing membranes locate; the second tube capillary tube stretches out of the metal base and is positioned by the pins; and the tail fiber sleeve is fixed at the lower end of the metal base to be communicated with atmosphere. The metal capillary tubes are titanium tubes; and the metal base is made of stainless steel. The sensor can be applied to inflammable, explosive and strongly-corrosive liquid, and has the advantages of wide dynamic range, an FS with the precision of 0.5%, a linearity of 99.7%, electromagnetic interference resistance, easy reusability and the like.

Owner:WUHAN UNIV OF TECH

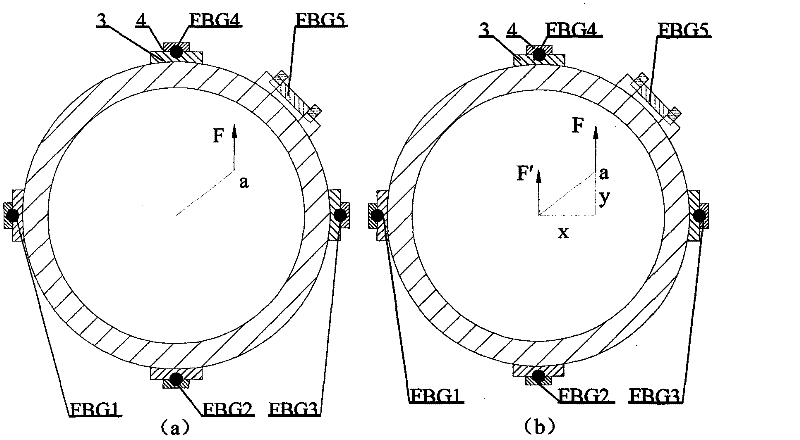

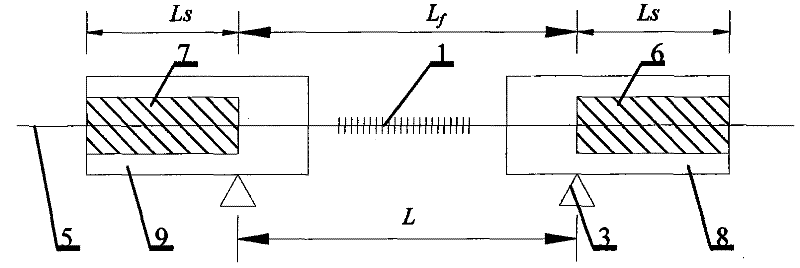

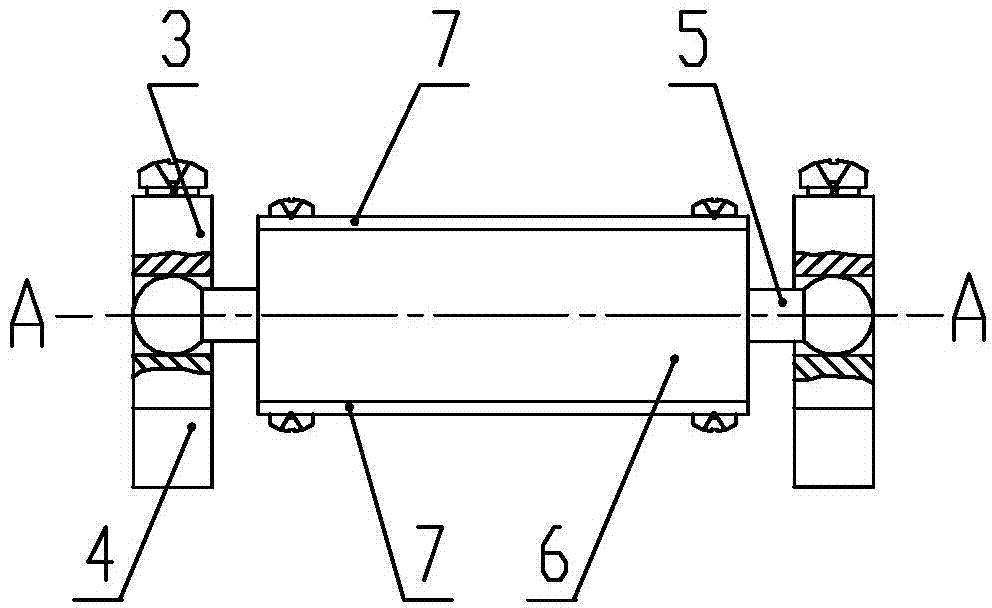

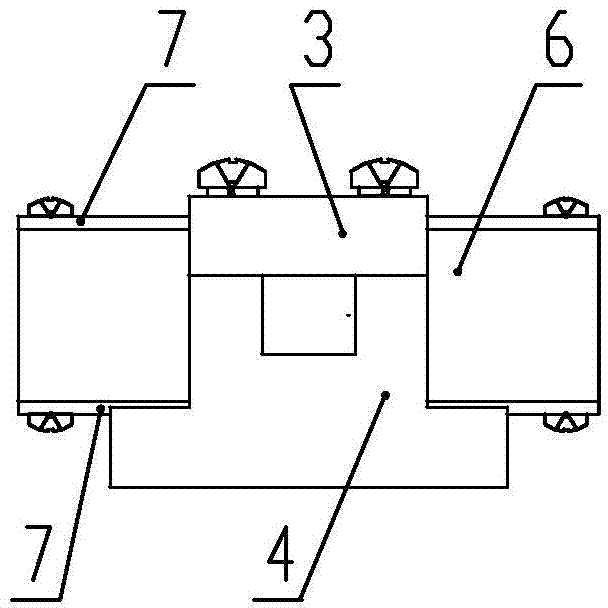

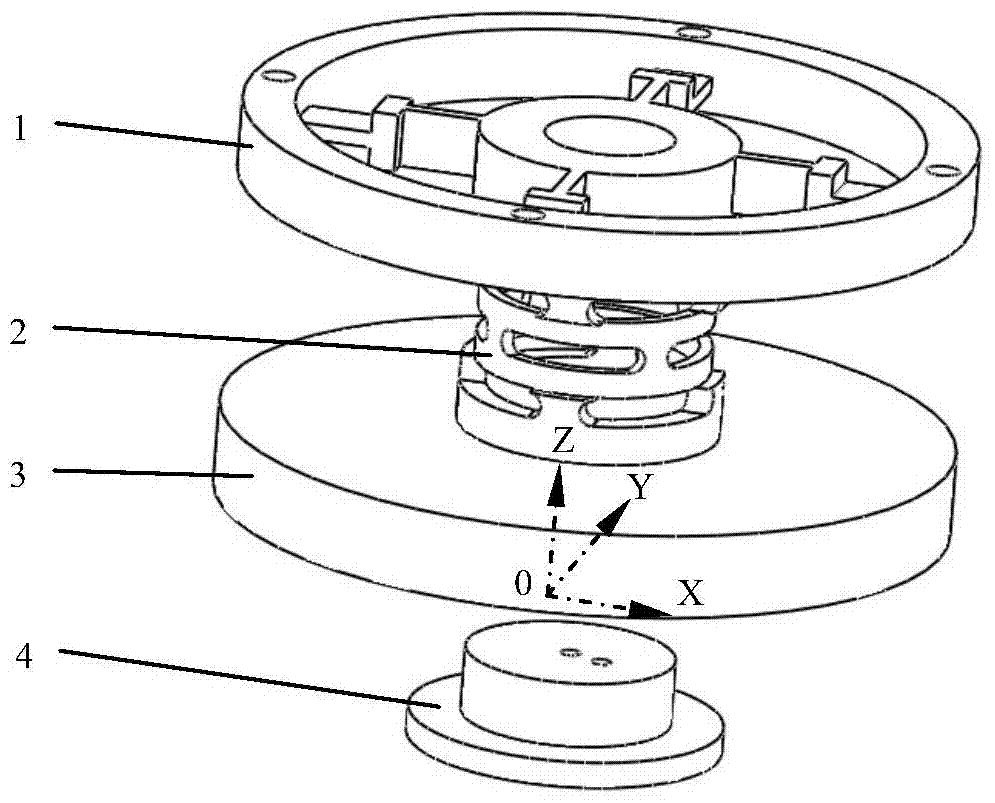

