Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Play a role in heterogeneous nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

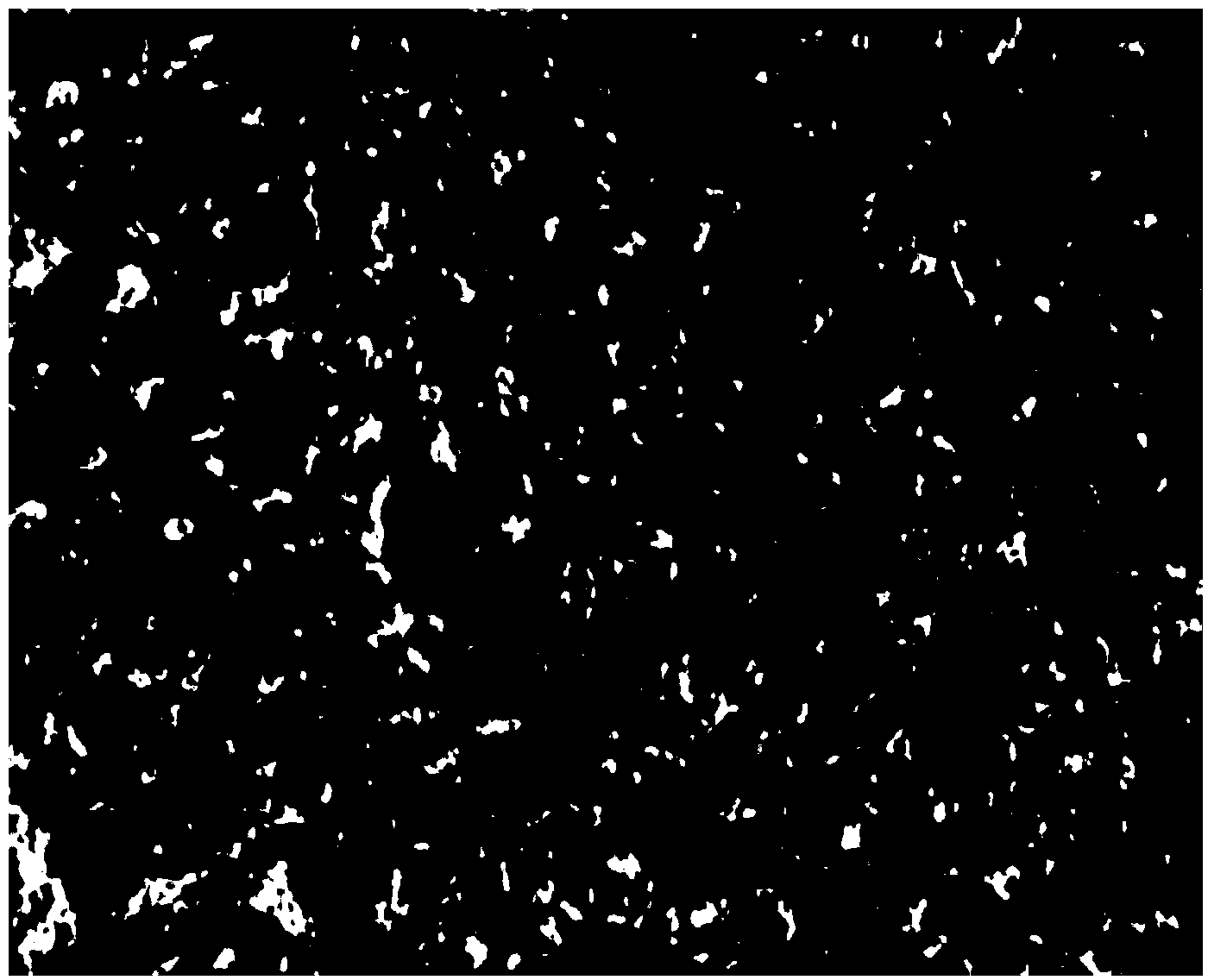

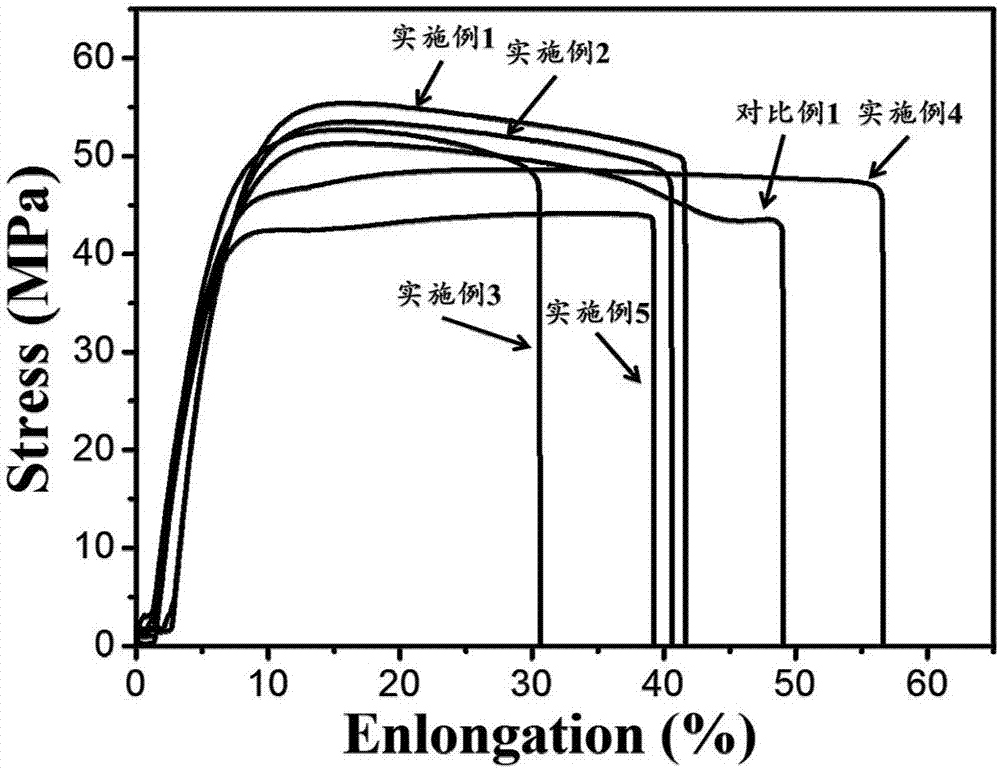

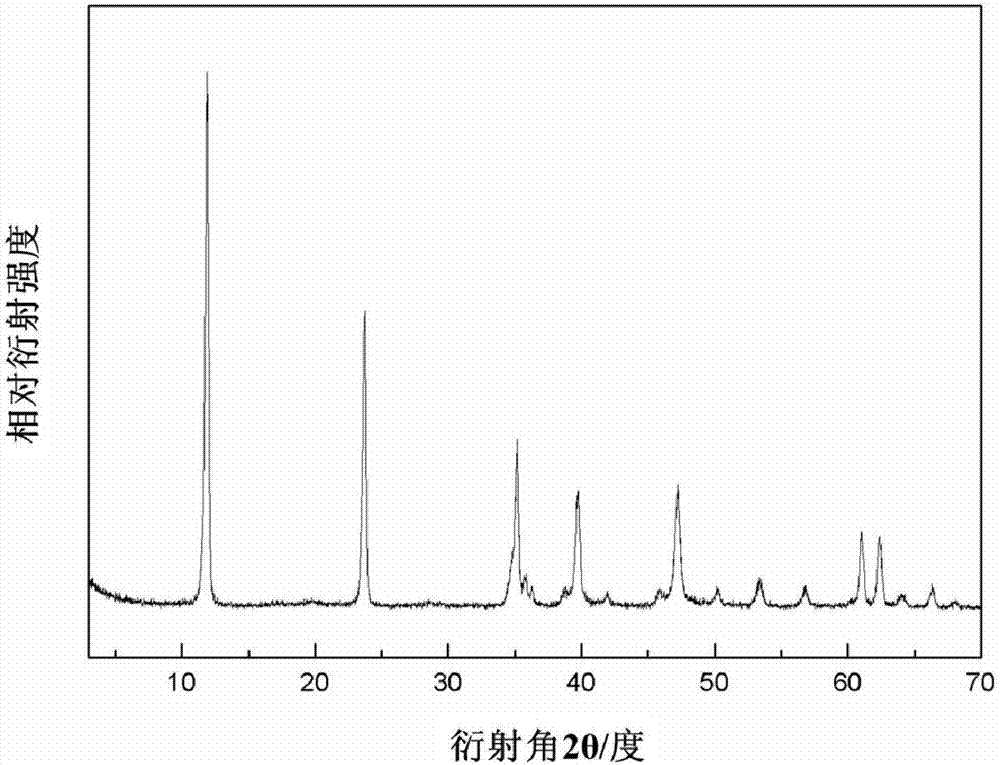

High-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and preparation method thereof

The invention discloses high-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and a preparation method thereof. The alloy comprises the following specific components in percentage by weight: 9.50-10.80% of Li, 3.00-5.00% of Al, 0.50-0.70% of Y, 0.10-0.30% of Zr and the balance of Mg; the alloy has the structural characteristics that an alpha phase, a beta phase and a precipitated phase exist at the same time, wherein the alpha phase is a Mg-based solid solution and is in a close-packed hexagonal structure, the beta phase is a Li-based solid solution and is in a body-centered cubic structure, and the precipitated phase is a rare earth compound Al2Y; and the alloy has the characteristics of low density, high plasticity and higher strength. The preparation method disclosed by the invention is a normal-temperature plastic deformation method which combines casting with equal channel angular extrusion or traditional extrusion deformation process; and compared with the traditional high-temperature deformation process, the preparation method has good practicality and is simpler and more convenient to operate, and can be used for effectively lowering the production cost, thus the preparation method has good industrial production prospects.

Owner:SOUTH CHINA UNIV OF TECH

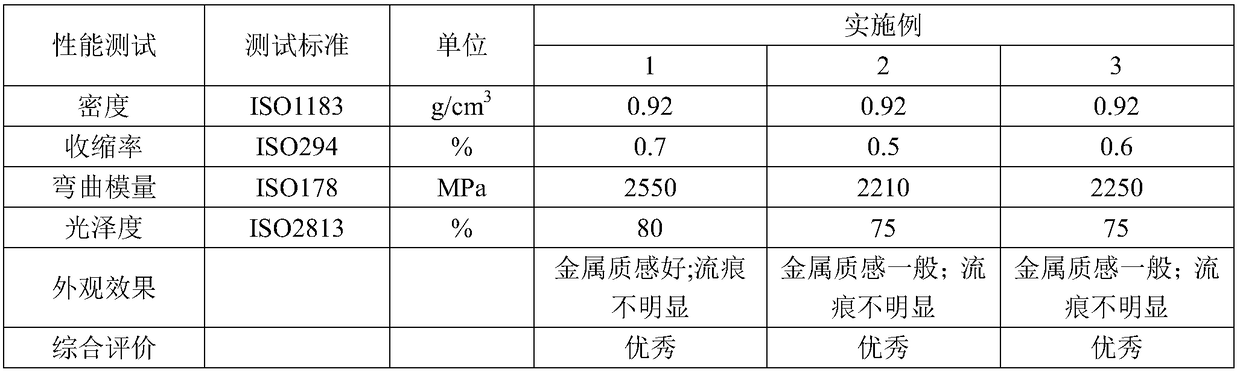

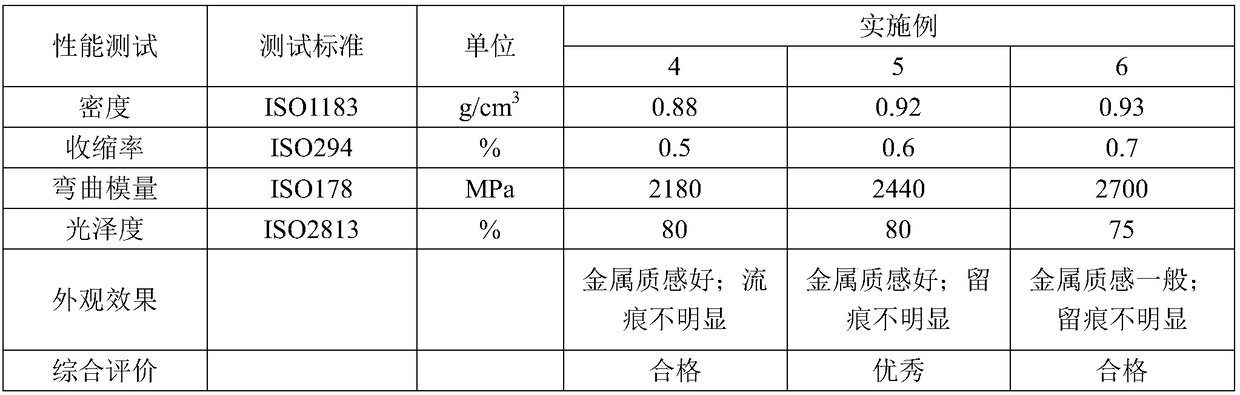

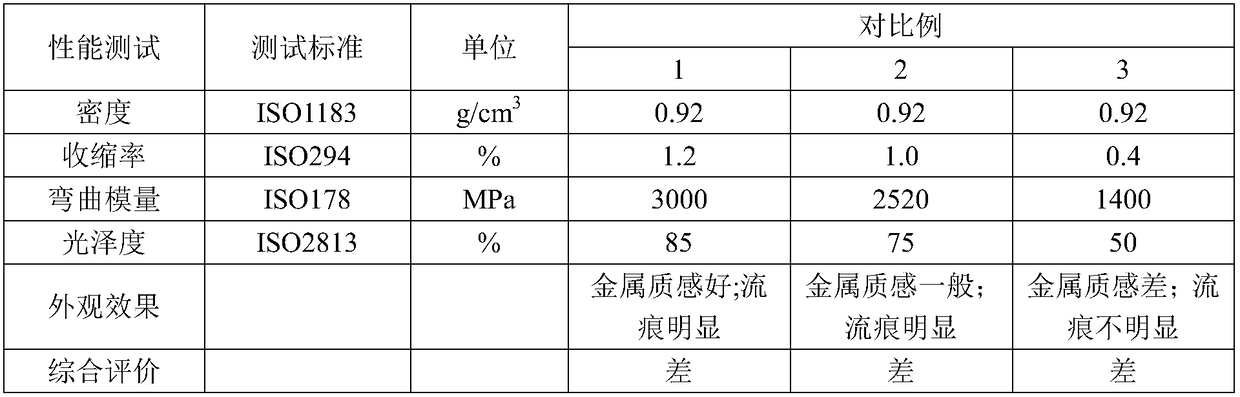

Low-density and low-shrinkage-rate silver metal texture polypropylene composite material and preparation method thereof

The invention discloses a low-density and low-shrinkage-rate silver metal texture polypropylene composite material and a preparation method thereof. The polypropylene composite material comprises high-crystallized polypropylene, high-melt-value polypropylene, low low-shrinkage-rate polypropylene, hollow glass beads, ultra-white and ultra-fine talcum powder, toughening fillers, metal pigments, nano-zinc sulfide, hyperbranched resin, antioxidants and scratch-resistant agents. In the injection molding process of the free-spraying polypropylene composite material, obvious welding marks on the surface of the material are omitted, the appearance of the material approaches to spraying effects, components can be directly used, later spraying treatment is omitted, cost is saved, the material is green and environmentally friendly, the density of the material is much lower than that of common modified polypropylene, lightweight requirements of clients are met, the shrinkage rate of the material is lower than 0.5, the material can directly replace ABS (acrylonitrile butadiene styrene) in the field such as household electric appliance shells, secondary mold opening is omitted, and cost is saved.

