Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Small residual strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

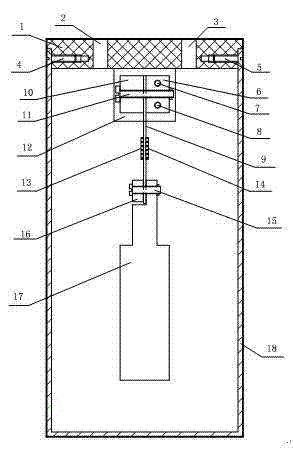

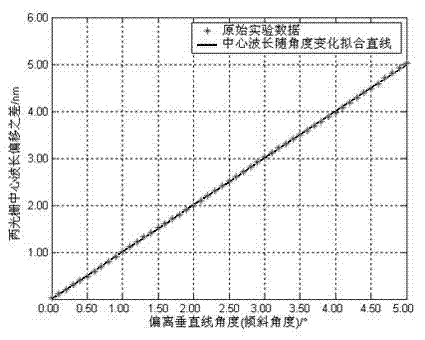

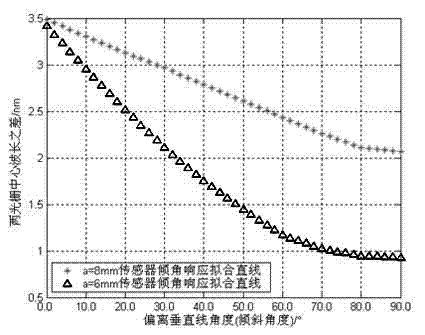

Inclination Sensor Based on Fiber Bragg Grating and Its Inclination Measurement Method

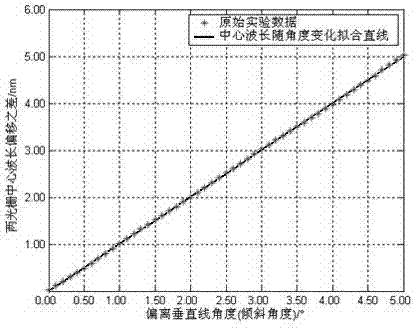

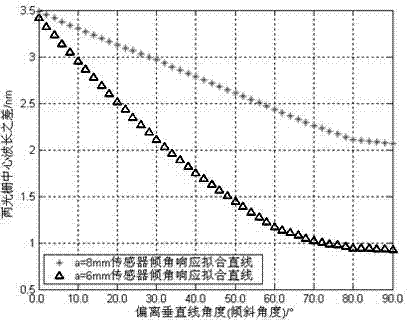

InactiveCN102288162AHigh measurement accuracyImprove machining accuracyIncline measurementGratingFiber Bragg grating

The invention relates to a tilt angle sensor based on optical fiber Bragg gratings and a method for measuring a tilt angle of the tilt angle sensor and belongs to the technical field of measurement of a structural tilt angle. The tilt angle sensor comprises a fixed base plate (12), a fixed pressing block (6), a thin-wall type uniform-section metal beam (9) and a quality block (7), wherein the upper end of the thin-wall type uniform-section metal beam (9) is arranged on the fixed base plate (12) in a mode of fitting with the fixed pressing block through a first movable pressing block (10) and a fifth screw (11); the quality block (7) is fixed at the lower end of the thin-wall type uniform-section metal beam (9) through a sixth screw (15) and a second movable pressing block (16); and a first optical fiber Bragg grating (13) and a second optical fiber Bragg grating (14) are respectively adhered to opposite positions on two sides of the thin-wall type uniform-section metal beam (9). By the method, the size and direction of the tilt angle can be detected according to a correspondence relation between the change of central wavelengths of the two optical fiber Bragg gratings and the tiltangle. The invention is high in measurement accuracy and has a temperature self-compensation function.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