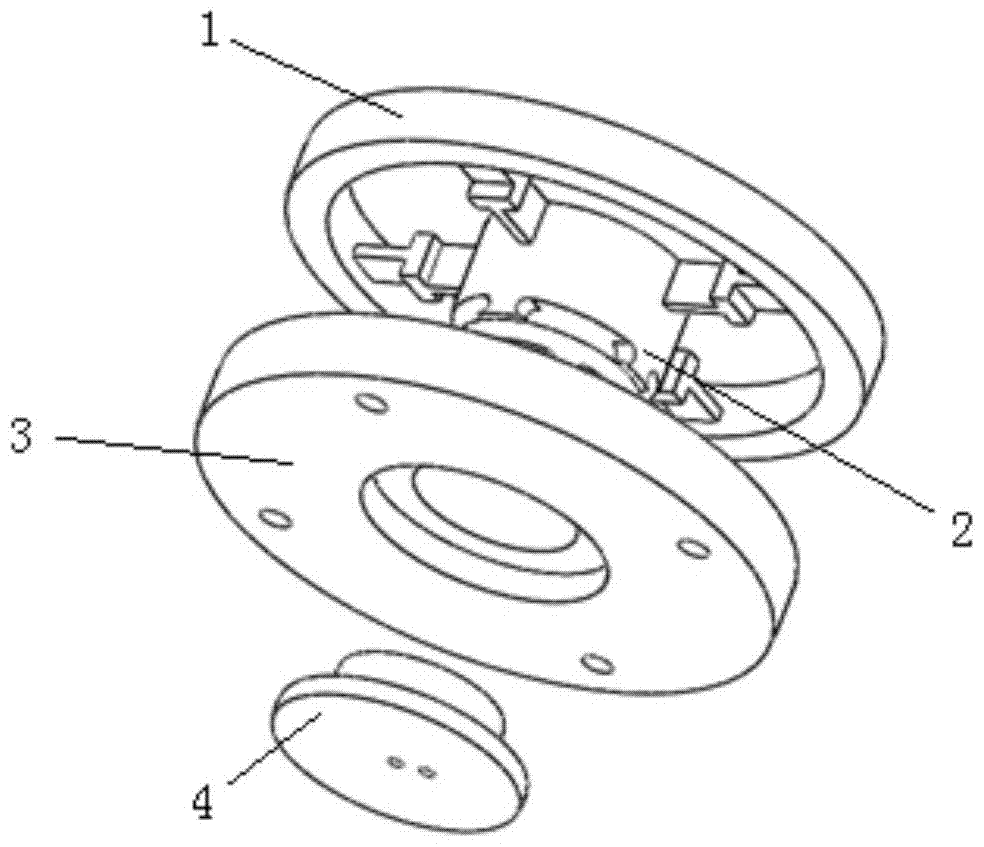

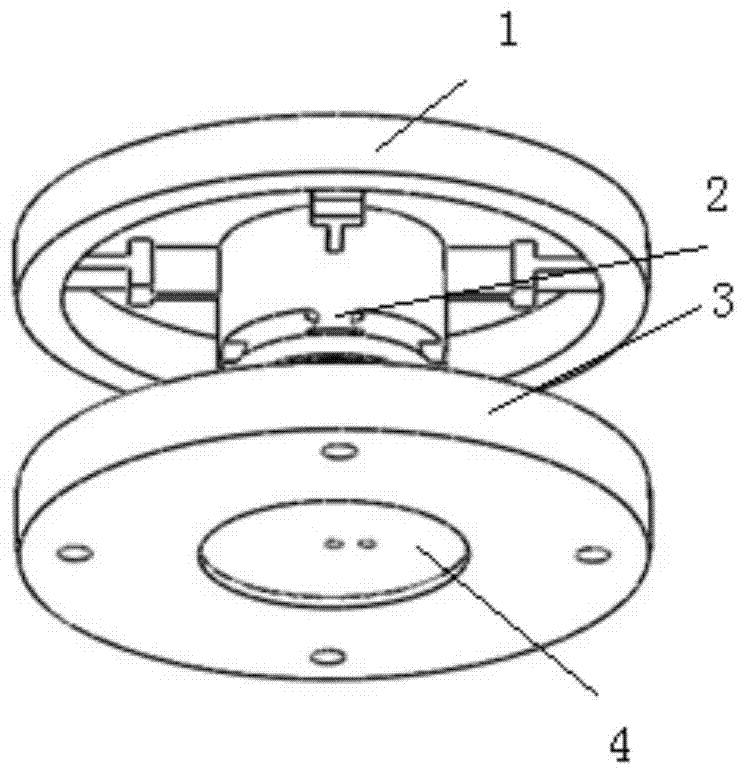

Fiber grating six-dimensional force sensor and its main structure and measurement method

ActiveCN105181193BThe main structure has good symmetryEasy to processForce measurement by measuring optical property variationFiberResistive sensors

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com