Owner:WANHUA CHEM GRP CO LTD +1

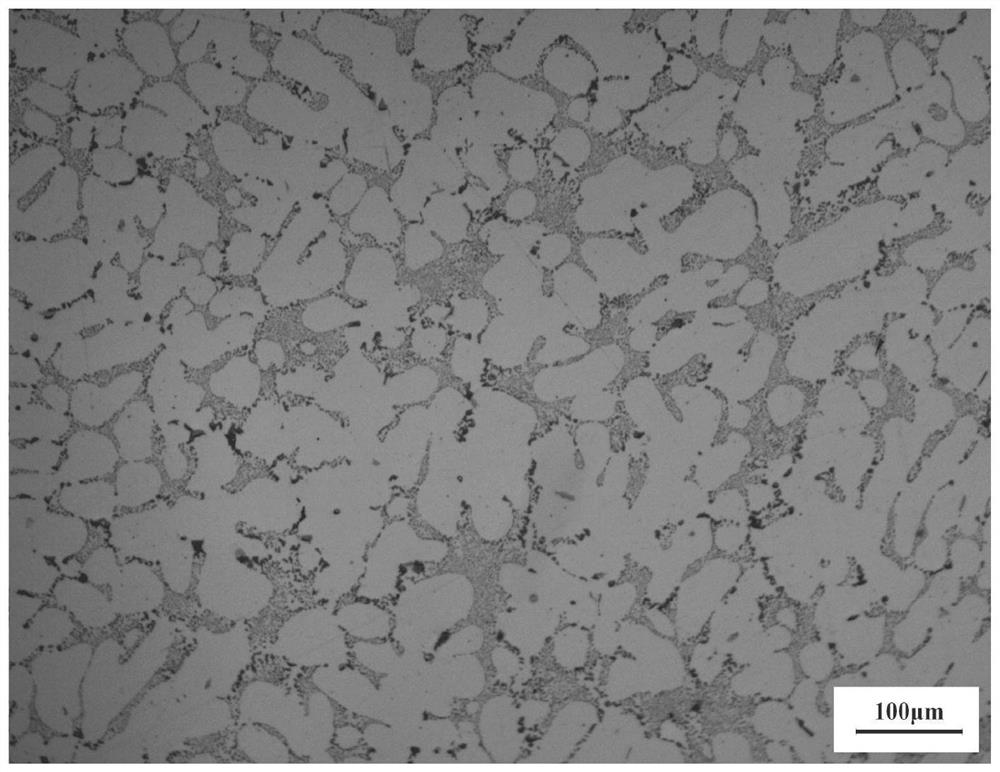

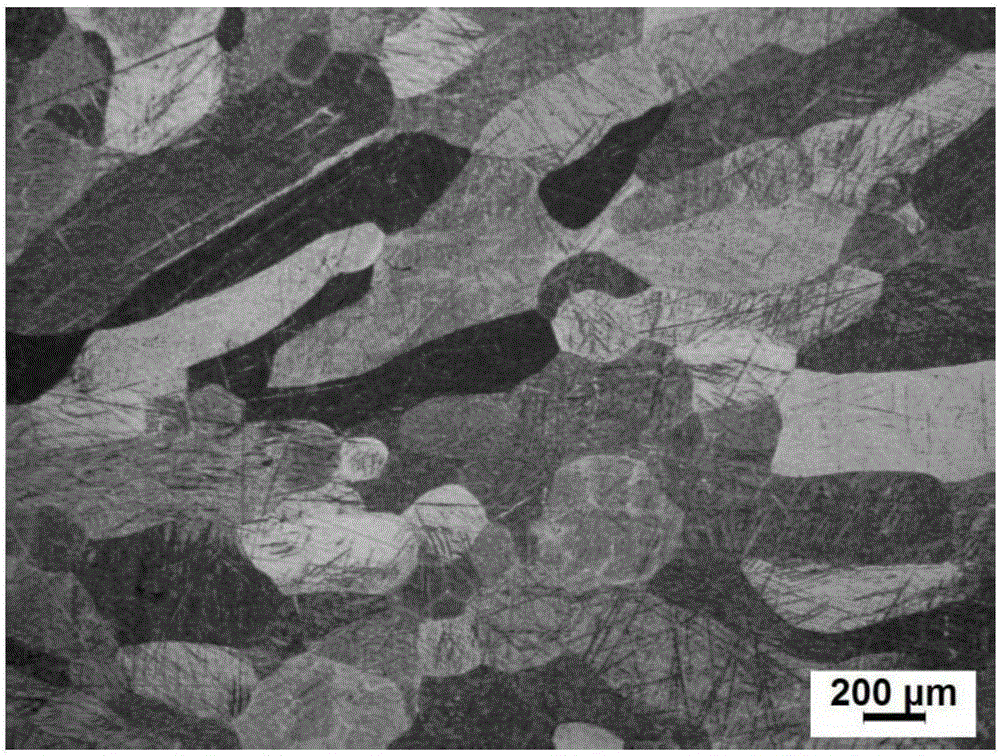

High-strength and high-elasticity-modulus casting Mg-RE alloy and preparation method thereof

The invention discloses a high-strength and high-elasticity-modulus casting Mg-RE alloy and a preparation method thereof. The casting Mg-RE alloy comprises 8-14wt% of Gd, 2-6wt% of Y, 1-5wt% of Zn, 0.5-2.5wt% of Si, 0.4-1wt% of Zr, the impurity elements of Fe, Cu and Ni and the balance of Mg, wherein the total content of the impurity elements of Fe, Cu and Ni is smaller than 0.02wt%. The preparation method includes the steps of smelting and heat treatment. According to the preparation method, Si is added and reacts with Mg and RE in an MG alloy to generate a high-elasticity-modulus Si-containing phase, meanwhile, Zn is added and reacts with Mg and RE in the Mg alloy to generate a stable eutectic phase, in this way, the crystallization range of an alloy melt is reduced, melt fluidity is improved, and accordingly through the following corresponding heat treatment process, the alloy has high room-temperature strength and elasticity modulus.

Owner:SHANGHAI JIAO TONG UNIV

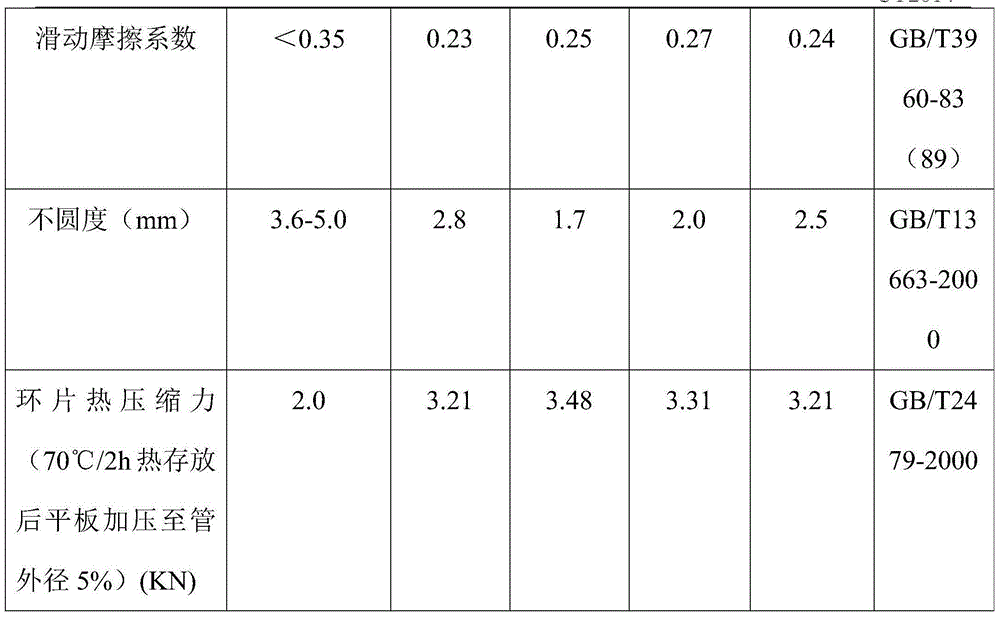

Anti-impact MPP (molypermalloy powder core) electric protection tube

The invention discloses an anti-impact MPP (molypermalloy powder core) electric protection tube. The anti-impact MPP electric protection tube is prepared from the following raw materials in parts by weight: 90-110 parts of polypropylene, 5-15 parts of ethylene-propylene-diene monomer, 10-25 parts of talcum powder, 3-10 parts of brucite powder, 5-12 parts of modified micro silicon powder, 0.8-2 parts of colouring agent, 5-15 parts of nano mica, 0.5-2 parts of antioxidant, 0.5-2 parts of polytetrafluoroethylene, 10-25 parts of modified shell powder, 5-15 parts of modified hectorite, 5-25 parts of novel organic montmorillonite, 5-18 parts of melamine cyanurate, 10-25 parts of modified crystal whisker, 15-30 parts of long glass fiber, 3-8 parts of expandable graphite and 5-20 parts of intumescent flame retardants. The anti-impact MPP electric protection tube has excellent impact resistance, flame retardance, ageing resistance, cold resistance and heat resistance.

Owner:安徽宁国市高新管业有限公司

Method for preparing high-hardness and high-toughness abrasion resistant balls through laser cladding

InactiveCN105297005AGood wear resistanceRefined crystal structureFoundry mouldsFurnace typesScrapTungsten

The invention discloses a method for preparing high-hardness and high-toughness abrasion resistant balls through laser cladding. The method comprises the following steps that scrap steel, chrome steel, rare earth alloy, manganese steel, molybdenum steel, vanadium steel, tungsten residues, silicon iron, titanium ingots, zirconium ingots, aluminum ingots and magnesium ingots are smelted, so that liquid alloy is obtained; ball billets are obtained by pouring the liquid alloy; tempered balls are obtained by conducting heat treatment on the ball billets; and laser cladding is conducted with Fe-based alloy and wolfram carbide (WC) powder serving as cladding powder after the tempered balls are cleaned, and the high-hardness and high-toughness abrasion resistant balls are obtained. The Fe-based alloy comprises C, Cr, Co, Ni, Mo, Ti, V and B. The power of laser cladding is 2500-3000W. The diameter of a light spot is 3-5 mm. The movement speed of the light spot is 10-15 mm / s. The thickness of a cladding layer is 5-10 [mu]m. According to the method for preparing the high-hardness and high-toughness abrasion resistant balls through laser cladding, the process is simple, conditions are easy to control, and an obtained finished product is high in hardness, good in toughness and long in service life.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

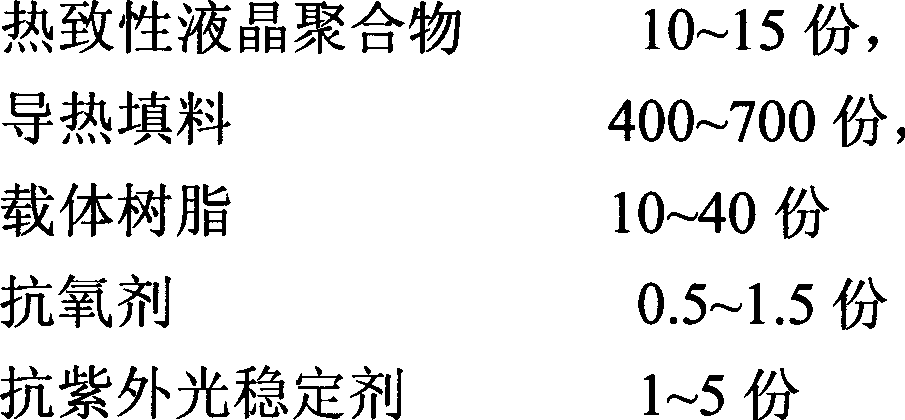

Method for preparing polyamide-based heat conduction composite material through melt blending

InactiveCN103862589AImprove flow processabilityImprove intrinsic thermal conductivityForm processingPolyamide

The invention relates to a method for preparing polyamide 6-based heat conduction plastic through melt blending. The method comprises the following steps: 1, preparing a multifunctional master batch from an elastomer which contains a polar group and is used as a carrier and coupling agent treated heat conduction inorganic filler particles, an antioxidant, an ultraviolet stabilizing agent and the like through a double-screw extruder; and 2, preparing the heat conduction composite material from polyamide 6, a thermotropic liquid crystal polymer and the master batch prepared in the first step through the double-screw extruder. The polyamide 6-based composite material prepared by the method disclosed by the invention is high in heat conduction performance, high in forming processing property and high in mechanical property, is suitable for injection molding, and can be widely applied to electronic appliances, mobile phone shells and LED (light emitting diode) lamp products; the heat dissipation performance of a product at high temperature is improved, and the service life of the product is prolonged.

Owner:HANGZHOU QIANSHI TECH

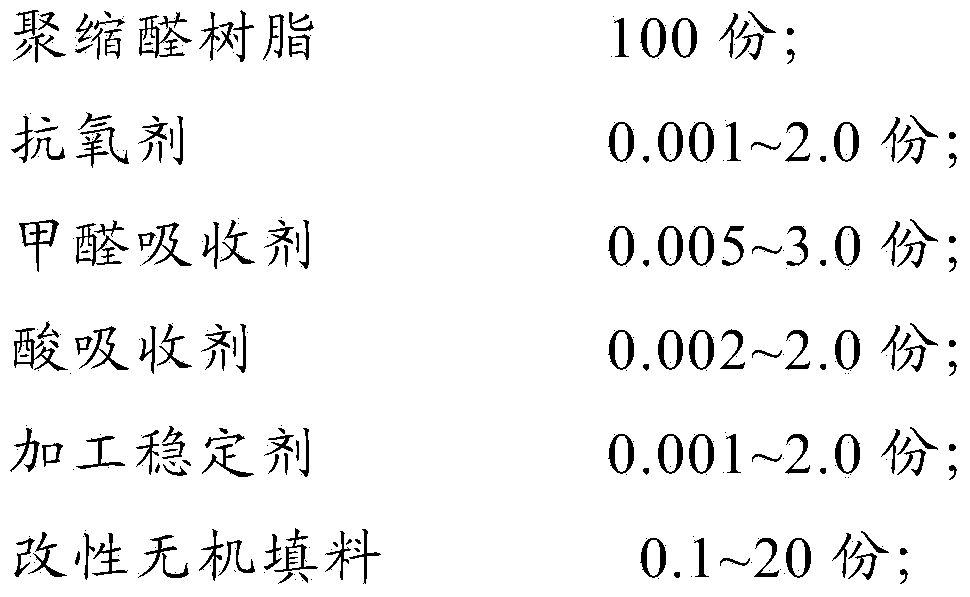

Polyacetal resin composition and preparation method thereof

ActiveCN103450628AHigh strengthImprove toughnessPigment treatment with organosilicon compoundsPigment physical treatmentNucleationUltimate tensile strength

The invention provides a polyacetal resin composition. The polyacetal resin composition comprises 100 parts of polyacetal resin, 0.001-2.0 parts of an antioxidant, 0.005-3.0 parts of a formaldehyde absorbent, 0.002-2.0 parts of an acid absorbent, 0.001-2.0 parts of a processing stabilizer and 0.1-20 parts of a modified inorganic filler, wherein the modified inorganic filler is obtained by using a modifying agent for modifying an inorganic filler at a rotating speed of 3000-50000r / pm at the temperature of 60-200 DEG C. The modified inorganic filler can be ensured for improving the compatibility of a composition matrix so as to realize uniform dispersion, and meanwhile plays a role in heterogeneous nucleation in the crystallization process of the composition so as to reduce the size of crystal nucleuses, thus the strength and the roughness of the obtained polyacetal resin composition are obviously improved. Experiment results show that the tensile strength of the polyacetal resin composition is 63-70MPa, and the notch impact strength of the polyacetal resin composition is 8.0-11.0KJ / m<2>.