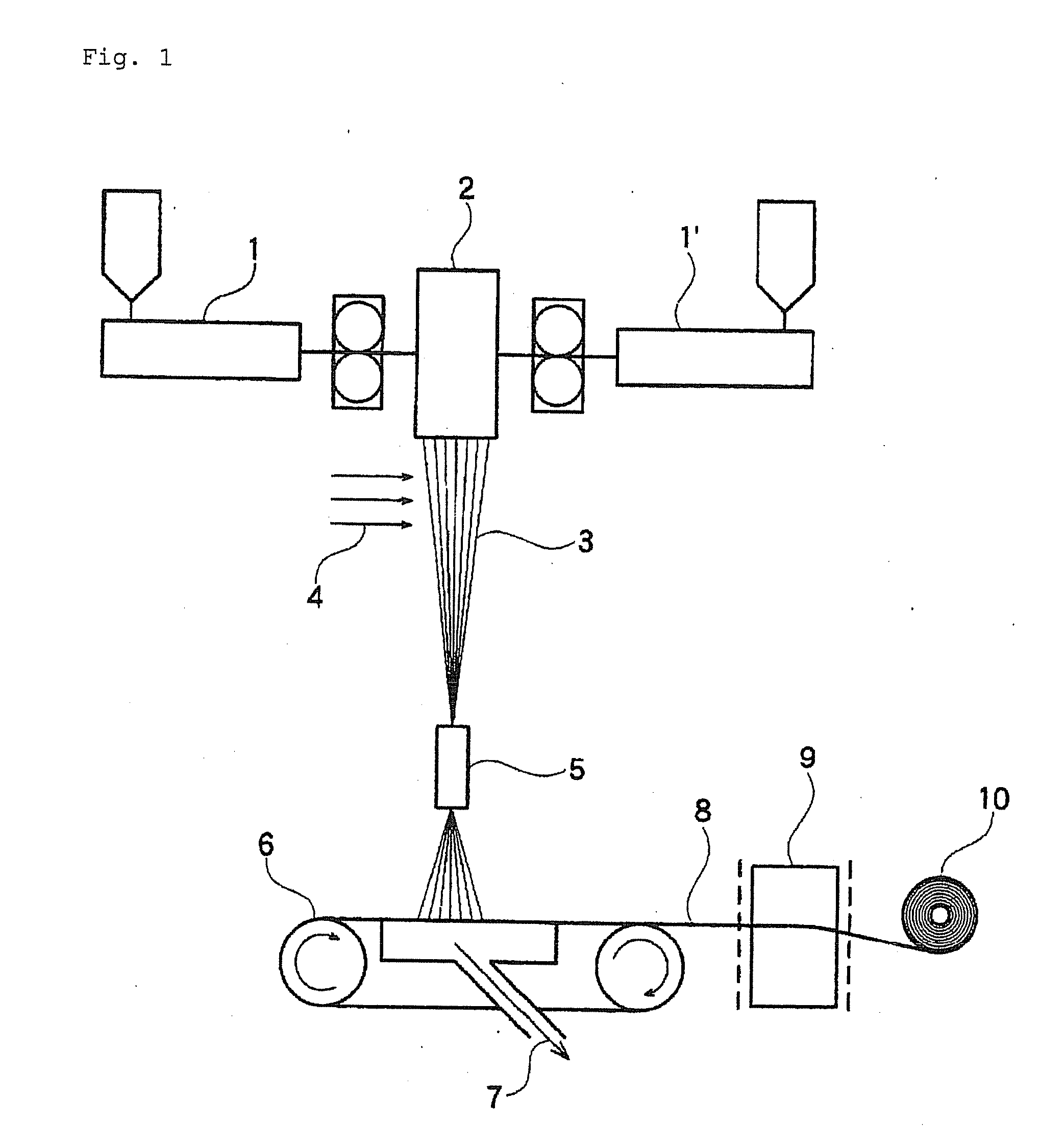

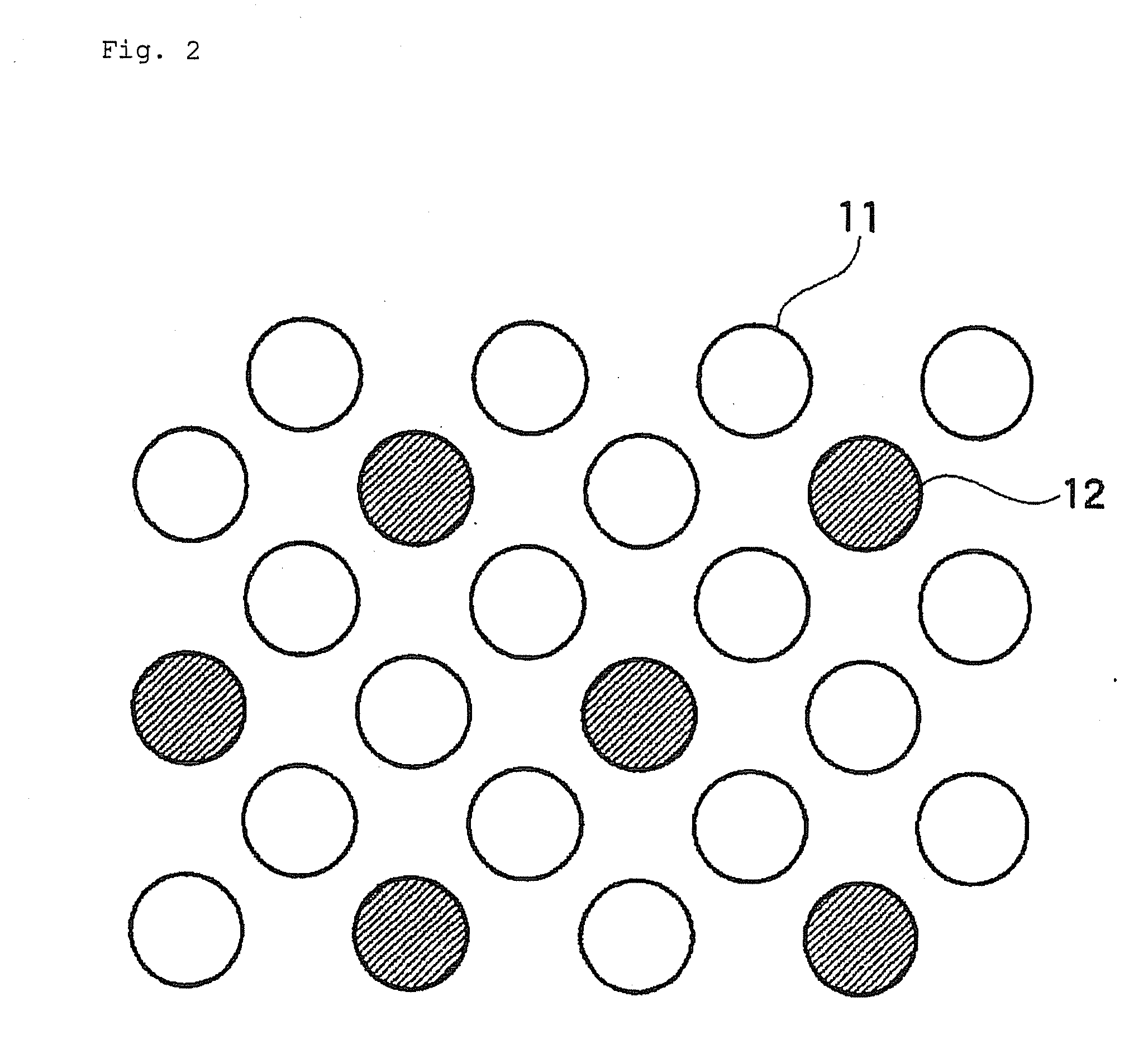

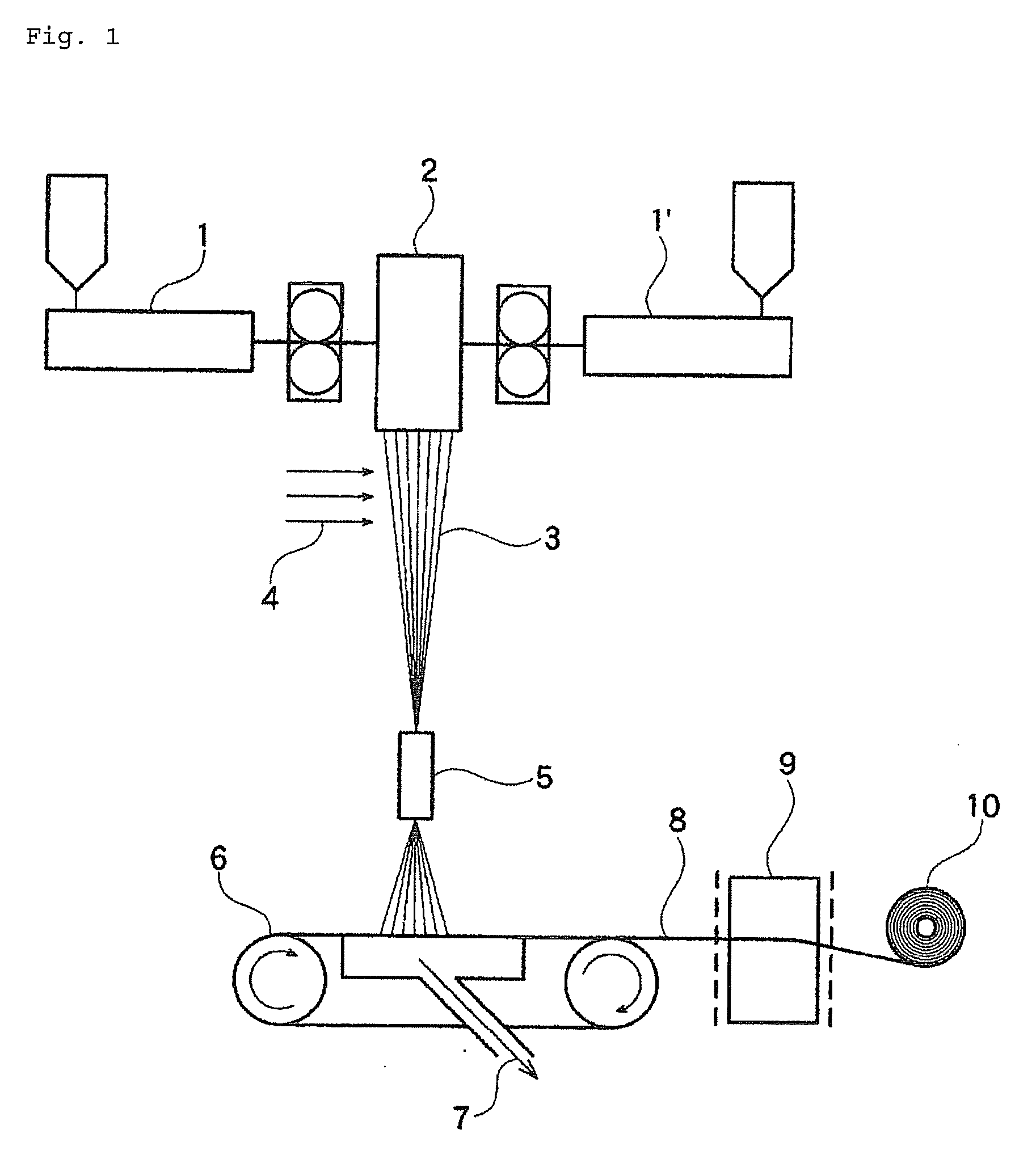

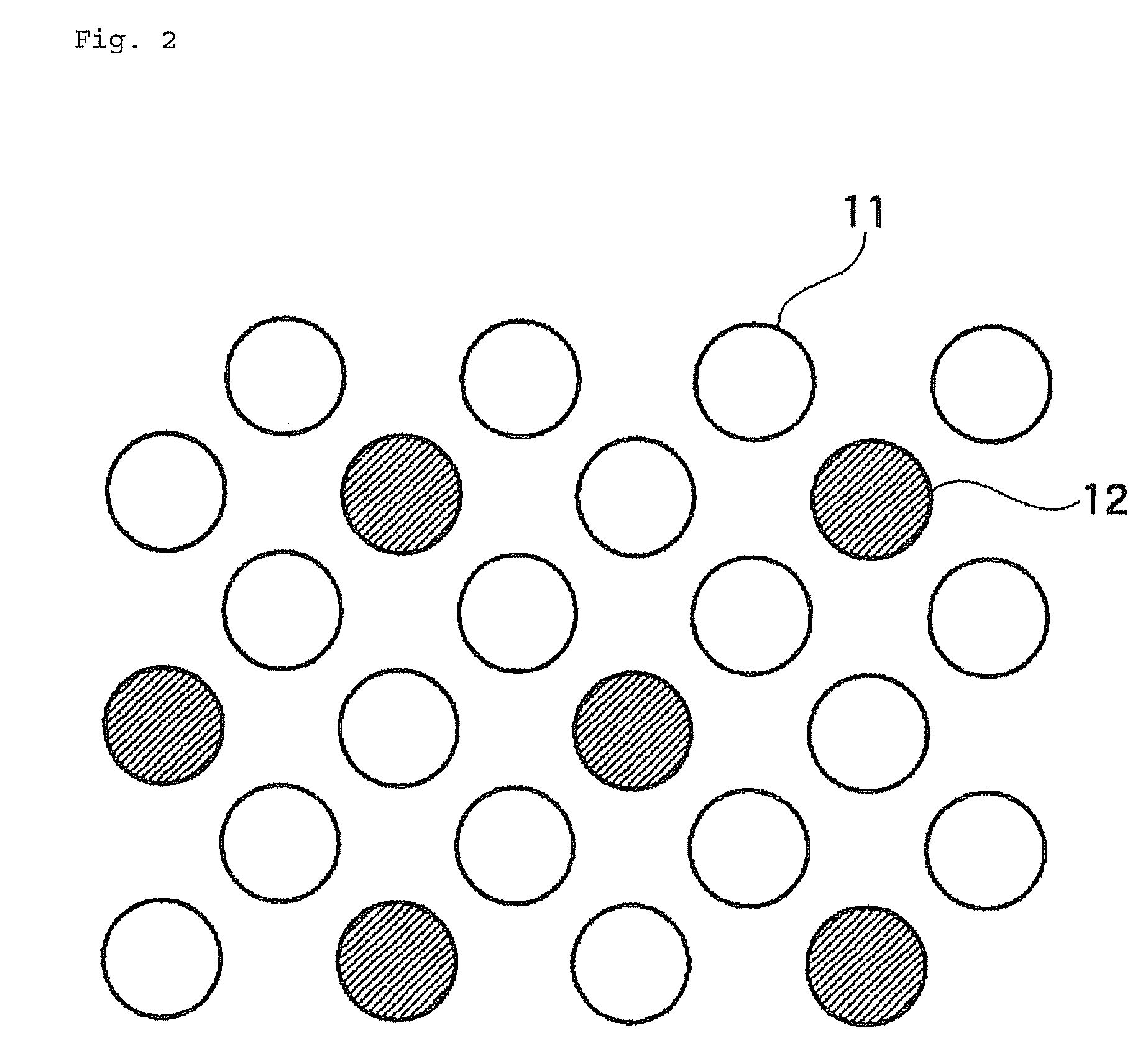

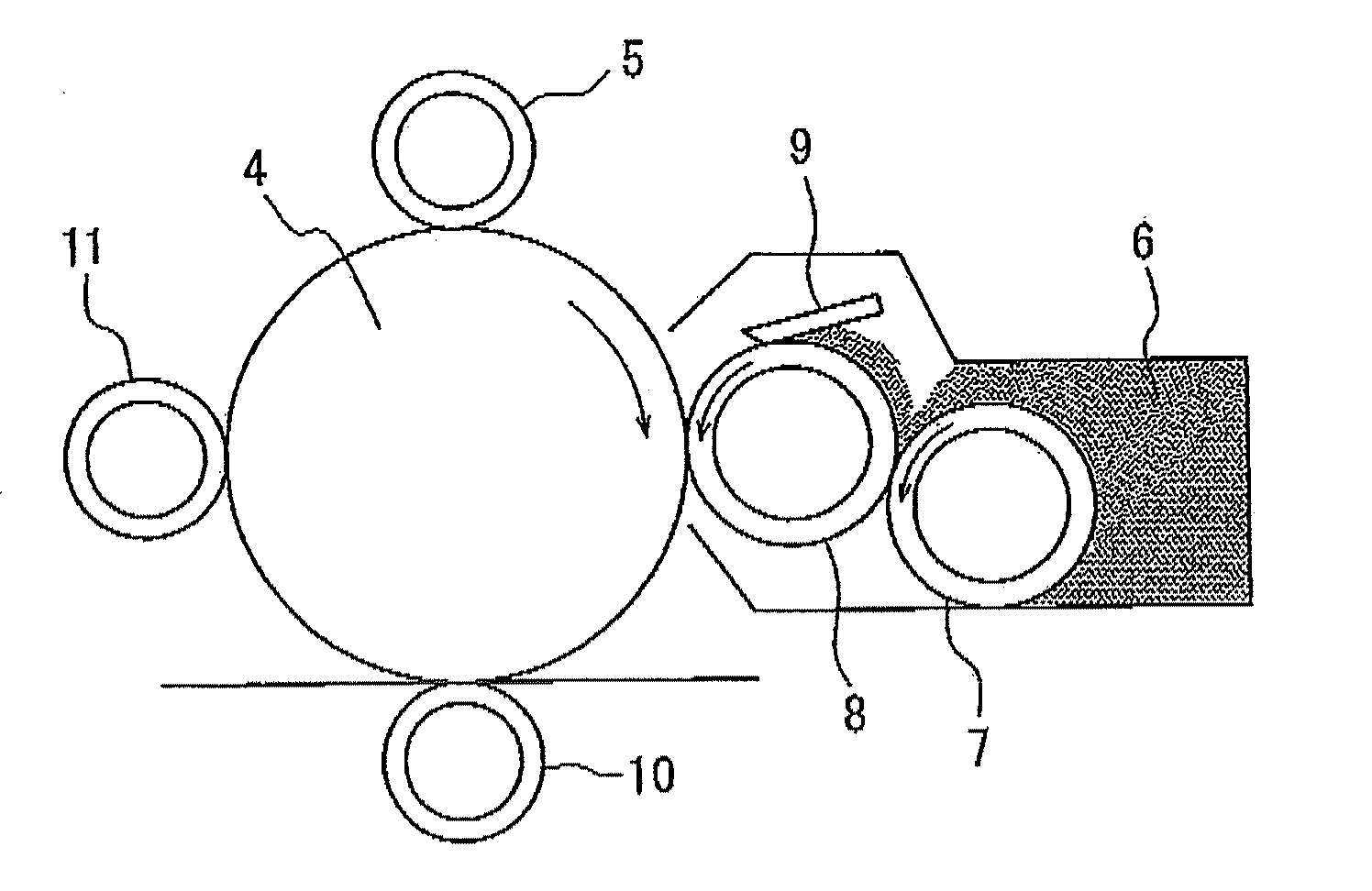

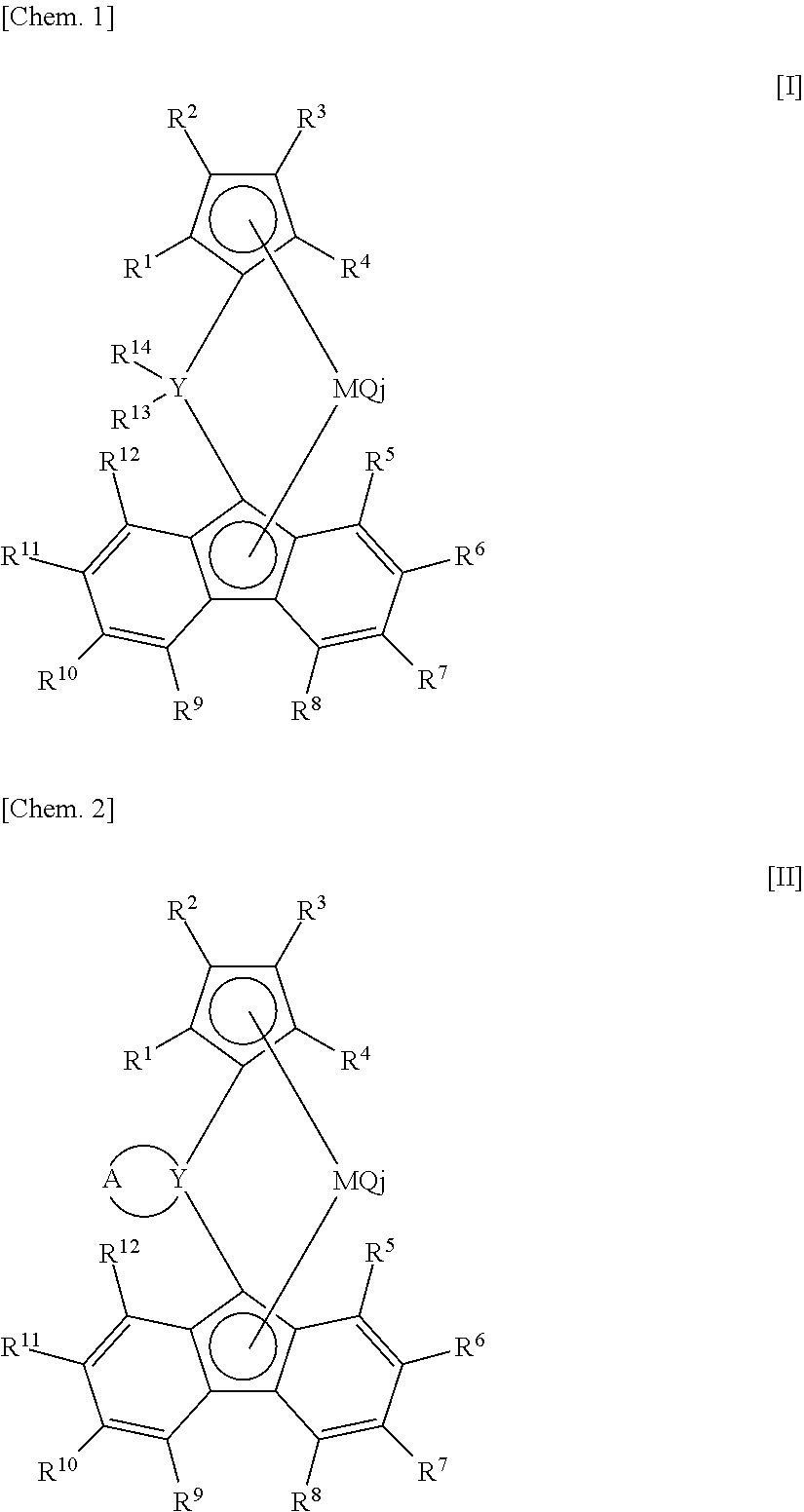

Polypropylene Nonwoven Fabric and Use Thereof

ActiveUS20080014819A1Excellent in appearance propertyExcellent in stretch propertyFilament/thread formingAdhesive dressingsResidual strainPolymer science

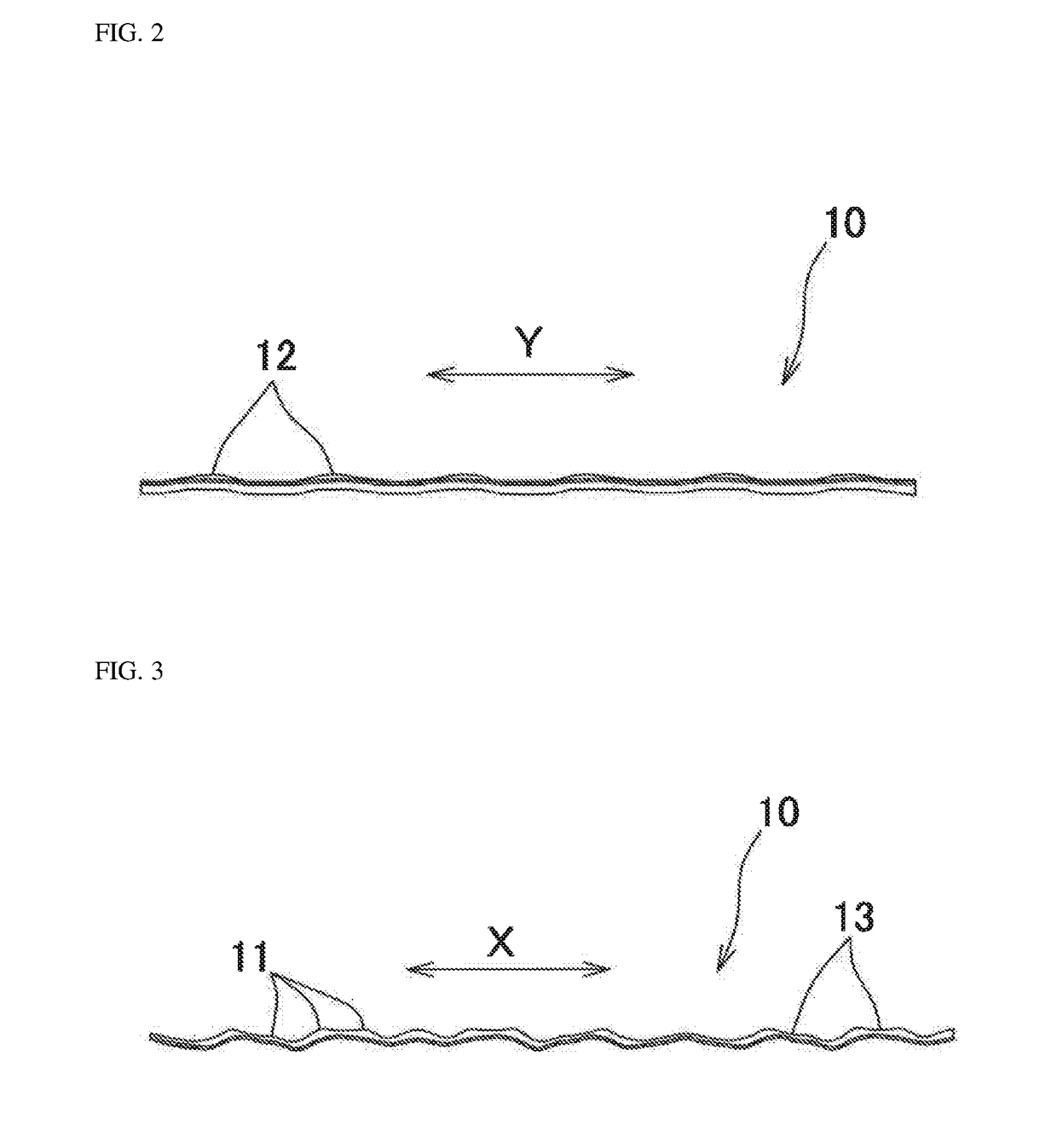

A polypropylene based nonwoven fabric is excellent in surface appearance and stretch properties and exhibits a small residual strain and excellent adhesiveness to polyolefins. The nonwoven fabric is obtained by forming a polypropylene resin composition comprising 1 to 40 weight parts of (i) an isotactic polypropylene, and 60 to 99 weight parts of (ii) a propylene / ethylene / α-olefin copolymer obtained by copolymerizing 45 to 89 mole % of propylene, 10 to 25 mole % of ethylene and the balance of α-olefin having 4 to 20 carbon atoms (with the proviso that the copolymerized amount of the α-olefin having 4 to 20 carbon atoms does not exceed 30 mole %), characterized by a small residual strain after stretching at a stretch ratio of 150%. The nonwoven fabric can be effectively used as sanitary materials or the like by virtue of its characteristics including stretch properties.

Owner:MITSUI CHEM INC

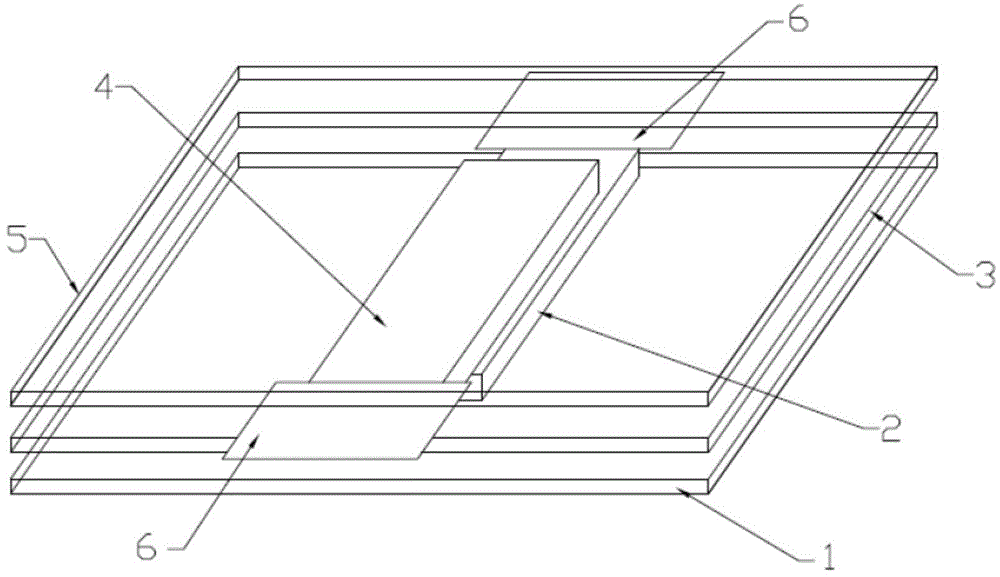

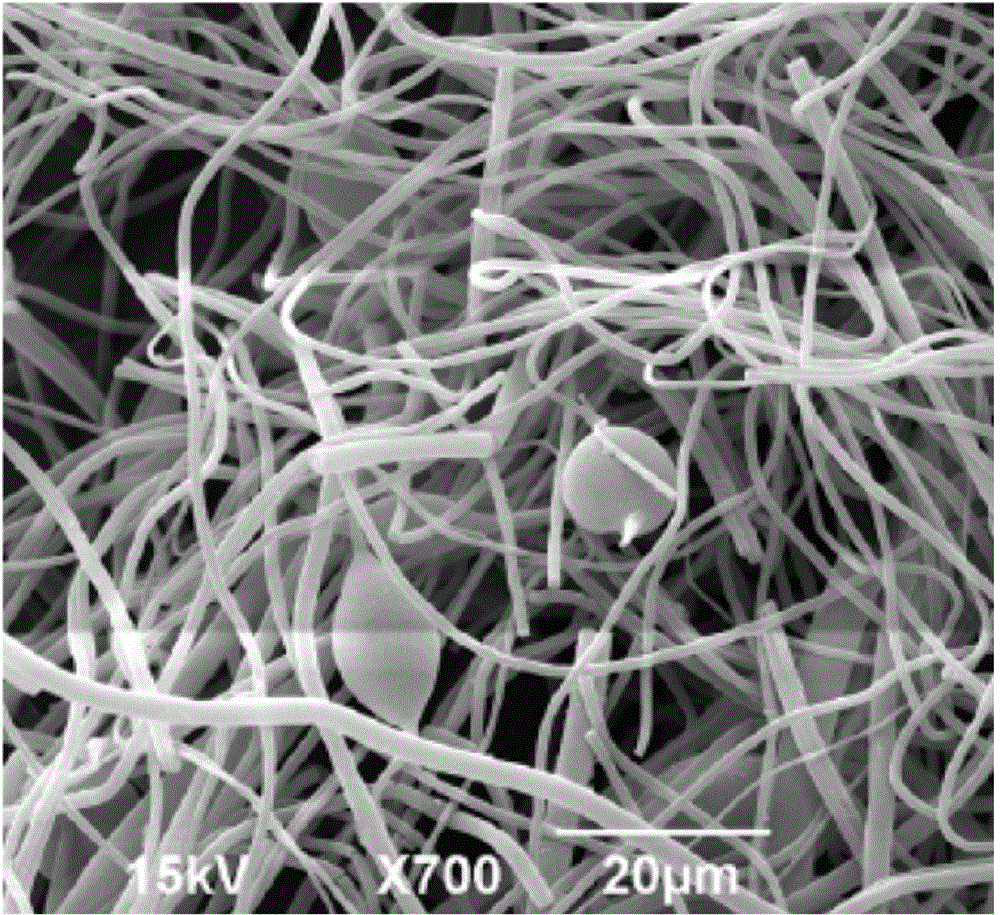

Capacitive ultrathin flexible stress sensor and producing method thereof

ActiveCN104897316AWith directional deposition functionSimple preparation processForce measurementFiberCapacitance

The invention discloses a capacitive ultrathin flexible stress sensor and a producing method thereof. The capacitive ultrathin flexible stress sensor comprises a bottom elastic protective film, a bottom electrospun nanofiber conductive film electrode, a middle elastic insulated isolating film, a top electrospun nanofiber conductive film electrode, a top elastic protective film, and two metallic electrodes, wherein the two metallic electrodes are connected with the top electrospun nanofiber conductive film electrode and the bottom electrospun nanofiber conductive film electrode respectively. The top electrospun nanofiber conductive film electrode is a conductive nanofiber film produced through an electrostatic spinning method and deposited directionally on the top surface of the middle elastic insulated isolating film and the bottom electrospun nanofiber conductive film electrode is a conductive nanofiber membrane produced through an electrostatic spinning method and deposited directionally on the top surface of bottom elastic protective film. The stress sensor is stretchable in a large range and can be used for measuring a large stretching range. The capacitance of the stress sensor is determined by the induction area of the stretched stress sensor. The stress sensor is simple in preparation technology and has good application prospect.

Owner:QINGDAO UNIV

Polypropylene nonwoven fabric and use thereof

ActiveUS20080287027A1Nice appearanceMaintain good propertiesFilament/thread formingAdhesive dressingsResidual strainPolyolefin

A polypropylene based nonwoven fabric is excellent in surface appearance and stretch properties and exhibits a small residual strain and excellent adhesiveness to polyolefins. The nonwoven fabric is obtained by forming a polypropylene resin composition comprising 1 to 40 weight parts of (i) an isotactic polypropylene, and 60 to 99 weight parts of (ii) a propylene / ethylene / α-olefin copolymer obtained by copolymerizing 45 to 89 mole % of propylene, 10 to 25 mole % of ethylene and the balance of α-olefin having 4 to 20 carbon atoms (with the proviso that the copolymerized amount of the α-olefin having 4 to 20 carbon atoms does not exceed 30 mole %), characterized by a small residual strain after stretching at a stretch ratio of 150%. The nonwoven fabric can be effectively used as sanitary materials or the like by virtue of its characteristics including stretch properties.

