Strain sensor and application thereof

A technology of strain sensor and thin film resistor, which is applied in the field of sensors, can solve problems such as the measurement hysteresis of the adhesive sensor, the easy failure of the adhesive, and the impact on the concrete structure, so as to improve the service life and detection accuracy, and avoid the hysteresis of the test and the impact on the concrete structure. Effects of creep resistance, improvement of integration degree and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

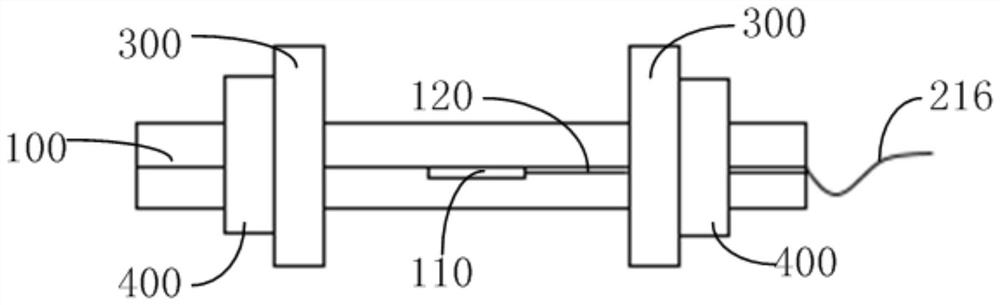

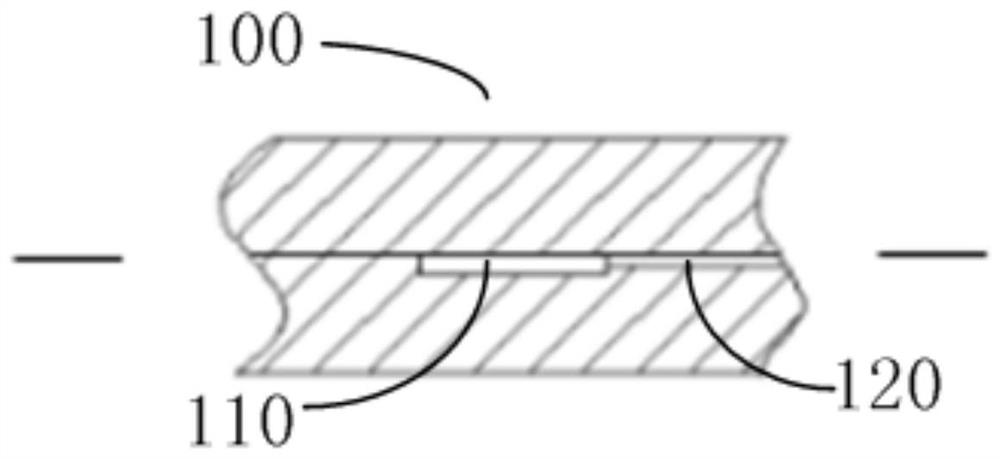

[0072] in such as Figure 1~4 In the specific example shown, the strain sensor provided by the present invention includes an elastic member 100 , a detection module 200 and a fixing member 300 for fixing the elastic member 100 . Such as image 3 and 4 As shown, the elastic member 100 is a cylindrical elastic rod made of two longitudinally cut semi-cylindrical nylon elastic struts bonded by epoxy resin adhesive at 170°C and 30 MPa, and the elastic member 100 can adapt to the interlayer strain of the asphalt pavement. And deformation. A first groove 111 and a second groove 121 communicating with the first groove 111 are provided on the semi-cylindrical surface of one of the elastic struts, so that the two elastic struts cooperate to form the installation cavity 110 and the wire passing hole 120 . One end of the second groove 121 is connected to the center of one side of the first groove 111 , and the other end of the second groove 121 extends to the end of the elastic member ...

Embodiment 2

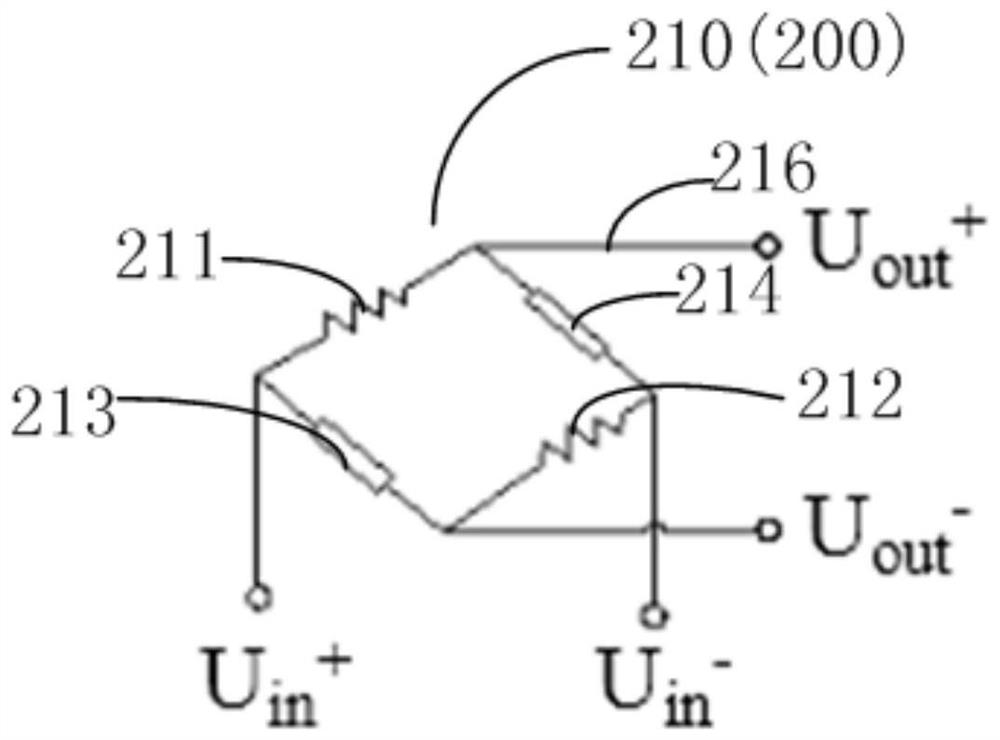

[0078] The structure of the strain sensor in this embodiment is substantially the same as that in Embodiment 1, except that the positions and structures of the first thin-film resistor 211 , the second thin-film resistor 212 , the third thin-film resistor 213 and the fourth thin-film resistor 214 are different. The specific structure is as follows:

[0079] refer to figure 2 , 3 , 5 and 6, it can be seen that the elastic member 100 is a cylindrical elastic rod made of two longitudinally cut semi-cylindrical nylon elastic struts bonded by epoxy resin adhesive at 170°C and 30MPa, and the elastic member 100 can be used along with the asphalt pavement Deformation due to interlayer strain. Wherein, the corresponding positions on the semi-cylindrical surfaces of the two elastic struts are provided with a first groove 111 and a second groove 121 communicating with the first groove 111, so that the two elastic struts cooperate to form a mounting cavity 110 and wire hole 120. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com