Owner:YUNNAN YUNTIANHUA

Graphene-oxide-modified polypropylene composite material

The invention discloses a graphene-oxide-modified polypropylene composite material which is prepared from graphene-oxide-modified polypropylene, ethylene propylene diene monomer rubber, a butadiene-acrylonitrile copolymer, a silane coupling agent, zinc borate, magnesium hydroxide, pentaerythritol, epoxy soybean oil, tritolyl phosphate, pentaerythritol stearate, yttrium oxide, nano mica powder, talcum powder, silicon micropowder, 1,3,2,4-di(3,4-dimethylbenzylidene)sorbitol, an ethylene-octylene copolymer and 2-hydroxy-4-n-octyloxy diphenyl ketone. The graphene-oxide-modified polypropylene composite material has the advantages of high strength, excellent heat resistance, excellent flame retardancy and favorable heat stability.

Owner:ANHUI LANTONG TECH CO LTD

Preparation method of high-toughness heat-treatment-free material suitable for castings with various wall thicknesses

According to the preparation method of the high-toughness heat-treatment-free material suitable for castings with various wall thicknesses, by adding Nb, B, other rare earth elements and other microelements, the nucleation mechanism of aluminum alloy is changed, the castings obtain fine and uniform metallographic structures, and therefore the overall mechanical property of the castings is improved.

Owner:天津新立中合金集团有限公司

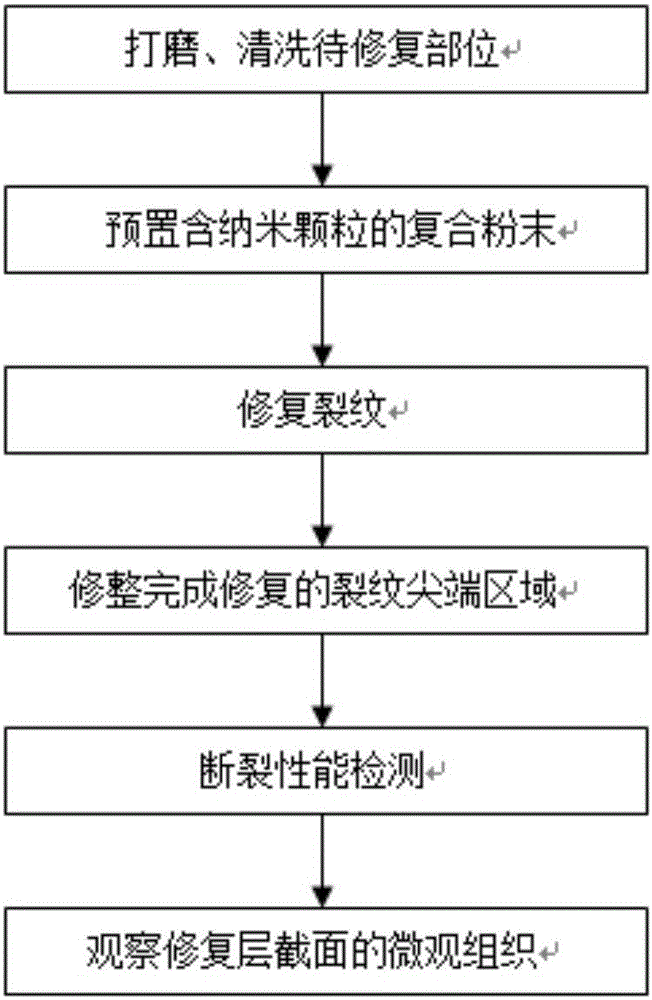

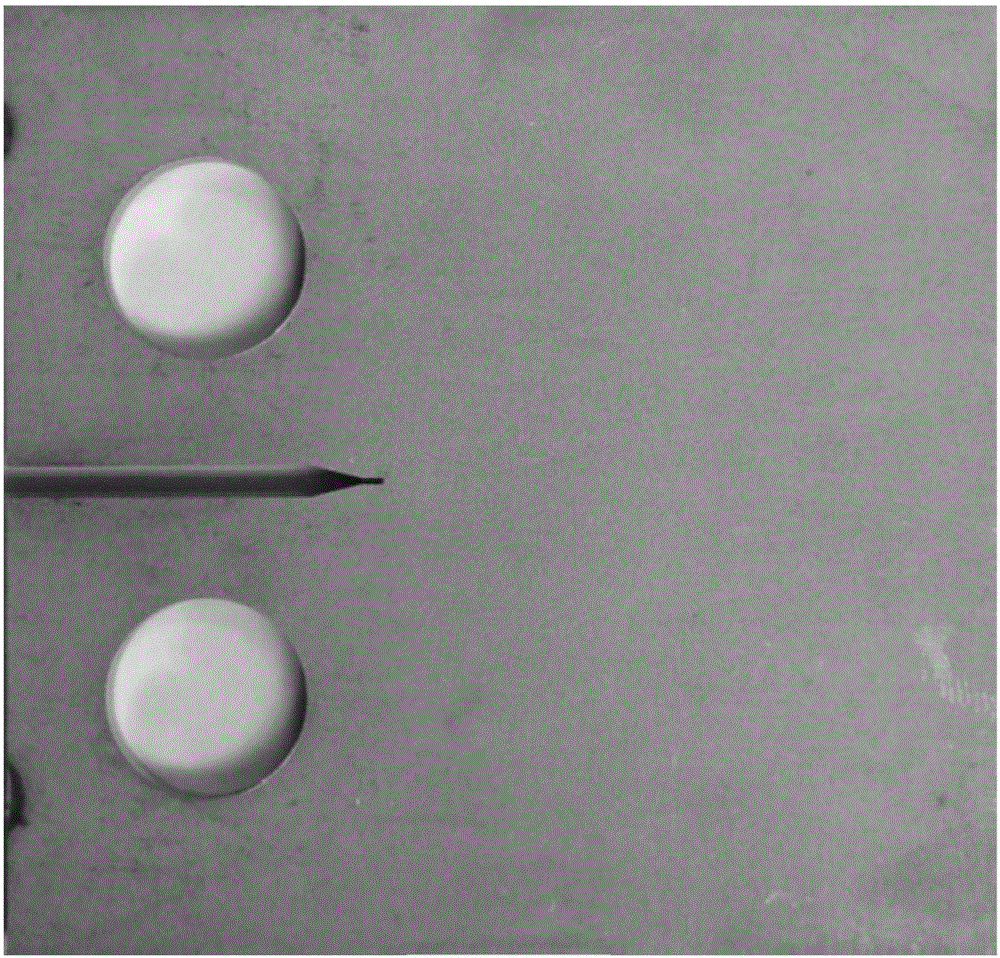

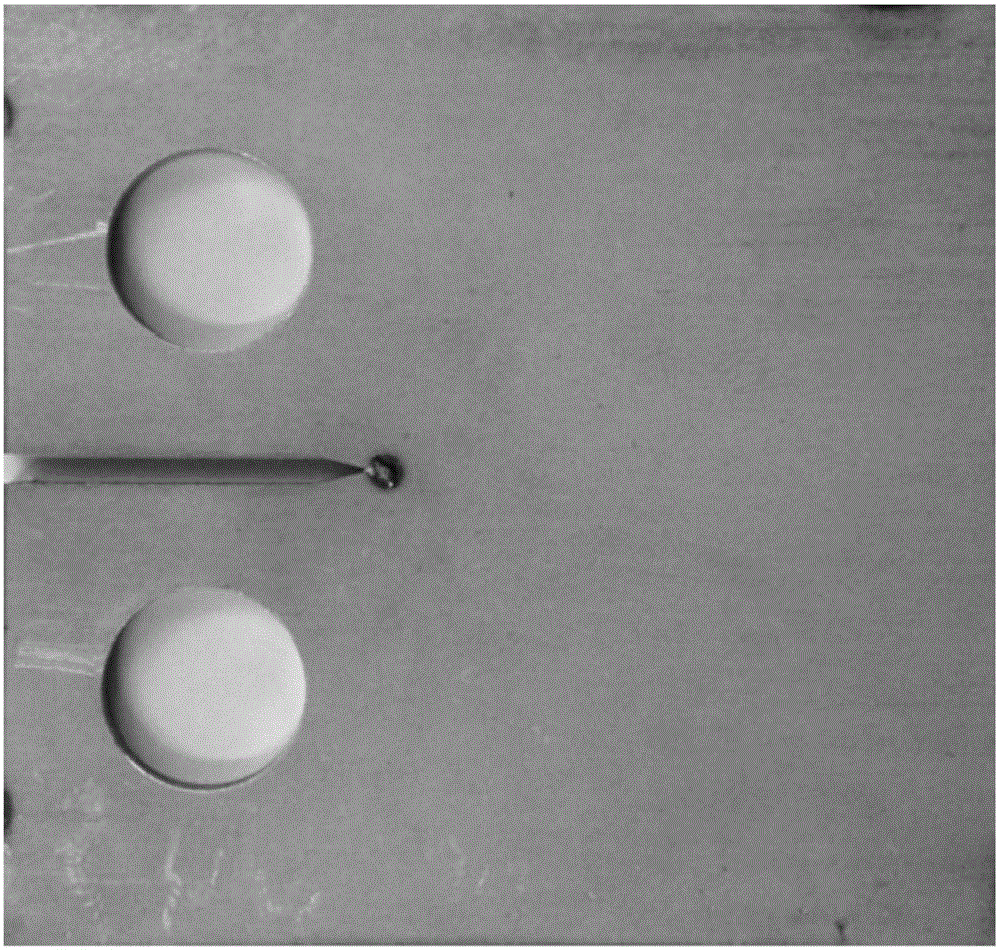

Method for repairing microcrack tip on stainless steel surface by means of nano-particles

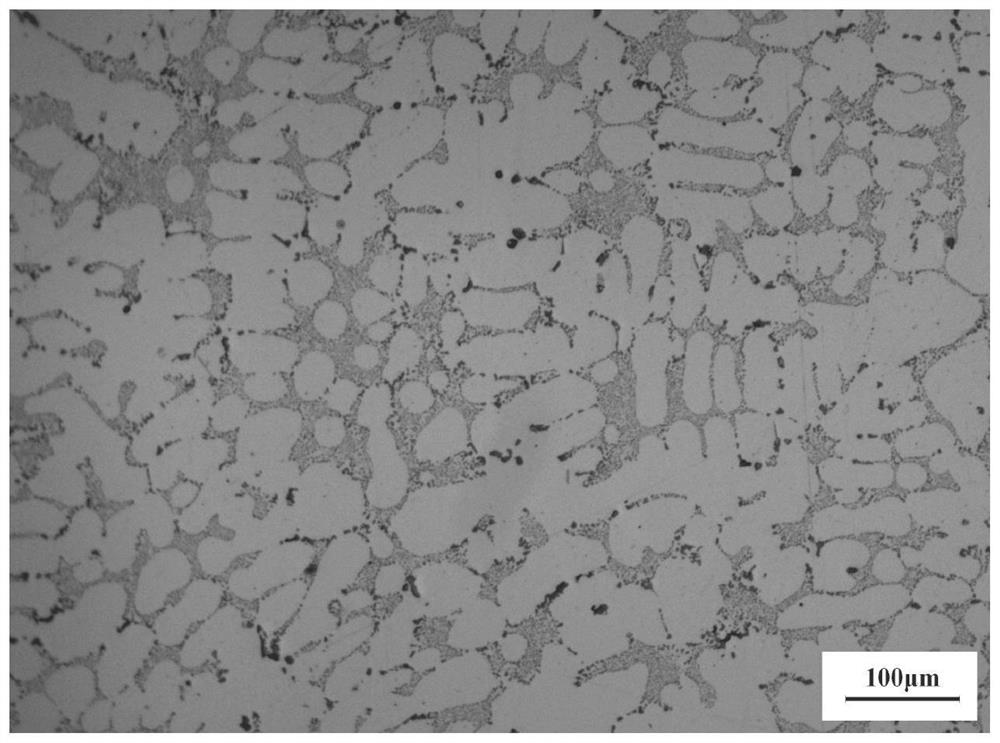

ActiveCN105714286AImprove densification performanceExtended service lifeMetallic material coating processesHeat-affected zoneNanoparticle

The invention provides a method for repairing a microcrack tip on a stainless steel surface by means of nano-particles. The method is suitable for stainless steel with microcracks on the surface. The method comprises the steps that the to-be-repaired microcrack tip on the stainless steel surface is treated; composite powder containing the nano-particles is arranged on the microcrack tip in advance; the composite powder and a part of a matrix are fused by means of lasers; the repaired microcrack tip region is finished; and the fracture property of the stainless steel matrix obtained after repairing is detected, and the microstructure of the section of a repair layer is observed. The repairing method is high in flexibility, and repairing can be carried out many times; and meanwhile, the problems of large deformation, a large heat affected zone and the like in a conventional method are avoided in the repairing method. According to the repairing method, the microcrack tip is closed again, the matrix and the composite powder arranged on the microcrack tip in advance are in metallurgical bonding, and the defects of cracks, pores and the like do not exist in the bonding region; grains of the repair layer of the microcrack tip are refined, and the structural compactness is improved; and in addition, the fracture property generated after repairing is remarkably improved.