Owner:MITSUI CHEM INC

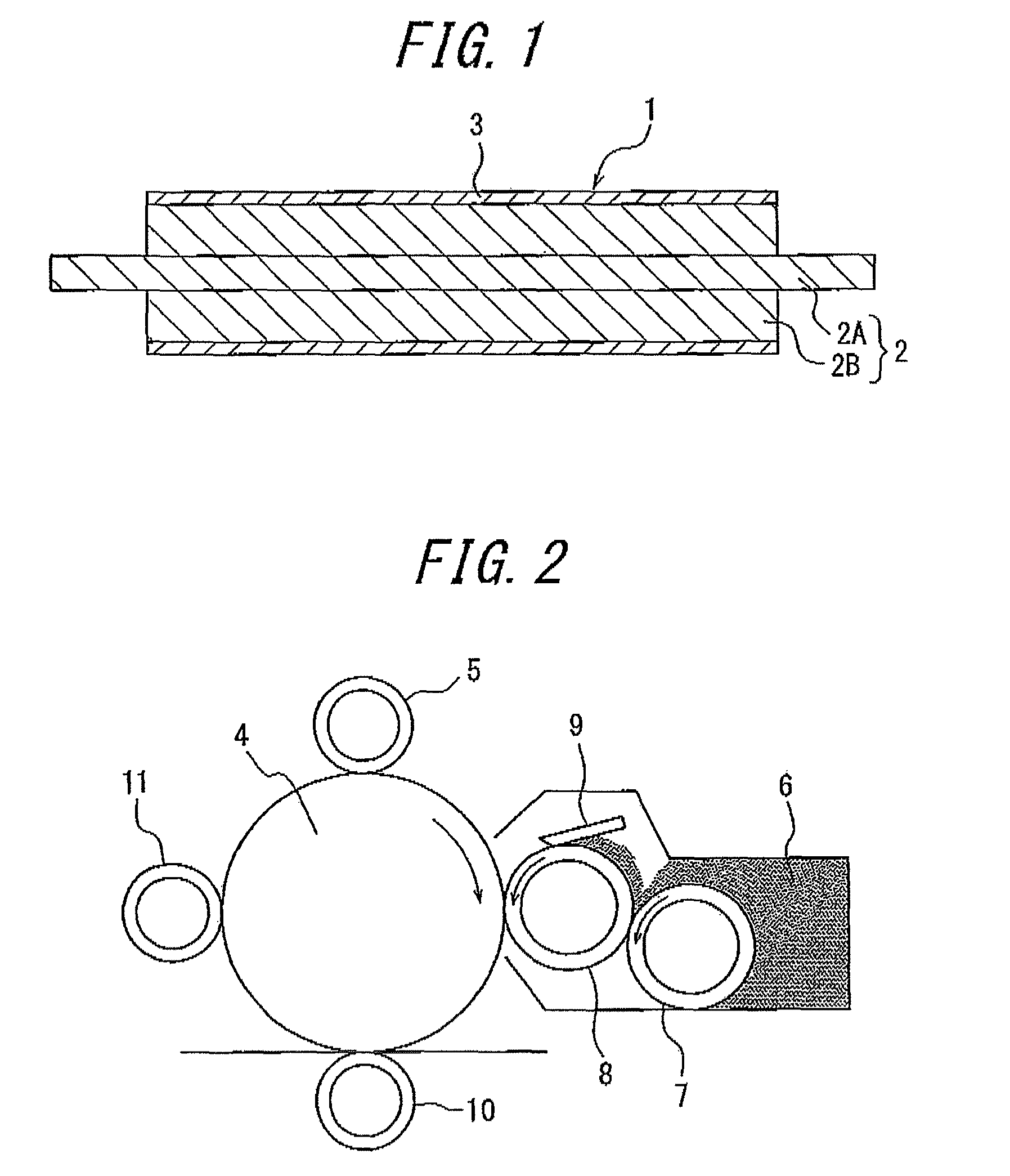

Conductive elastic roller and image forming apparatus comprising the same

ActiveUS20100014891A1Reduce hardnessSmall compression residual strainShaft and bearingsPortable power-driven toolsResidual strainElectrical conductor

This invention is a conductive elastic roller (1) comprising a shaft member (2) and one or more elastic layers (3) disposed on an outside of the shaft member (2) in a radial direction, wherein at least one of the elastic layers (3) is composed of an ultraviolet-curing type resin formed by curing a raw material for the elastic layer comprising a urethane acrylate oligomer (A), a photo-polymerization initiator (B) and a conductive agent (C) through ultraviolet irradiation, and the urethane acrylate oligomer (A) is a urethane acrylate oligomer synthesized by using as a polyol a polyether polyol (a1) having a proportion of primary hydroxyl groups in hydroxyl groups located at molecular ends of not less than 40% obtained by an addition polymerization of propylene oxide to a polyhydric alcohol alone, or the polyether polyol (a1) and another polyol (a2), and provides a conductive elastic roller (1) provided with an elastic layer having a low hardness, a small compression residual strain and an improved stain resistance to an adjoining member such as Organic Photoconductors or the like.

Owner:ARCHEM INC

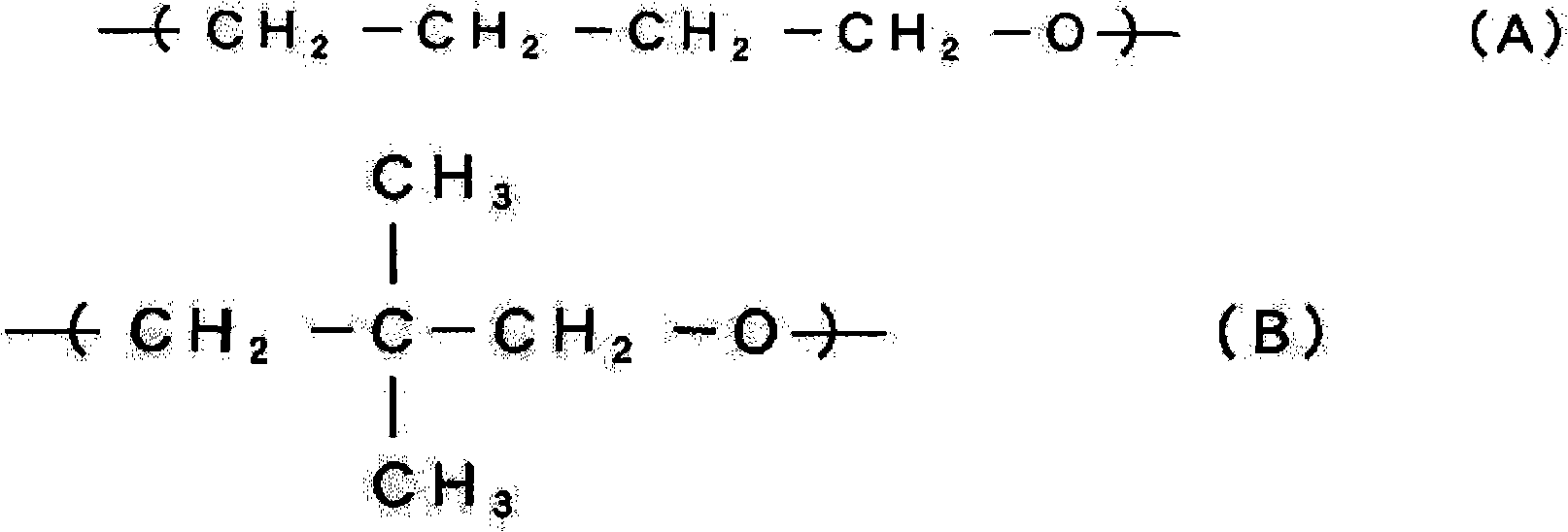

Ethylene copolymer, composition including the copolymer, and shaped article and film or sheet formed from the ethylene copolymer or the composition

ActiveUS20140296423A1Excellent mechanical propertiesExcellent formabilityInksProduction rateRubber elasticity

Objects of the invention are to obtain ethylene copolymers which have excellent rubber elasticity even without being crosslinked and maintain sufficient shaping processability even when filled with significantly large amounts of additives, and to provide methods for producing with good productivity films or sheets having flexibility and high stretchability. The invention is directed to an ethylene copolymer (X) including structural units derived from a component [A], a component [B] and a component [C] which are ethylene [A], an α-olefin of 3 to 20 carbon atoms [B] and a polyene and / or a cyclic olefin [C]. In the ethylene copolymer, (1) the content of structural units derived from the ethylene [A] is in the range of 50 to 90 mol % in 100 mol % of all the structural units in the copolymer (X); (2) the content of structural units derived from at least one polyene and / or the cyclic olefin [C] is in the range of 1.0 to 5.0 mol % in 100 mol % of all the structural units in the copolymer (X); and (3) the intrinsic viscosity [η] of the ethylene copolymer (X) as measured at 135° C. in a decalin solution is in the range of 7.8 to 13.0 dl / g. The invention also concerns with a composition including the ethylene copolymer (X), and uses.

Owner:MITSUI CHEM INC

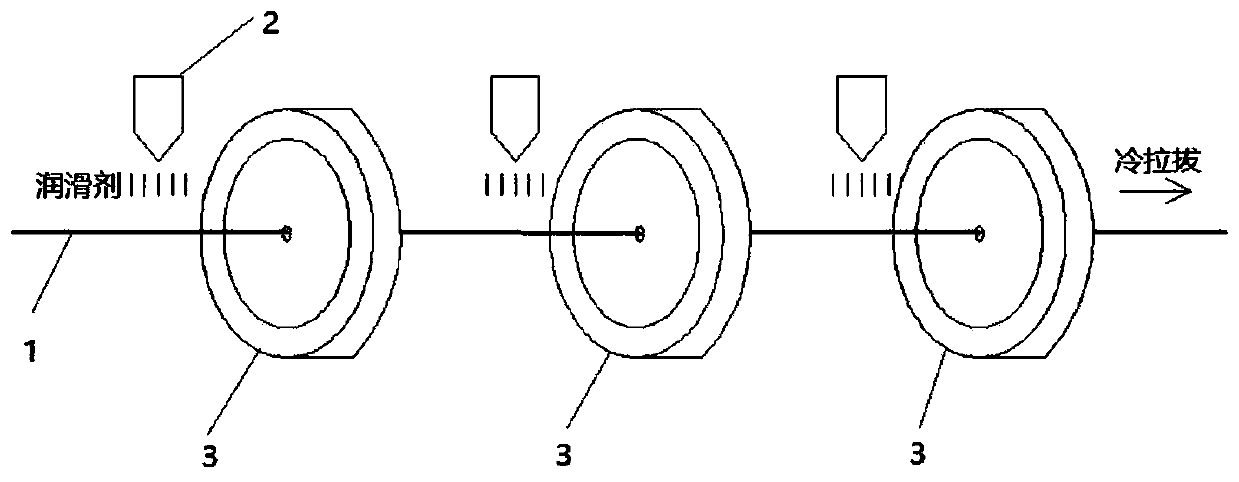

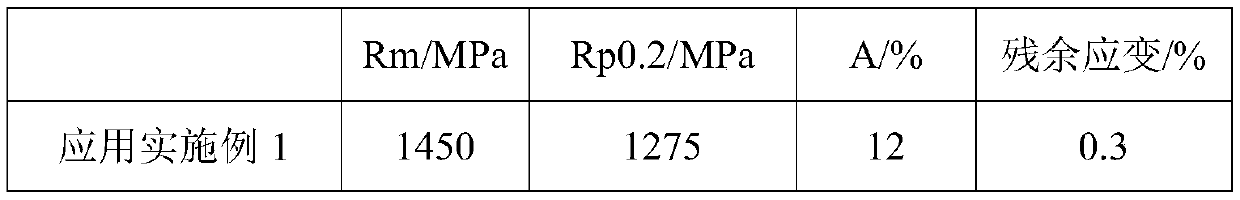

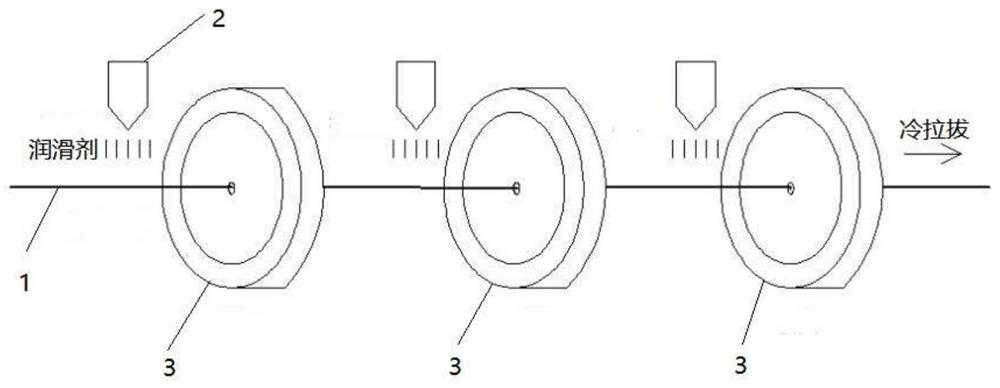

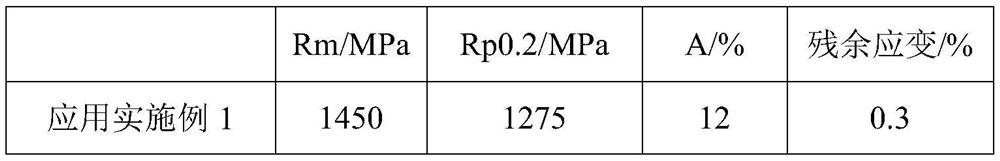

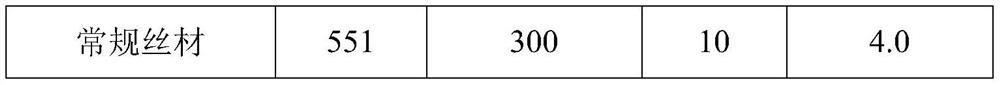

Processing method of nickel-titanium shape memory alloy high-strength wire material

ActiveCN111346942AImprove performanceHigh strengthExtrusion cleaning devicesShape-memory alloyTitanium

The invention discloses a processing method of a nickel-titanium shape memory alloy high-strength wire material. The processing method comprises the following steps that (1), a nickel-titanium alloy wire blank is subjected to peeling treatment, and the nickel-titanium alloy thick wire material is obtained; (2), the nickel-titanium alloy thick wire material in the first step is subjected to hot drawing, and the thick wire material in the nickel-titanium alloy is obtained; and (3), high-temperature annealing and water quenching are carried out on the thick wire material in the nickel-titanium alloy in the second step; (4), cold drawing and on-line annealing treatment are carried out on the thick wire material in the high-temperature annealed and water-quenched nickel-titanium alloy obtainedin the third step, and the nickel-titanium alloy fine wire material is obtained; and (5), on-line aging treatment and peeling treatment are carried out on the nickel-titanium alloy fine wire materialobtained in the fourth step, and the nickel-titanium shape memory alloy high-strength wire material is obtained.

