Elastic conductive organic-inorganic hybrid airgel and its preparation method and application

An elastic conductive, hybrid gas technology, applied in conductive, organic-inorganic hybrid stress-sensing airgel materials and its preparation, and elastic fields, can solve the problems that conductive gels cannot be applied to stress sensing, etc., and achieve low cost , strong controllability, simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

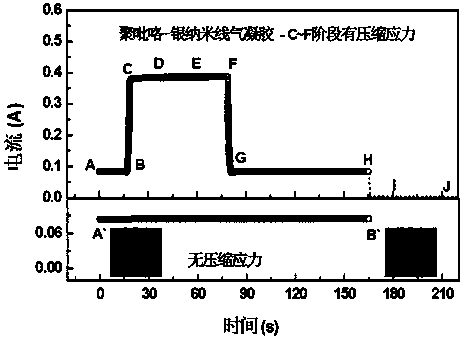

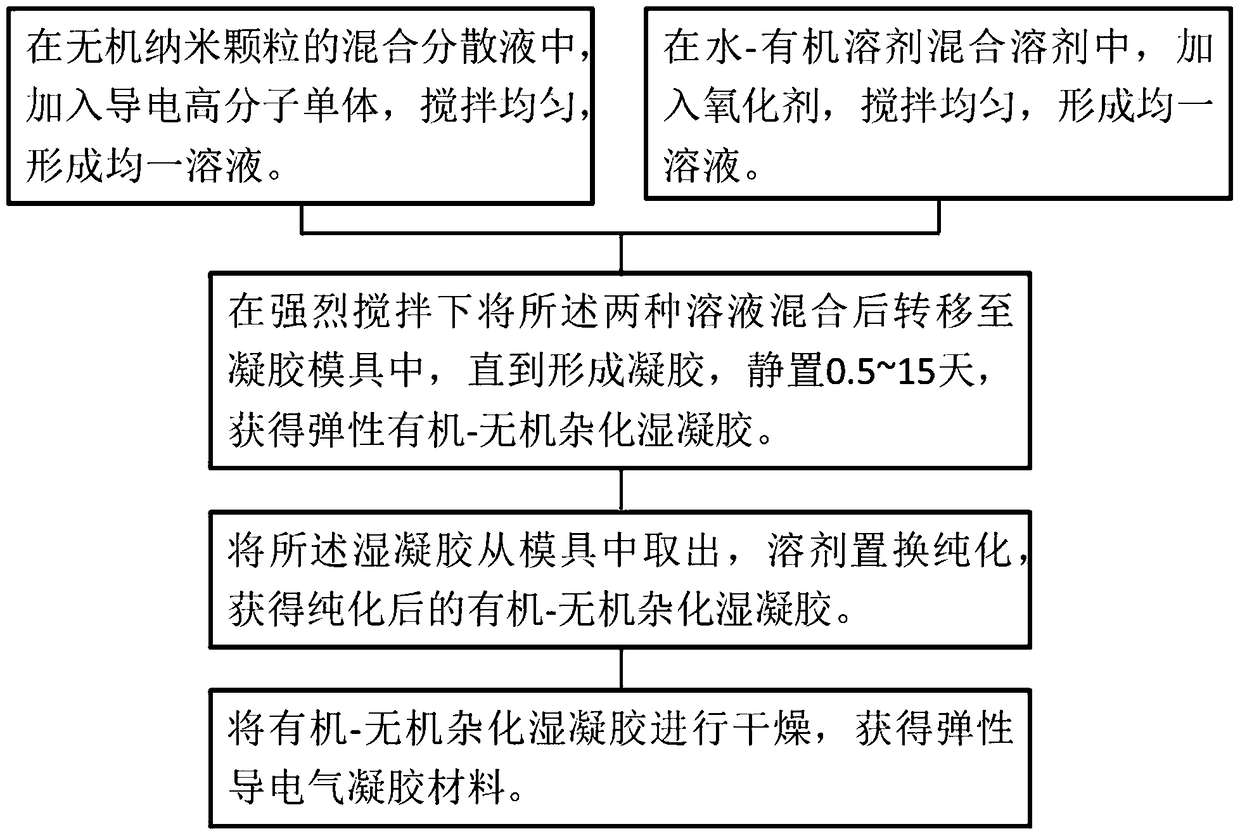

[0067] Still taking the preparation method of a kind of elastic, conductive, silver nanowire-polypyrrole hybrid airgel in the present invention as an example, refer to figure 1 , which may include the following steps:

[0068] a. Dissolving the intrinsically conductive polymer monomer in the mixed solvent dispersion formed by water and an organic solvent of the silver nanowire to form a polymer monomer solution;

[0069] Wherein, the organic solvent can be at least selected from ethanol, ethylene glycol, glycerol, acetone, methyl ethyl ketone, acetonitrile, tetrahydrofuran, N,N-dimethylformamide, N,N-dimethylacetamide Any of dimethyl sulfoxide, but not limited thereto. The volume ratio of water and organic solvent in the mixed solvent is preferably 1:10˜10:1.

[0070] b. dissolving the oxidizing agent in a mixed solvent composed of water and an organic solvent to form a homogeneous solution of the oxidizing agent;

[0071] Wherein, the oxidizing agent is preferably silver n...

Embodiment 1

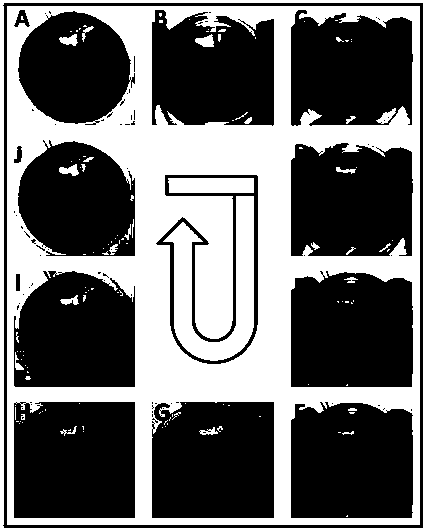

[0088] Example 1 Please see again figure 1 , add 2.24mmol, 155μL of pyrrole (Pyrrole) monomer to 1.5mL silver nanowire / water-ethanol (v / v 1:5) mixed solution with a concentration of 9.43mg / mL, mix well and place in an ice-water bath 30min. Microscopic morphology of silver nanowires Figure 2a-Figure 2b . At the same time, 2.24mmol, 0.381g silver nitrate (AgNO 3 ) was dissolved in 1.5mL water-ethanol (v / v 1:5) mixed solution, mixed well and placed in an ice-water bath for 30min. Under strong magnetic stirring, the silver nitrate solution was added to the pyrrole monomer solution, stirred evenly, transferred to a gel mold, and left to stand in an ice-water bath for about 2 hours to form a gel. Transfer it to a constant temperature water bath at 35°C and let it stand for 2 days. The obtained gel was taken out from the reaction vessel, and deionized water was added to the wet gel, and after soaking for 3 hours, the deionized water was poured out. After repeating 8 times, the ...

Embodiment 2

[0089] Example 2 see again figure 1 , add 1.34mmol, 93.07μL of pyrrole (Pyrrole) monomer to 2mL water-ethylene glycol (v / v 3:1) mixed solution with a concentration of 220mg / mL silver nanowires, mix well and place at 35°C 10min in a constant temperature water bath. At the same time, 0.67mmol, 0.114g silver nitrate (AgNO 3) was dissolved in 1mL of water-ethylene glycol (v / v 3:1) mixed solution, mixed well and then placed in a constant temperature water bath at 35°C for 10min. Under strong magnetic stirring, the silver nitrate solution was added to the pyrrole monomer solution, stirred evenly, then transferred to a gel mold, and left to stand in an ice-water bath for about 2 days to form a gel. Transfer it to a constant temperature water bath at 65°C and let it stand for 1 day. The obtained gel was taken out from the reaction vessel, and deionized water was added to the wet gel, and after soaking for 5 hours, the deionized water was poured out. After repeating 6 times, the dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com