Owner:DALIAN UNIV OF TECH

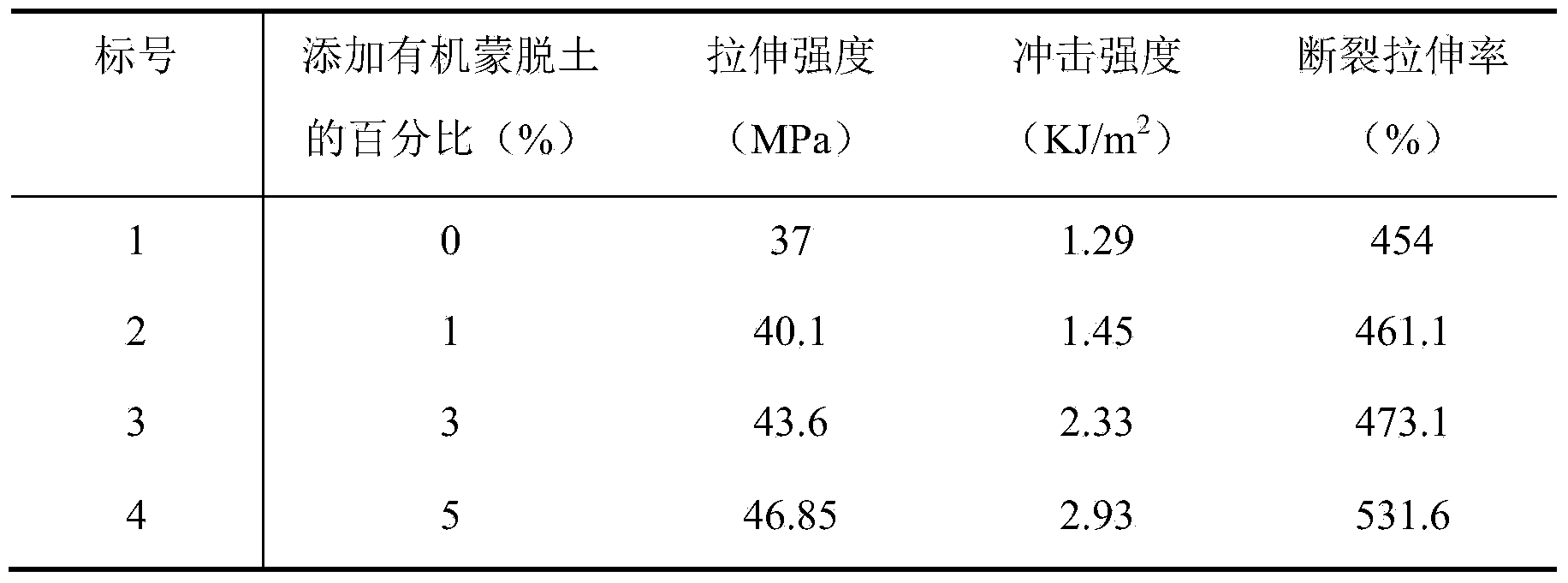

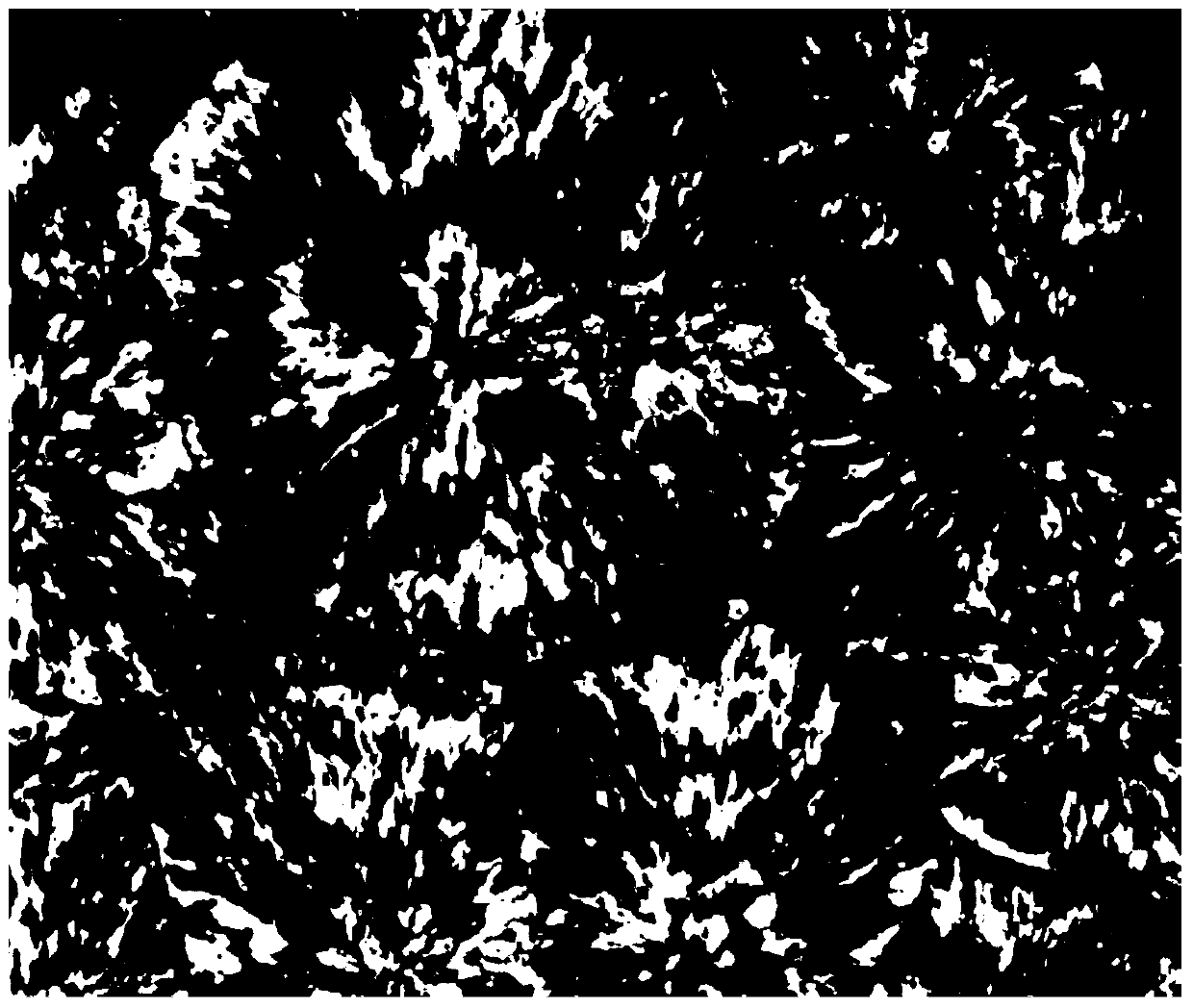

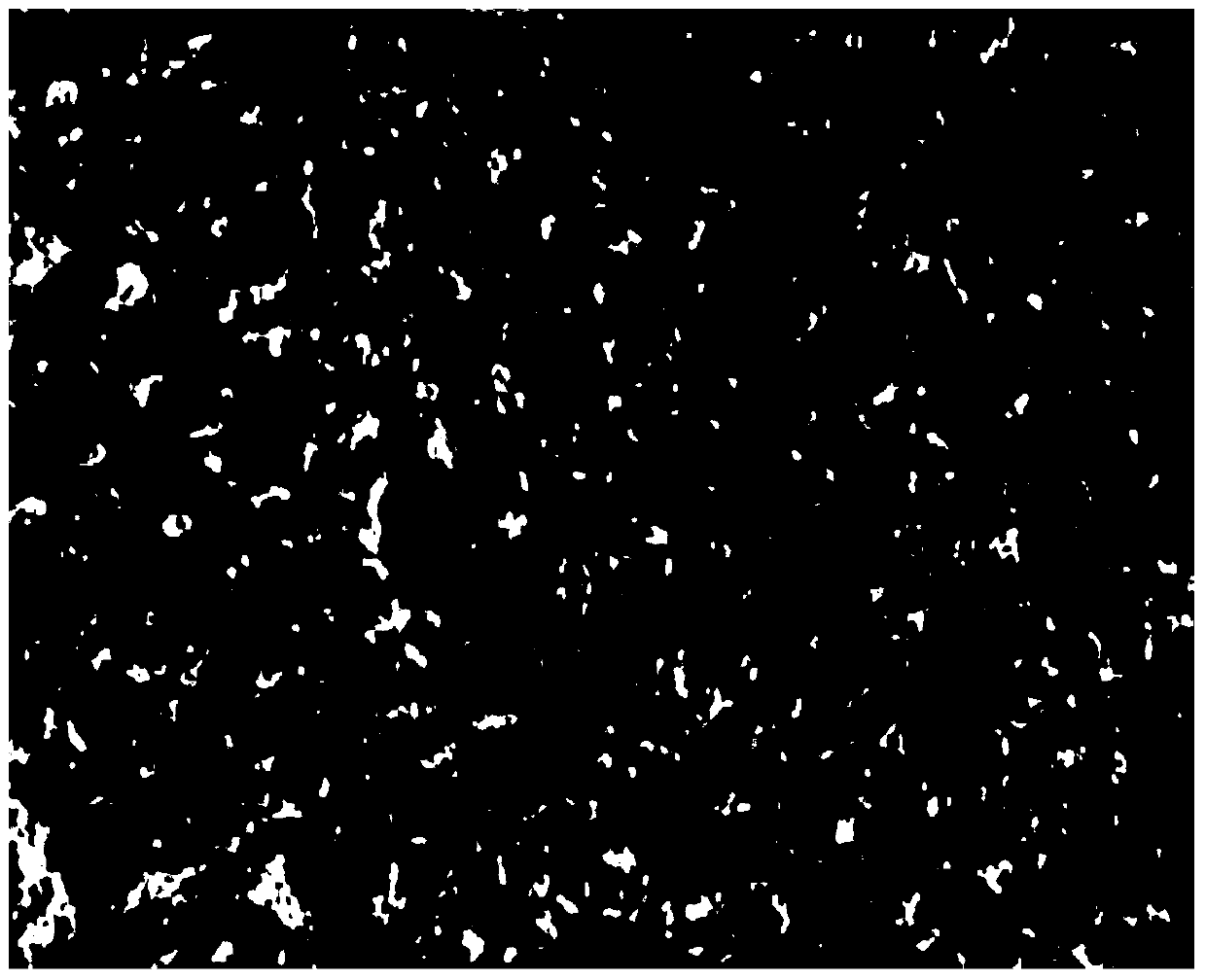

Organic montmorillonite (OMMT) and method for modifying polypropylene resin by using same

The invention relates to a preparation method of organic montmorillonite (OMMT), which comprises the following step: sequentially modifying sodium-base montmorillonite with cetyl trimethylammonium bromide, epoxy resin, isophorone diisocyanate and octadecylamine to obtain the OMMT. The invention also relates to a technique for modifying a polypropylene resin by using the OMMT, which comprises the following steps: 1) preparing the following components in percentage by weight: 0.1% of immobilized antioxidant, 0.5% of lubricant, 1-5% of OMMT and 98.4-89.4% of polypropylene; 2) adding the materials into a high-speed mixer according to the percentage by weight, and uniformly mixing; and 3) sending the uniform mixture into an extruder, and carrying out melt granulation to obtain the OMMT-modified polypropylene resin master batch. Under the heterogeneous nucleation action of the OMMT, the crystallization temperature of the polypropylene is enhanced. Due to the nano effect, the polypropylene is toughened and reinforced; and the OMMT and polypropylene macromolecular chain have strong interfacial action, thereby enhancing the tensile strength of the polypropylene.

Owner:TIANJIN LISHUN PLASTIC PRODS

Polyacetal resin composition and preparation method thereof

The invention provides a polyacetal resin composition, which comprises the following components: 100 parts of polyacetal resin, 0.001-2.0 parts of antioxygen, 0.005-3.0 parts of formaldehyde absorbent, 0.002-2.0 parts of acid absorbent, 0.001-2.0 parts of processing stabilizer, 0.1-20 parts of modified inorganic filler, and 0.005-2.0 parts of dispersant, wherein the dispersant is one or more of mineral oil, oligomerization polyolefin, fatty acid of C12-C20, dimethyl polysiloxane and dimethyl polysiloxane obtained by using hydrogen, phenyl, halogenated phenyl, halogenated alkyl and fluorinated ester to replace methyl; and the modified inorganic filler is obtained by modifying an inorganic filler and a modifier at 10-100 DEG C at the rotation speed of 500-10000 rpm. On the premise of increasing the tensile strength, the toughness of the polyacetal resin composition is obviously increased; and furthermore, the notch impact strength and the breaking elongation are higher.

