Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about How to "Improve crystallization speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

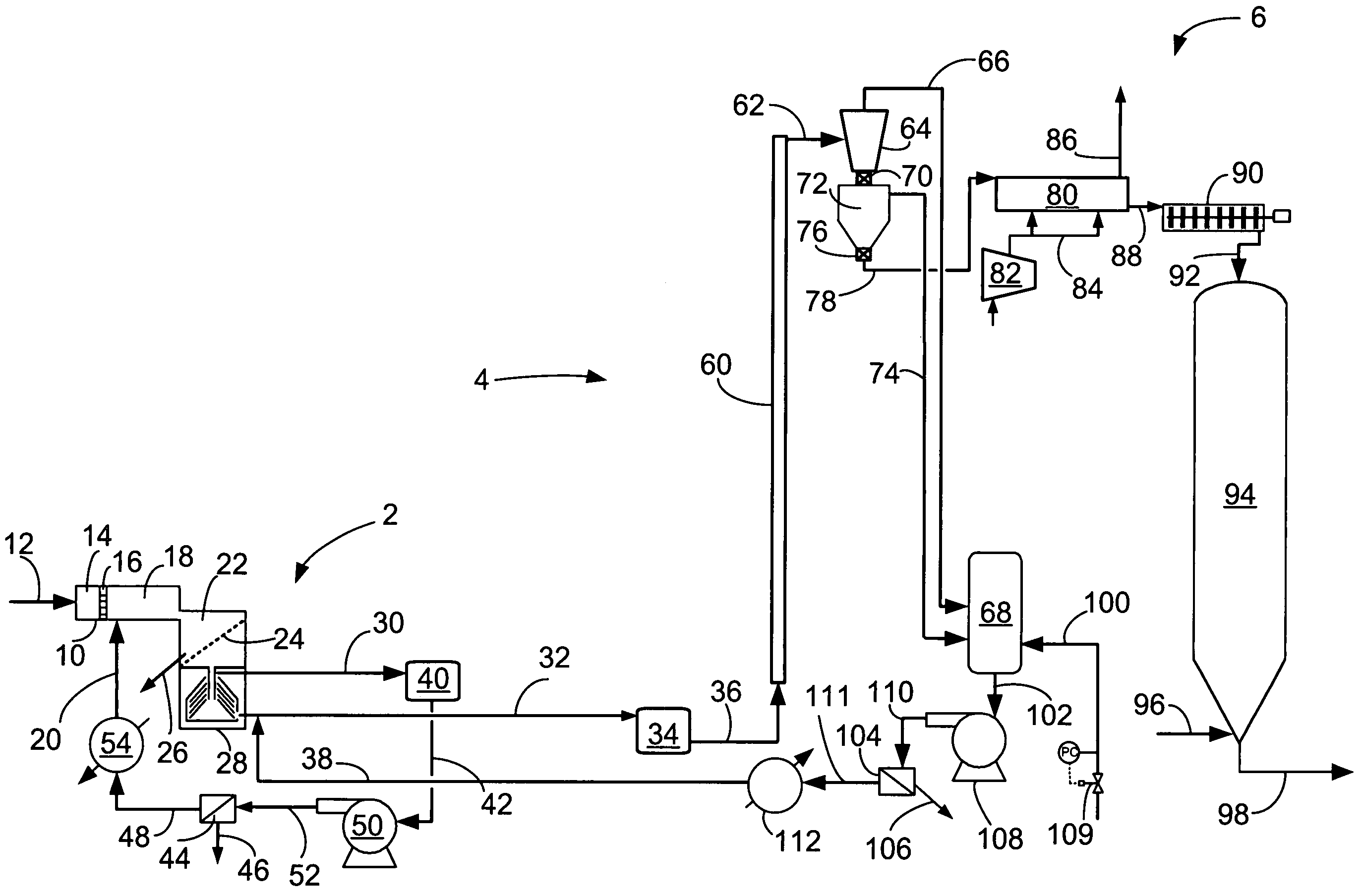

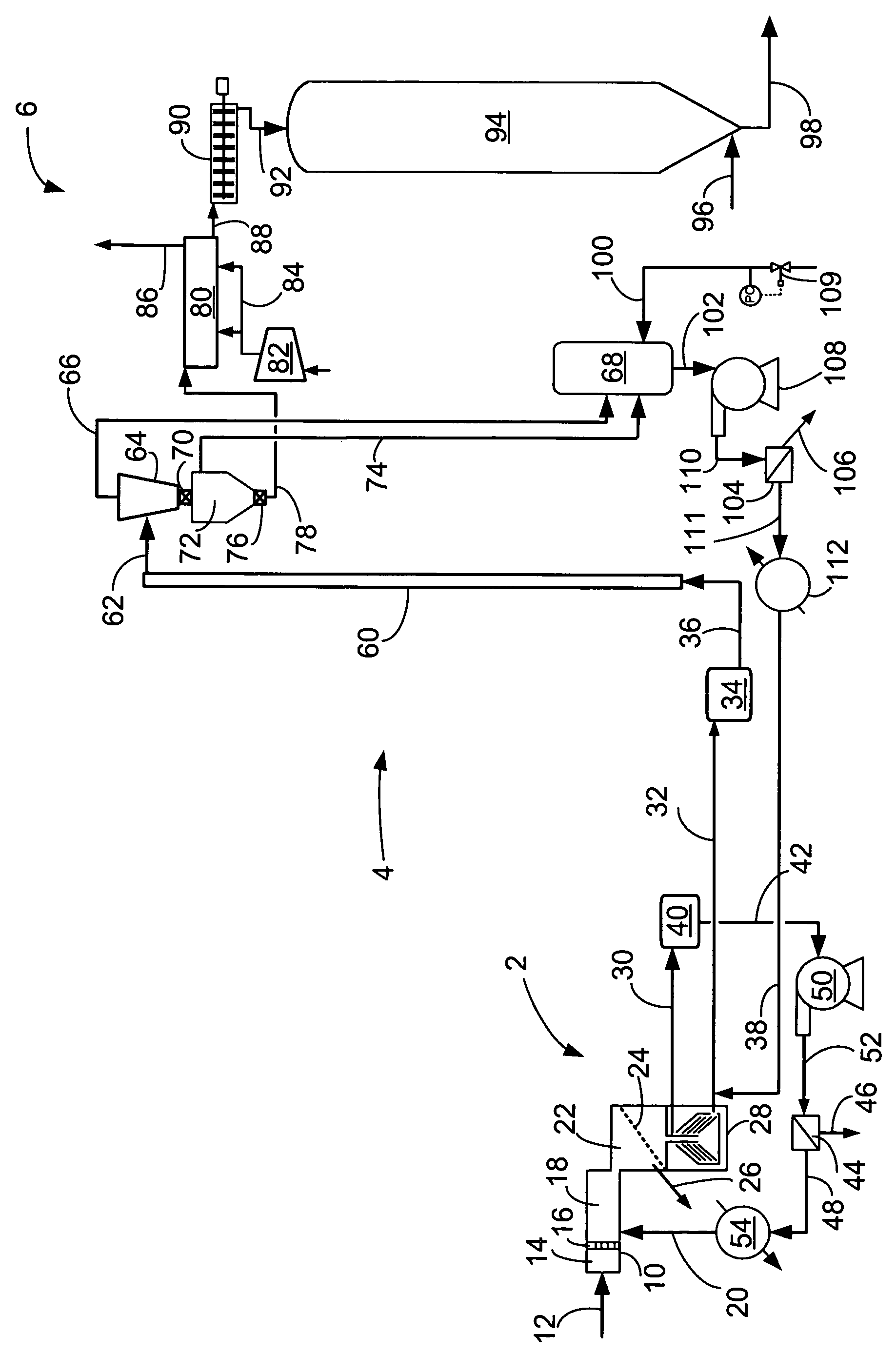

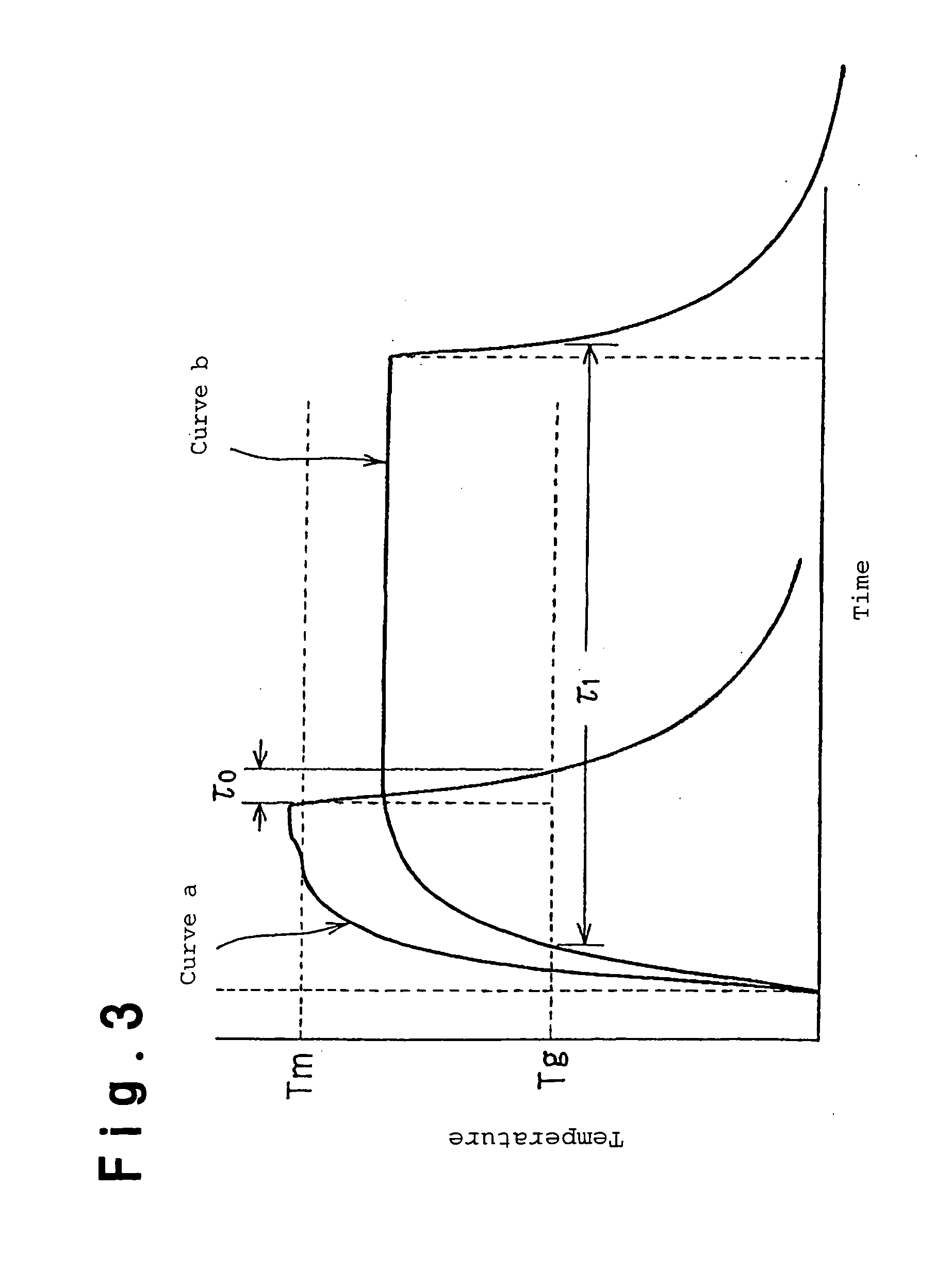

Method and apparatus for crystallizing polymer particles

ActiveUS7250486B1Save heatEfficiently formedChemical/physical/physico-chemical stationary reactorsPolymer scienceShell molding

The present invention is a process and apparatus for conserving loss of heat while forming and crystallizing polymer particles in a liquid. The cooling liquid quenches the polymer during particle molding to facilitate shaping. The cooling liquid cools the polymer particles not below a temperature that allows adequate crystallization to occur. Cooling liquid is quickly switched with a warming liquid, so the temperature of the polymer is in the crystallization range and the heat of crystallization self-heats the polymer to a higher temperature.

Owner:UOP LLC

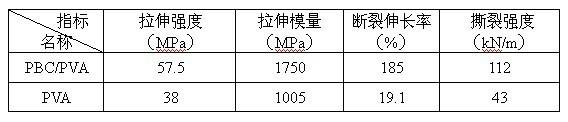

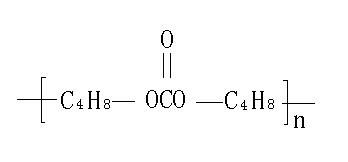

Biodegradable polycarbonate butylene terephthalate composite material and preparation method of biodegradable polycarbonate butylene terephthalate composite material

The invention relates to a biodegradable polycarbonate butylene terephthalate composite material and a preparation method of the biodegradable polycarbonate butylene terephthalate composite material. The biodegradable polycarbonate butylene terephthalate composite material is characterized in that the material comprises the following components in part by weight: 30 to 70 parts of aliphatic polycarbonate butylene terephthalate, 10 to 40 parts of other biodegradable materials, 1.0 to 10 parts of filler, 0.5 to 1.5 parts of rare earth composite nucleating agent, 0.5 to 1.5 parts of dispersant, 4.0 to 15 parts of plasticizer, 1.5 to 4 parts of heat resistance stabilizer, 0.05 to 1.5 parts of antioxidant, 0.5 to 1.0 part of lubricant, 0.1 to 1.0 part of anti-block agent and 0.05 to 0.5 part of biodegradation accelerator. The composite material has high melt strength, good film forming ability, high tensile strength, high tearing strength and good light-conversion effect.