Owner:西安华创新材料有限公司

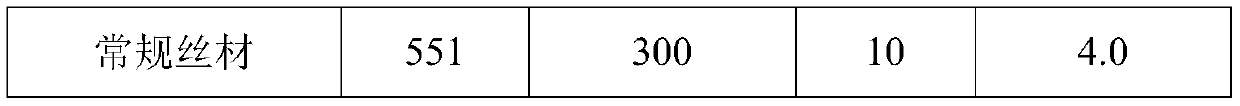

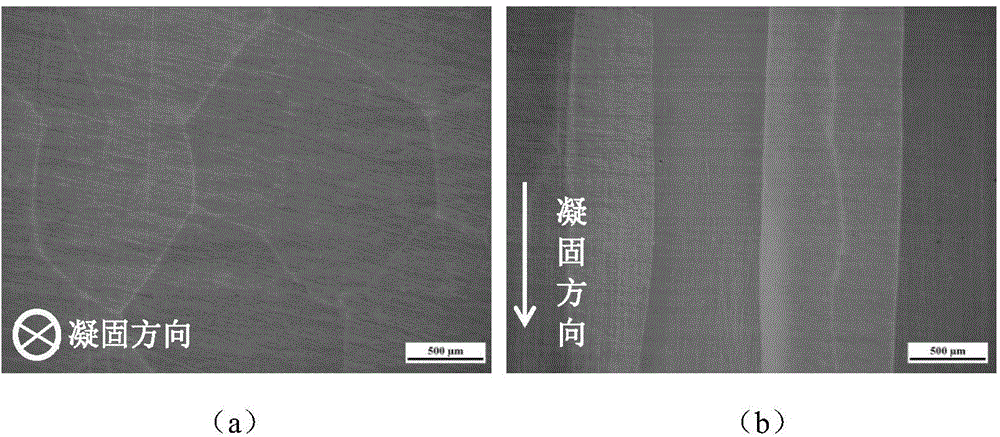

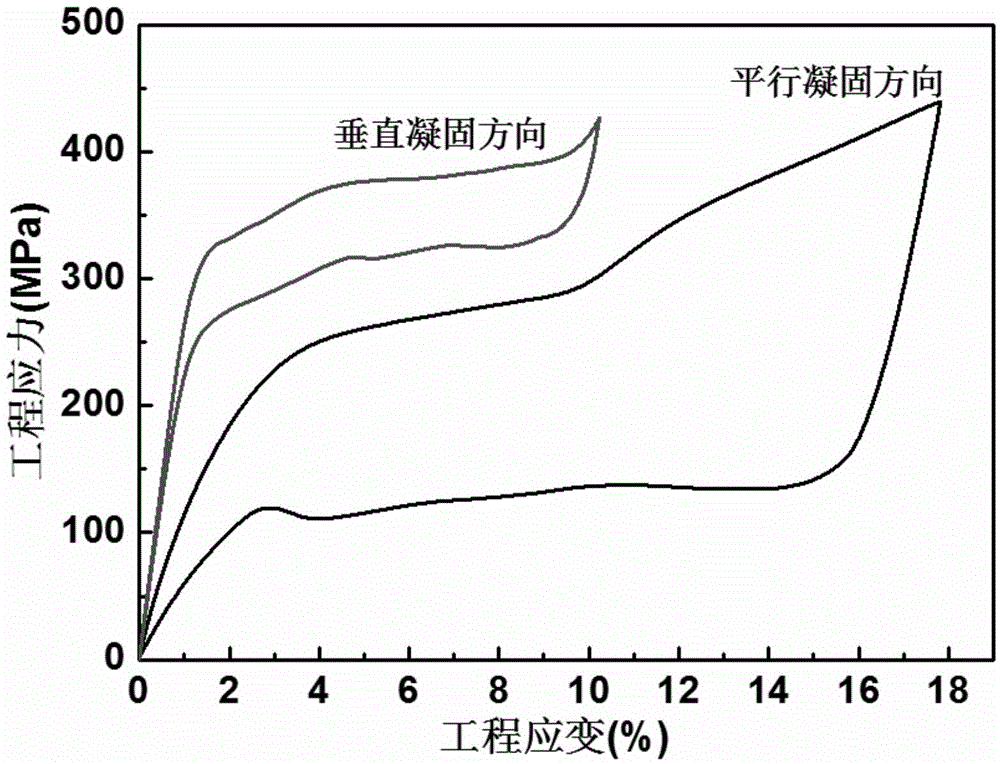

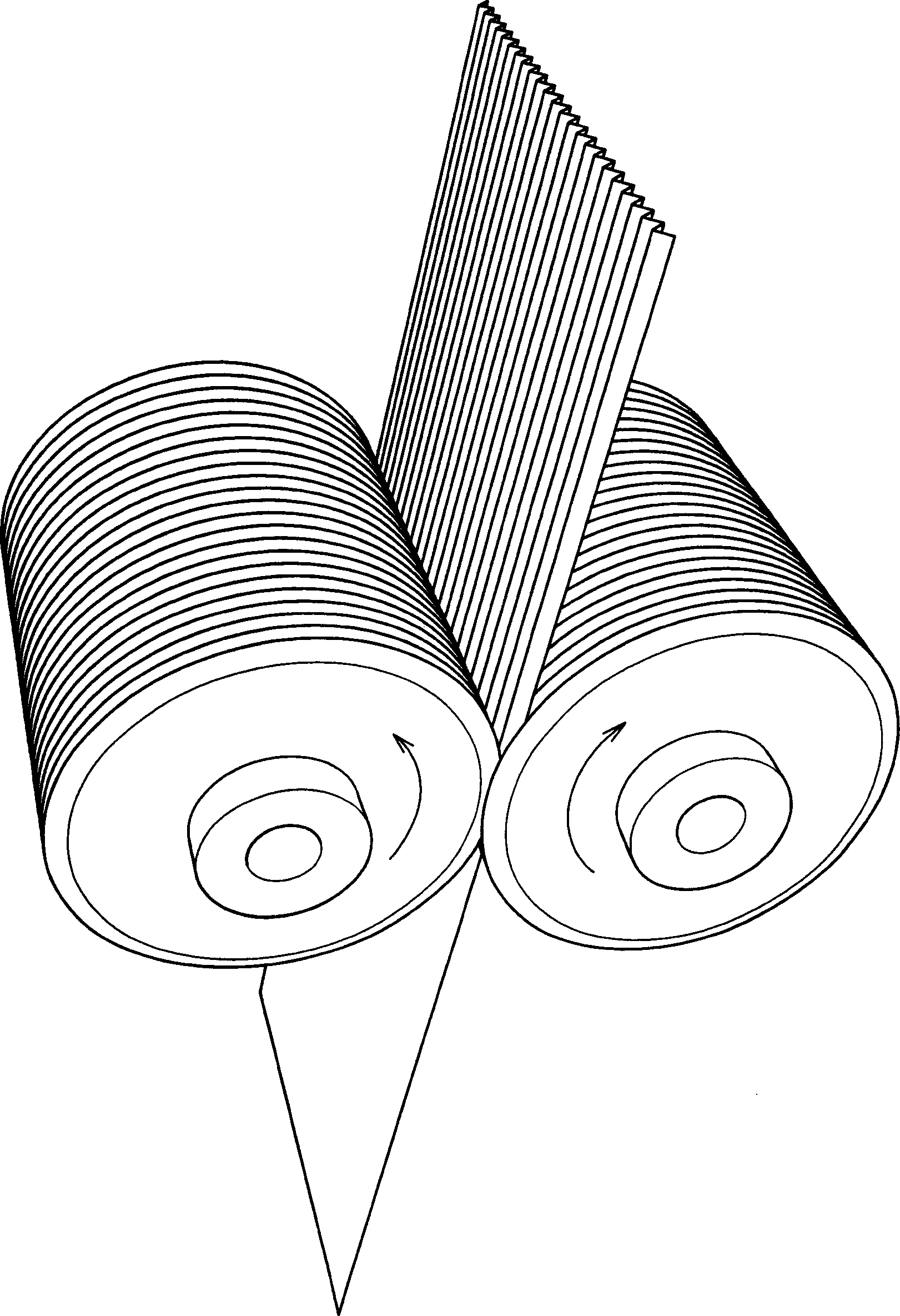

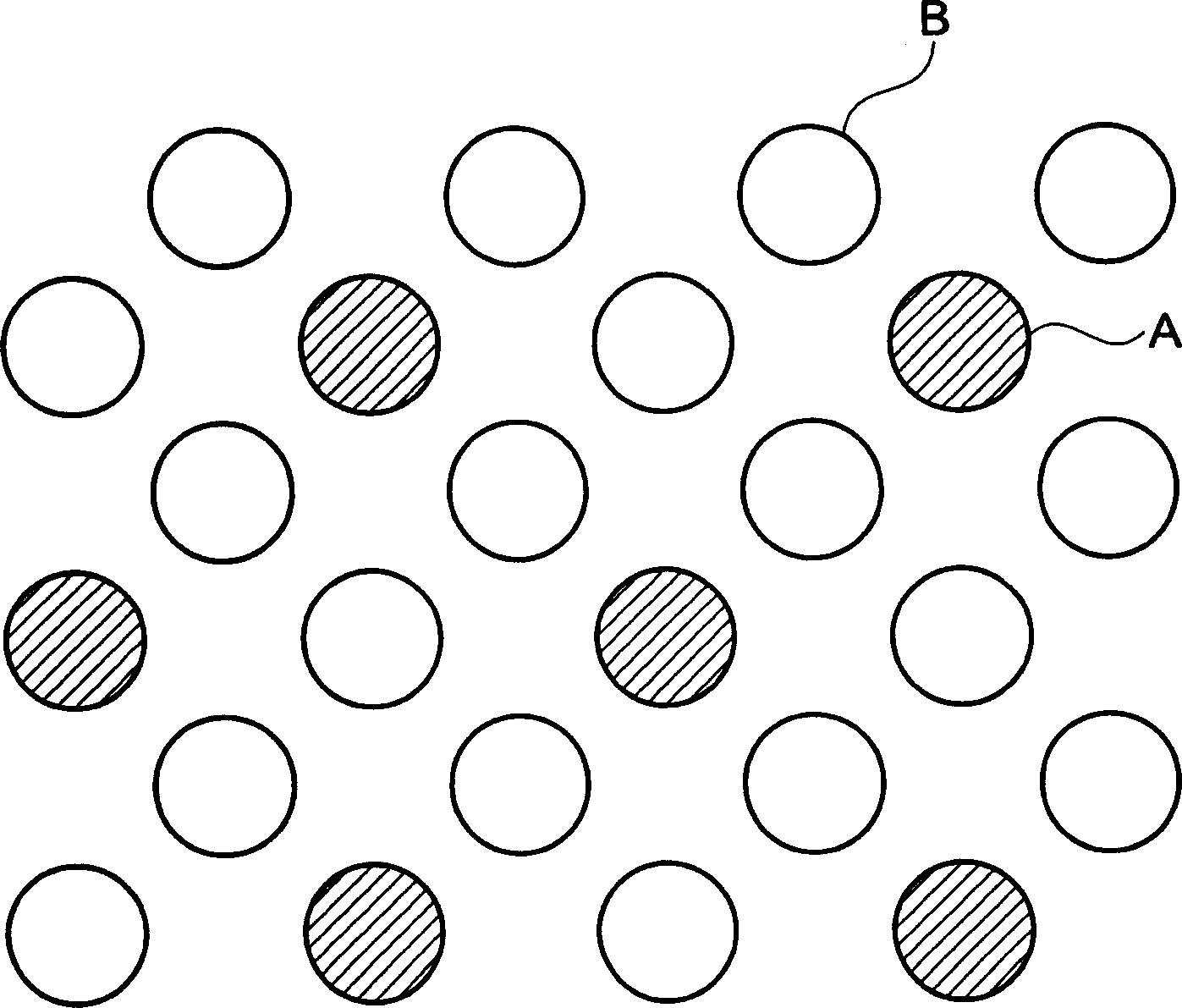

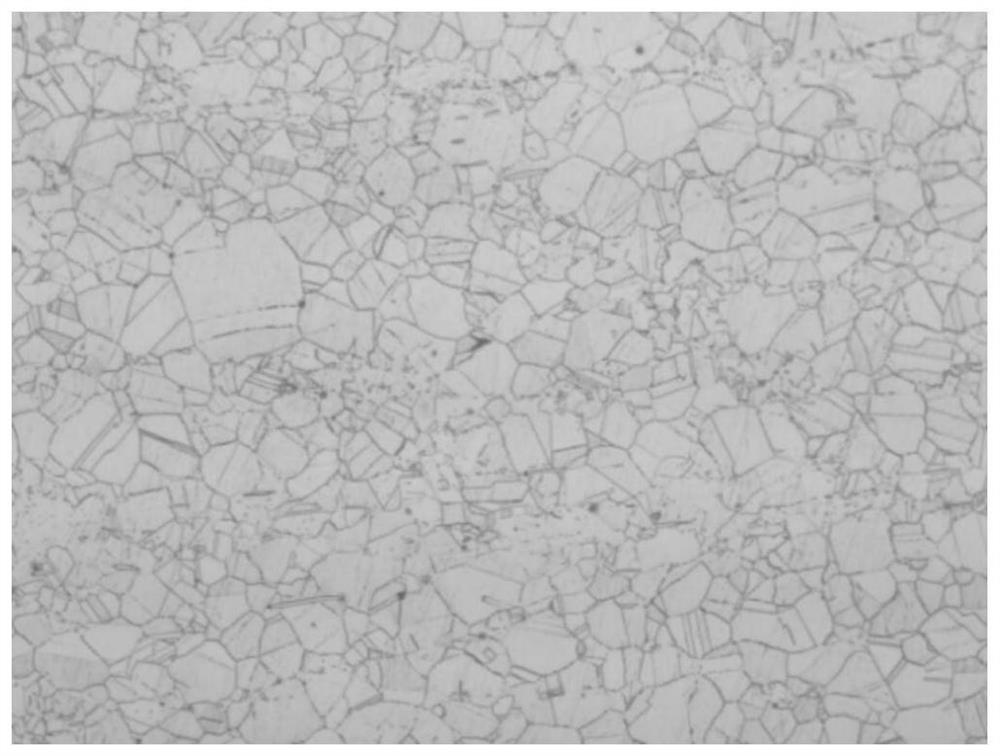

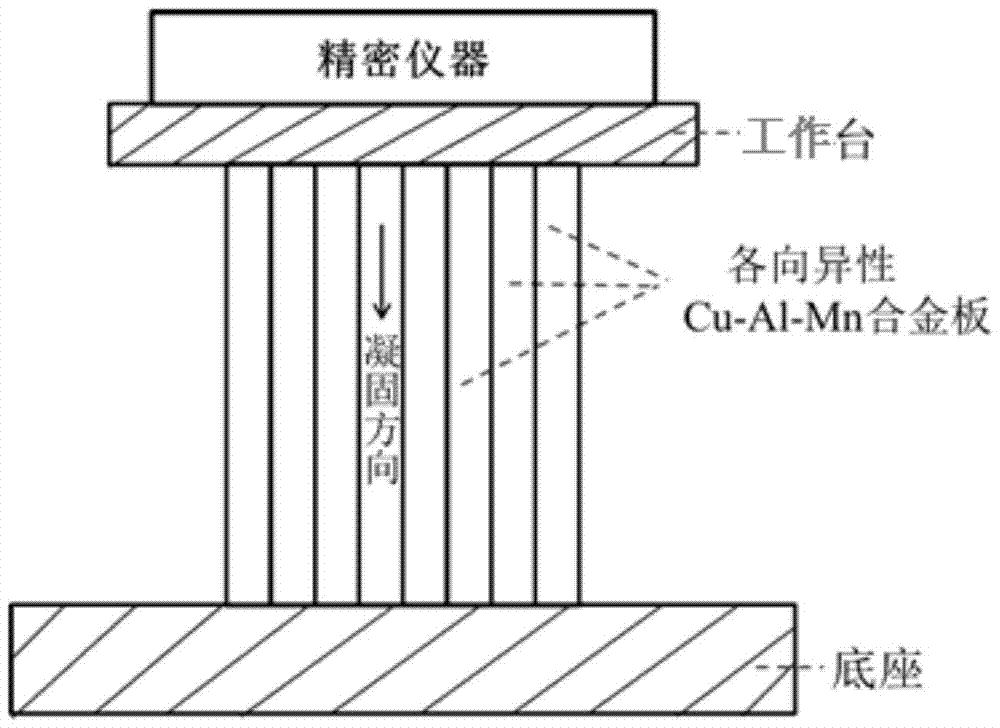

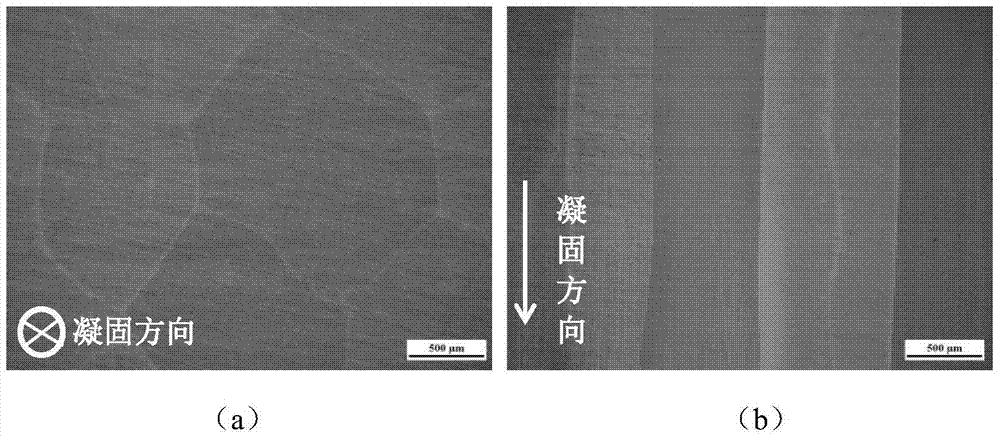

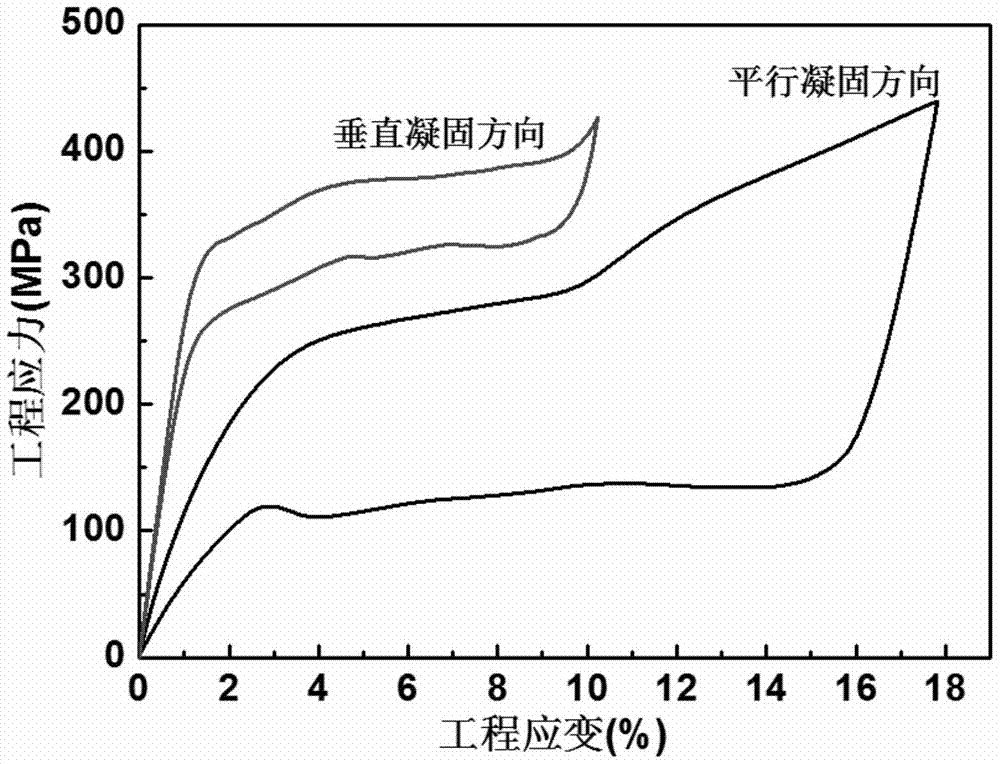

Cu-Al-Mn shape memory alloy damping device for precise instrument and manufacturing method of Cu-Al-Mn shape memory alloy damping device

ActiveCN104963994ALow priceImprove energy absorptionNon-rotating vibration suppressionDamping functionShape-memory alloy

The invention discloses a Cu-Al-Mn shape memory alloy damping device for a precise instrument and a manufacturing method of the Cu-Al-Mn shape memory alloy damping device. The damping device comprises a workbench, a damping assembly and a base. The damping assembly connects the workbench with the base. The damping assembly is composed of a plurality of columnar crystal tissue Cu-Al-Mn shape memory alloy plates with high anisotropism. The Cu-Al-Mn shape memory alloy damping device has the advantages that the damping device has the functional anisotropism, in other words, 10% or more high recovery strain can be provided in the vertical direction, the damping performance is superior, and good energy absorbing and damping functions are achieved; 7% or more high recovery strain in the horizontal direction can be provided, the energy absorbing and damping functions are achieved, and due to higher strength and rigidity of plates in the thickness direction, the damping device has good inclination resisting and shaking resisting functions, and the precise instrument can be kept stable in the using, or moving or transporting process.

Owner:UNIV OF SCI & TECH BEIJING

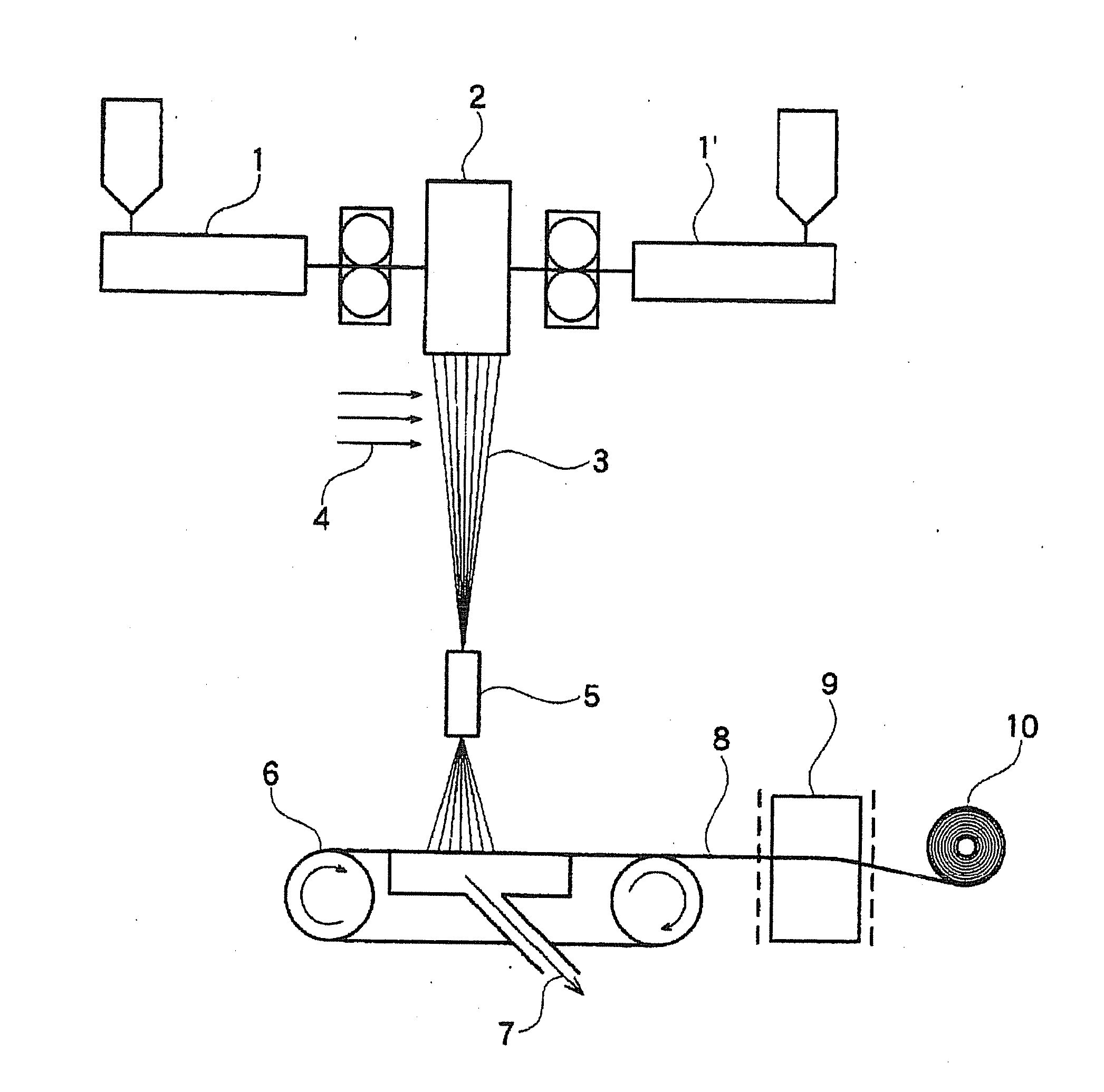

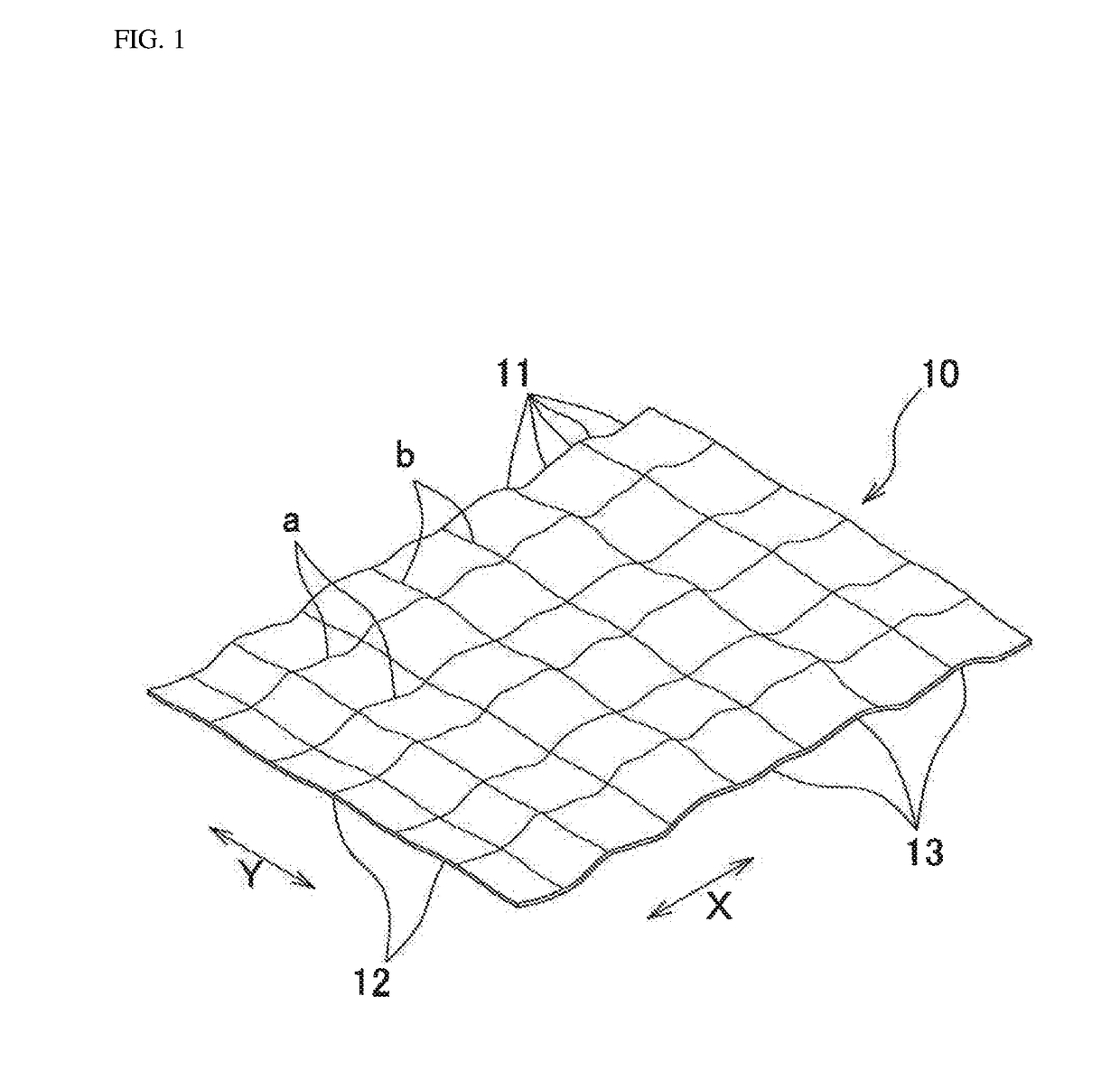

Mixed fiber and, stretch nonwoven fabric comprising said mixed fiber and method for manufacture thereof

A fiber mixture according to the invention comprises fibers A comprising a polymer A containing a thermoplastic polyurethane elastomer and fibers B comprising a thermoplastic polymer B other than the thermoplastic polyurethane elastomer, said thermoplastic polyurethane elastomer having a solidifying point of 65 DEG C or above as measured by a differential scanning calorimeter (DSC) and containing 3.00x10<6> or less polar-solvent-insoluble particles per g counted on a particle size distribution analyzer, which is based on an electrical sensing zone method, equipped with an aperture tube having an orifice of 100 mu m in diameter. An elastic nonwoven fabric comprises the fiber mixture.