Owner:YUNNAN YUNTIANHUA

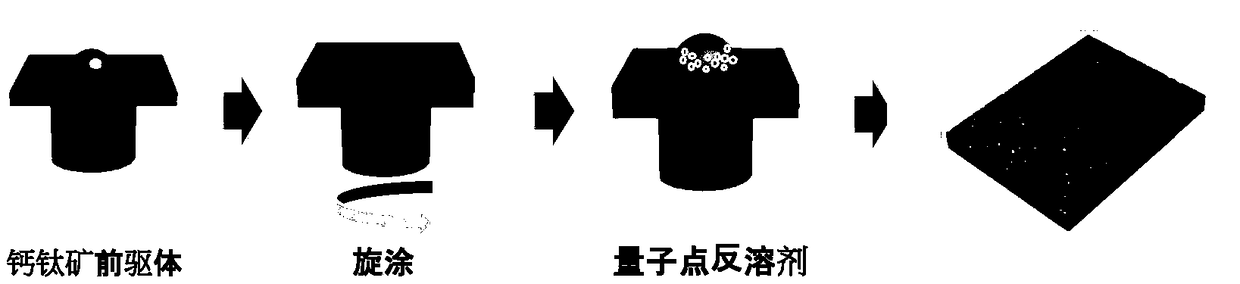

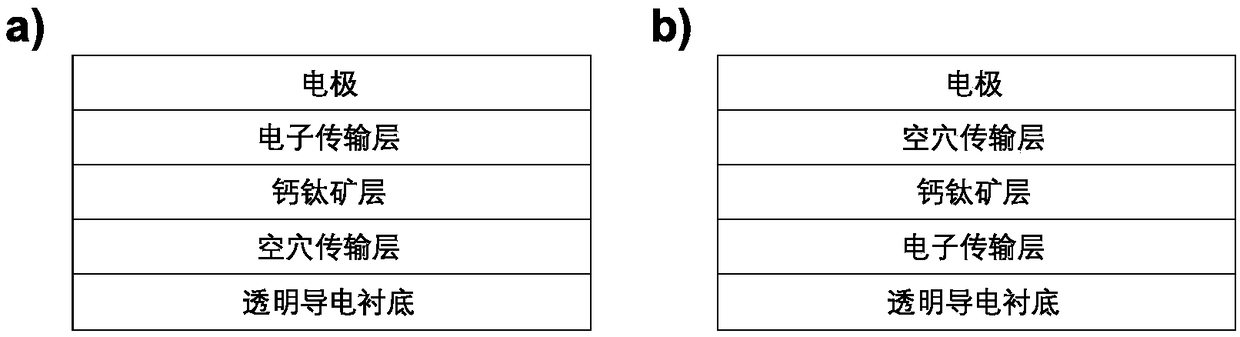

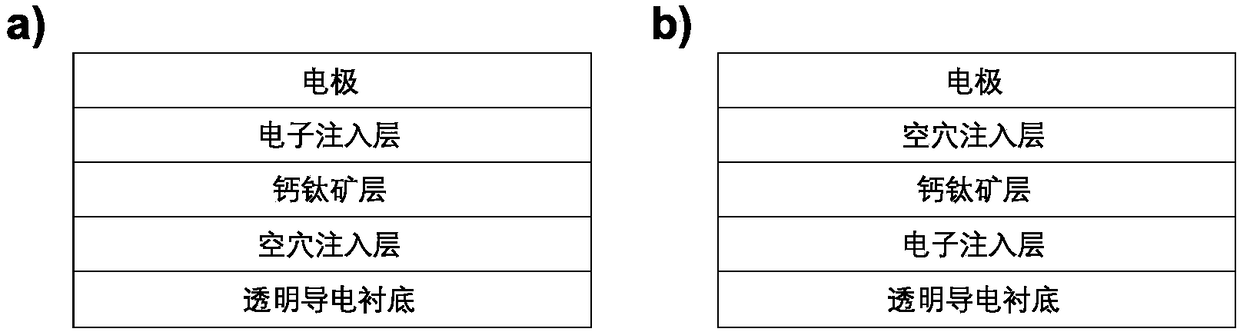

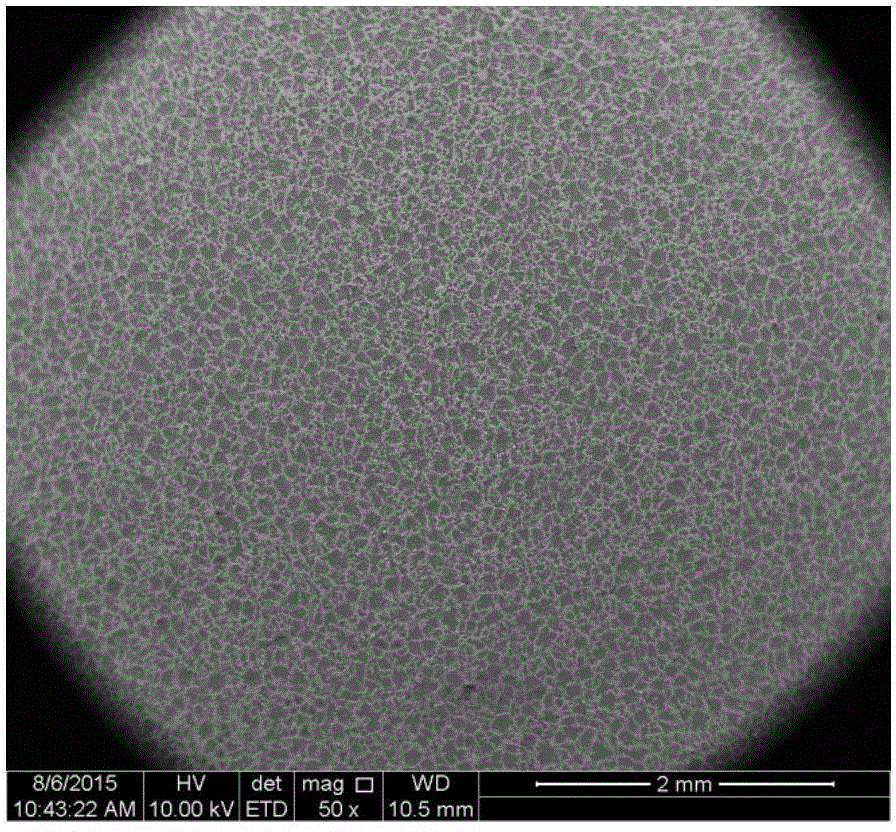

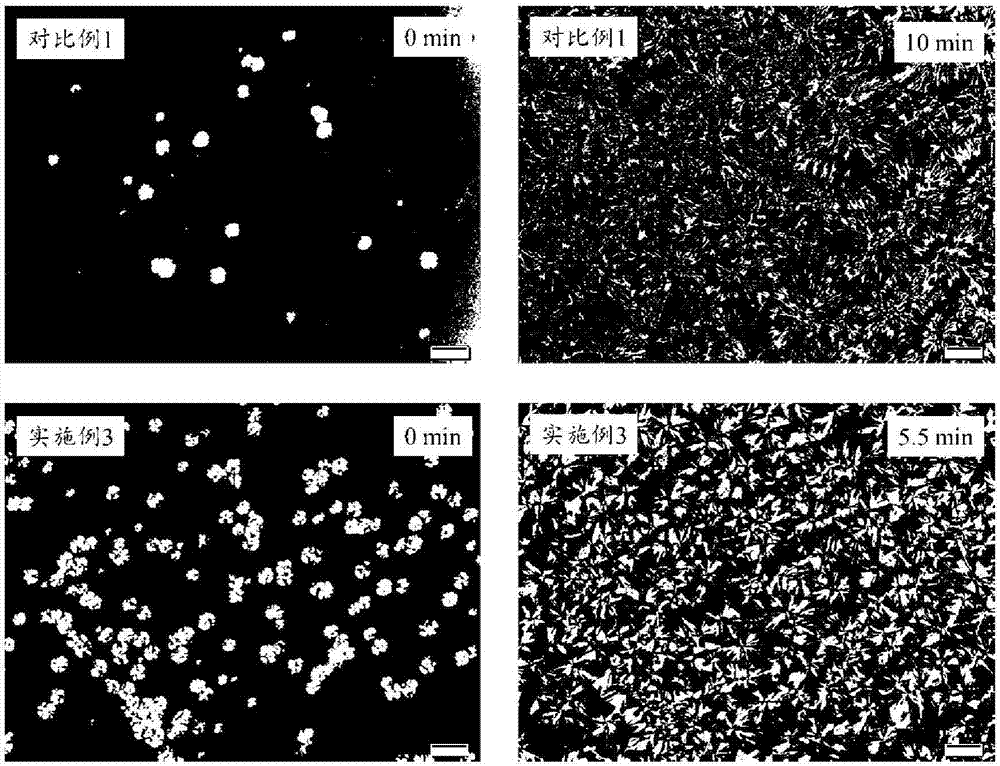

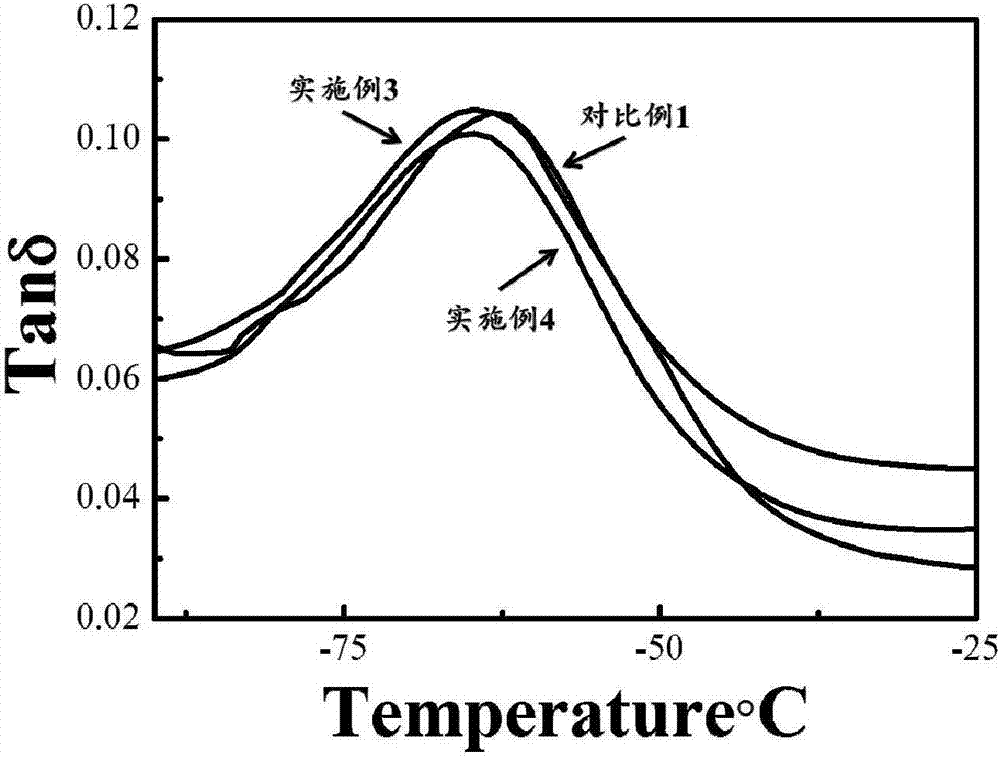

Method for nucleation growth of polycrystal perovskite thin film by perovskite quantum dots and related photoelectric device

InactiveCN108336232AHigh crystallinityLow free energy barrierMaterial nanotechnologySolid-state devicesPerovskite solar cellAnti solvent

The invention discloses a method for nucleation growth of a polycrystal perovskite thin film by perovskite quantum dots and a related photoelectric device. A perovskite quantum dot anti solvent at certain concentration is introduced to a precursor solution of the perovskite thin film to be processed at a certain temperature to complete nucleation growth of the polycrystal perovskite thin film through quantum dot induction. The perovskite thin film is used as a light absorption layer (or carrier recombination); by adopting a p-i-n or n-i-p structure and by introducing an electron transfer (or inject) layer, a hole transport (or inject) layer and an electrode and the like, a perovskite solar cell (or a perovskite light emitting diode) is prepared. The method is simple and high in process compatibility, so that the crystallization quality of the perovskite thin film is obviously improved, and the photoelectric conversion efficiency of the solar cell, and the light emitting performance andother performance of the light emitting diode are improved.

Owner:ZHEJIANG SCI-TECH UNIV

Novel non-rare earth cast magnesium alloy and preparation method thereof

ActiveCN105154733AImprove mechanical propertiesImprove performanceRare earthUltimate tensile strength

The invention provides a novel non-rare earth cast magnesium alloy. The alloy is an Mg-Bi-Zr-Zn alloy and comprises the following components by weight percent: 0.5-8wt% of Bi, 0.35-1.0wt% of Zr, 0.1-2.0wt% of Zn and the balance of Mg. The novel non-rare earth cast magnesium alloy has the beneficial effects that the obvious grain refinement effect of the element Zr in an Mg-Bi alloy series is found on the basis of Mg-Bi, thus improving the strength and plasticity of the alloy; the strength of the alloy is improved in an auxiliary manner by using a small quantity of the element zinc, thus developing the high-strength cast magnesium alloy from the alloy series; the yield strength is 140-155MPa; the tensile strength is 245-285MPa; and the elongation is about 6.5%.

Owner:HEBEI UNIV OF TECH

Internally-plasticized antistatic polyformaldehyde material and preparation method thereof

The invention discloses an internally-plasticized antistatic polyformaldehyde material and a preparation method thereof. The polyformaldehyde material is a mixture of polyformaldehyde and ironic liquid. The preparation method comprises the following steps: respectively carrying out vacuum drying on polyformaldehyde and ironic liquid at 80-120 DEG C for 24-48 hours; adding the dried polyformaldehyde and ironic liquid into fusion mixing equipment in a mass ratio of 100 to (0.01-10), and carrying out fusion mixing at 170-200 DEG C, so as to obtain a mixture; and discharging the mixture out of the fusion mixing equipment, and cooling to the room temperature, so as to obtain the polyformaldehyde material. The polyformaldehyde material disclosed by the invention has excellent antistatic performance; by adding ironic liquid, the size of a spherocrystal of a polyformaldehyde matrix can be effectively reduced, so that a certain plasticization effect is achieved; and only common fusion mixing equipment is used in the preparation method, so that the industrial preparation is simple.