Owner:JIANGSU XINGYE PLASTIC +1

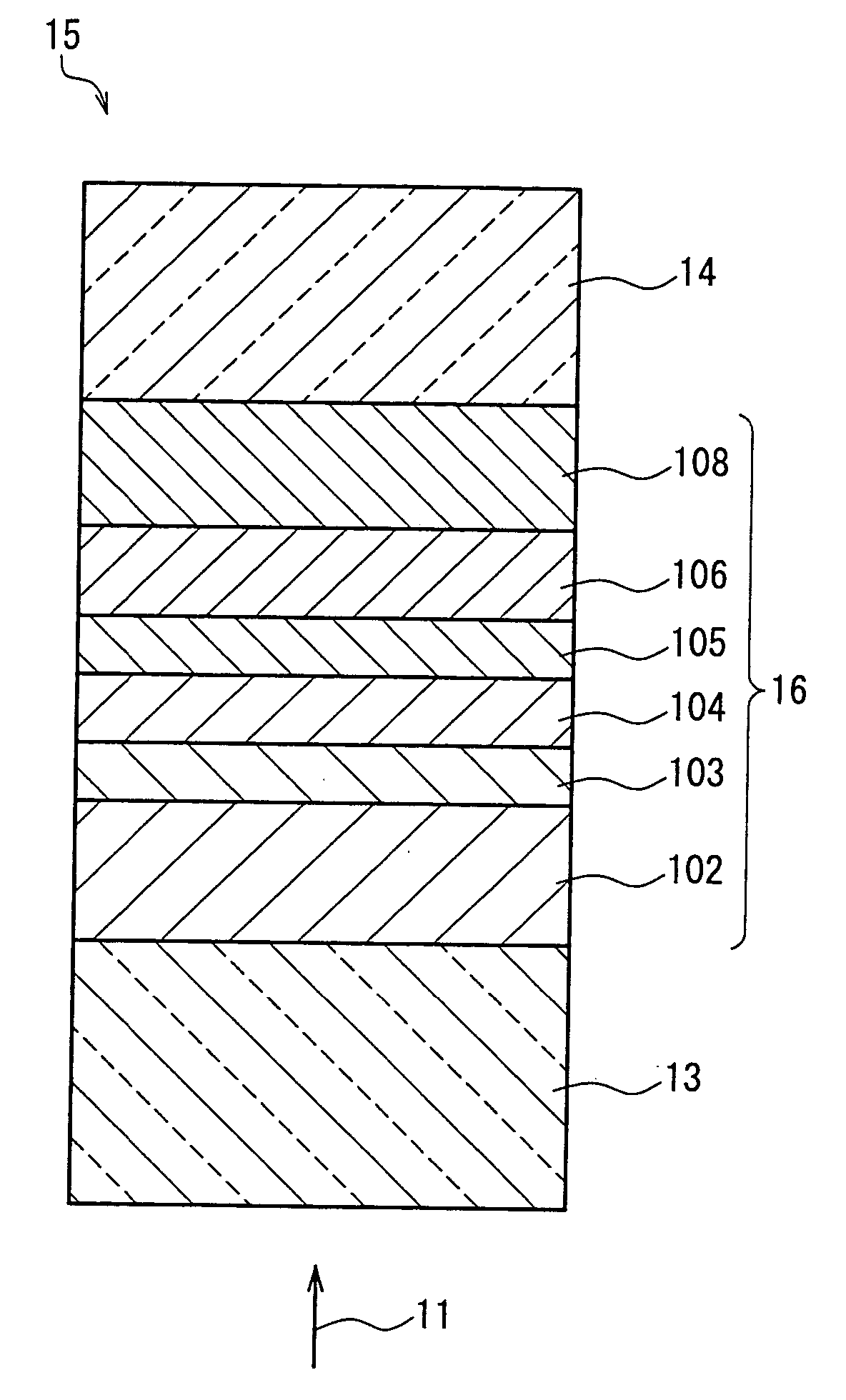

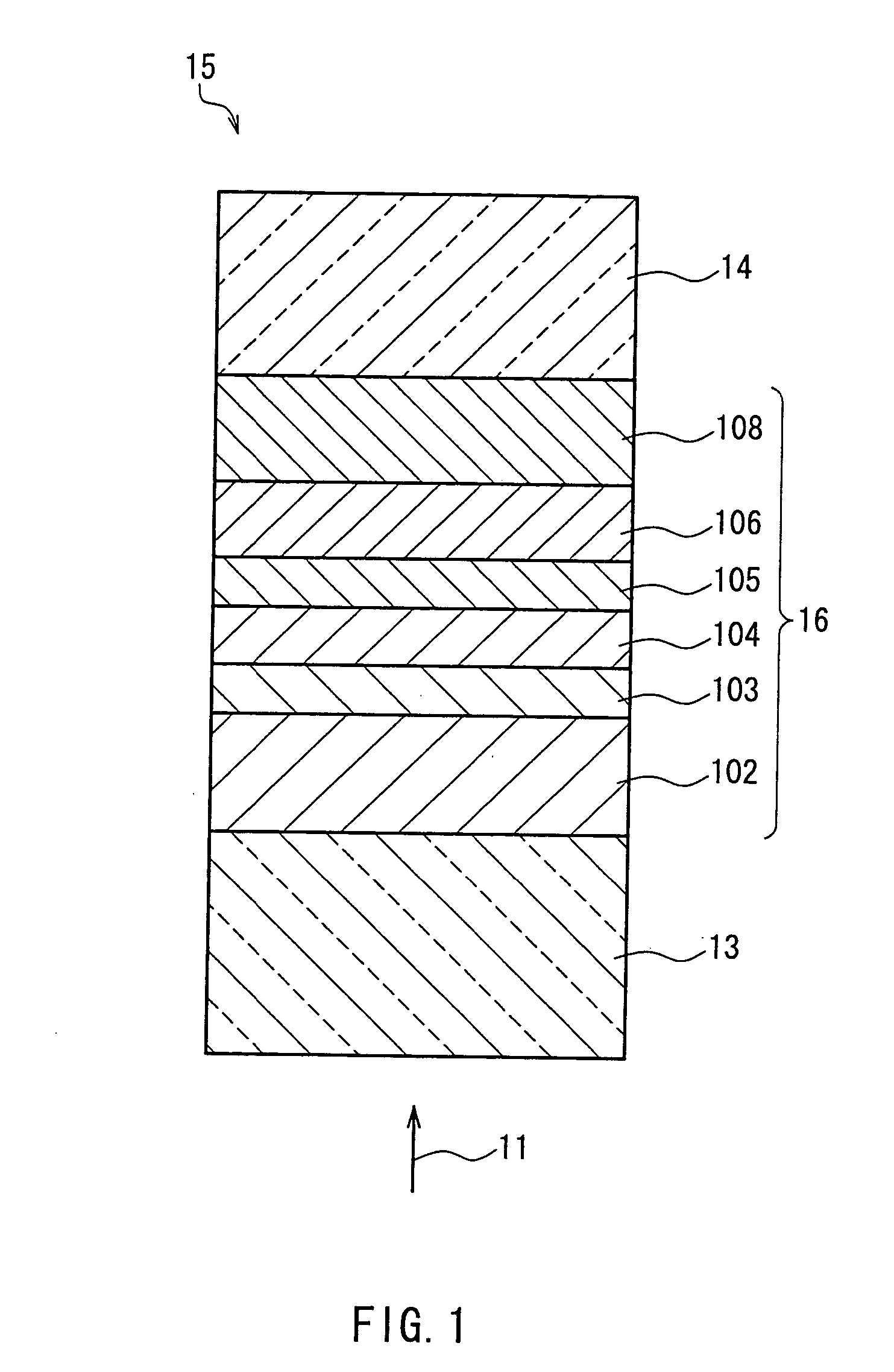

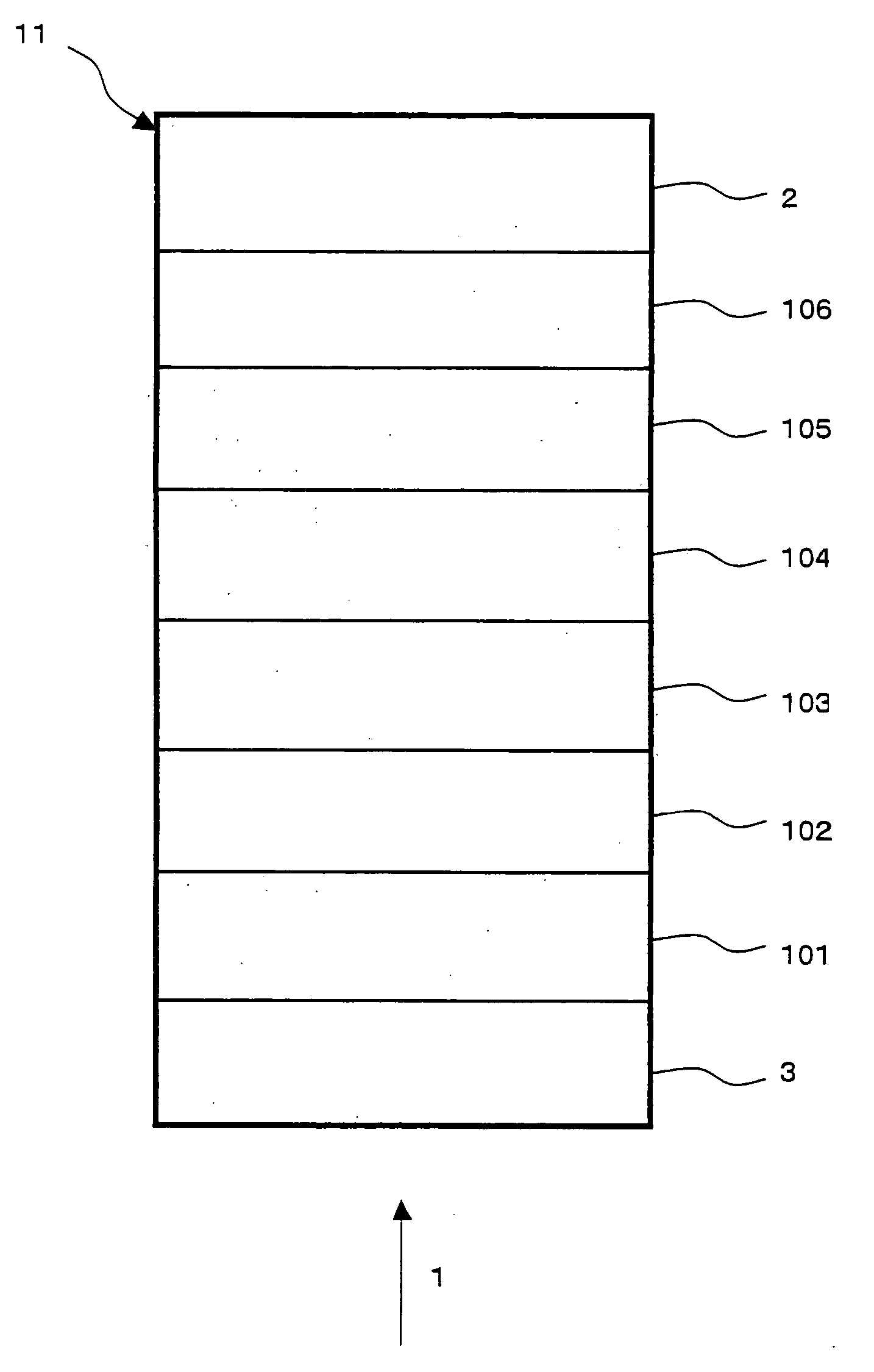

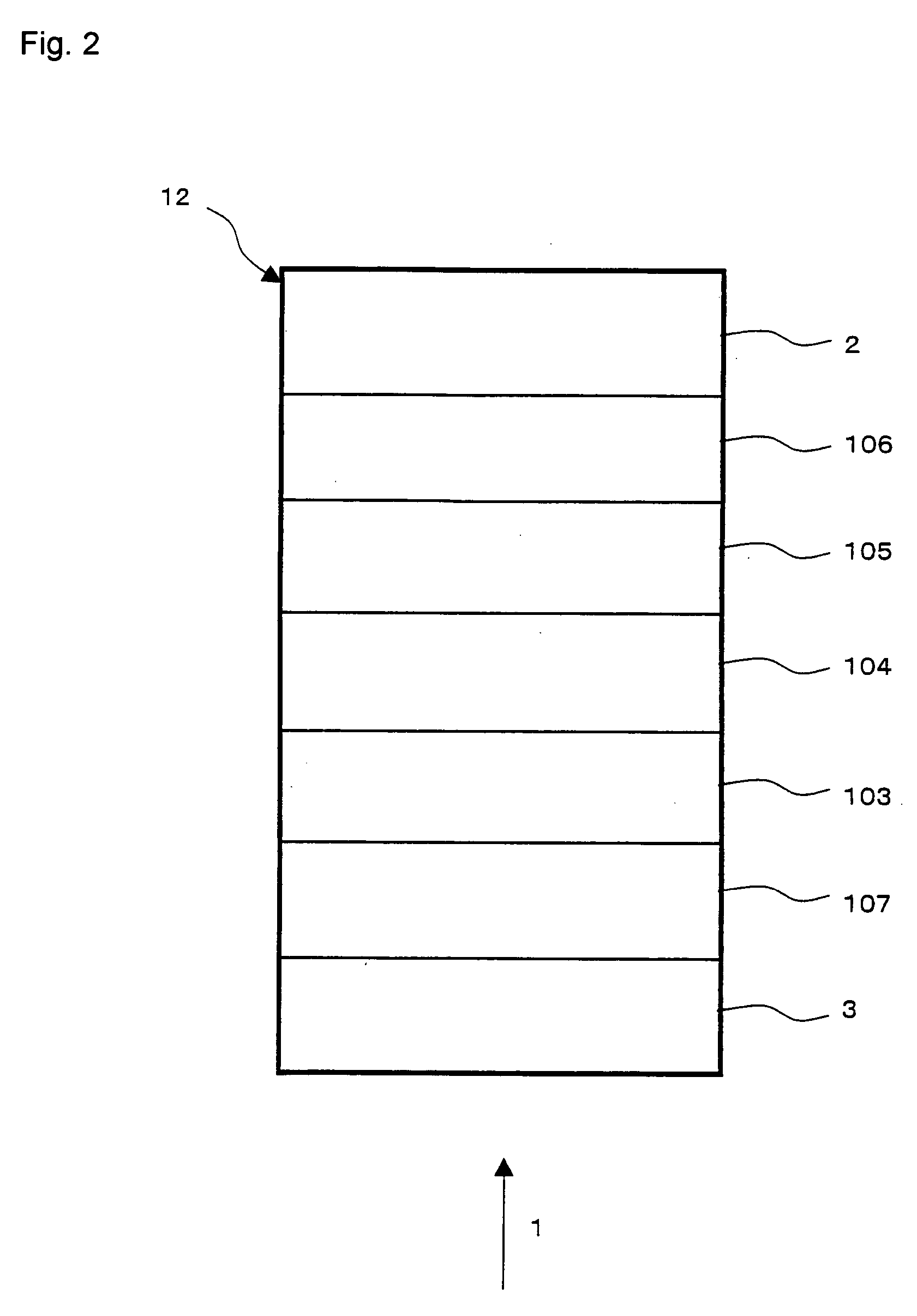

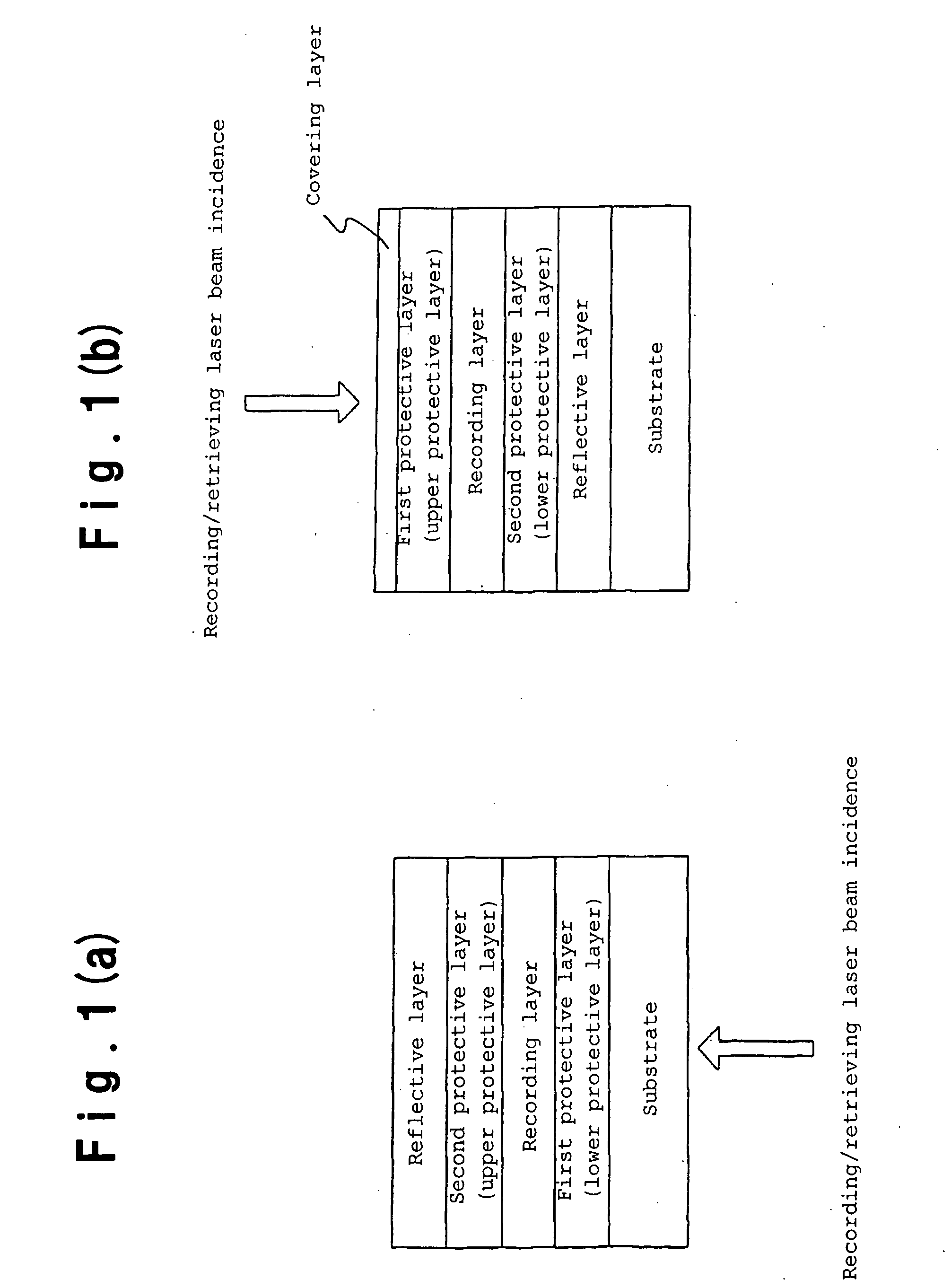

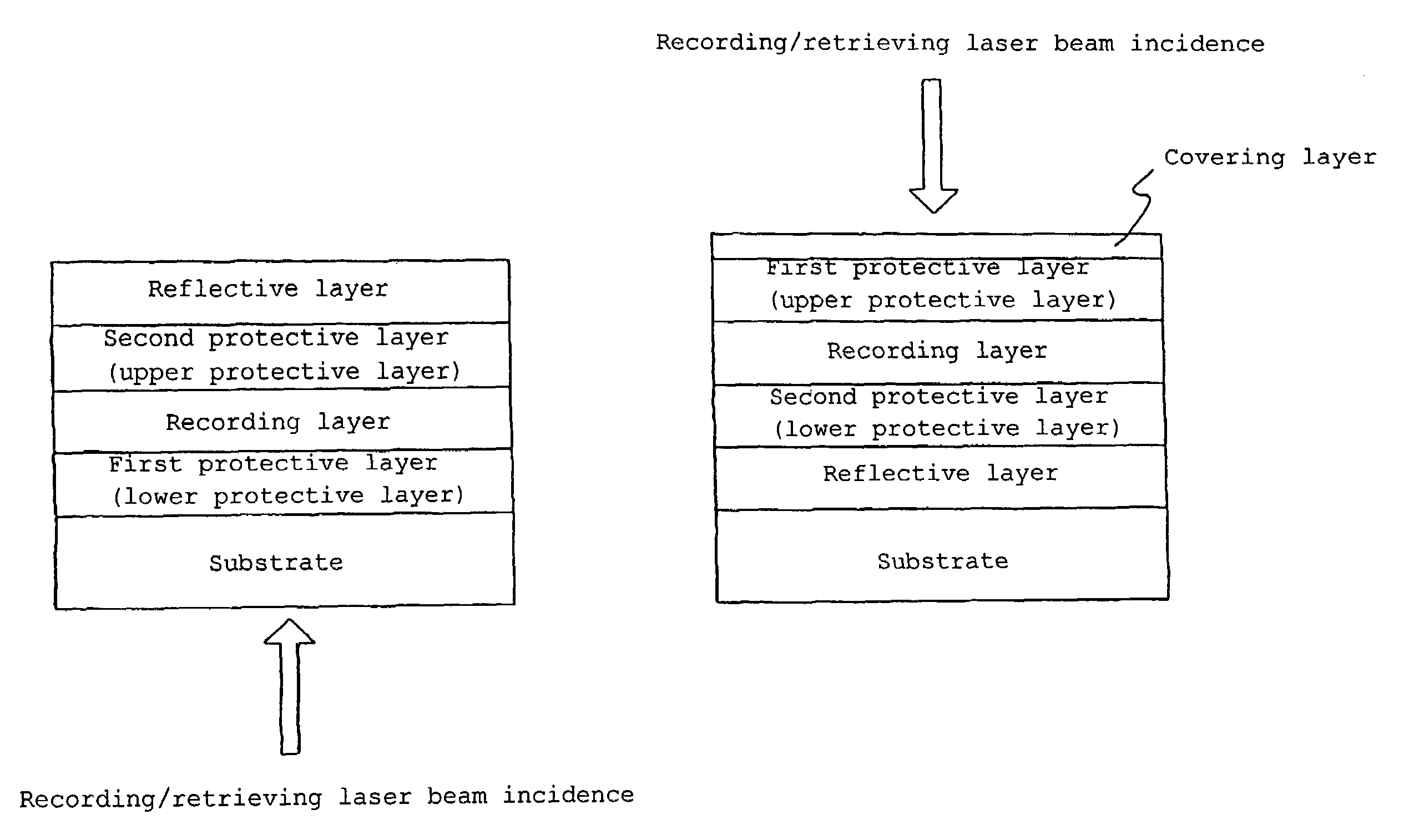