Owner:MITSUI CHEM INC

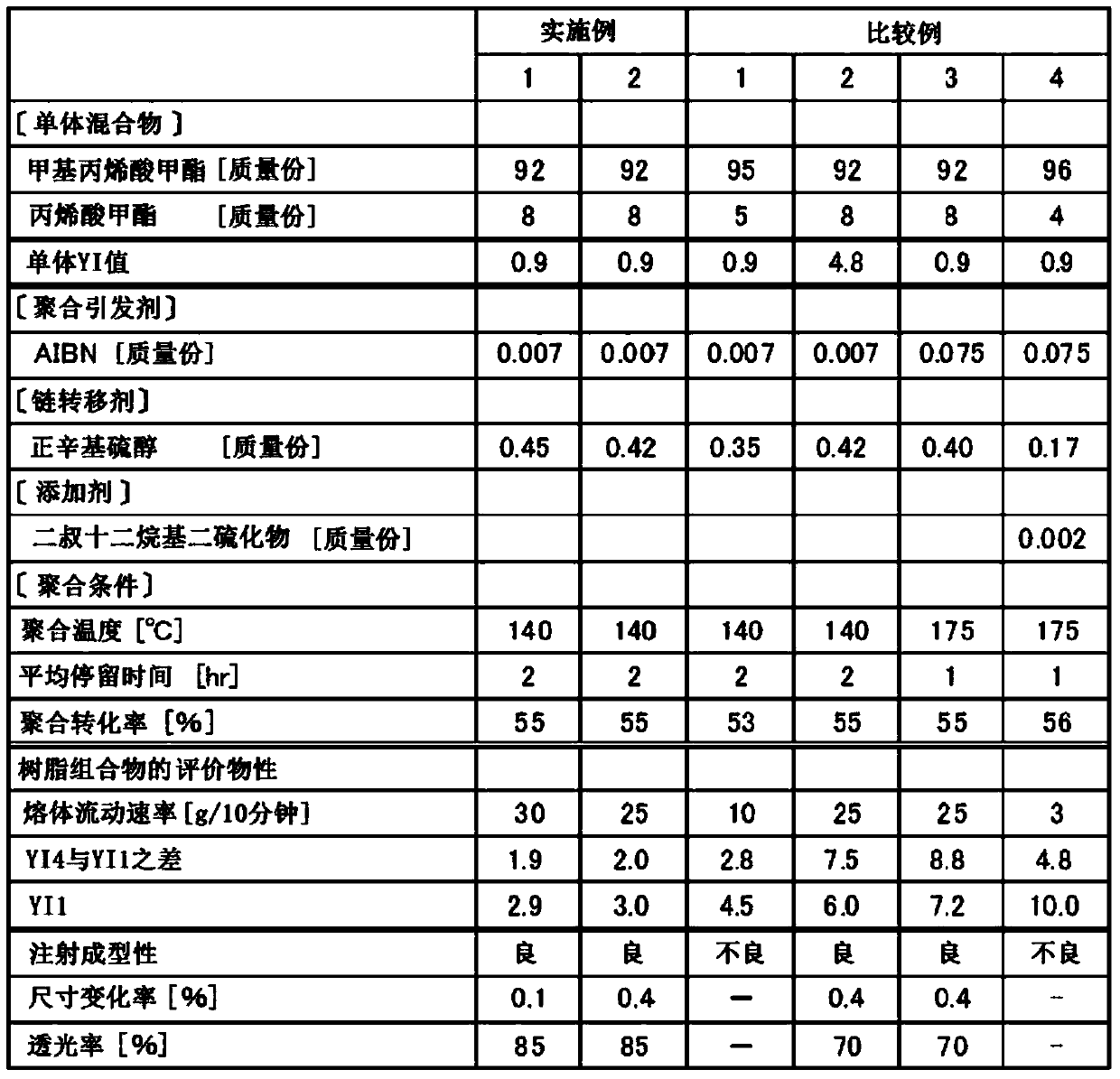

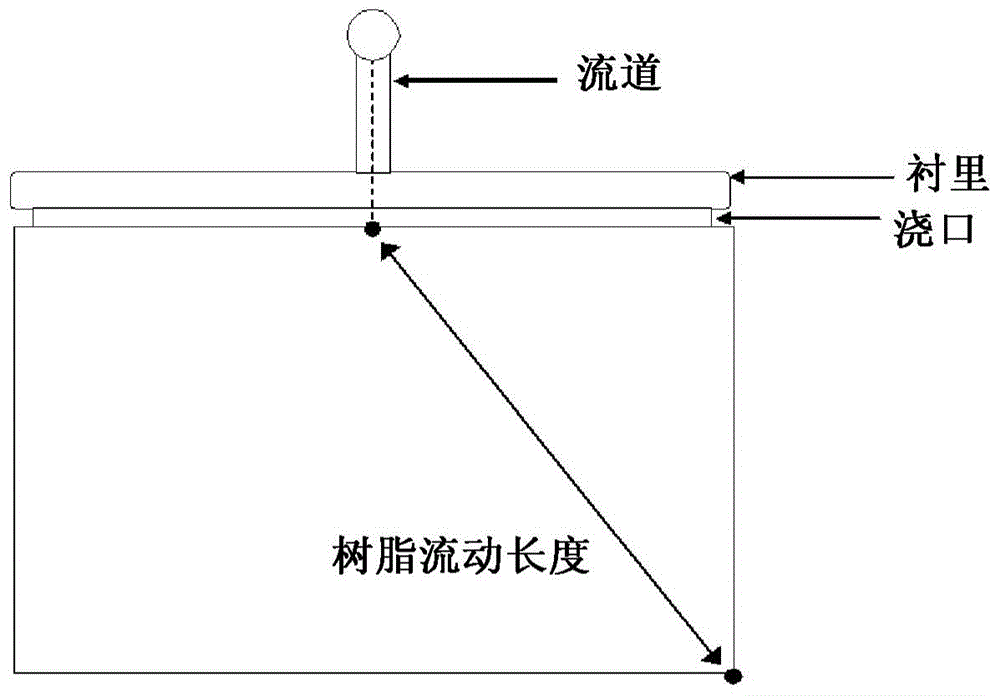

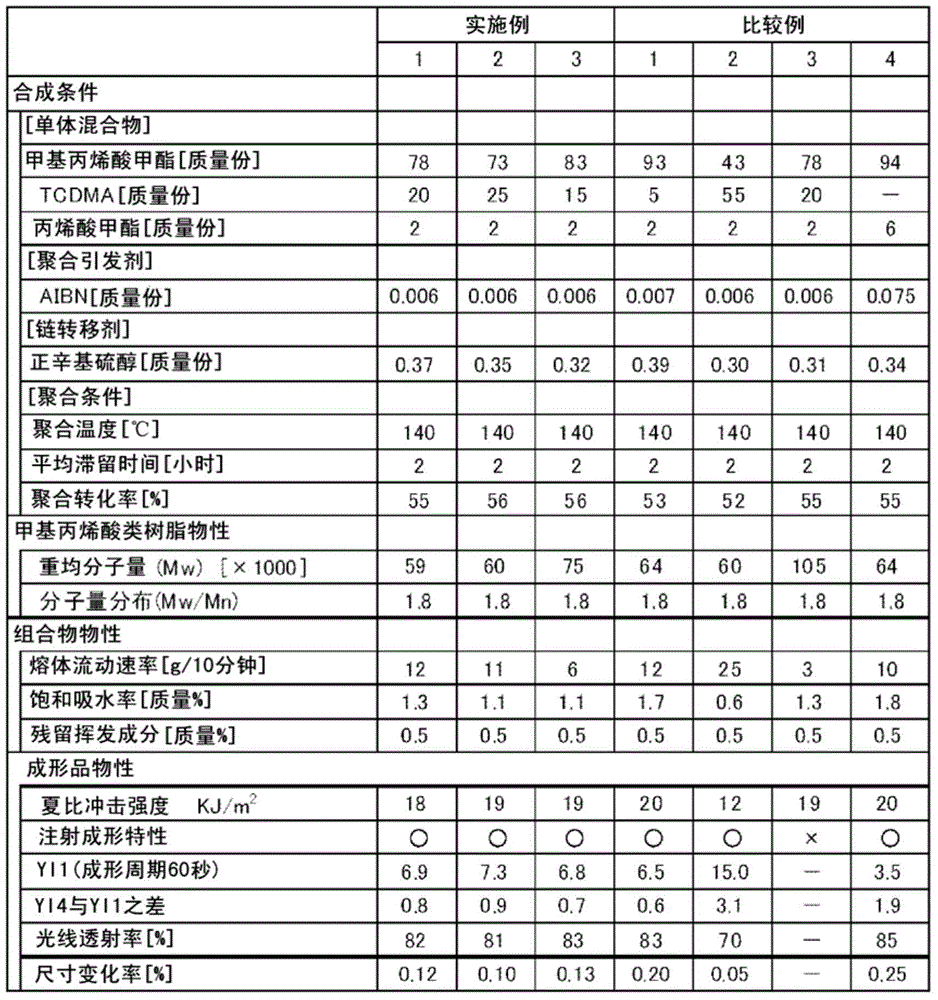

(meth) acrylic resin composition

ActiveCN104271663AExcellent injection moldabilityGood lookingCoatingsMethyl methacrylateStructural unit

A (meth) acrylic resin composition containing at least 99.5% by mass (meth) acrylic resin including 80%-100% by mass of a structural unit derived from methyl methacrylate and 0%-20% by mass of a structural unit derived from acrylic ester; having a difference of no more than 3 between a yellow index (YI4) at an optical path length of 200 mm in an injection-molded article obtained at a cylinder temperature of 280°C and a molding cycle of 4 minutes, and a yellow index (YI1) at an optical path length of 200 mm in an injection-molded article obtained at a cylinder temperature of 280°C and a molding cycle of one minute; and having a melt flow rate of at least 25g / 10 mins. under conditions of 230°C and a 3.8 kg load.

Owner:KURARAY CO LTD

Expanded porous polytetrafluoroethylene film having elastic recovery property in thickness-wise direction of the film, production process thereof, and use of the porous film

InactiveUS20070154699A1Increase elasticityEasy to useNon-insulated conductorsStuffed mattressesDrawing ratioElastic modulus

An expanded porous polytetrafluoroethylene film having residual strain of at most 11.0% as measured after a load required to indent a rod, which is in a columnar form that its outer diameter is at least 2 mm and at least 1.9 times as much as the thickness of the film, and has a smooth plane perpendicular to its axis at a free end surface thereof and a modulus of longitudinal elasticity of at least 1.0×104 kgf / mm2, up to 20% of the film thickness at a strain rate of 100% / min from the free end surface is applied repeatedly 20 times, and a production process of the porous film, in which a step of compressing an expanded porous polytetrafluoroethylene film having a high draw ratio is provided.

Owner:SUMITOMO ELECTRIC IND LTD

Conductive elastic roller and image forming apparatus comprising the same

ActiveUS8337373B2Reduce hardnessImprove dyeing effectShaft and bearingsPortable power-driven toolsResidual strainElectrical conductor

There is provided a conductive elastic roller (1) comprising a shaft member (2) and one or more elastic layers (3) disposed on an outside of the shaft member (2) in a radial direction, wherein at least one of the elastic layers (3) is composed of an ultraviolet-curing type resin formed by curing a raw material for the elastic layer comprising a urethane acrylate oligomer (A), a photo-polymerization initiator (B) and a conductive agent (C) through ultraviolet irradiation, and the urethane acrylate oligomer (A) is a urethane acrylate oligomer synthesized by using as a polyol a polyether polyol (a1) having a proportion of primary hydroxyl groups in hydroxyl groups located at molecular ends of not less than 40% obtained by an addition polymerization of propylene oxide to a polyhydric alcohol alone, or the polyether polyol (a1) and another polyol (a2), and provides a conductive elastic roller (1) provided with an elastic layer having a low hardness, a small compression residual strain and an improved stain resistance to an adjoining member such as Organic Photoconductors or the like.

Owner:ARCHEM INC

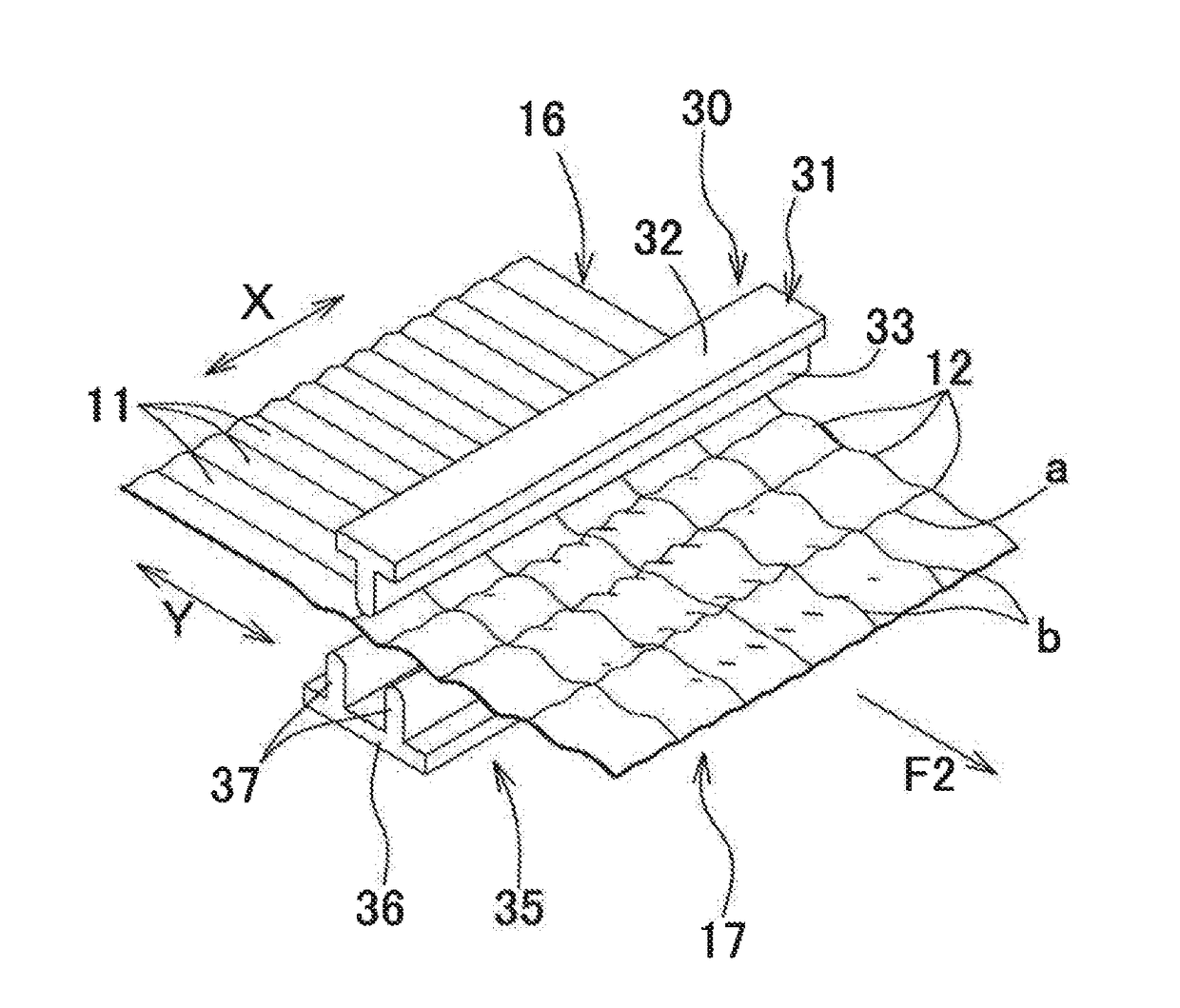

Method of manufacturing metal embossed plate

InactiveUS20180281040A1Lowering residual strainIncreasing the thicknessVehicle componentsEngineering

First corrugated portions in a first direction are sequentially formed by die-pressing a raw metal plate. Second corrugated portions formed in a second direction intersecting the first direction are sequentially formed by die-pressing a primary formed plate having the first corrugated portions using elongate projections, so that each of the second corrugated portion has a half-height and a pitch larger than those of each of the first corrugated portion. Third corrugated portions formed approximately in the first direction are sequentially formed by die-pressing a secondary formed plate having the second corrugated portions using elongate projections, so that each of the third corrugated portions has a half-height and a pitch larger than those of the first corrugated portion.