Owner:安徽贺赢新材料科技有限公司

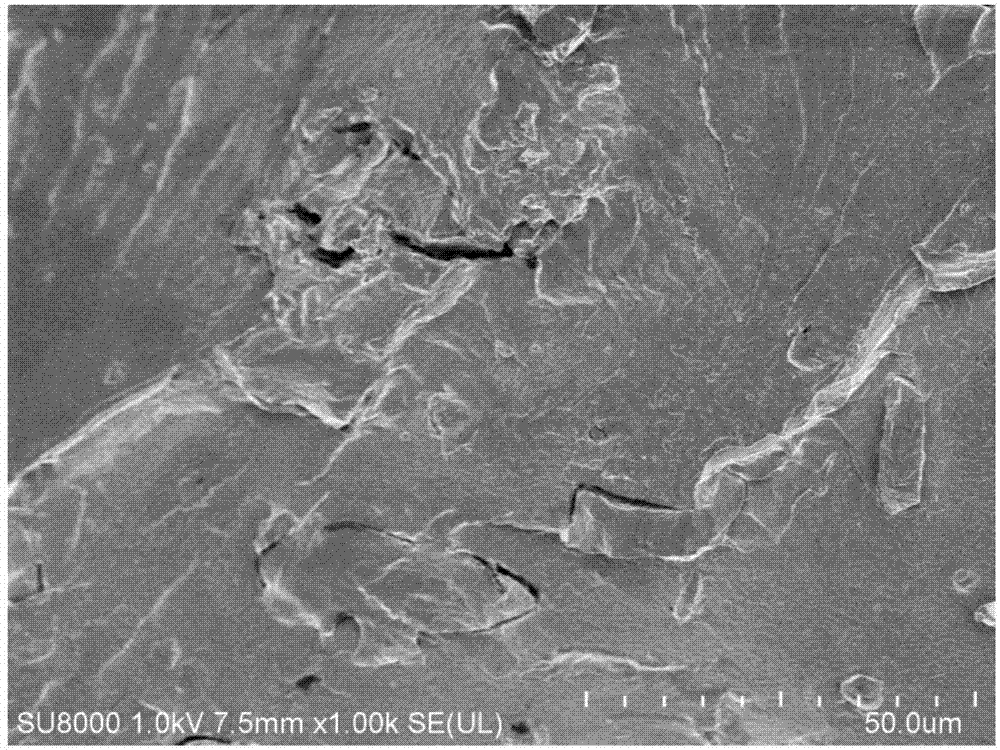

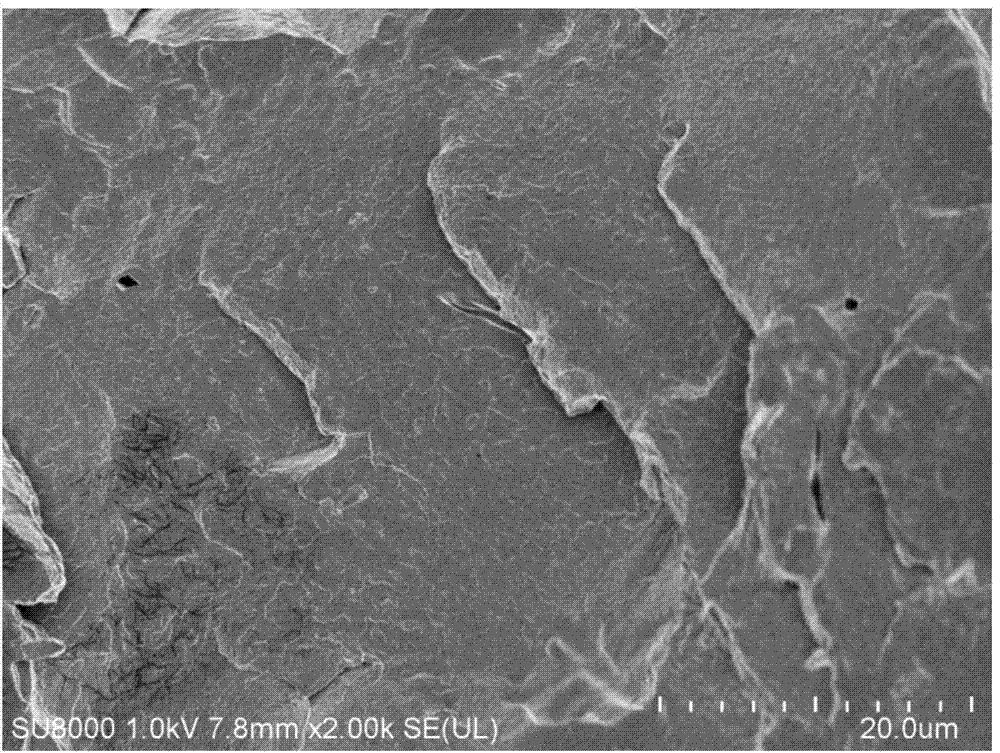

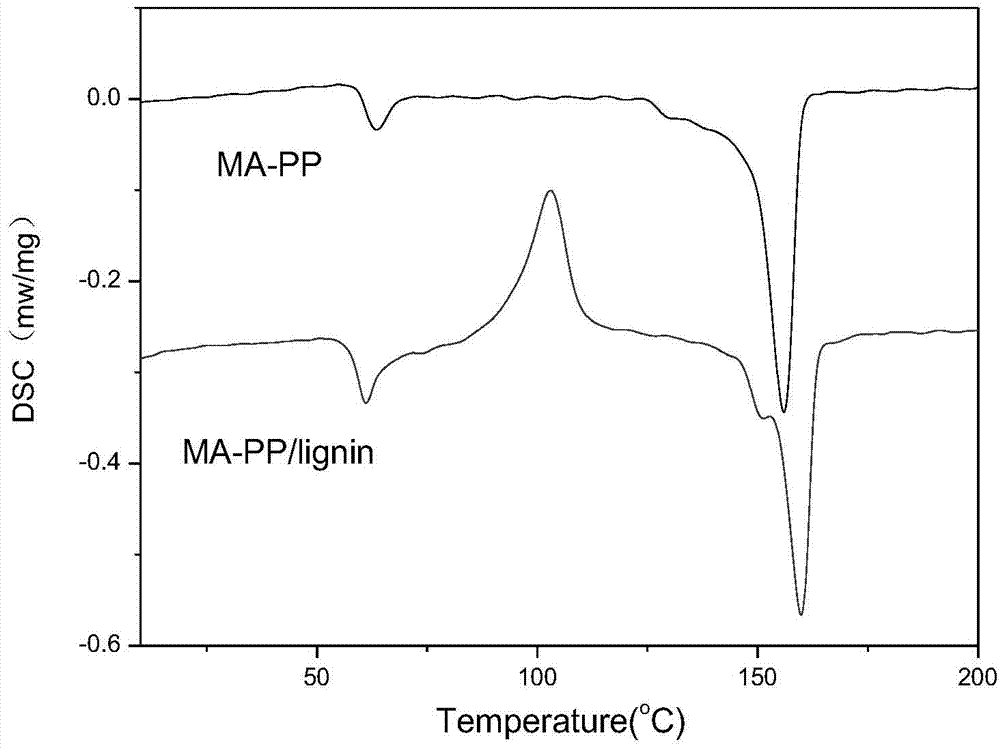

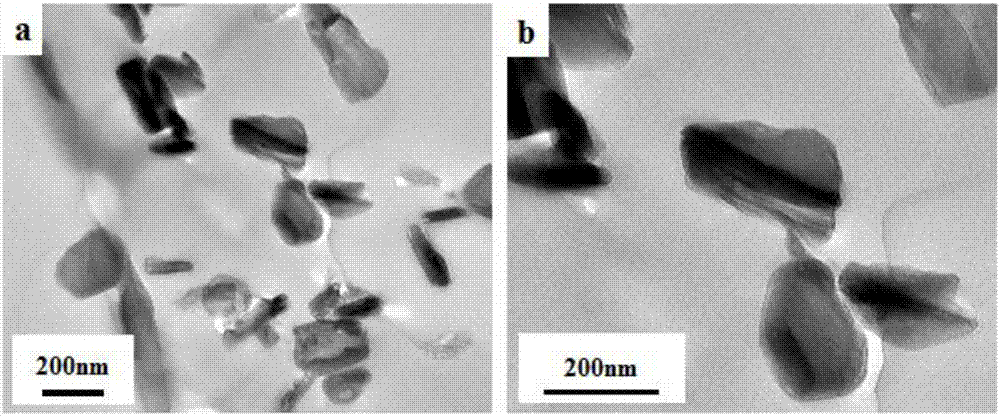

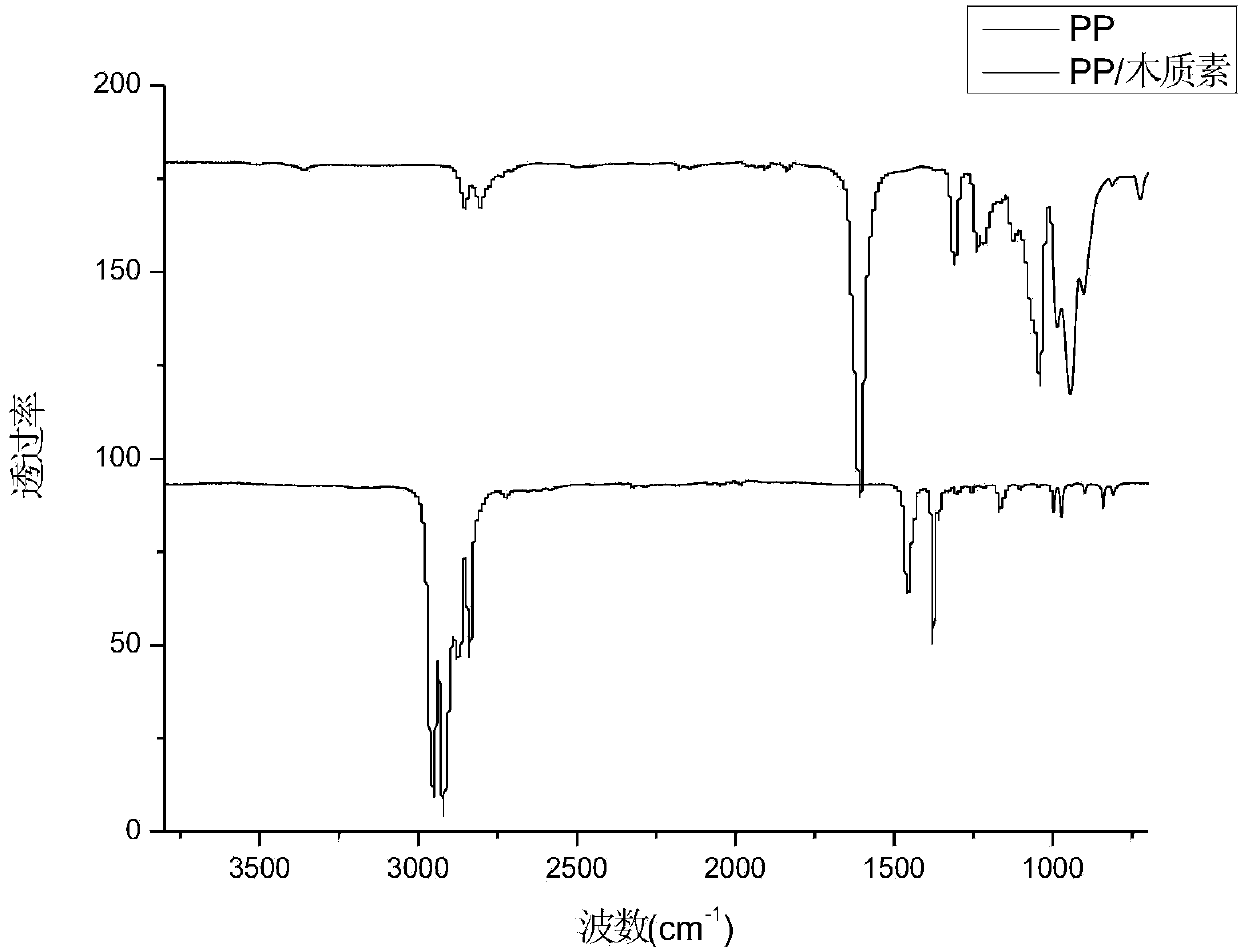

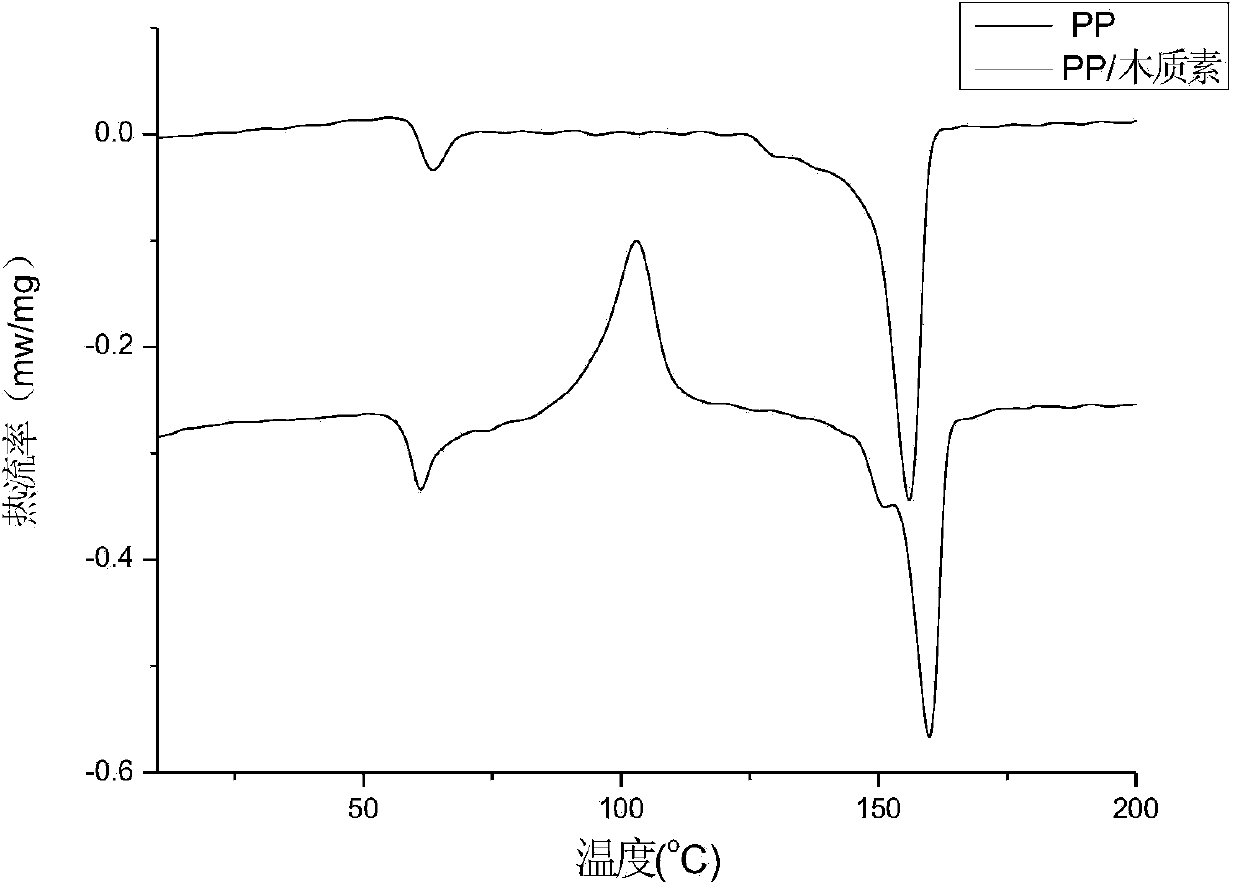

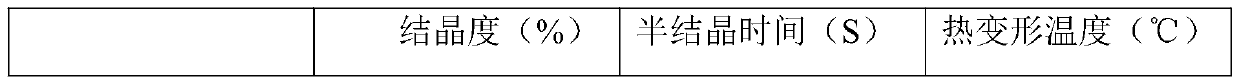

Method for improving thermal degradation capacity of maleic anhydride grafted polypropylene plastic

The invention relates to a method for improving the thermal degradation capacity of maleic anhydride grafted polypropylene plastic. The method comprises the following steps: (1) carrying out graft modification on lignin and maleic anhydride, so as to obtain esterified modified lignin; (2) uniformly mixing the modified lignin with maleic anhydride grafted polypropylene, and carrying out melt blending on the mixed material at 150-240 DEG C, so as to obtain uniform-blended blends; and (3) melting the blends at 170-230 DEG C, jetting the obtained mixture melt into a mold, and cooling to obtain a blended sample strip. The method has the beneficial effects that the process is simple, the operation is convenient, the cost is low, and the heat resistance of a composite material can be improved due to the influence of a three-dimensional network structure of the lignin; and meanwhile, the crystallization degree and capacity of the polypropylene can be improved by virtue of the modified lignin, the thermal degradation capacity of the polypropylene is greatly improved, the service life of the polypropylene plastic is prolonged, and the method can be industrially generalized.

Owner:浙江诺瓦新材料有限公司

High tenacity one-dimensional titanium dioxide nanowire modified PP material and preparation method thereof

The invention provides a high tenacity one-dimensional titanium dioxide nanowire modified PP material and a preparation method thereof, and belongs to the field of high polymer materials. The PP material is prepared from the following components in parts by weight: 50-80 parts of polypropylene, 5-40 parts of modified one-dimensional TiO2 nanowire, 1-2 parts of an antioxidant, 1-2 parts of a lightstabilizer and 5-10 parts of a fire retardant; the modified one-dimensional TiO2 nanowire is obtained by adding one-dimensional TiO2 nanowire into a surfactant for surface modification, the diameter of the modified one-dimensional TiO2 nanowire is 10-200nm, and the length is 50nm-5micron. The invention further provides the preparation method of the high tenacity one-dimensional titanium dioxide nanowire modified PP material. The material has the high tenacity.

Owner:芜湖万隆新材料有限公司

Method for preparing polypropylene/hydrotalcite nanometer composite material by using hydrotalcite as nucleating agent

The invention discloses a method for preparing a polypropylene / hydrotalcite nanometer composite material by using hydrotalcite as a nucleating agent, and belongs to the technical field of polymer / inorganic nanometer composite material preparation. According to the method, the prepared hydrotalcite is washed by acetone and is then dispersed into xylene; next, the materials are added into the molten polypropylene xylene solution; stirring is performed; through ethanol extraction, the polypropylene / hydrotalcite nanometer composite material is obtained. The method has the advantages that the hydrotalcite which is not dried is directly added into the polypropylene solution; the agglomeration of the powder body hydrotalcite in polypropylene substrates can be avoided; the polarity is reduced by the hydrotalcite washed by the acetone; the compatibility of the hydrotalcite and the nonpolar polypropylene is improved, so that the dispersibility of the hydrotalcite in the polypropylene is better. The high-dispersibility hydrotalcite achieves the heterogeneous nucleation effect in the polypropylene crystallization process; the effects of inducing the polypropylene crystallization and accelerating the crystallization speed are achieved.

Owner:BEIJING UNIV OF CHEM TECH

High-performance PLA alloy material and preparation method thereof

The invention relates to a high-performance PLA alloy material and a preparation method thereof. The high-performance PLA alloy material is composed of 70-90 parts of polylactic acid, 10-30 parts of an ethylene-octylene random copolymer, 0.4-0.8 parts of an ethylene-glycidyl methacrylate copolymer, 8-14 parts of modified nano silicon dioxide and 0.3-0.7 parts of an antioxidant. The material is prepared by mixing and extruding the components hereinabove. The POE is used for improving the flexibility of the PLA, wherein a compatibilizer EGMA is added for improving compatibility of the PLA / POD mixture, thereby increasing the interface bonding force between the two phases and improving the performance of the mixture. The modified nano silicon dioxide can improve the strength, rigidity and toughness of the polymer. The PLA alloy material is high in strength, is good in toughness and is environment-friendly, and can be widely used in the fields of package materials, toys, electronic appliance and household article.

