Method for transferring micro-light emitting diodes, micro-light emitting diode device and electronic device

A technology of micro-light-emitting diodes and transfer methods, which is applied in the direction of circuits, electrical components, and electric solid-state devices, can solve problems such as mismatch and lower product quality, and achieve the effects of easy control, avoiding heating, and easy programming control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

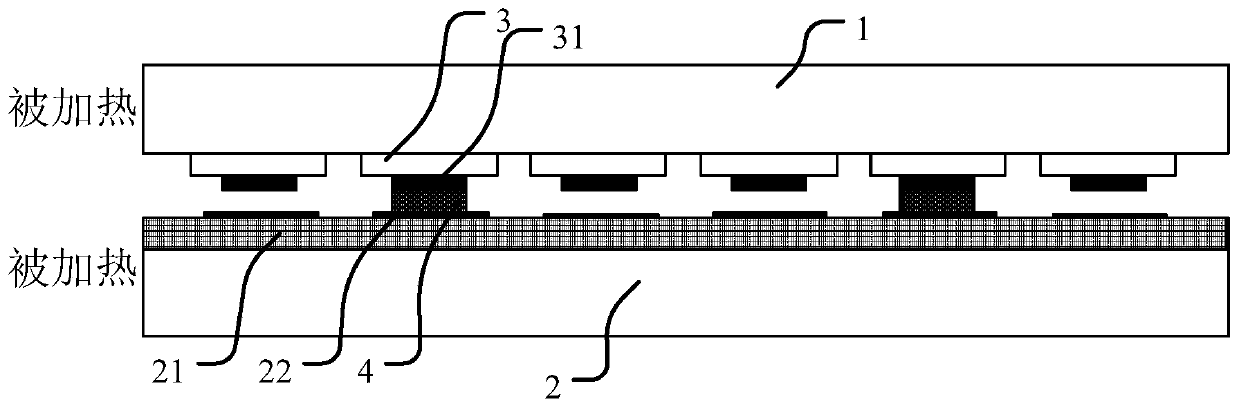

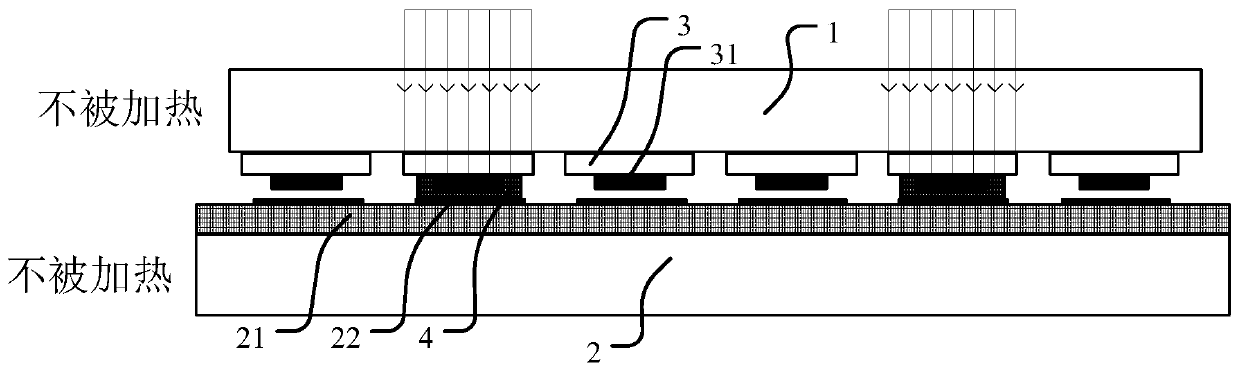

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

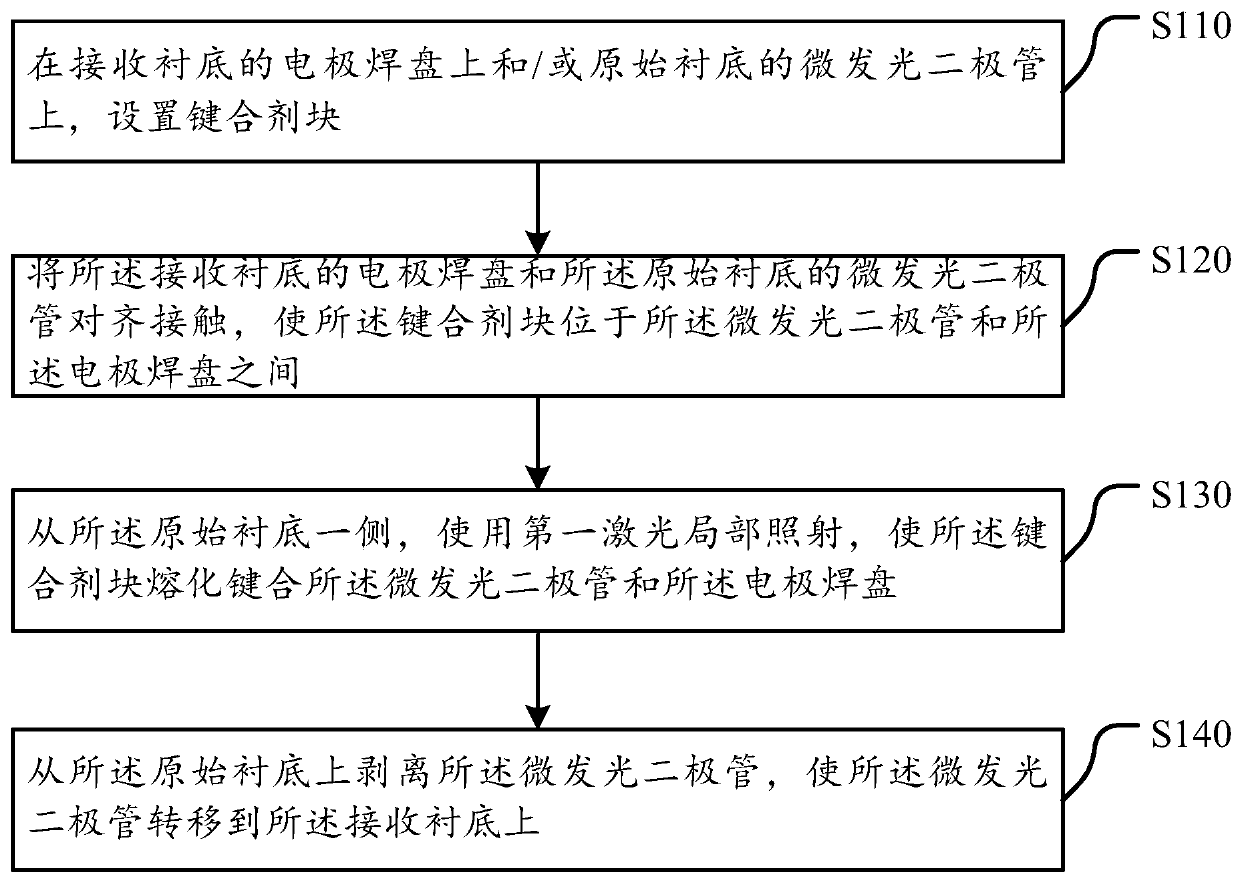

[0032] figure 2 Schematically shows an embodiment of the micro light emitting diode transfer method of the present invention, as figure 2 As shown, the method includes the following steps:

[0033] Step S110 , disposing a bonding agent block on the electrode pads of the receiving substrate and / or on the micro light emitting diodes of the original substrate. Usually, one bonding agent block is arranged on each receiving electrode pad or one bonding agent block is arranged on each micro light emitting diode to be transferred.

[0034] Step S120, aligning and contacting the electrode pads of the receiving substrate and the micro-light emitting diodes of the original substrate, so that the bonding agent block is located between the micro-light-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com