Owner:KOKUSAN BUHIN INDS

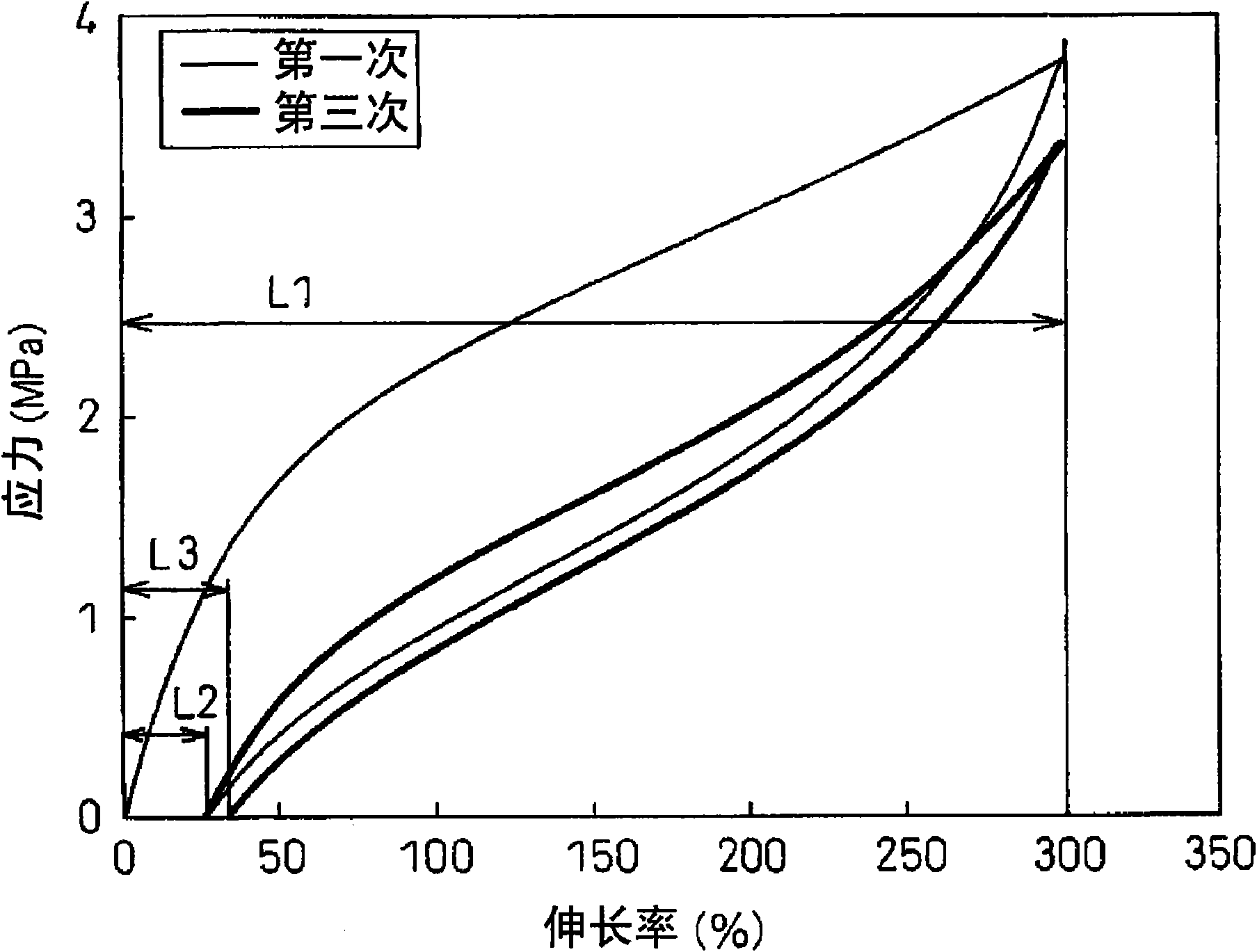

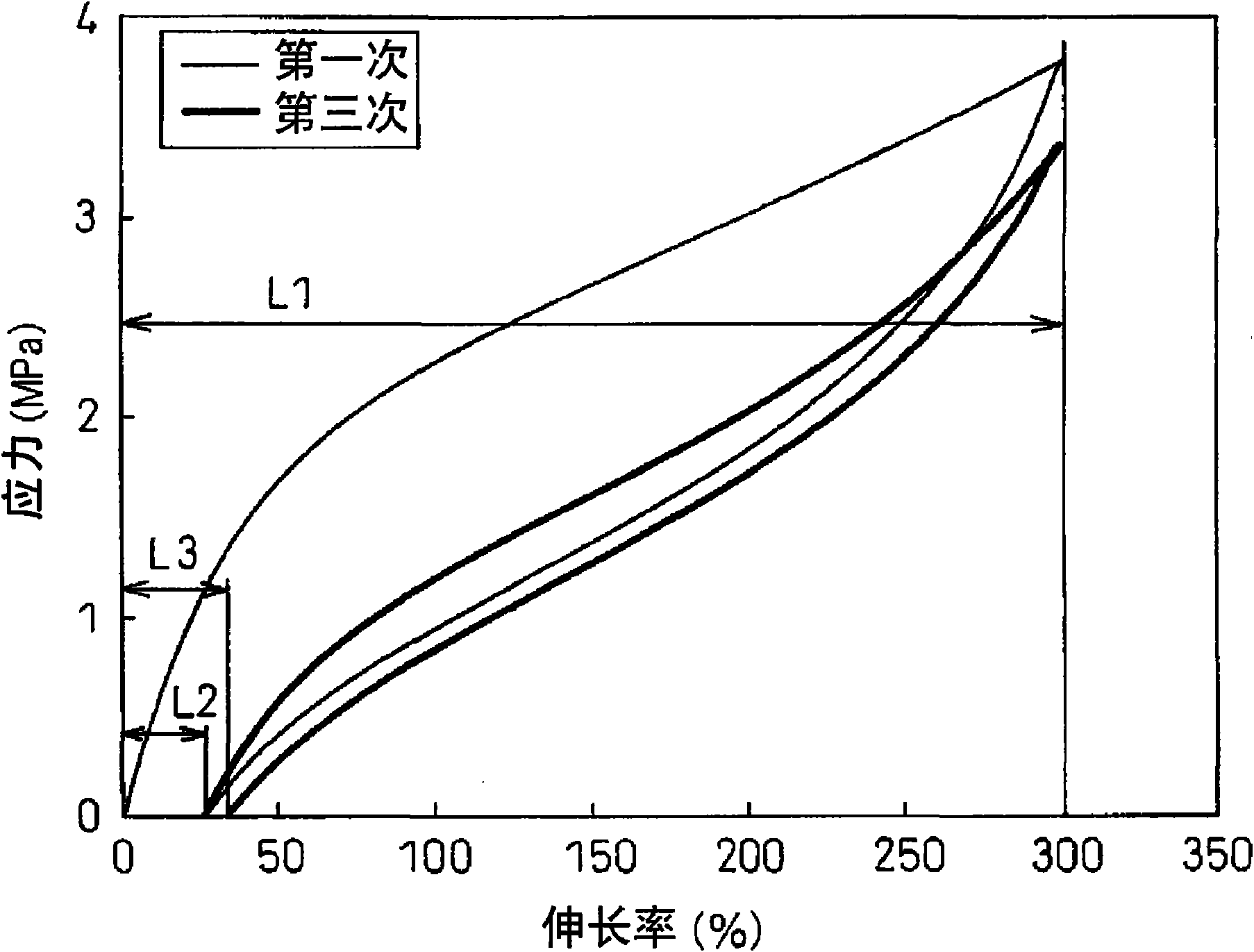

Thermoplastic polyurethane tape

The object is to provide a thermoplastic polyurethane tape having an excellent elasticity function. The polyurethane tape is a thermoplastic polyurethane tape characterized by having a residual strain of 5 to 40% after stretching by 300% at 20 DEG C, preferably having a rate of recovery of 85% or higher after repeating the 300%-stretching / recovery cycle three times at -10 DEG C.

Owner:ASAHI KASEI FIBERS CORPORATION

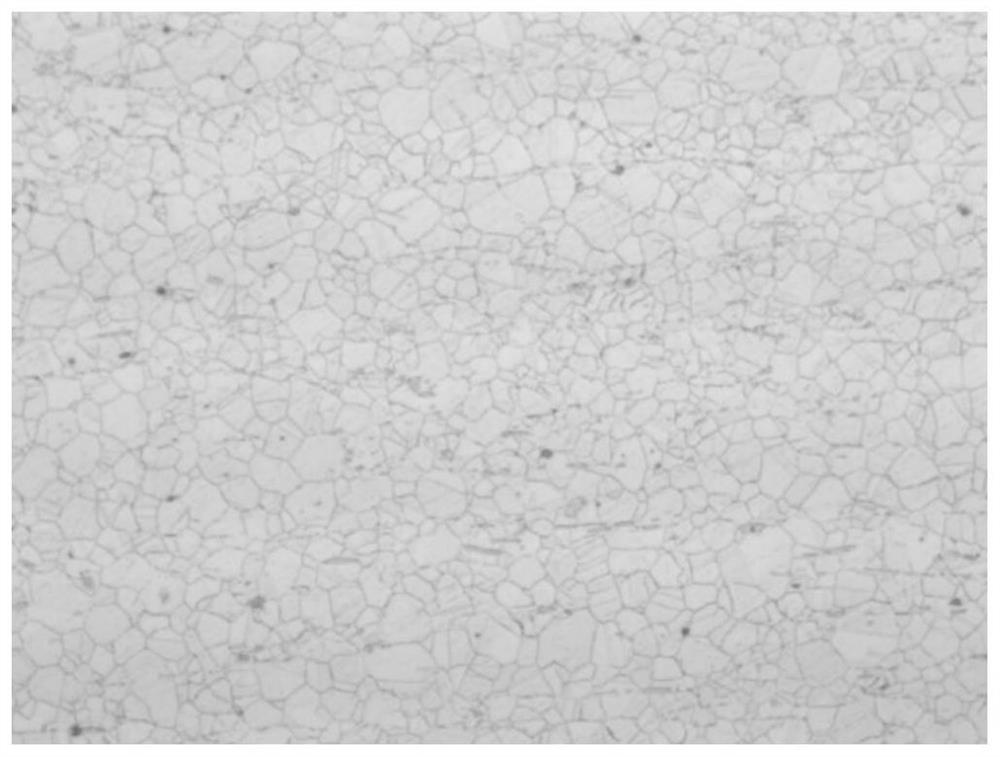

Manufacturing method of fine-grain NiCr20TiAl alloy forged material

InactiveCN112813292ASpread evenlyEvenly distributedMetal-working apparatusFurnace typesSolution treatmentSmelting process

The invention discloses a manufacturing method of a fine-grain NiCr20TiAl alloy forged material, which comprises the following steps: in the smelting process, controlling the C element to be 0.06-0.10%, controlling the Cr element to be 20.0-22.0%, and adding 0.15-0.50% of Mo element at the same time; the vacuum induction melting and electroslag remelting ingot is subjected to a high-temperature homogenization heat treatment process, so that the C, Cr and Mo elements are uniformly diffused; and the heating temperature and the deformation time of the final heating number are controlled during forging. Through the measures, the NiCr20TiAl alloy forged material produced through the method can eliminate the grain coarsening tendency during subsequent high-temperature solution treatment, the forged material is subjected to solution heat treatment at the temperature of 1050-1080 DEG C for 8 h, the average grain size can obtain five-level fine grains or a better level, and meanwhile the forged material has good obdurability after aging treatment.

Owner:苏州集萃高合材料科技有限公司

Hydrogenated styrene polymer resin composition and optical elements

To provide a resin composition which is suitable for use as a material for optical parts and disk substrates and molded products thereof. The resin composition comprises: (1) 10 to 90 wt % of a first hydrogenated, polymerized styrene which contains a hydrogenated, polymerized styrene unit in an amount of more than 95 wt % and 99.99 wt % or less and has a weight average molecular weight of 30,000 to 300,000; and (2) 10 to 90 wt % of a second hydrogenated, polymerized styrene which contains a hydrogenated, polymerized styrene unit in an amount of 60 to 95 wt % and has a weight average molecular weight of 30,000 to 200,000, “wt %” being based on 100 wt % of the total of the first hydrogenated, polymerized styrene and the second hydrogenated, polymerized styrene.

Owner:TEIJIN LTD +1

Stretch nonwoven fabric and method for production thereof

ActiveUS7659218B2Feel goodNarrow distributionWoven fabricsNon-woven fabricsThermoplastic polyurethaneFiber diameter

A spunbonded elastic nonwoven fabric according to the invention comprises fibers formed from a polymer comprising a thermoplastic polyurethane elastomer, wherein the thermoplastic polyurethane elastomer has a starting temperature for solidifying of 65° C. or above as measured by a differential scanning calorimeter (DSC) and contains 3.00×106 or less polar-solvent-insoluble particles per g as counted on a particle size distribution analyzer, which is based on an electrical sensing zone method, equipped with an aperture tube having an orifice of 100 μm in diameter, and wherein the fibers have diameters such that the standard deviation of fiber diameters (Sn) divided by the average fiber diameter (Xave) (Sn / Xave) gives a value of 0.15 or less.

Owner:MITSUI CHEM INC

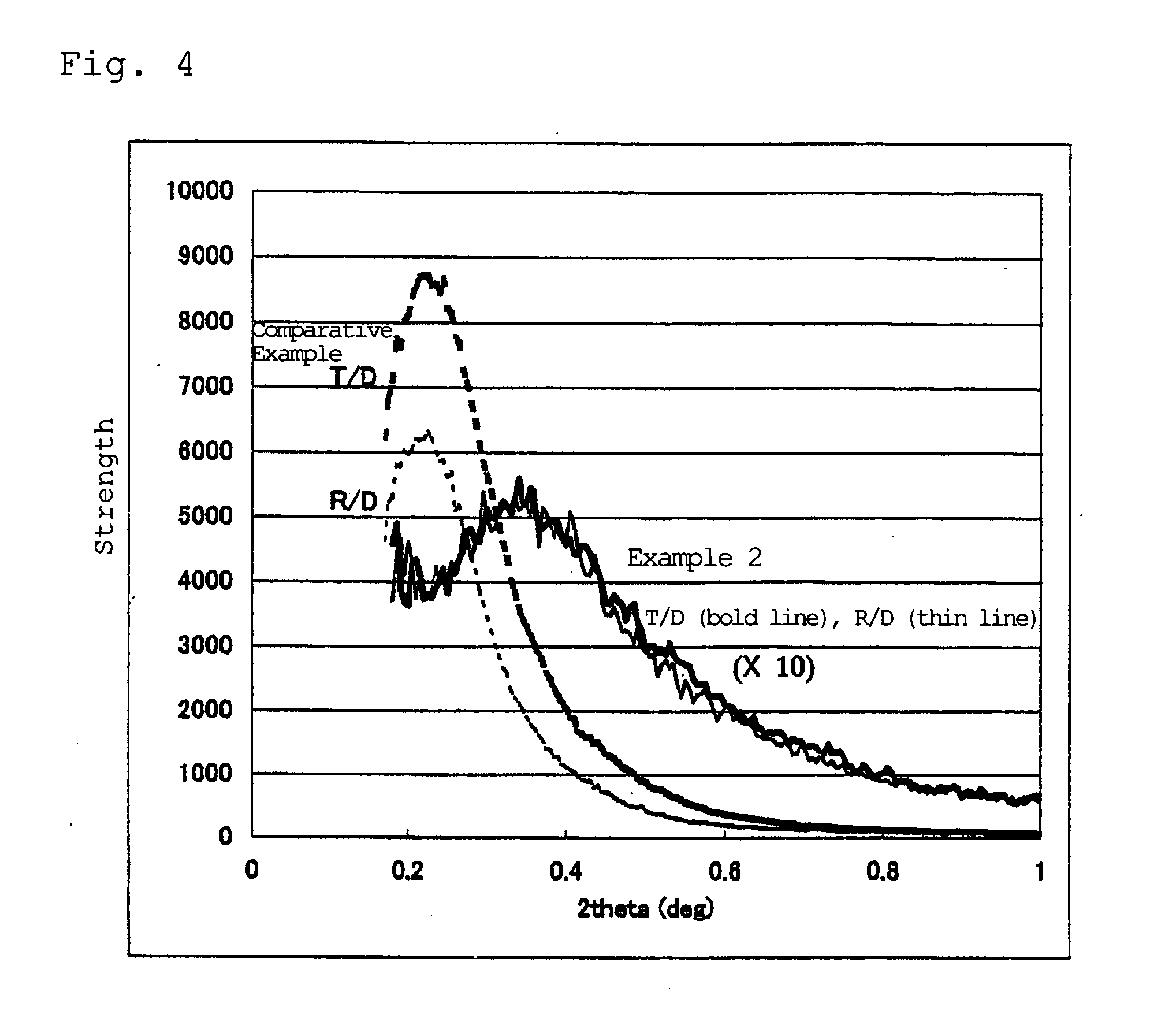

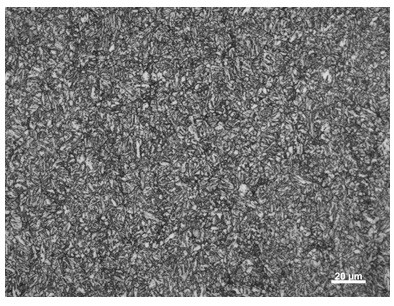

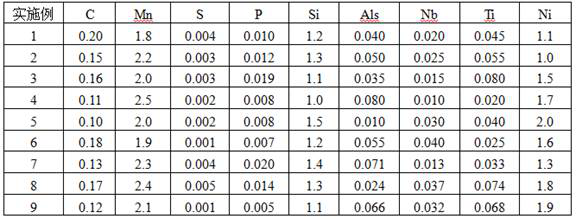

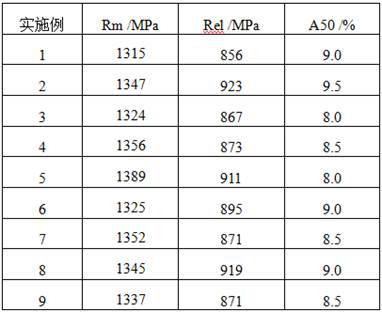

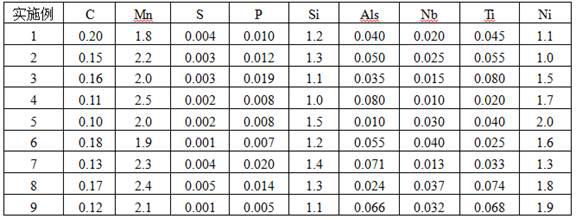

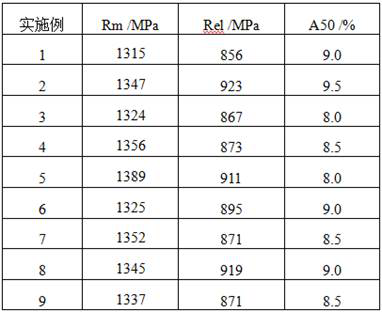

1300Mpa grade high tenacity cold-formed steel plate and production method thereof

ActiveCN112795837AImprove plasticityHigh yield strengthFurnace typesProcess efficiency improvementChemical compositionContinuous annealing

The invention relates to a 1300Mpa grade high tenacity cold-formed steel plate and a production method thereof and belongs to the technical field of metallurgy. The steel plate comprises the chemical components in percent by mass: 0.1-0.2% of C, 1.8-2.5% of Mn, less than or equal to 0.005% of S, less than or equal to 0.02% of P, 1.0-1.5% of Si, less than or equal to 0.08% of Als, 0.01-0.04% of Nb, 0.02-0.08% of Ti, 1.0-2.0% of Ni and the balance Fe and inevitable impurities. The production method comprises the following steps: steelmaking, continuous rolling, heating, rolling, pickling, continuous annealing and level pulling straightening. A temperature of a soaking zone in the continuous annealing step is 760-820 DEG C, and an insulating time is 60-225s. The yield strength of the steel plate is greater than or equal to 850 MPa, a tensile strength is greater than or equal to 1300 MPa, and a ductility A50 is greater than 8%. The steel plate has a good cold-forming property and meets a requirement on light weight steel for an automobile.