Owner:HEFEI GENIUS NEW MATERIALS

Method for improving heat stability of polypropylene plastic

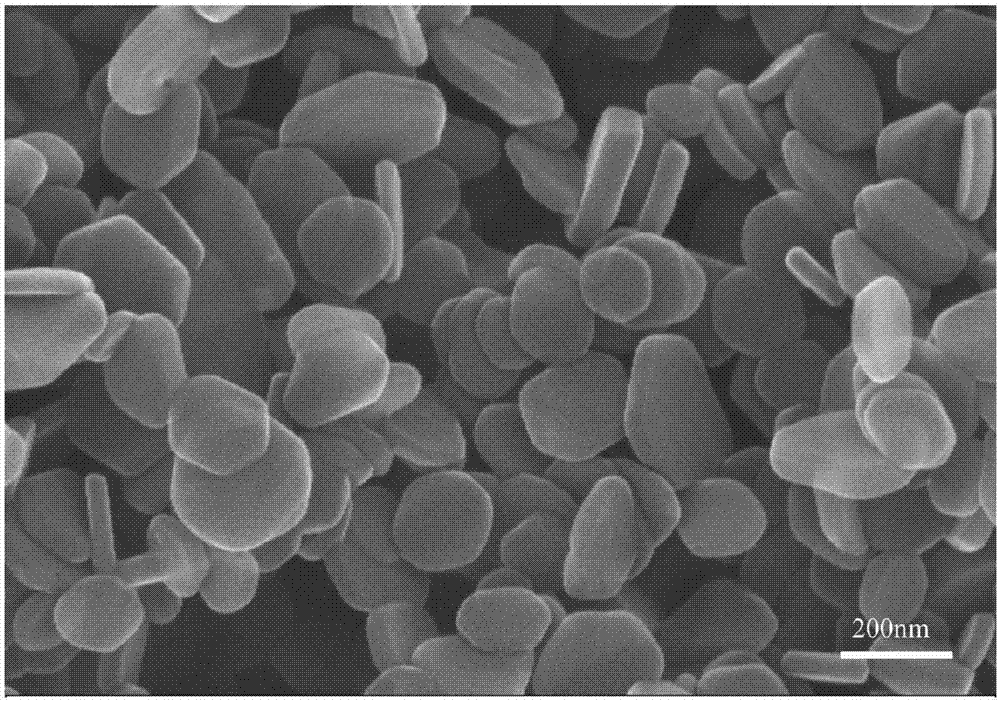

InactiveCN103788485AEvenly dispersedPlay a role in heterogeneous nucleationHeat stabilityInjection molding machine

The invention relates to a method for improving the heat stability of polypropylene plastic. The method comprises the steps of (1) uniformly mixing lignin and polypropylene according to a mass ratio of (5:95)-(20:80), and performing melt blending on a mixture under the temperature of 150-250 DEG C to obtain a uniformly mixed blend; and (2) adding the blend into a material feeding hopper of a micro injection molding machine for melting under the temperature of 170-240 DEG C, injecting a mixture melt into a mold, and cooling to obtain a blended sample. The technology of the method disclosed by the invention is simple; an operating method is simple, and the cost is low; the lignin can realize a certain heterogeneous nucleation function in a polypropylene crystallization process, so that the crystallinity and the crystallization property of polypropylene can be improved; meanwhile, due to the influence of a three-dimensional meshed structure of the lignin, the heat resistance of a composite material can be improved; and the method can be popularized industrially and has a good application prospect.

Owner:DONGHUA UNIV

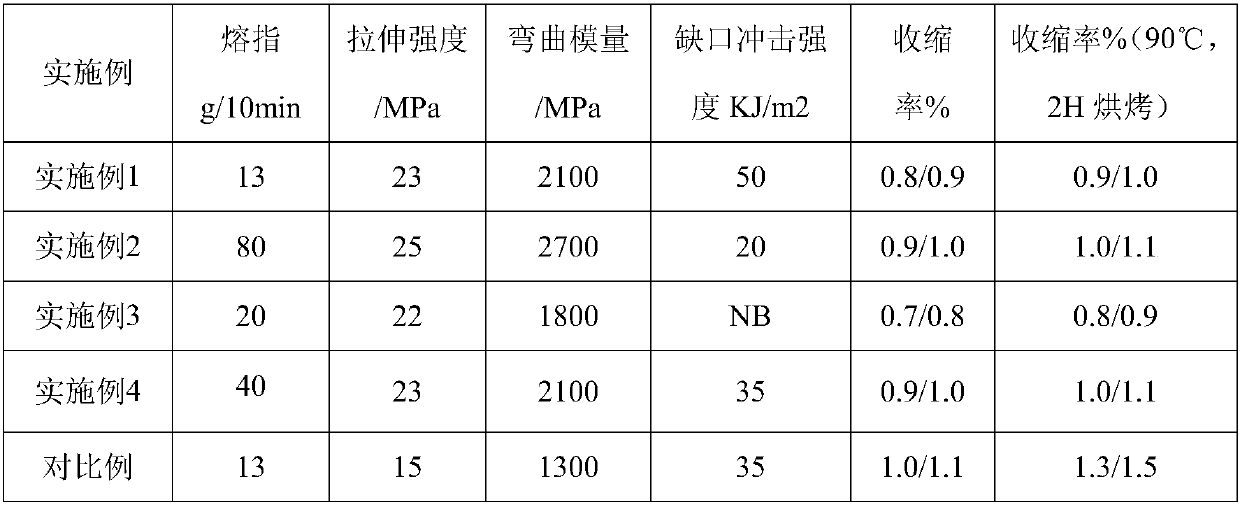

High-rigidity and high-toughness polypropylene composite material and preparation method thereof

InactiveCN109575450ADoes not affect liquidityPlay a role in heterogeneous nucleationThin walledAntioxidant

The invention discloses a high-rigidity and high-toughness polypropylene composite material which comprises, by weight, 40-80 parts of co-polypropylene, 5-20 parts of mineral fillers, 3-10 parts of reinforcing agents, 10-25 parts of toughening agents, 0-3 parts of compatilizers, 02-1 parts of nucleation master batch, 0.1-0.5 part of coupling agents, 0.1-0.5 part of antioxidants and 0.1-0.5 part oflubricating agents and light stability agents. The materials are mixed and extruded to prepare the composite material, the nucleation master batch is provided with mixture of nano-scale rare earth oxide Y2O3 and arylamine TMB (tetramethylbenzidine)-5, and the blending weigh ratio is 1:1-1:4. According to the composite material, the co-polypropylene and the mineral fillers, the reinforcing agentsand the toughening agents are compounded, the strength of the composite material is improved, the contraction rate of a resin substrate is reduced, dimensional stability of the material is ensured, and the modified polypropylene composite material can be widely applied to thin-walled automotive interior and exterior decoration products.

Owner:HEFEI GENIUS NEW MATERIALS

Modified polylactic acid composite material capable of being quickly crystallized and preparation method thereof

PendingCN110903618AChange in crystallization propertiesImprove temperature resistanceCrystallinityInjection moulding

The invention discloses a modified polylactic acid composite material capable of being quickly crystallized. The modified polylactic acid composite material comprises polylactic acid, a dispersion lubricant and a nucleating agent, wherein the nucleating agent is an inorganic nucleating agent and / or an organic nucleating agent; the preparation method comprises the steps of mixing, granulating and injection molding. The organic nucleating agent and the inorganic nucleating agent are introduced, rapid crystallization of the polylactic acid composite material is achieved through the synergistic effect of inorganic components, and the crystallinity of the composite material is improved, wherein the inorganic nucleating agent does not melt in the processing and forming process of the composite material and exists in a solid form, the material is adsorbed on the surface of the inorganic nucleating agent, and a role is played in heterogeneous nucleation in the crystallization process. And theorganic nucleating agent mainly plays a role in homogeneous nucleation in the processing process. Through the synergistic effect of the two nucleating agents, the crystallization speed of the composite material can be increased, and the crystallinity is improved.

Owner:湖南省菱越新材料有限公司

PBAT fiber and preparation method thereof

ActiveCN113122952AFast crystallizationAvoid stickingMonocomponent copolyesters artificial filamentMelt spinningIsophthalic acid

The invention relates to a PBAT fiber and a preparation method. Molecular chain segments of the PBAT fiber comprise a butylene terephthalate chain segment, a butylene adipate chain segment and an isophthalic acid-5-sodium sulfoisophthalic acid butanediol ester chain segment, the molar content of the butylene adipate chain segment is 50%-150% relative to the molar content of the butylene terephthalate chain segment, and the molar content of the isophthalic acid-5-sodium sulfoisophthalic acid butanediol ester chain segment is 0.5%-4% relative to the molar content of the terephthalic acid butanediol ester chain segment; and the breaking strength of the PBAT fiber is 2.0-5.5 cN / dtex, the elongation at break is 15%-60%, and the AA rate is greater than or equal to 98%. The preparation method comprises the following steps that terephthalic acid and adipic acid are correspondingly esterified and then subjected to pre-polycondensation, then two prepolymers are mixed, an isophthalic acid-5-sodium sulfonate ester is added, then final polycondensation is carried out, and finally the PBAT fiber is prepared by a melt spinning method. According to the PBAT fiber, the balance relation between the crystallization capacity and the performance of PBAT is regulated and controlled through the length of the chain segment, and the performance of the fiber is improved by introducing SSIPA into the chain segment.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK +1

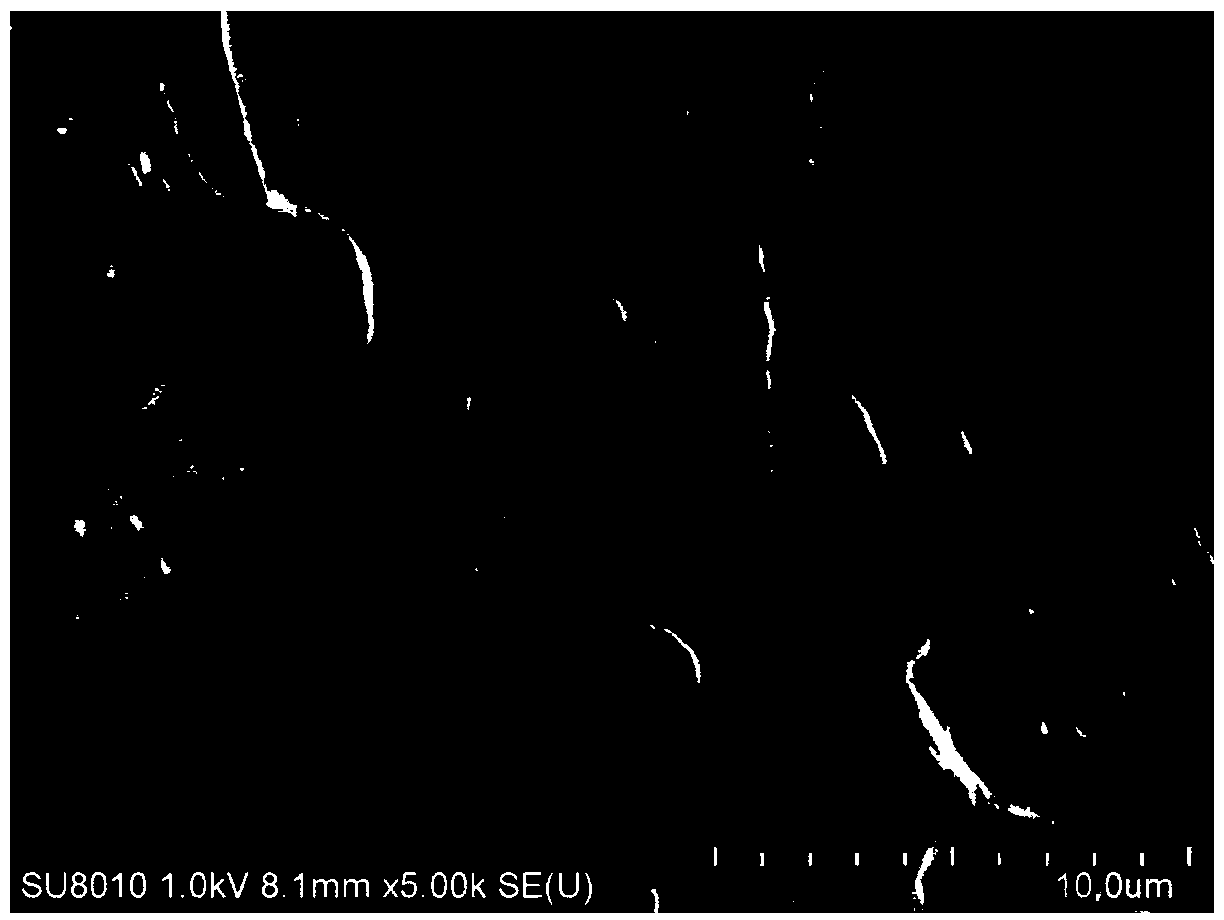

Modified lignin carbon dot and preparation method and application thereof

The invention provides a modified lignin carbon dot and a preparation method and application thereof, and relates to the technical field of nano materials. According to the preparation method of the modified lignin carbon dot, a lignin-based carbon source, water and a silane coupling agent are subjected to a hydrothermal reaction, and the modified lignin carbon dot is obtained; or hydrothermal reaction is performed on the lignin-based carbon source and water to obtain the lignin carbon dot, and hydrothermal reaction is performed on the lignin carbon dot, water and a silane coupling agent to obtain the modified lignin carbon dot. The silane coupling agent is utilized to modify the lignin carbon dot so that the dispersity of the lignin carbon dot is improved, the lignin carbon dot has multifunctionality, the high temperature resistance, oxidation resistance and scratch resistance of the composite material can be improved, and the friction coefficient of the composite material is reduced. Results of the embodiment show that when the modified lignin carbon dot is added into polypropylene, the degradation temperature of the composite material is increased by 20 DEG C, the oxidation induction period is 4.65 min, the friction coefficient is reduced to 0.164, and the scratch resistance is good.