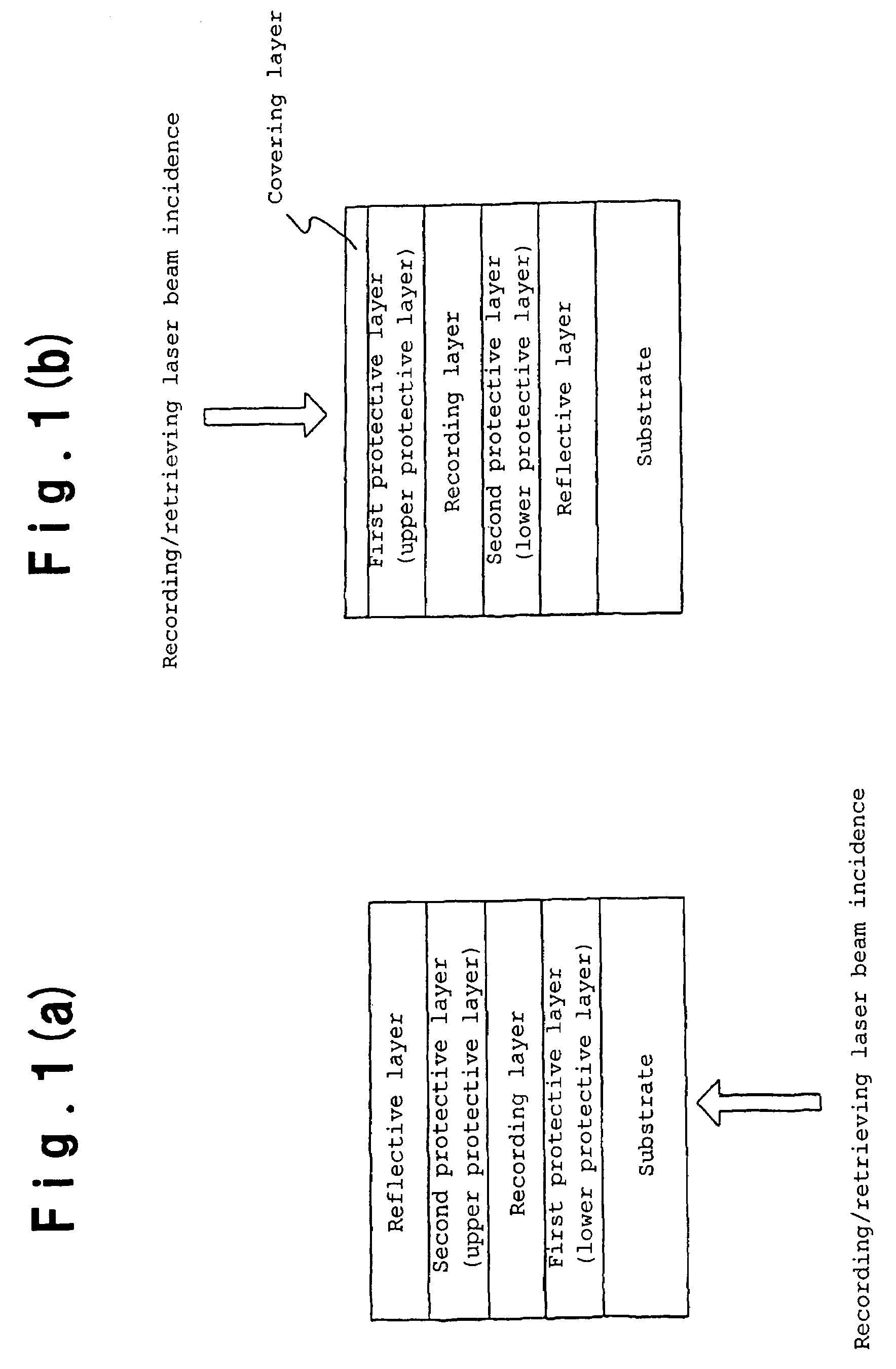

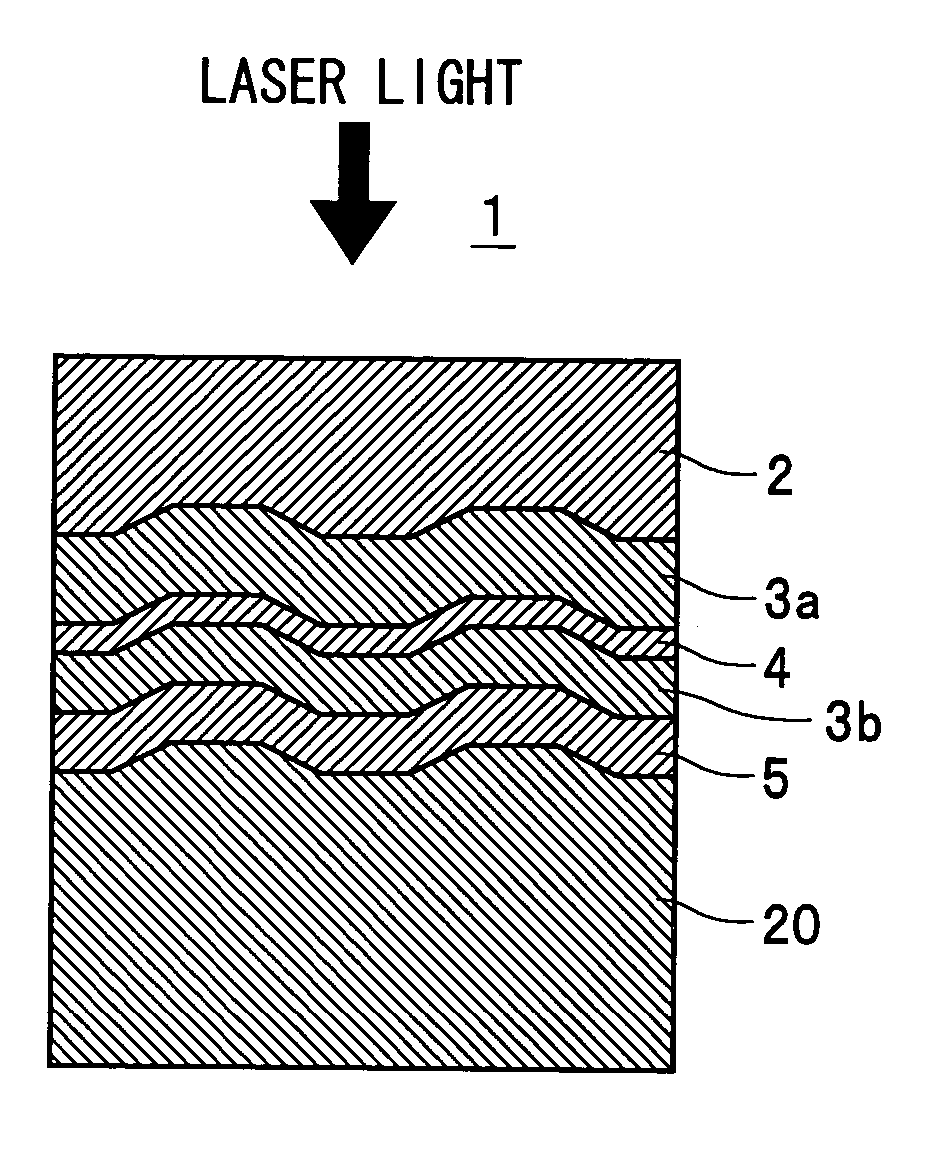

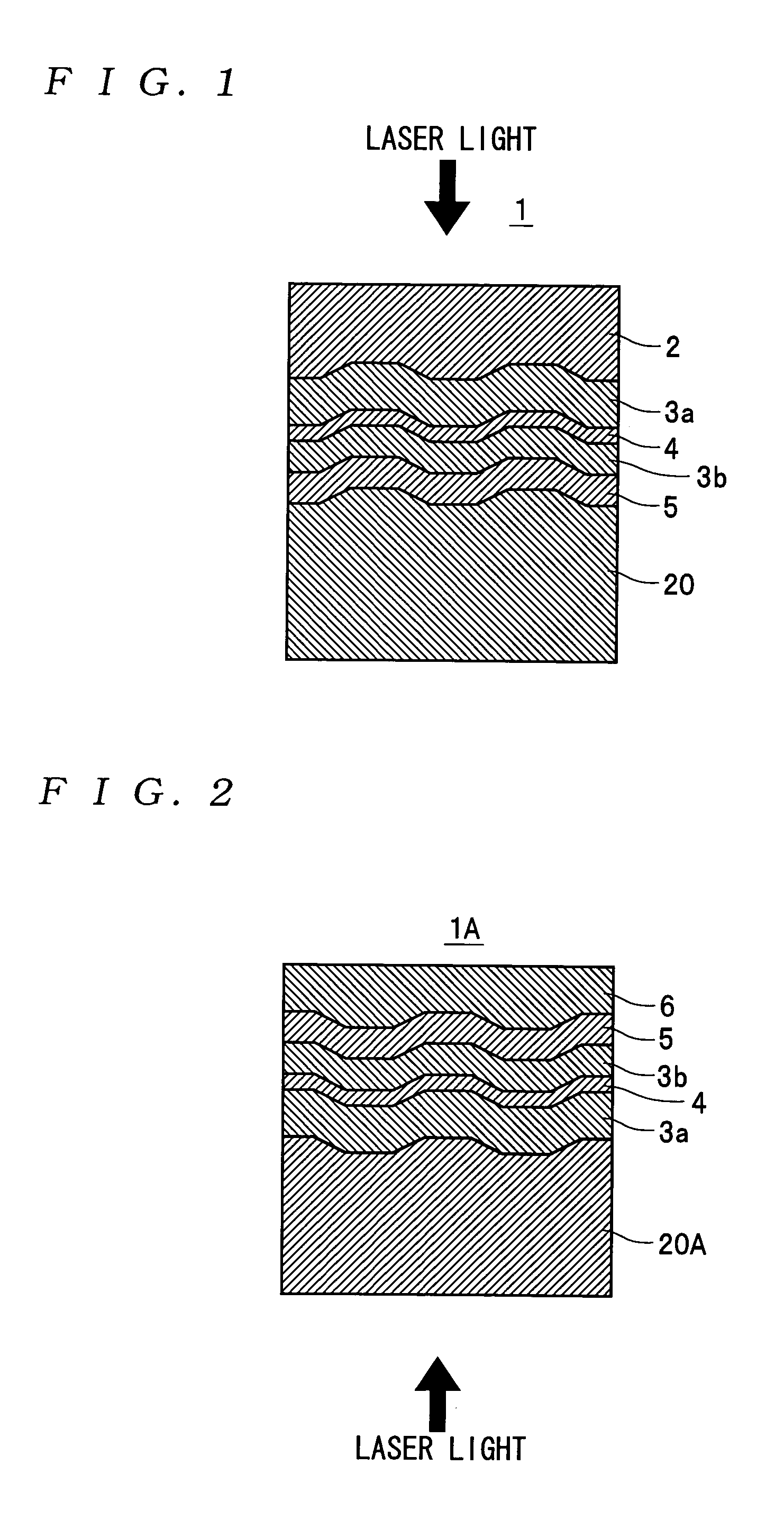

Information recording medium and medium for manufacturing the same

InactiveUS20050074694A1Decrease in recording sensitivityDecrease in signal intensitySenses disorderRadiation applicationsInformation layerAmorphous phase

An information recording medium includes a substrate and an information layer formed on the substrate. The information layer includes a recording layer whose phase can be changed between a crystalline phase and an amorphous phase by irradiation with a laser beam or application of electric energy; a Cr-containing layer including at least Cr and O, arranged in contact with a first surface of the recording layer; and a Ga-containing layer including at least Ga and O, arranged in contact with a second surface of the recording layer.