Owner:TANGSHAN IRON & STEEL GROUP +2

Tilt angle sensor based on optical fiber Bragg gratings and method for measuring tilt angle of tilt angle sensor

InactiveCN102288162BHigh measurement accuracyImprove machining accuracyIncline measurementGratingFiber Bragg grating

The invention relates to a tilt angle sensor based on optical fiber Bragg gratings and a method for measuring a tilt angle of the tilt angle sensor and belongs to the technical field of measurement of a structural tilt angle. The tilt angle sensor comprises a fixed base plate (12), a fixed pressing block (6), a thin-wall type uniform-section metal beam (9) and a quality block (7), wherein the upper end of the thin-wall type uniform-section metal beam (9) is arranged on the fixed base plate (12) in a mode of fitting with the fixed pressing block through a first movable pressing block (10) and a fifth screw (11); the quality block (7) is fixed at the lower end of the thin-wall type uniform-section metal beam (9) through a sixth screw (15) and a second movable pressing block (16); and a first optical fiber Bragg grating (13) and a second optical fiber Bragg grating (14) are respectively adhered to opposite positions on two sides of the thin-wall type uniform-section metal beam (9). By the method, the size and direction of the tilt angle can be detected according to a correspondence relation between the change of central wavelengths of the two optical fiber Bragg gratings and the tiltangle. The invention is high in measurement accuracy and has a temperature self-compensation function.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

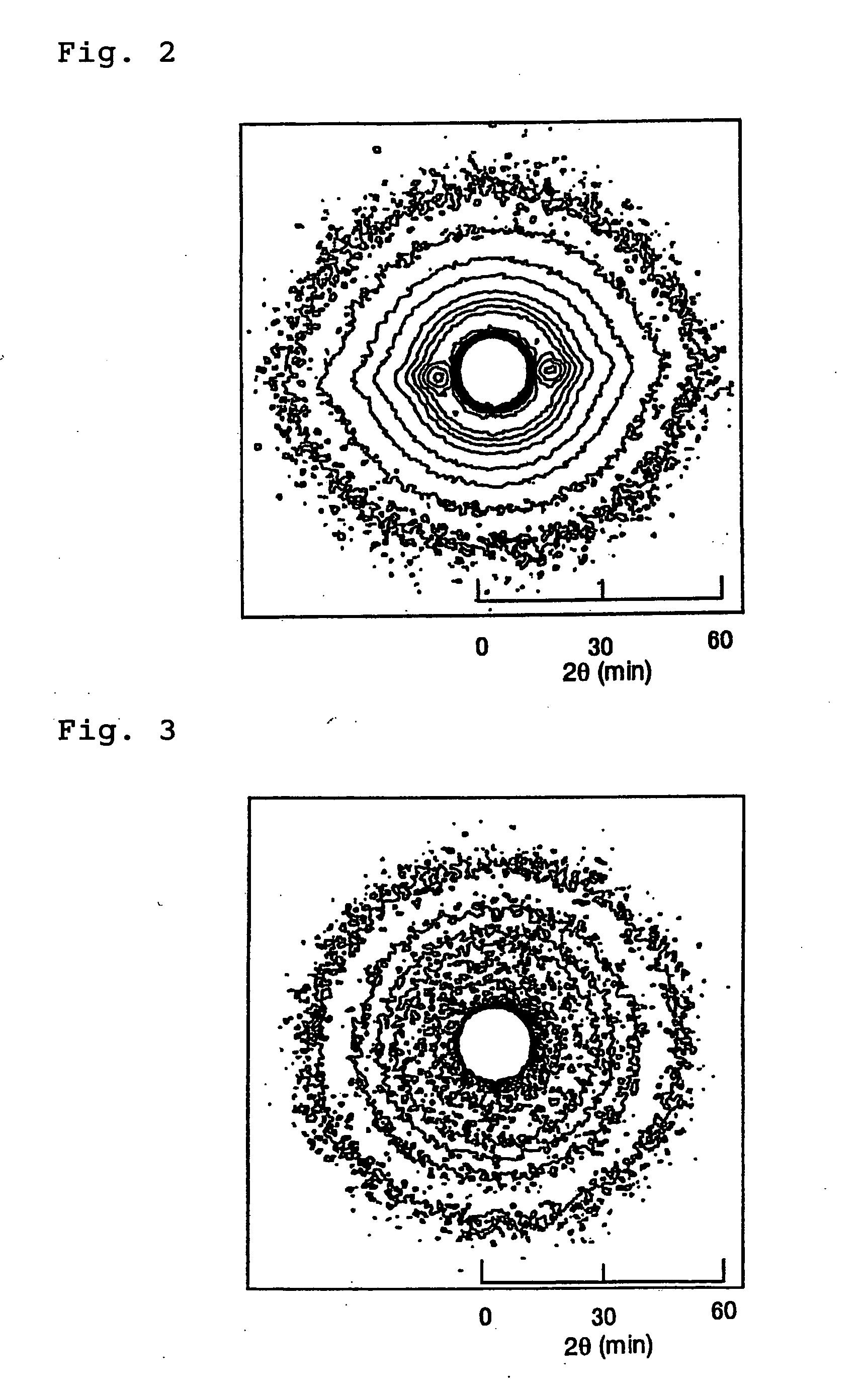

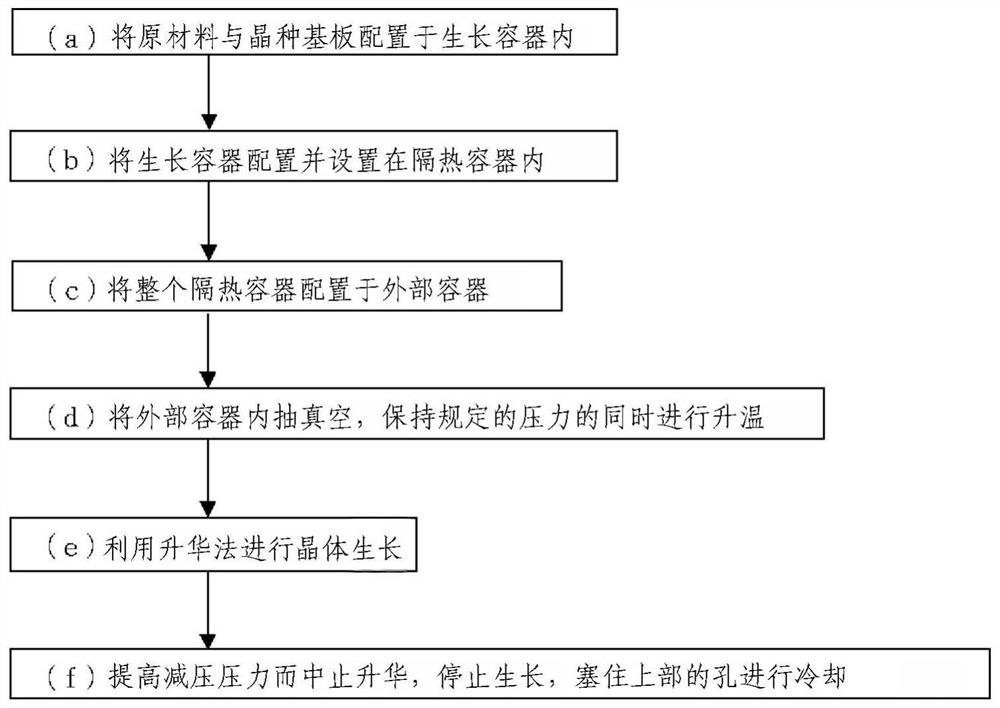

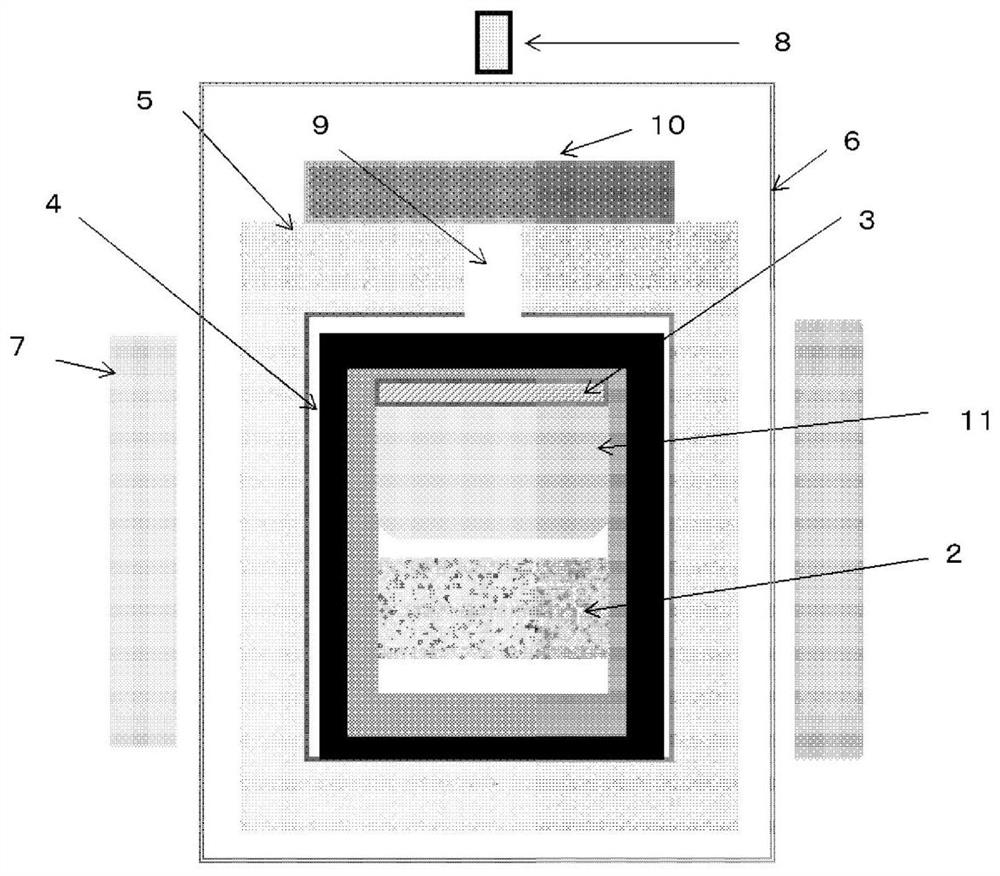

Production method and production device of silicon carbide single crystal

PendingCN111918988AUniform temperatureSolve the cooling problemAfter-treatment apparatusPolycrystalline material growthCarbide siliconMetallurgy

This production method of silicon carbide single crystal, for sublimating a silicon carbide raw material to grow a silicon carbide single crystal on a seed crystal substrate with a silicon carbide single crystal growth device provided with at least a growth vessel and a heat insulation vessel having a temperature measurement hole around said growth vessel, is characterized by measuring the temperature of the growth vessel through the temperature measurement hole during growth of the silicon carbide single crystal, and by blocking the temperature measurement hole with a shielding member when growth of the silicon carbide single crystal is complete and the silicon carbide single crystal is cooled. In this way, a production method and production device of a silicon carbide single crystal areprovided which decrease breakage and cracking of silicon carbide single crystal ingots and wafers.

Owner:SHIN-ETSU HANDOTAI CO LTD

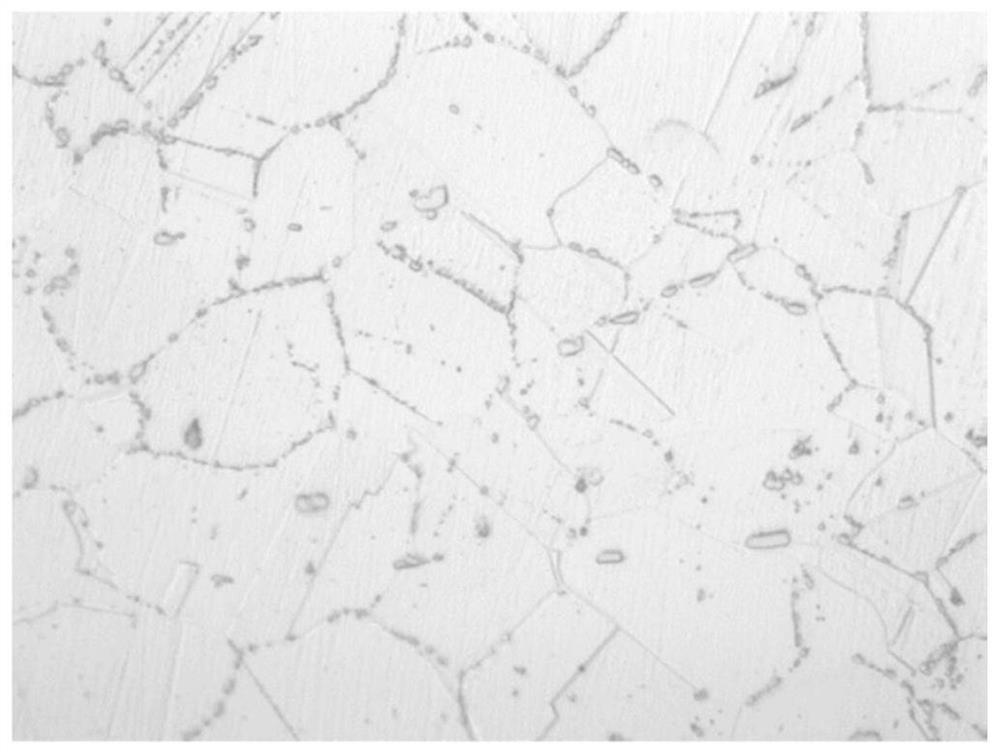

Method for making NiTi alloy ossicular fixator of easy taken-out type

InactiveCN100403996CSmall residual strainContinuous cohesionInternal osteosythesisNiti alloyMemory processing

A bone fixer able to be easily taken out is prepared from NiTi alloy through pre-treating, quenching at 780-830 deg.C, thermally mechanical treating with 0.2-0.3 strain for each deformation, bidirectional shape memory processing, cutting for shaping, and chemical polishing. It must be cooled at -6-10 deg.C before implantation or taking-out.

Owner:HARBIN ENG UNIV

Methacrylic resin composition

Owner:KURARAY CO LTD

A kind of 1300mpa grade high toughness cold-formed steel plate and its production method

ActiveCN112795837BImprove plasticityHigh yield strengthFurnace typesProcess efficiency improvementChemical compositionContinuous annealing

A 1300Mpa-grade high-toughness cold-formed steel sheet and a production method thereof belong to the technical field of metallurgy. The chemical composition and mass percentage content of the steel plate are C: 0.1-0.2%, Mn: 1.8-2.5%, S≤0.005%, P≤0.02%, Si: 1.0-1.5%, Als≤0.08%, Nb: 0.01-0.04%, Ti: 0.02-0.08%, Ni: 1.0-2.0%, and the balance is Fe and inevitable impurities. The production method includes the steps of steelmaking, continuous casting, heating, rolling, acid rolling, continuous annealing, and leveling and leveling; the temperature of the soaking section of the continuous annealing step is 760-820 DEG C, and the holding time is 60-225s. The steel plate of the invention has a yield strength of ≥850 MPa, a tensile strength of ≥1300 MPa, and an elongation of A50 of ≥8%, has good cold forming performance, and meets the requirements of lightweight automobile steel.

Owner:TANGSHAN IRON & STEEL GROUP +2

(meth)acrylic resin composition

ActiveCN104271663BExcellent injection moldabilityGood lookingCoatingsAcrylic resinOptical path length

A (meth)acrylic resin composition containing 99.5% by mass or more of a (meth)acrylic resin containing 80 to 100% by mass of methyl methacrylate-derived and 0 to 20% by mass of structural units derived from acrylate, the optical path length of the injection molded product obtained from the (meth)acrylic resin composition at a cylinder temperature of 280°C and a molding cycle of 4 minutes is 200mm The difference between the yellow index YI4 and the yellow index YI1 of the injection molded product with an optical path length of 200mm obtained at a barrel temperature of 280°C and a molding cycle of 1 minute is 3 or less, and the melt under the conditions of 230°C and 3.8kg load The flow rate is above 25 g / 10 minutes.

Owner:KURARAY CO LTD

Cu-al-mn shape memory alloy damping device for precision instruments and manufacturing method thereof

ActiveCN104963994BIncrease dampingGood anti-tiltNon-rotating vibration suppressionDamping functionShape-memory alloy

The invention discloses a Cu-Al-Mn shape memory alloy damping device for a precise instrument and a manufacturing method of the Cu-Al-Mn shape memory alloy damping device. The damping device comprises a workbench, a damping assembly and a base. The damping assembly connects the workbench with the base. The damping assembly is composed of a plurality of columnar crystal tissue Cu-Al-Mn shape memory alloy plates with high anisotropism. The Cu-Al-Mn shape memory alloy damping device has the advantages that the damping device has the functional anisotropism, in other words, 10% or more high recovery strain can be provided in the vertical direction, the damping performance is superior, and good energy absorbing and damping functions are achieved; 7% or more high recovery strain in the horizontal direction can be provided, the energy absorbing and damping functions are achieved, and due to higher strength and rigidity of plates in the thickness direction, the damping device has good inclination resisting and shaking resisting functions, and the precise instrument can be kept stable in the using, or moving or transporting process.

Owner:UNIV OF SCI & TECH BEIJING

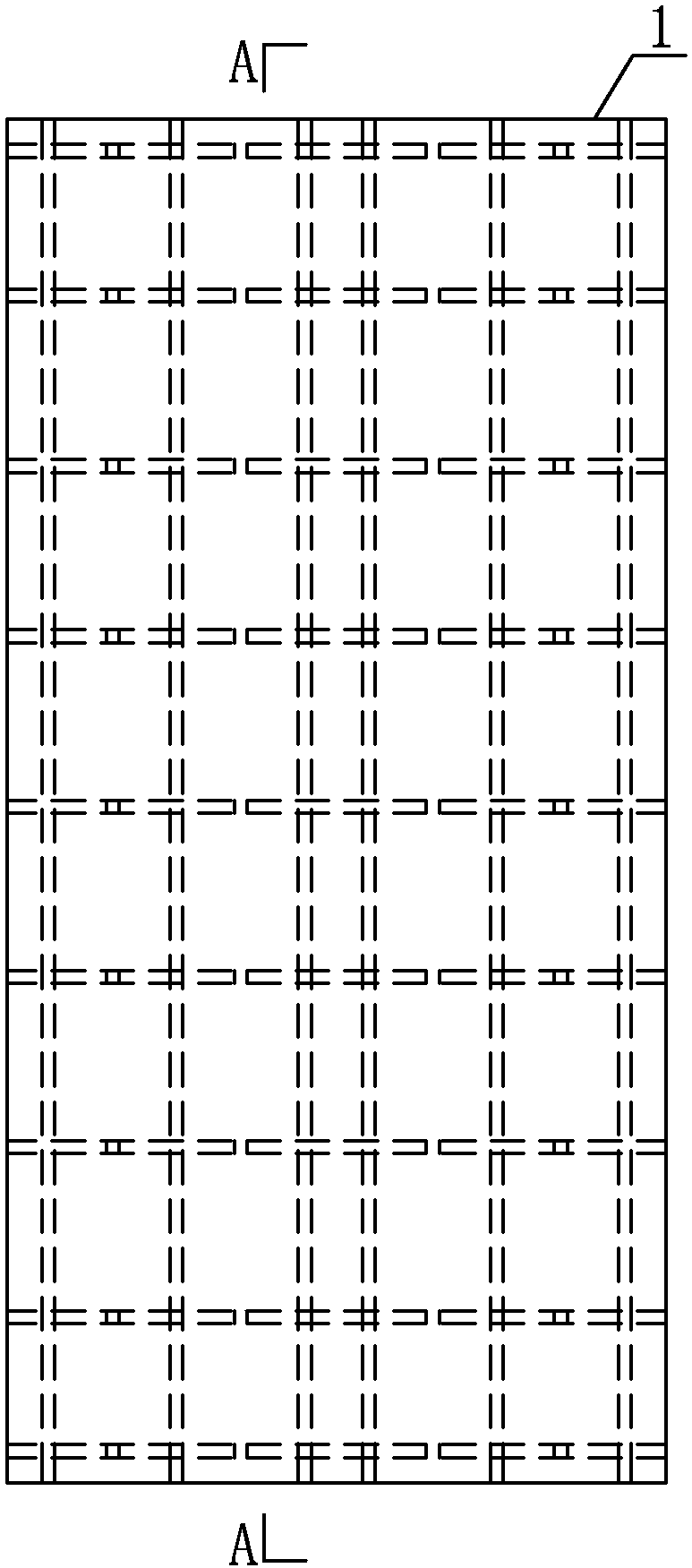

Construction method of staggered assembled steel plate-rpc anti-blast door

ActiveCN105781364BImprove finenessHigh reactivityCeramic shaping apparatusWar-like protectionEngineeringRebar

The invention discloses a staggered splicing type steel plate-RPC anti-detonation door and a construction method thereof. According to the anti-detonation door, a cavity formed by a door leaf front side steel plate, a door leaf reverse side steel plate and a plurality of inner ribbed beams is filled with an RPC inner core. The construction method of the anti-detonation door comprises the steps that firstly, the door leaf front side steel plate, the door leaf reverse side steel plate and the inner ribbed beams are manufactured according to the size; secondly, the number of needed steel bars is calculated; thirdly, steel bar holes are formed in the inner ribbed beams in the length direction; fourthly, the door leaf front side steel plate is welded to the odd-number inner ribbed beams, and the door leaf reverse side steel plate is welded to the even-number inner ribbed beams; fifthly, the door leaf front side steel plate and the door leaf reverse side steel plate are spliced in a staggered manner, and the steel bars penetrate the steel bar holes; sixthly, reactive powder concrete is poured in the cavity formed by the door leaf front side steel plate, the door leaf reverse side steel plate and the multiple inner ribbed beams and is standing for 48 h; seventhly, the anti-detonation door is conveyed into a steam curing room at the temperature of 90 DEG C to be cured for 72 h; and eighthly, after 28 days, the RPC and the steel plates are effectively bonded to form the steel plate-RPC anti-detonation door. The staggered splicing type steel plate-RPC anti-detonation door and the construction method thereof are applied to anti-detonation protection projects.

