Laminated manufacturing method for three-dimensional microstructure polymer microfluidic chip

A technology of a microfluidic chip and a manufacturing method, applied in the directions of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve problems such as inapplicability of three-dimensional microstructure, and achieve mass manufacturing, popularization, application, and optimization. The effect of the step process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

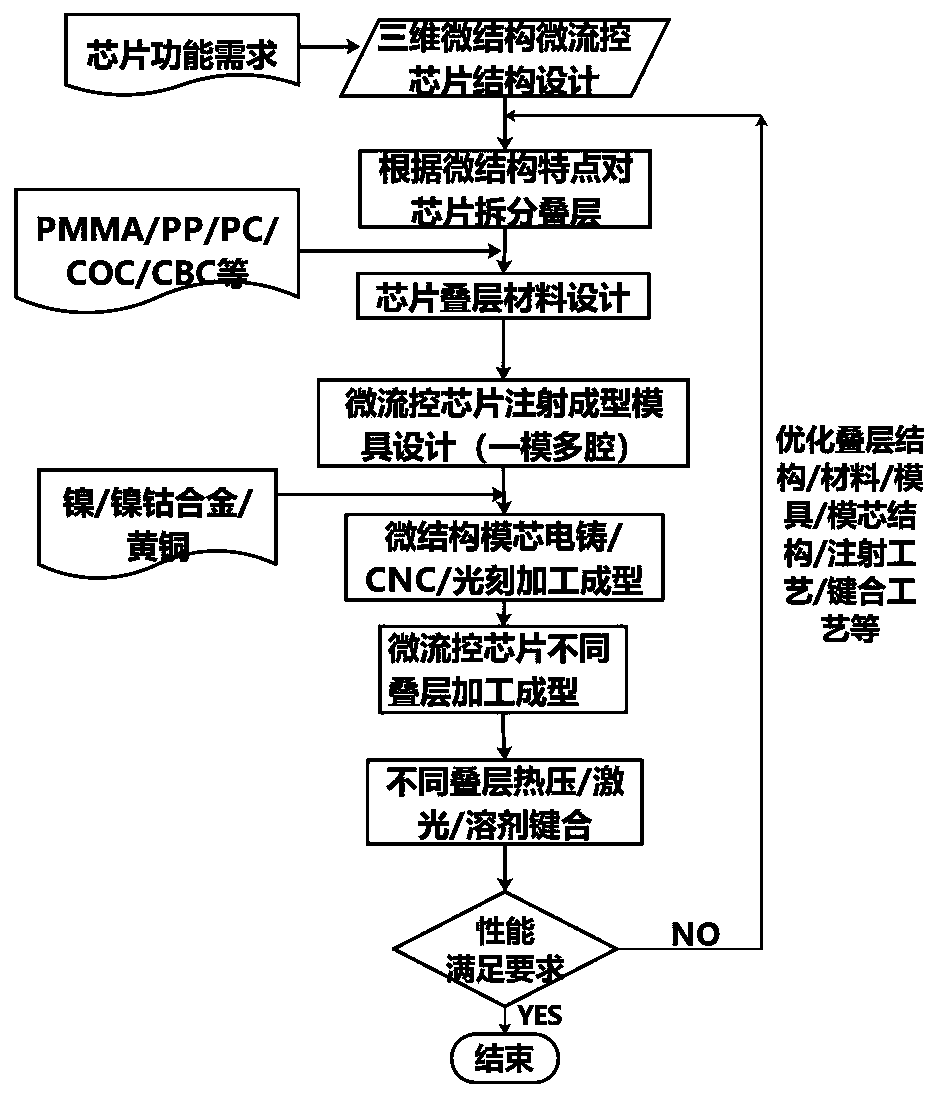

[0042] like figure 1 As shown, a method for manufacturing a three-dimensional microstructure polymer microfluidic chip, the specific steps are as follows:

