Load Cell Elements for Use in Wet Water Environments

A load sensor and water environment technology, applied in the field of sensors, can solve problems such as load sensor element drop, load sensor element lag, bubble cracks, etc., to improve sensitivity and accuracy of measurement results, avoid strain transmission errors and pressure Affect problems, eliminate the effects of zero drift and creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

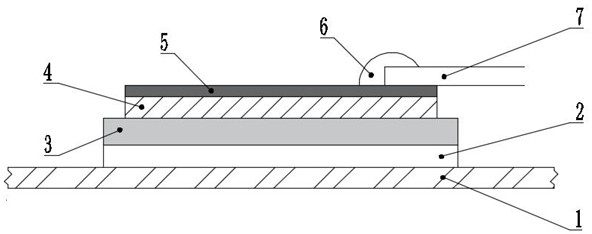

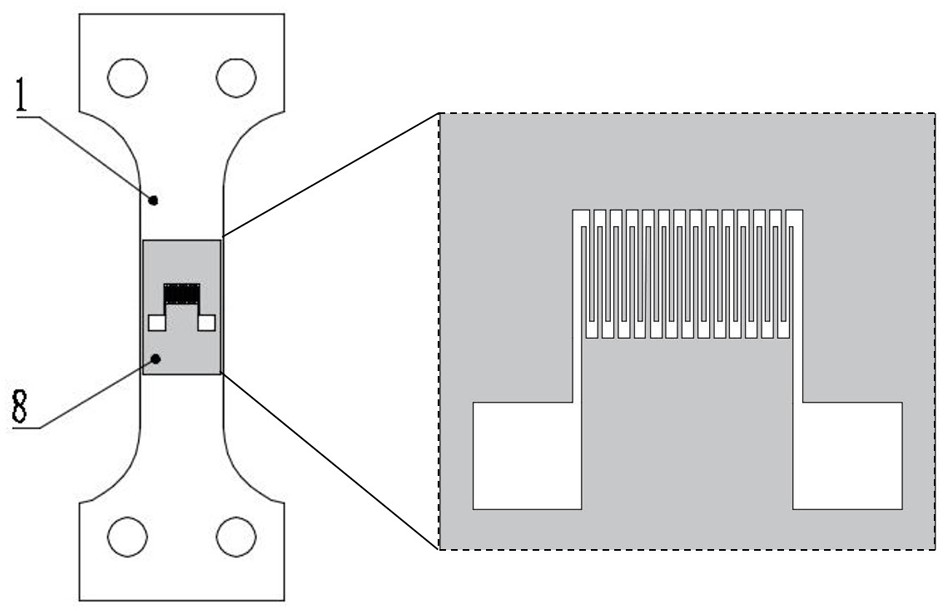

[0040] like figure 1 As well as figure 2 Show, a load sensor element for the humid water environment, including the base 1. The transition buffer layer on the surface of the base 2. The functional layer on the upper surface 4. The protective layer on the surface of the function layer 5; the base is made of 316L stainless steel material, the transition buffer layer is CRNI film, and the insulating layer is TIO TIO. 2 membrane. The functional layer is FeCRMN alloy film, and the protective layer is AL 2 O 3 membrane. Two lead 7 connect to the function layer through weld 6;

[0041] The preparation method of a load sensor element includes the following steps:

[0042] (3-1) Put the bases after pre-processing in the sputtering room of the magnetic sputter to fix and organize;

[0043] Use 400#, 600#, 800#, 1000#, 1500#, 2000#sandpaper to polish in order, and then use the 0.1 μm diamond spray polishing agent for mechanical polishing to make mark. The base with a smooth surface is placed...

Embodiment 2

[0058] The difference between this embodiment and Example 1 is:

[0059] The CRNI membrane is a transition buffer layer with a thickness of 500nm.

[0060] Pump the sputtering room to 5.0 × 10 -4 PA, the temperature of the substrate of the sample transfers to the substrate temperature of the sample to 300 ° C, adjust the partial pressure to 220 V, pass the sorbe to the splash room, control the gas flow of 50SCCM, increase the indoor air pressure in the splashing room, increase the indoor pressure To 2.0Pa, the voltage of the A target seat and B target seat rose to 310V for light discharge, so that the gas electrical ions were ionized, and the ion ions were bombarded with CR targets and NI targets, causing target sputtering; Adjust the indoor working air pressure to 0.6Pa for 15 minutes; after the sputtering process is stable, the voltage of the A target and B target seat stabilizes, and control the rotation speed of the sample transition to 5R / min, adjust the A target seat The vol...

Embodiment 3

[0063] The difference between this embodiment and Example 1 is:

[0064] TIO on the top of the CRNI film 2 The thickness of the membrane is 400nm, as TIO 2 Insulation;

[0065] Adjust the temperature controller of the spatter to make the substrate temperature of the sample rising to 400 ° C, and the oxygen flow is 10SCCM, so that AR: O 2 It is 0.2; turn on the radio frequency power supply, the air pressure in the splashing room during the sputtering process is 0.5Pa, the power of the C target seat during the sputtering process is 200W, and continuously splash 140min. 2 membrane;

[0066] The thickness of a splash grille -shaped FECRMN film on the cover table is 1000nm, as a functional layer;

[0067] The sputtering parameters in the process of sputtering FECRMN film are: Pump the sputtering room to be vacuum to 1.5 × 10 -4 PA, the temperature of the substrate is heated to 350 ° C, the plowing flow of 23SCCM, the air pressure in the sputtering room during the sputtering process is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com