Owner:HARBIN INST OF TECH

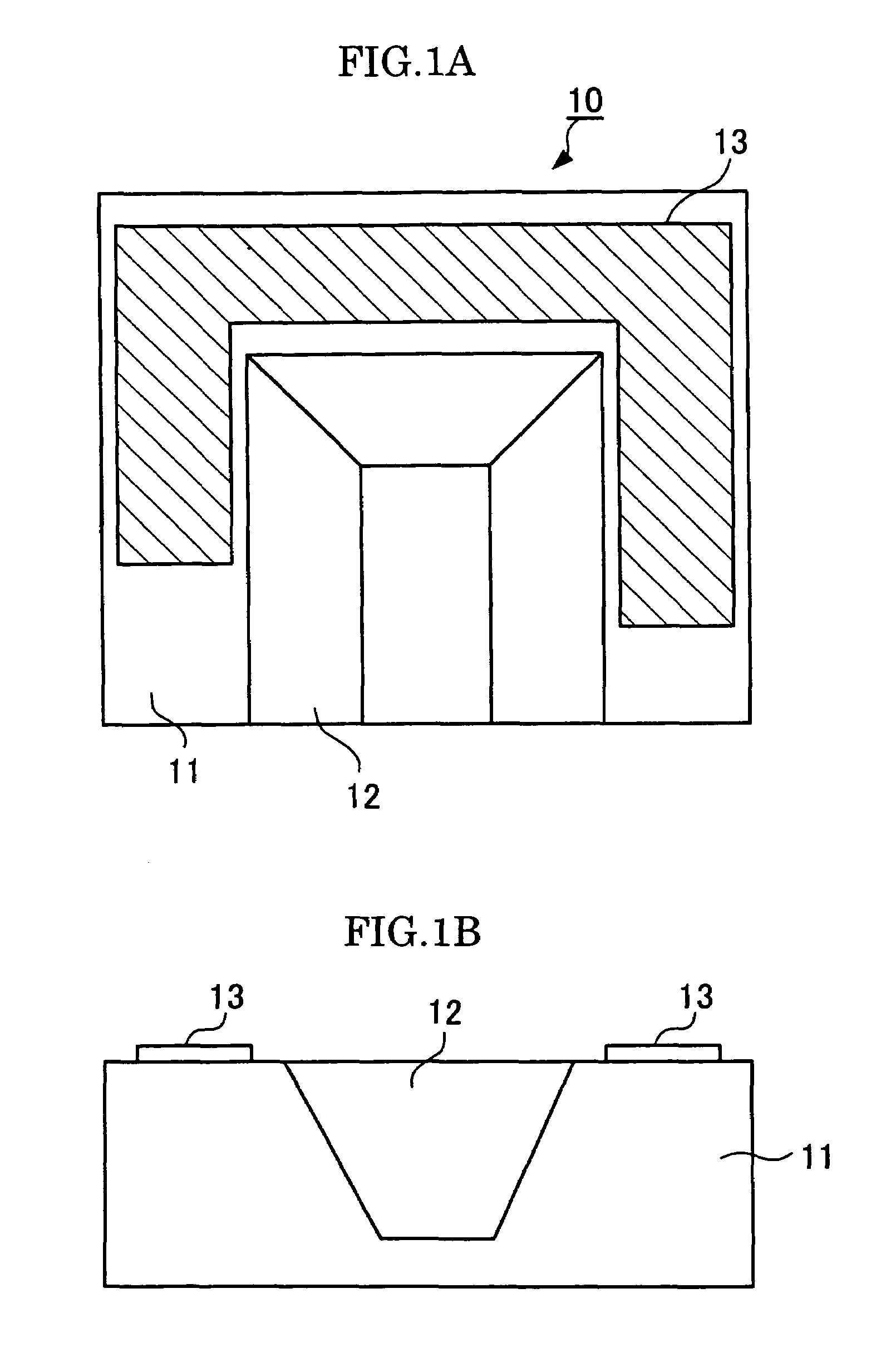

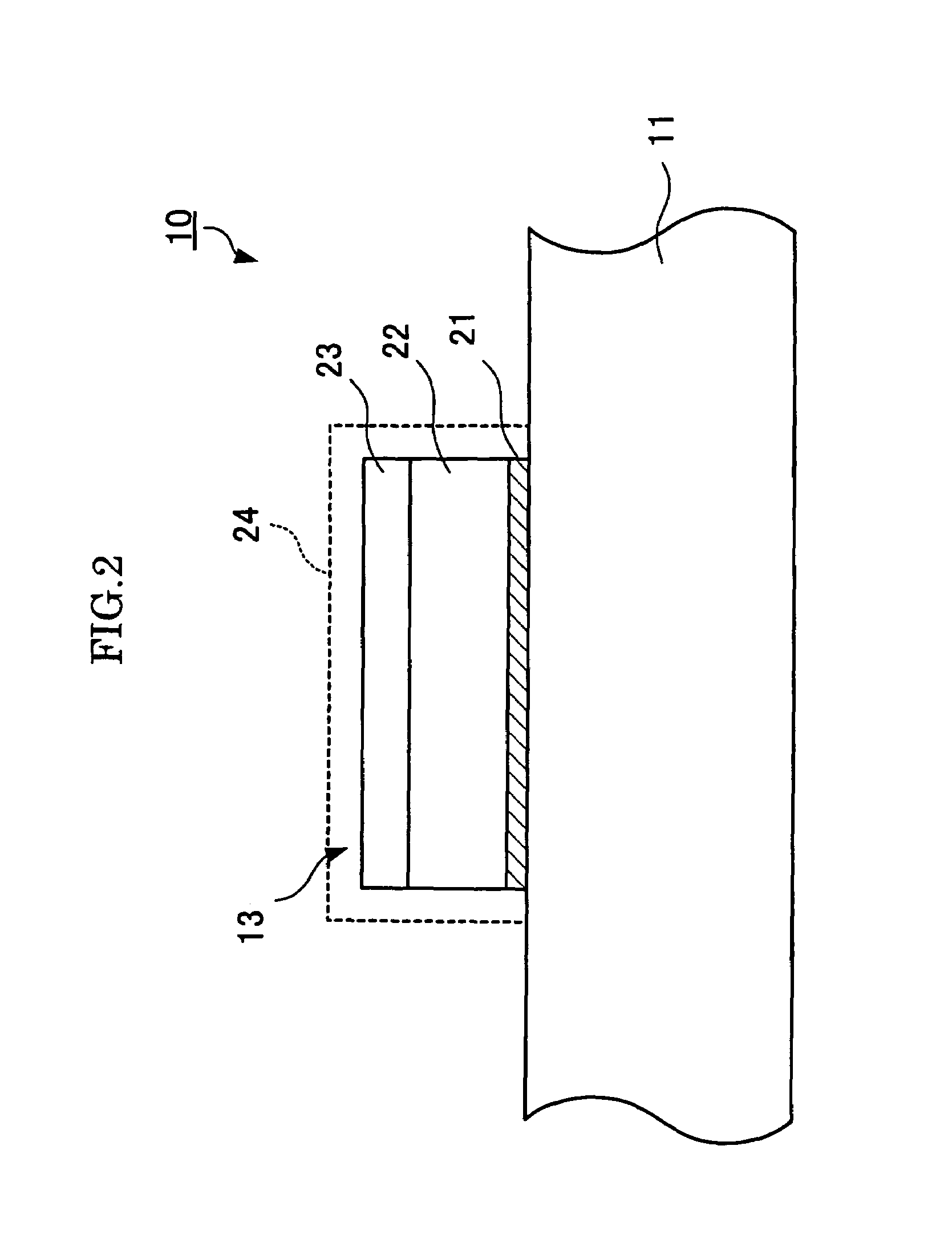

Method for manufacturing optical bench, optical bench, optical module, silicon wafer substrate in which wiring and groove are formed, and wafer

InactiveUS7118933B2Improve efficiencyIncrease productionDecorative surface effectsSemiconductor/solid-state device manufacturingOptical ModuleThin membrane

An optical bench on which an optical component is mounted comprises an Si substrate made of a silicon wafer, a groove disposed on the Si substrate and designed to mount the optical component thereon, and a metal thin-film wiring for driving the optical component or a driver component. The metal thin-film wiring is formed in an electroless plating process before a groove manufacturing process which forms the groove by micromachining by means of wet processing.

Owner:MAXELL HLDG LTD

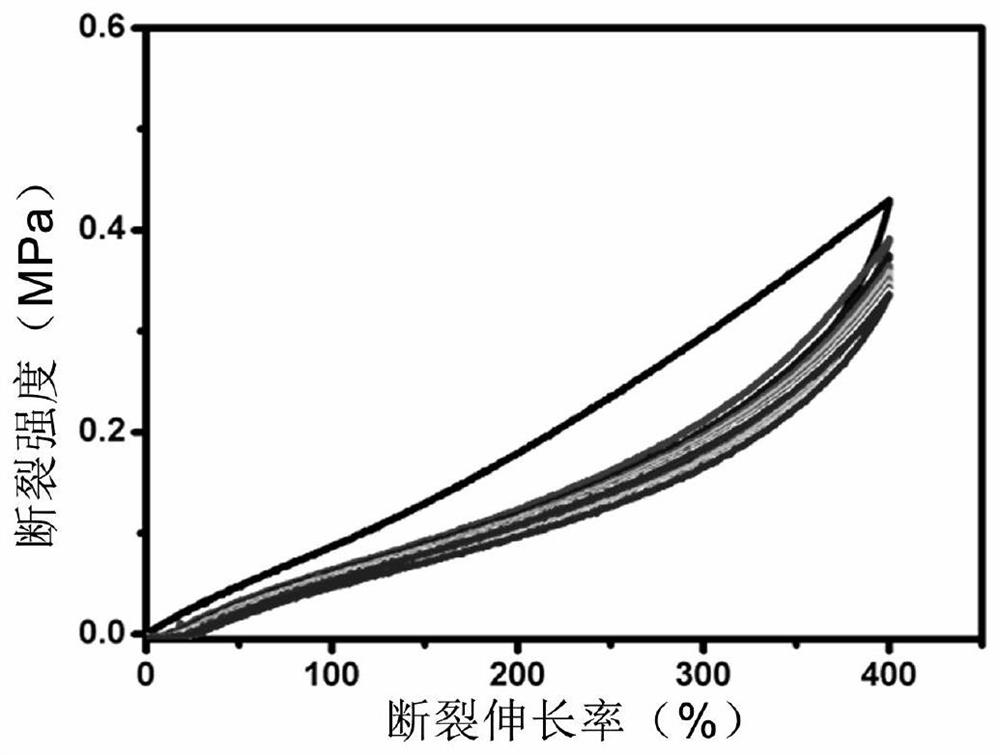

High-elasticity, repairable, super-durable and harmlessly treatable ionic conductor membrane and preparation method thereof

The invention discloses a high-elasticity, repairable, super-durable and harmlessly-treatable ionic conductor membrane and a preparation method thereof, and belongs to the technical field of stretchable ionic conductors. The preparation method comprises the following steps: covalently grafting a modifier onto a polymer under the catalysis of a catalyst to obtain a polymer matrix; heating and concentrating the polymer matrix solution at 25-70 DEG C, and uniformly mixing with the ionic liquid according to a certain mass ratio; and pouring the composite solution on a glass sheet to form a film by pouring, drying for 12-72 hours under the vacuum condition of 50-90 DEG C, and finally drying for 1-6 hours under the vacuum condition of 50-70 DEG C, thereby obtaining the ion conductor film which has excellent elasticity, is repairable, is super-durable and can be harmlessly treated. The preparation method is simple, the elasticity of the stretchable ionic conductor is greatly improved, the service life of the stretchable ionic conductor is greatly prolonged, and a new thought is provided for preparing the super-durable ionic conductor with the harmless discarding capacity.

Owner:JILIN UNIV

A processing method for nickel-titanium shape memory alloy high-strength wire

ActiveCN111346942BGood for continuous drawingSteady increase in work hardeningExtrusion cleaning devicesShape-memory alloyTitanium alloy

The invention discloses a method for processing a nickel-titanium shape memory alloy high-strength wire, which comprises the following steps: step 1) peeling a nickel-titanium alloy wire billet to obtain a nickel-titanium alloy thick wire; The nickel-titanium alloy thick wire material is hot-drawn, obtains the nickel-titanium alloy medium thick wire material; Step 3) the nickel-titanium alloy medium thick wire material in step 2) is carried out high-temperature annealing and water quenching; Step 4) step 3 ) through high-temperature annealing and water quenching in nickel-titanium alloy medium thick wire material is carried out cold drawing and on-line annealing treatment, obtains nickel-titanium alloy thin wire material; step 5) carries out the nickel-titanium alloy thin wire material in step 4) On-line aging treatment and peeling treatment can obtain nickel-titanium shape memory alloy high-strength wire.

Owner:西安华创新材料有限公司

Container formed by stretch forming and process for producing the same

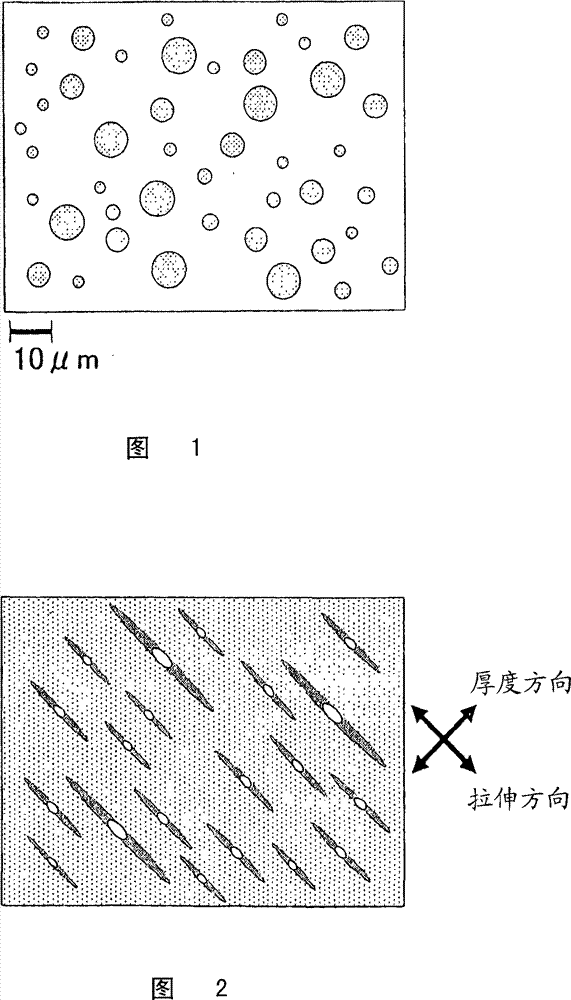

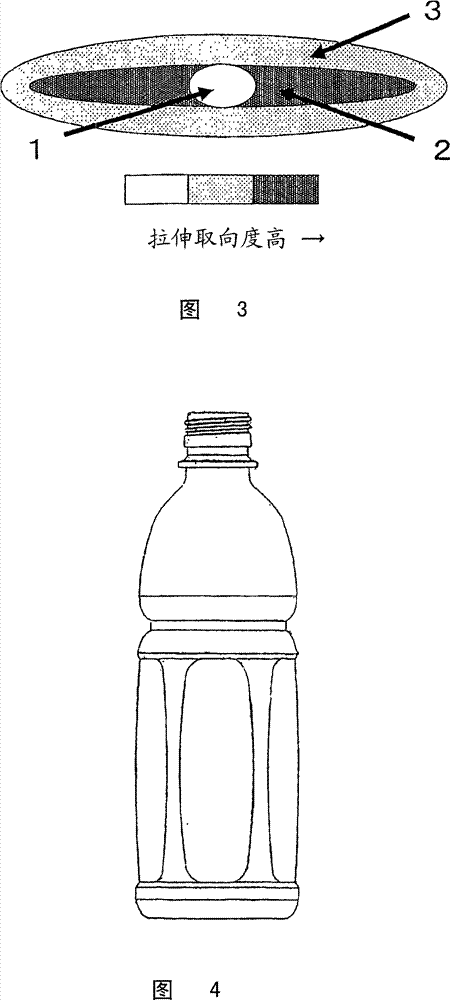

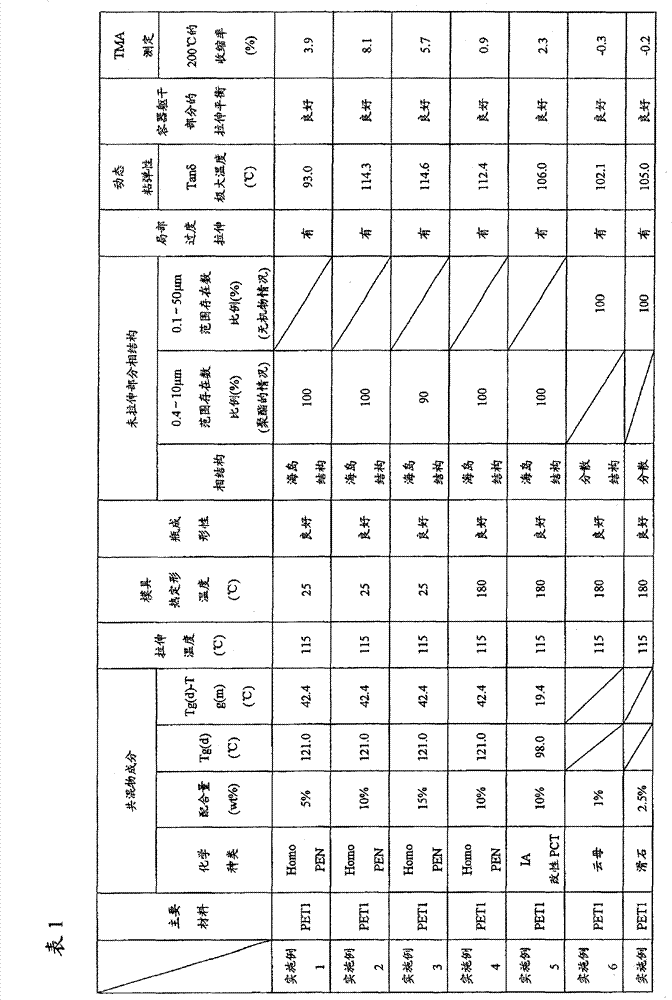

InactiveCN101223019BSmall residual strainGood stretch balanceRigid containersHollow articlesMechanical stretchingPolymer science

A stretch-formed container having a layer comprising a blend of an ethylene terephthalate type polyester resin and another material, characterized in that the layer comprising the blend has a dispersion structure composed of a continuous phase comprising the ethylene terephthalate type polyester resin and a dispersed phase comprising the other material and that at least the container body part has a tand maximum temperature of 115 DEG C or lower in a dynamic viscoelasticity examination. Due to the constitution, even when the mechanical stretching rate reaches a limit, strain hardening effectively occurs. Thus, a stretch-formed container of a polyester resin can be provided which has both of excellent heat resistance attributable to high-temperature stretching and a stretch balance attributable to strain hardening.

Owner:TOYO SEIKAN KAISHA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com