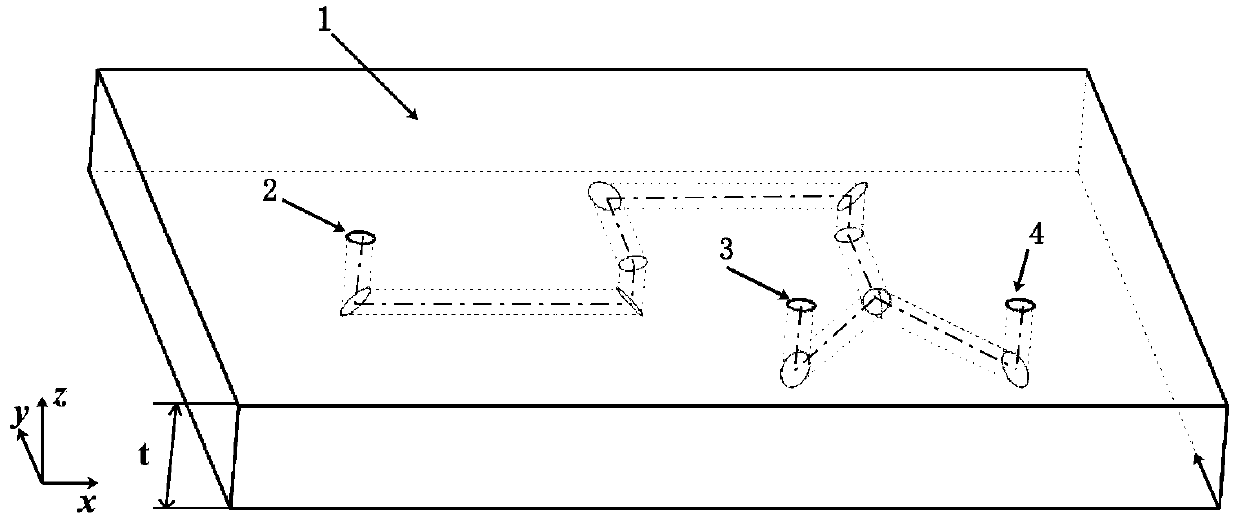

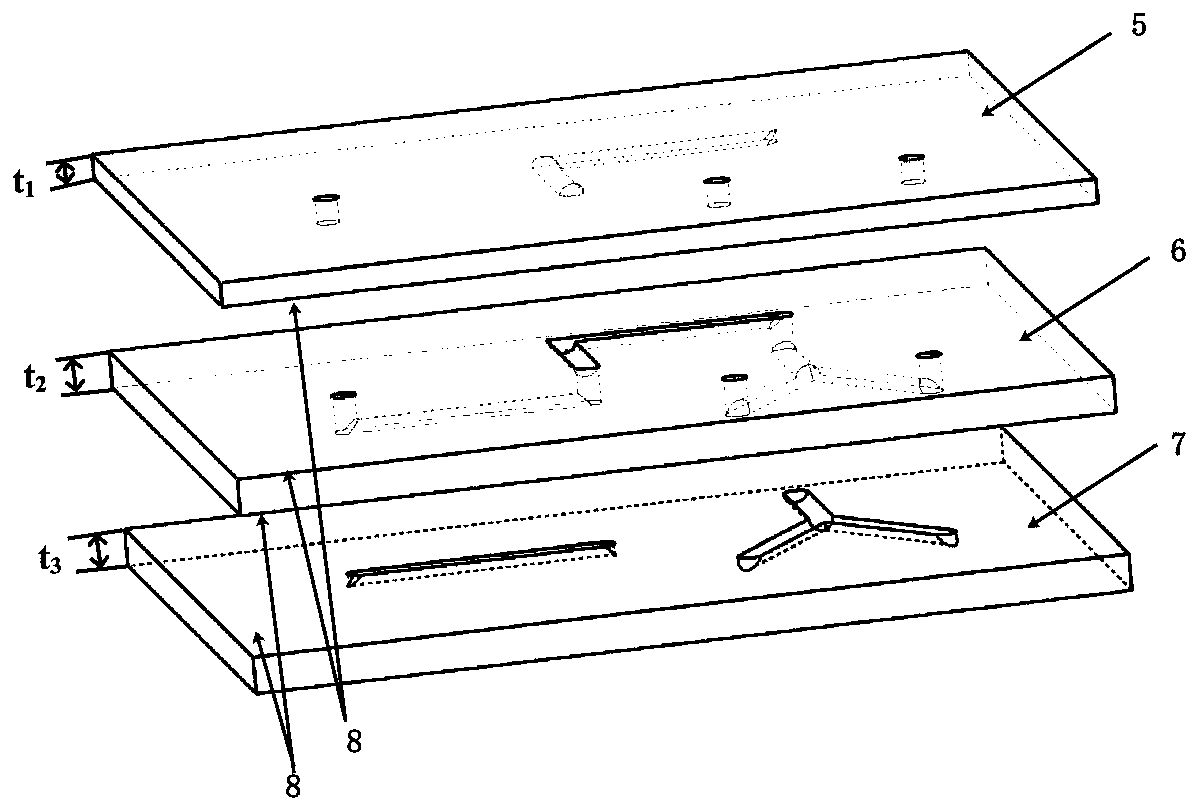

[0043] 1. Determine the microfluidic chip with three-dimensional microstructure according to the function of the chip, such as figure 2 shown. During the use of the chip, microfluid flow in three coordinates (x, y, z) directions can be realized. The chip has a solution inlet 2, a solution outlet I3, and a solution outlet II4. Structural analysis of the microfluidic chip with three-dimensional microstructure was carried out, and the chip was stacked and divided according to the number of x-direction channel planes in different z-directions of the chip. The chip is divided into three stacks, and the divided stacks are as follows image 3 As shown, including stack I5, stack II6 and stack III7. The split stack is as follows image 3 shown. There is a relationship t=t between the stack thickness and the total thickness ...

Embodiment 2

[0052] Make a three-dimensional microstructure microfluidic chip of PMMA material such as Figure 7 shown. Electroforming method is used to make different laminated mold cores, and the laminated layers are divided according to the structural characteristics such as Figure 7 As shown, it is divided into four laminates, and the ultrasonic micro-injection molding process is used for injection molding of different laminates. The injection-molded stacks are bonded by hot pressing or adhesive bonding to form a complete microfluidic chip with a three-dimensional microstructure, such as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com