Owner:HUNAN UNIV OF TECH

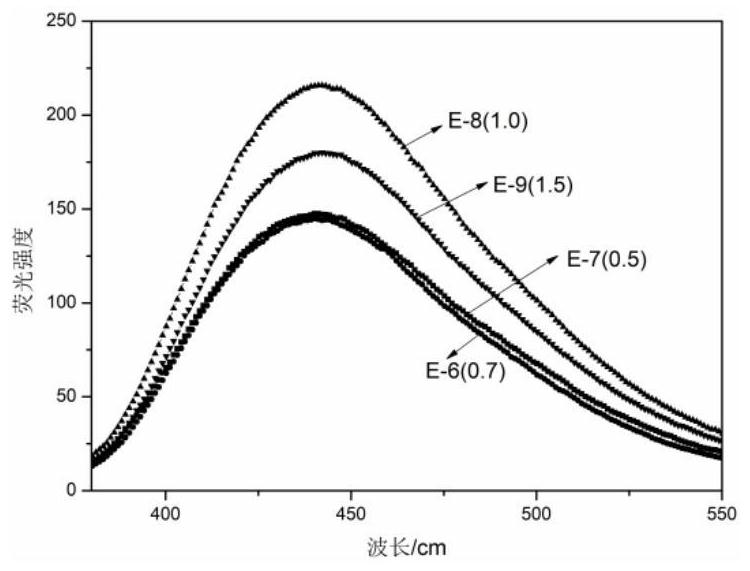

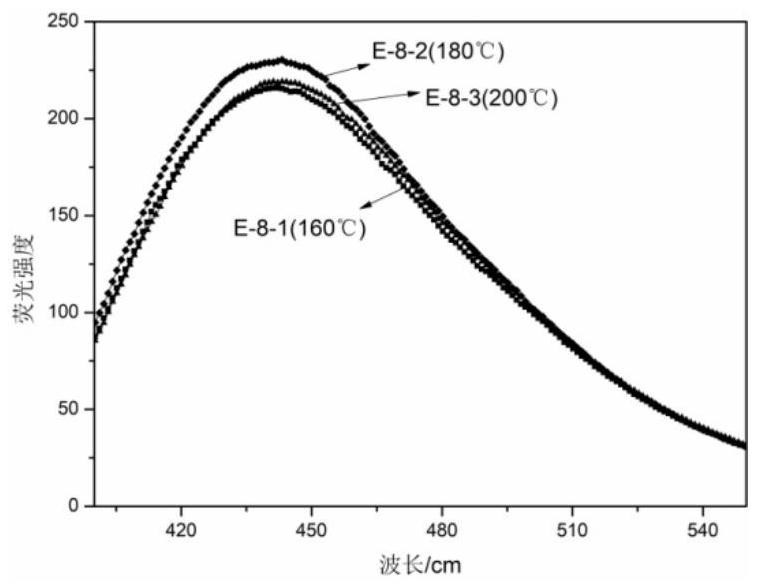

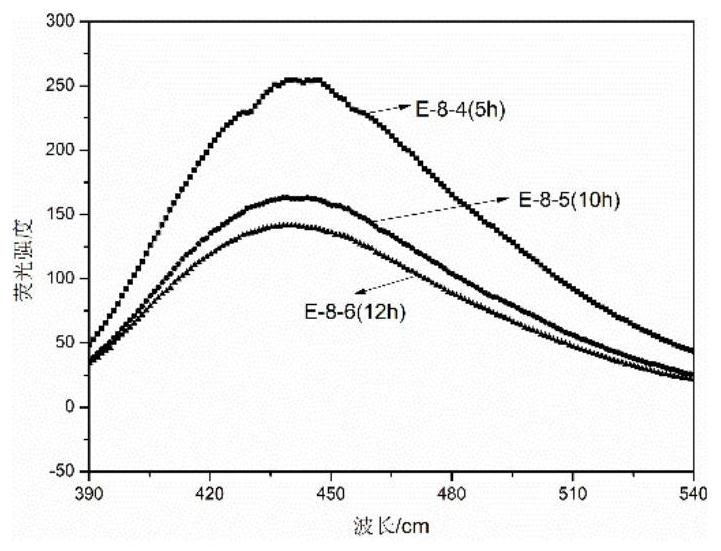

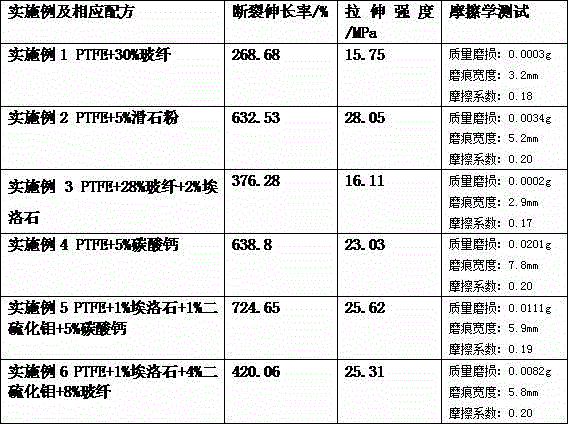

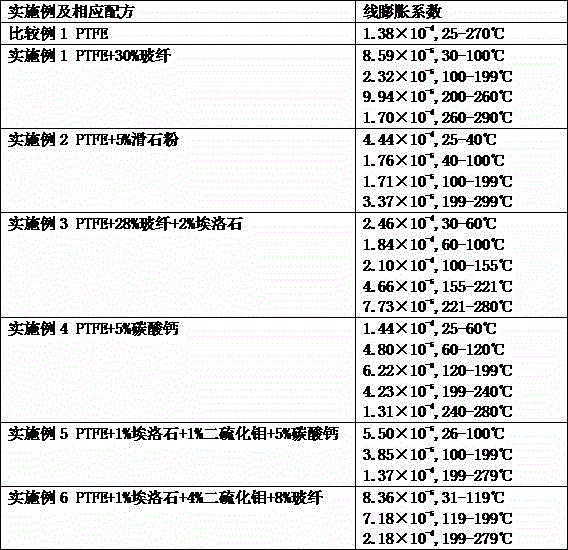

Preparation method for halloysite, ultrafine inorganic powder and PTFE micro-nano composite material

ActiveCN104987633AImproved crystallization behaviorImprove mechanical propertiesMicro nanoHalloysite

Provided is a preparation method for a halloysite, ultrafine inorganic powder and PTFE micro-nano composite material, and the method relates to the technical field of preparation of PTFE micro-nano composite materials. The method comprises steps of: firstly, preparing a uniform mixing of PTFE and inorganic powder through mechanical high speed blending; then shaping the obtained mixed powder through cold pressing, and performing mold releasing to obtain a sheet-like sample; and finally placing the sample in a muffle furnace, raising the temperature to 370-380 DEG C at a rising rate of 150-200 DEG C / h, keeping the temperature for 2 hours, and then cooling the sample to the room temperature along with the furnace, thereby obtaining a PTFE micro-nano composite material. According to the method provided by the invention, the crystallization behavior of the PTFE is improved through filling with inorganic micro-nano particles; excellent mechanical properties of the PTFE are maintained by regulating interfacial adhesion between the micro-nano particles and the PTFE; meanwhile, the PTFE is endowed with excellent wear resistance and creep resistance.

Owner:安徽桑瑞泰粉末材料有限公司

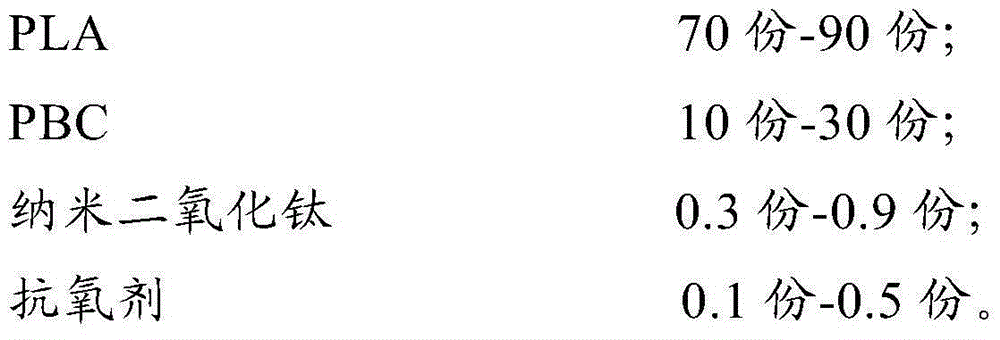

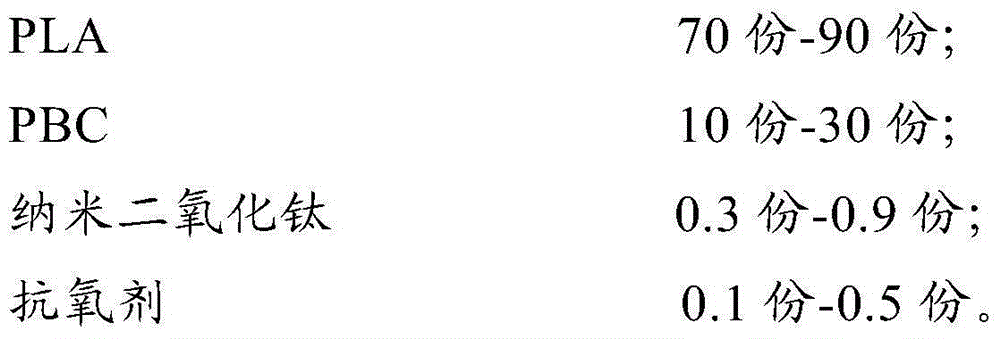

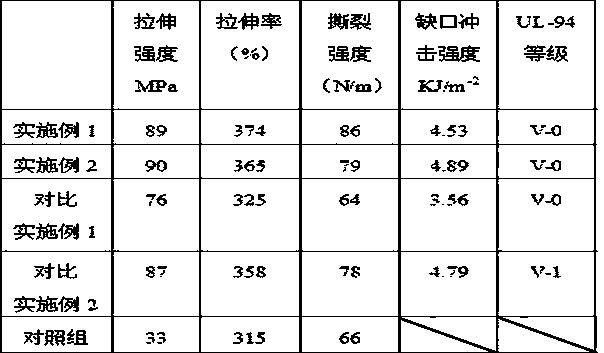

PLA (polylactic acid)-PBC (poly(butylene carbonate)) composite material and preparation method thereof

The invention provides a PLA (polylactic acid)-PBC (poly(butylene carbonate)) composite material and a preparation method thereof. The PLA-PBC composite material comprises components in parts by weight as follows: 70-90 parts of PLA, 10-30 parts of PBC, 0.3-0.9 parts of Nano-TiO2 and 0.1-0.5 parts of an antioxidant. Nano-TiO2 in the composite material has a heterogeneous nucleation function so as to increase the crystallization velocity and the crystallinity of PLA and PBC, and accordingly, the PLA-PBC composite material integrating advantages of PLA and PBC is obtained.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Polyvinyl alcohol modified water-resistant gypsum-polyamide 6 composite material and preparation method thereof

The invention discloses a polyvinyl alcohol modified water-resistant gypsum-polyamide 6 composite material and a preparation process of the composite material. The preparation process is characterized by comprising the following steps: mixing a polyvinyl alcohol solution, a barium chloride solution and a sodium methylsilanolate solution so as to obtain a composite glue solution; adding the composite glue solution into gypsum powder, and uniformly stirring so as to obtain water-resistant gypsum; adding ethanol into a coupling agent for diluting, adding the water-resistant gypsum into a high-speed mixer, spraying the diluted coupling agent into the gypsum by adopting an atomization method, and performing vacuum drying so as to obtain coupling modified water-resistant gypsum; adding distilled water into polyvinylpyrrolidone so as to obtain a surfactant solution; adding multiwalled carbon nanotubes, stirring, performing ultrasonic treatment in an ultrasonic cell disruption system, and centrifuging so as to carbon nanotube dispersion; drying polyamide, adding the polyamide into the high-speed mixer, spraying white oil onto the surface of polyamide 6 under spray conditions, and mixing at a high speed; and adding the previous obtained materials, mixing at the high speed, adding the materials into a twin-screw extruder for granulating, drying, thereby obtaining the composite material.

Owner:阜阳三环水泥制品有限公司

Flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate

InactiveCN109517291AGood oil resistanceImprove heat aging resistancePolyvinyl chlorideChlorinated paraffins

The invention discloses a flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate. The flame retardance heat aging resistant PVC foaming trough plate comprises the following raw materials in parts by weight: 60-70 parts of polyvinyl chloride, 10-28 parts of nitrile rubber, 5-13 parts of chlorinated polyethylene rubber, 4-9 parts of a thermoplastic polyurethane elastomer, 5-11 parts of polyamic acid, 2-8 parts of alpha-zirconium phosphate, 5-8 parts of attapulgite, 2-7 parts of muscovite, 3-9 parts of bamboo powder, 8-17 parts of composite foaming agent, 4-11 parts of flame retardant, 0.3-1 part of an aluminum-titanium composite coupling agent, 0.3-1.2 parts of dicumyl peroxide, 0.2-1.3 parts of sulfur, 1.7 parts of an accelerant, 15-30 parts of dioctyl phthalate, 2-9 parts of chlorinated paraffin, 1-3 parts of phenyl phosphorus dichloride, 3-5 parts of resorcinol, and 2-3 parts of a composite heat stabilizer. The flame retardance heat aging resistant PVC foaming trough plate provided by the invention has good heat aging resistance, excellent flame retardance and long service life.

Owner:安徽优丽普科技有限公司

Method for reinforcing polypropylene composite material by coupling modified short carbon fiber and pyridinium-modified montmorillonite

The invention discloses a method for reinforcing polypropylene composite material by coupling modified short carbon fiber and pyridinium-modified montmorillonite. The method comprises the following steps of putting a polypropylene plastic thin sheet, a thermoplastic elastomer and a compatilizer into an air blowing drying box to dry; uniformly mixing with the short carbon fiber treated by a silanecoupling agent, the surface-modified basalt fiber and a montmorillonite-reinforced flame-retardant system; melting, mixing and extruding at the setting processing temperature; cooling the extruded strip material, blow-drying and cutting into particles; putting the particle material into a constant-temperature drying box to dry; feeding into an injection molding machine to perform injection molding. The method has the advantages that by using the pyridinium-modified montmorillonite as a reinforcing material, and using the decabromodiphenyl ethane / antimony trioxide as a flame-retardant system, after the flame-retardant agent is added, the interlayer spacing of the montmorillonite in the polypropylene composite material is increased, and the dispersivity of the montmorillonite is improved; the thermal stability and flame-retardant property of the composite material are obviously improved, and the montmorillonite and the flame-retardant system can reach better flame-retardant synergistic effect in the polypropylene material.

Owner:QUANJIAO XIANGRUI PLASTIC

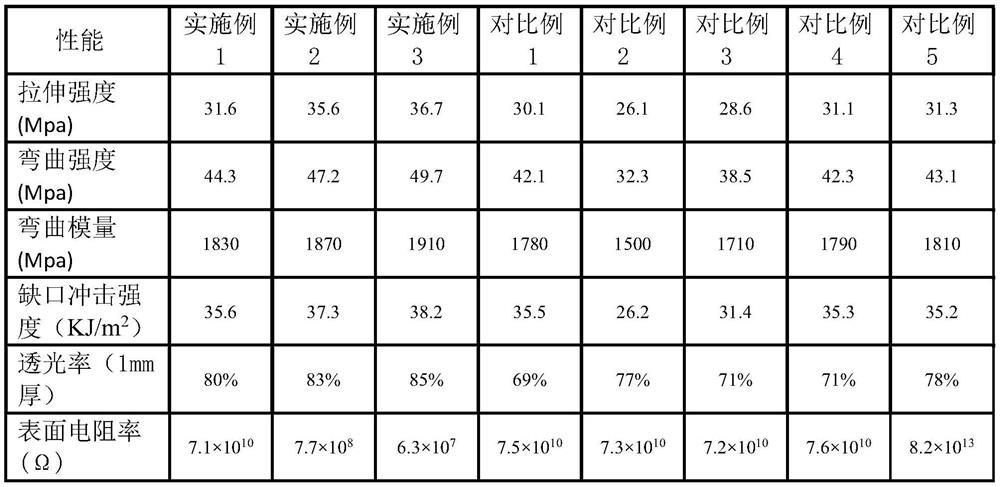

Transparent long-acting antistatic polypropylene composite material and preparation method thereof

PendingCN111995821AIncreased flexural modulusImprove mechanical propertiesPolypropylene compositesConductive polymer

The invention discloses a transparent long-acting antistatic polypropylene composite material and a preparation method thereof. The polypropylene composite material is prepared from the following rawmaterials in parts by weight: 100 parts of polypropylene random copolymer, 10-20 parts of ceramic particles, 1-5 parts of a transparent nucleating agent, 0.1-0.3 part of a lubricant, 0.1-0.5 part of acomposite antistatic agent and 0.1-0.3 part of an antioxidant, wherein the composite antistatic agent is prepared by coating a carbon nanotube with a conductive polymer. The composite material not only has relatively high transparency and glossiness and relatively excellent mechanical properties, but also has relatively excellent and lasting antistatic capability.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com