Preparation method for halloysite, ultrafine inorganic powder and PTFE micro-nano composite material

A technology of polytetrafluoroethylene and inorganic powder is applied in the field of preparation of polytetrafluoroethylene micro-nano composite materials, which can solve the problem that creep resistance cannot be effectively improved, elongation at break and tensile strength are decreased, heavy metal pollution, etc. problems, to achieve the effect of improving mechanical properties, excellent friction resistance and creep resistance, and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

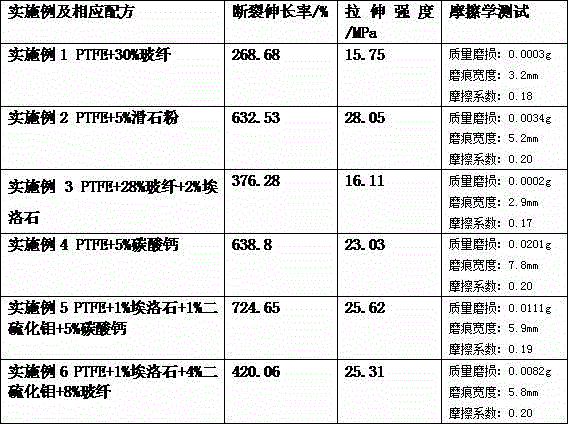

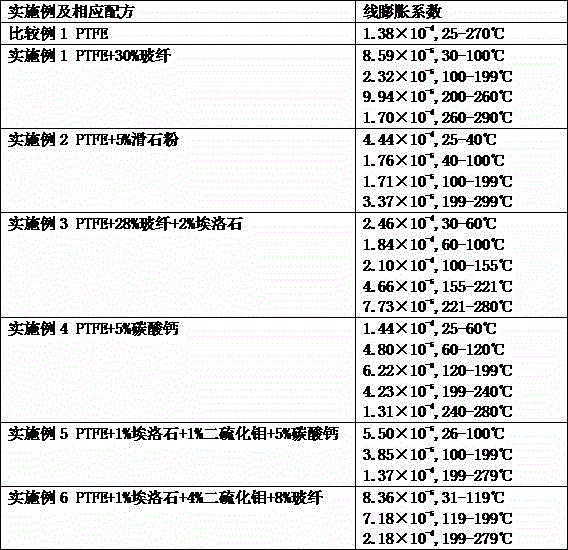

[0024] Mix polytetrafluoroethylene with a particle size of 25 μm and glass fiber at a mass ratio of 70:30, and prepare a homogeneous mixture of glass fiber / polytetrafluoroethylene by mechanical blending.

[0025] The prepared powder was cold-pressed under a pressure of 35MPa and kept under pressure for 2 minutes. The resulting flake sample was removed from the mold, placed in a muffle furnace, heated to 370~380°C at a heating rate of 200°C / hour, kept for 2 hours, and then the sintered product was cooled to room temperature with the furnace to obtain modified glass fiber PTFE composite material.

[0026] The glass fiber modified polytetrafluoroethylene composite material is tested according to GB / T 1040-92, and its elongation at break = 268.68%, tensile strength = 15.75MPa. GB / T 3960-1983 test, its wear amount = 0.2mg, friction coefficient = 0.18. At 40-100°C, the coefficient of linear expansion is nearly 2 orders of magnitude lower than that of pure PTFE.

Embodiment 2

[0028] The polytetrafluoroethylene with a particle size of 25 μm and the talc powder with a particle size of 4 μm were mixed at a mass ratio of 95:5, and a homogeneous mixture of talc powder / polytetrafluoroethylene was prepared by mechanical blending.

[0029] The prepared powder was cold-pressed under a pressure of 35MPa and kept under pressure for 2 minutes. The obtained flake sample was removed from the mold, placed in a muffle furnace, heated to 370~380°C at a heating rate of 200°C / hour, kept for 2 hours, and then the sintered product was cooled to room temperature with the furnace to obtain a modified talc powder PTFE composite material.

[0030] The talcum powder filled polytetrafluoroethylene composite material is tested according to GB / T 1040-92, and its elongation at break = 632.53%, tensile strength = 28.05MPa. GB / T 3960-1983 test, its wear amount = 3.5mg, friction coefficient = 0.2. At 40-300°C, the coefficient of linear expansion is nearly an order of magnitude l...

Embodiment 3

[0032] Mix polytetrafluoroethylene with a particle size of 25 μm, glass fiber, and halloysite through a 200-mesh sieve at a mass ratio of 70:28:2, and prepare halloysite / glass fiber / polytetrafluoroethylene by mechanical blending homogeneous mixture.

[0033] The prepared powder was cold-pressed under a pressure of 40 MPa, and kept under pressure for 2 minutes. The resulting flake samples were removed from the mold, placed in a muffle furnace, heated to 370-380°C at a heating rate of 200°C / hour, kept for 2 hours, and then the sintered product was cooled to room temperature with the furnace to obtain halloysite / Glass fiber / polytetrafluoroethylene micro-nano composite material.

[0034] The halloysite / glass fiber / polytetrafluoroethylene micro-nano composite material is tested according to GB / T 1040-92, and its elongation at break = 376.28%, tensile strength = 16.11MPa. GB / T 3960-1983 test, its wear amount = 0.2mg, friction coefficient = 0.18. At 60~220°C, the coefficient of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com