Owner:PANASONIC CORP

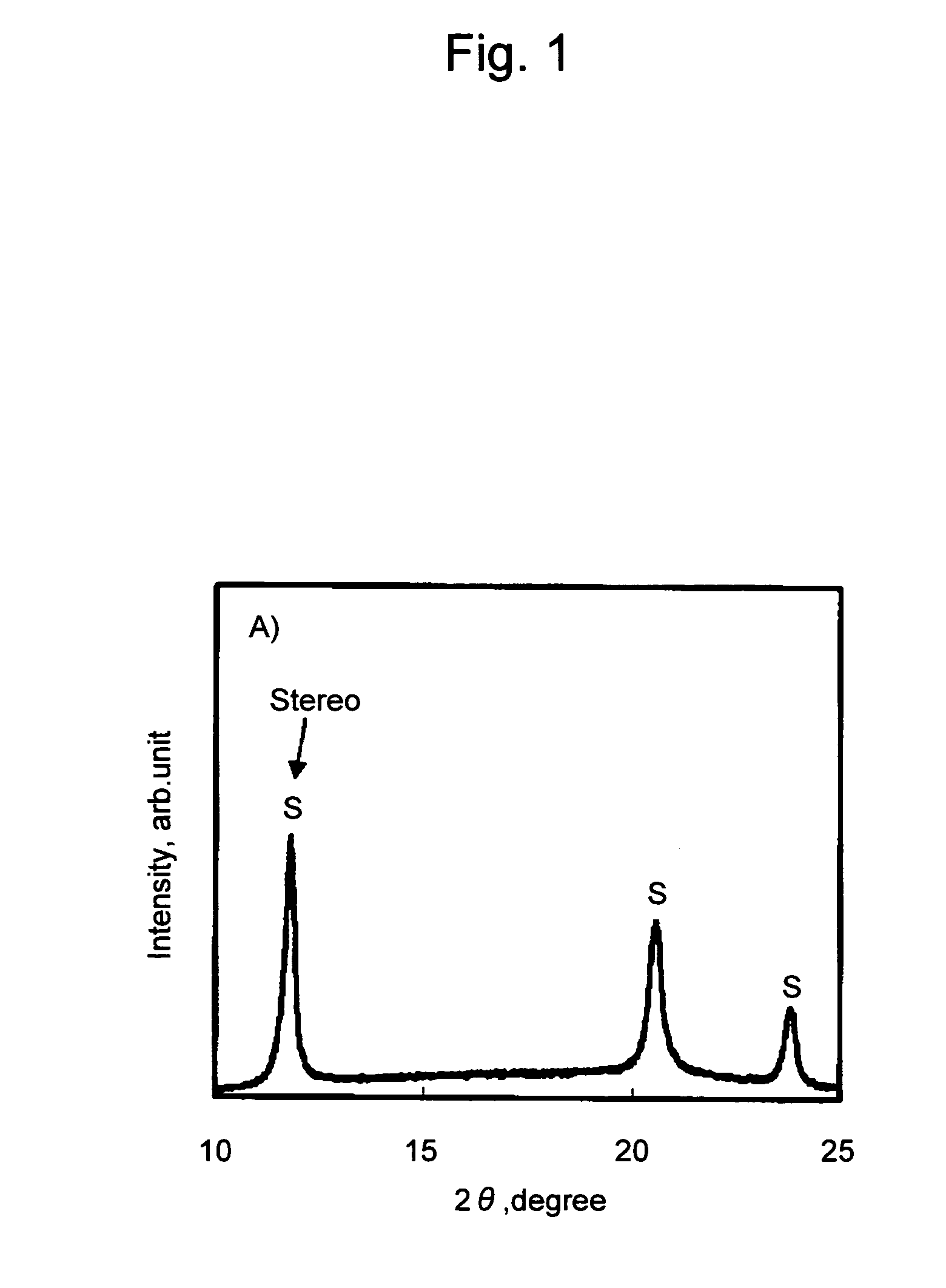

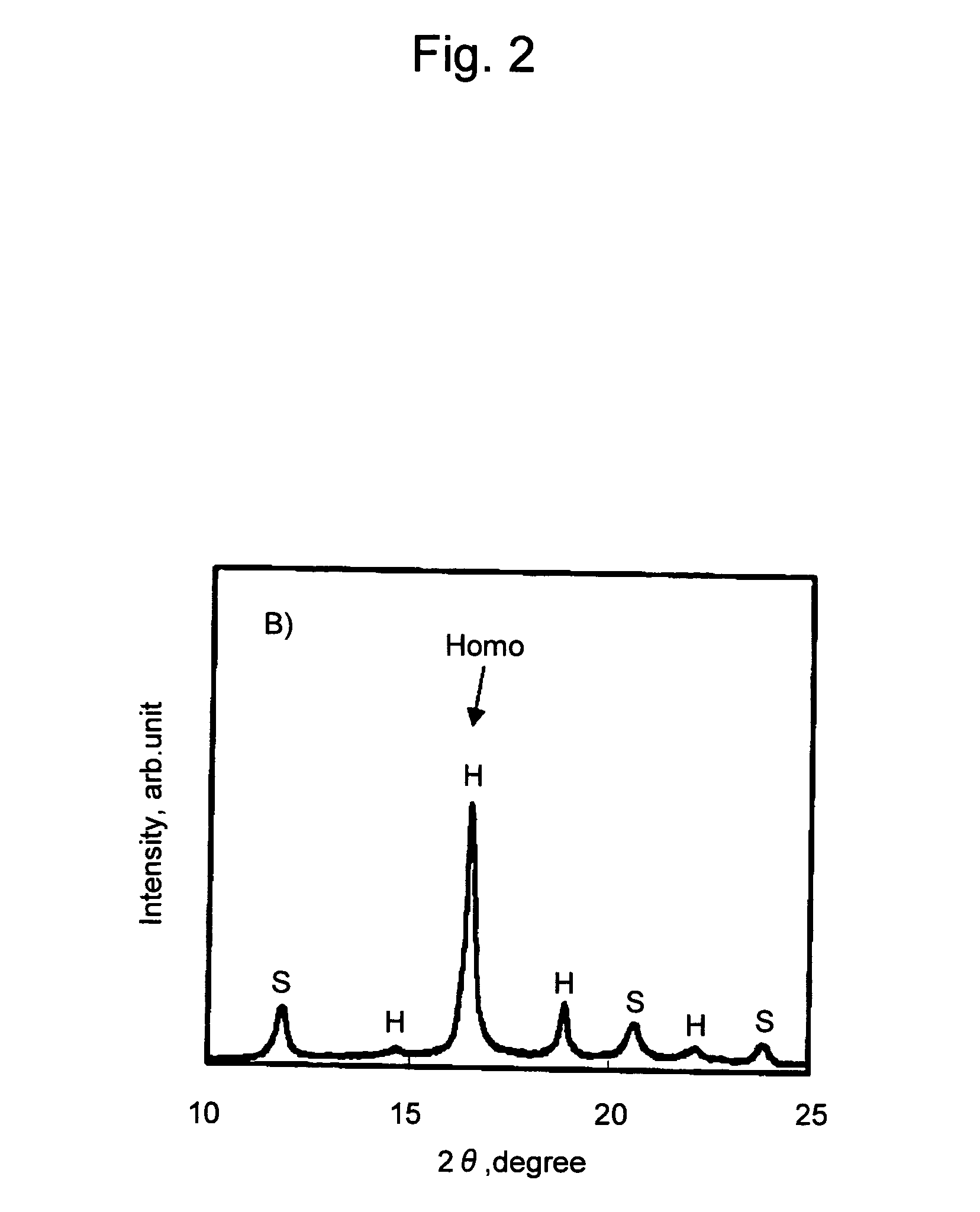

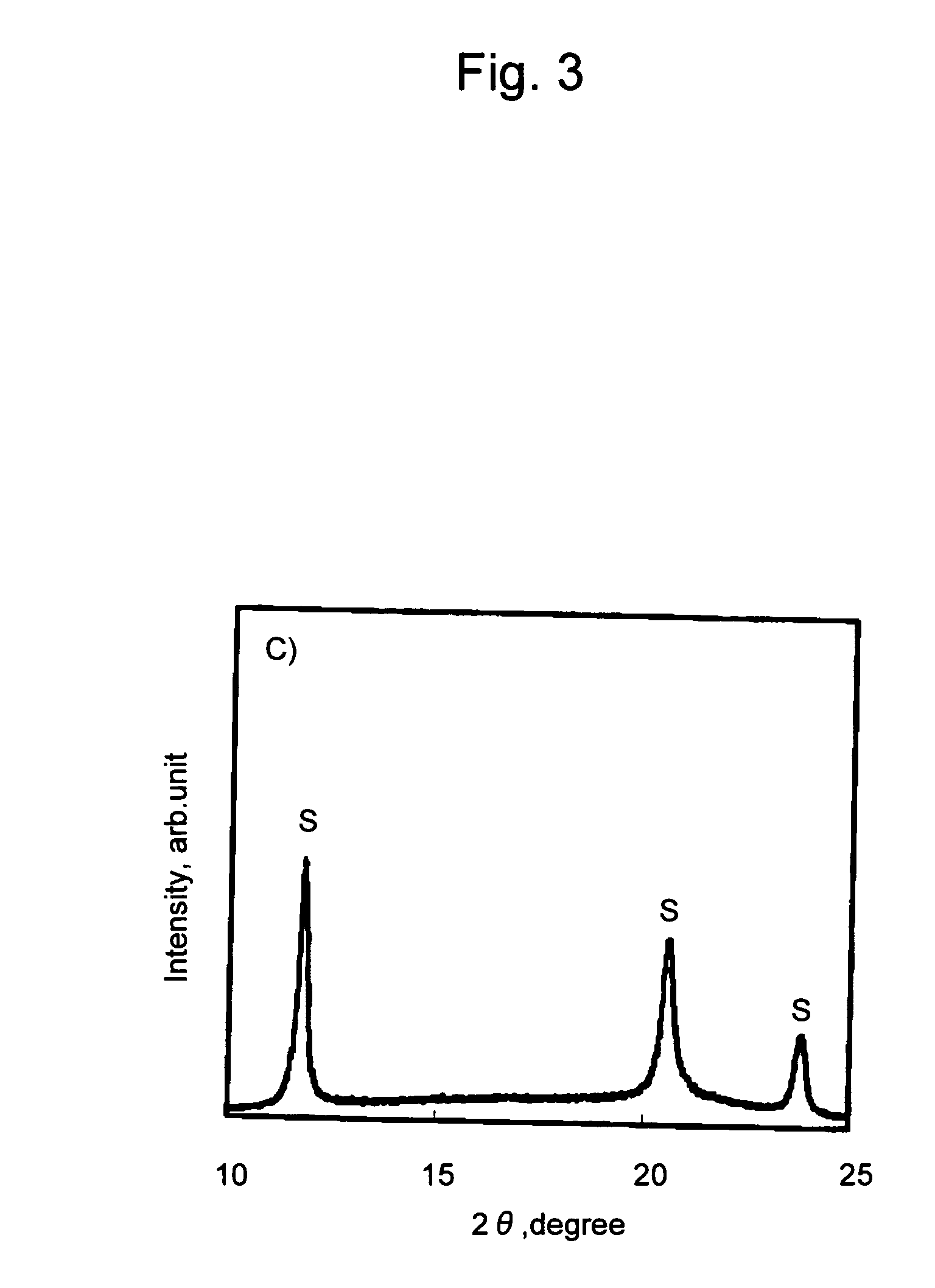

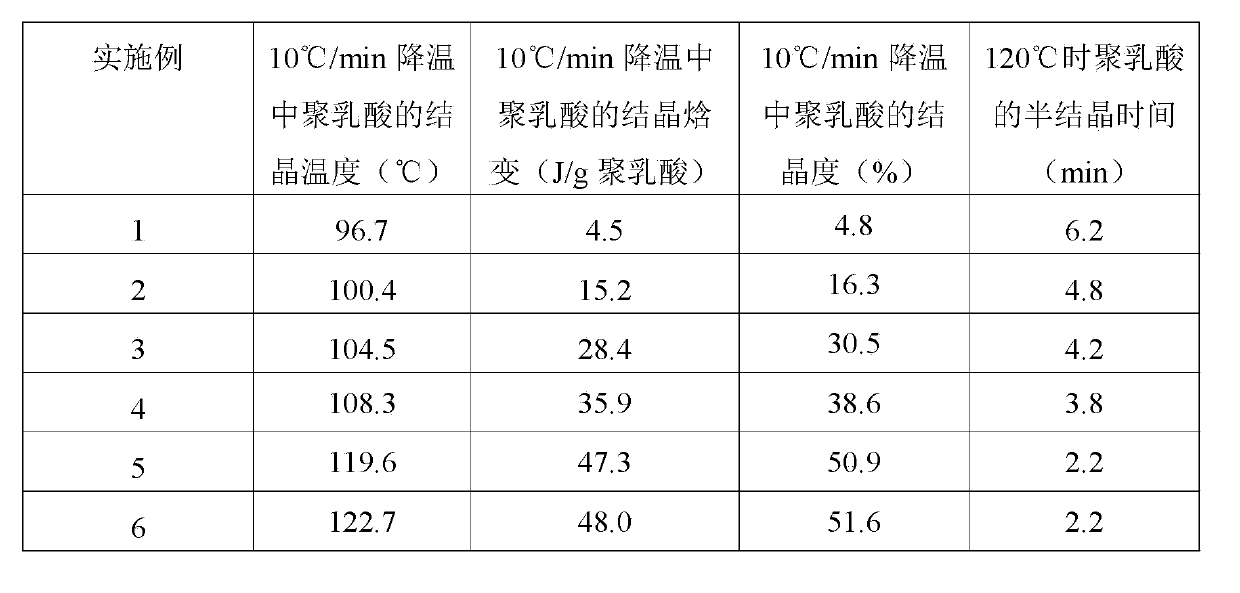

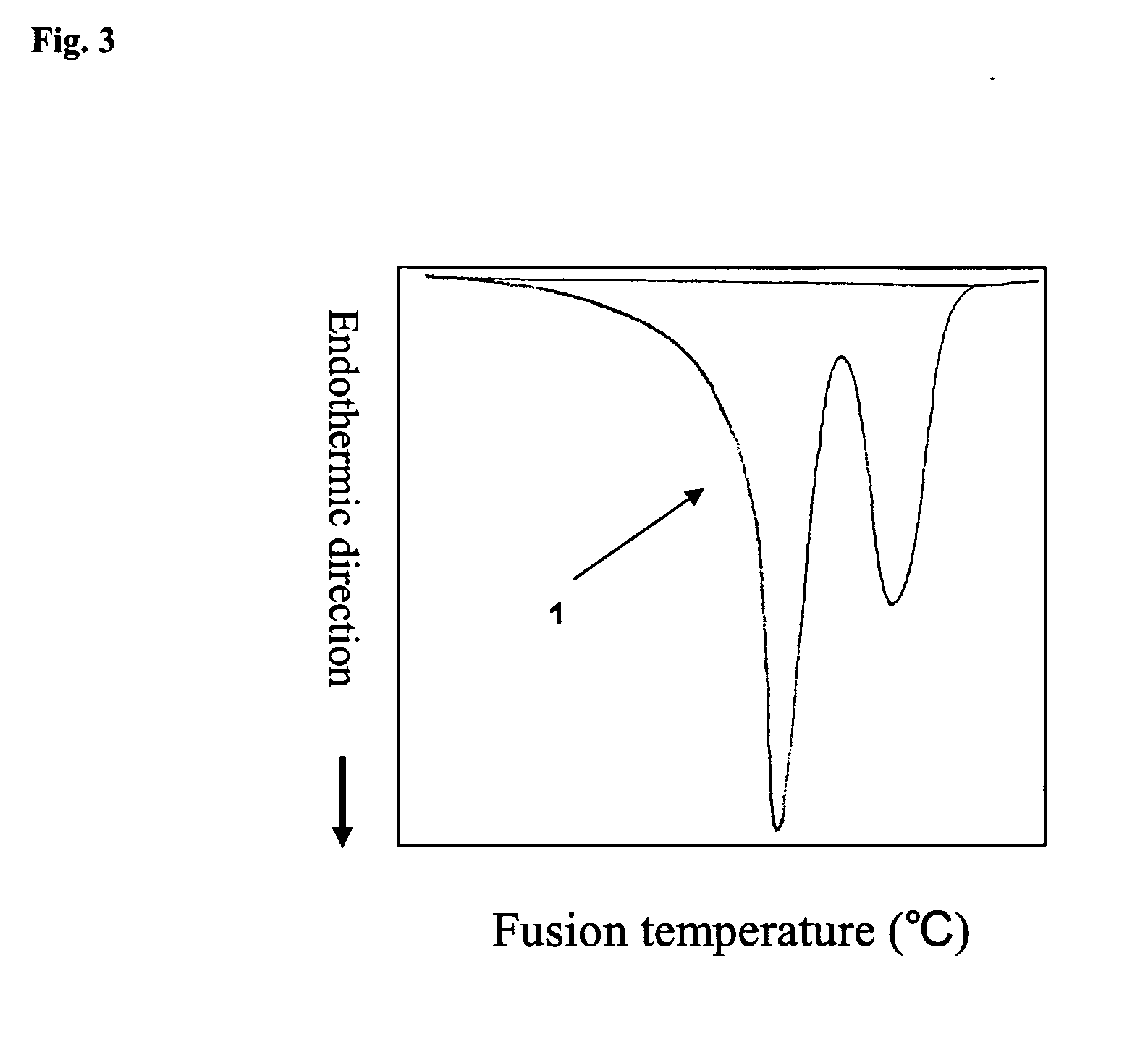

Polylactic Acid Resin and Composition and Molded Article of the Same

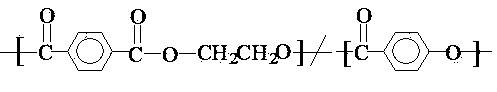

This invention provides a polylactic acid resin composition in which stereocomplex crystals of poly-L-lactic acid and poly-D-lactic acid can be selectively crystallized to obtain polylactic acid having a sufficiently high speed of crystallization and a sufficiently high ratio of stereocomplex crystal and a molded article thereof obtained via melt molding and crystallization of the same. Such polylactic acid resin composition comprises polylactic acid capable of generating stereocomplex crystallization and an aromatic urea compound represented by formula (1):wherein R1 represents an alkylene group having 1 to 10 carbon atoms; R2 represents an alkyl group having 1 to 25 carbon atoms; and m is an integer between 1 to 6.

Owner:TEIJIN LTD

Flame-retardant polyamide resin composition and molded article

ActiveUS20100069539A1Improve featuresHigh levelGroup 5/15 element organic compoundsSpecial tyresGlass fiberPolymer science

To provide a flame-retardant polyamide resin composition generally excellent in flame resistance, mechanical characteristics and electrical characteristics, and suitable for electrics / electronics components and vehicles. Used is a flame-retardant polyamide resin composition comprising, a polyamide resin (A), a phosphorus-containing flame retarder (B), and glass fiber having a non-circular cross-section (C), wherein the contents in the composition are 15 to 78% by weight for the polyamide resin (A), 2 to 20% by weight for the phosphorus-containing flame retarder (B), and 20 to 65% by weight for the glass fiber having a non-circular cross-section (C).

Owner:MITSUBISHI ENG PLASTICS CORP

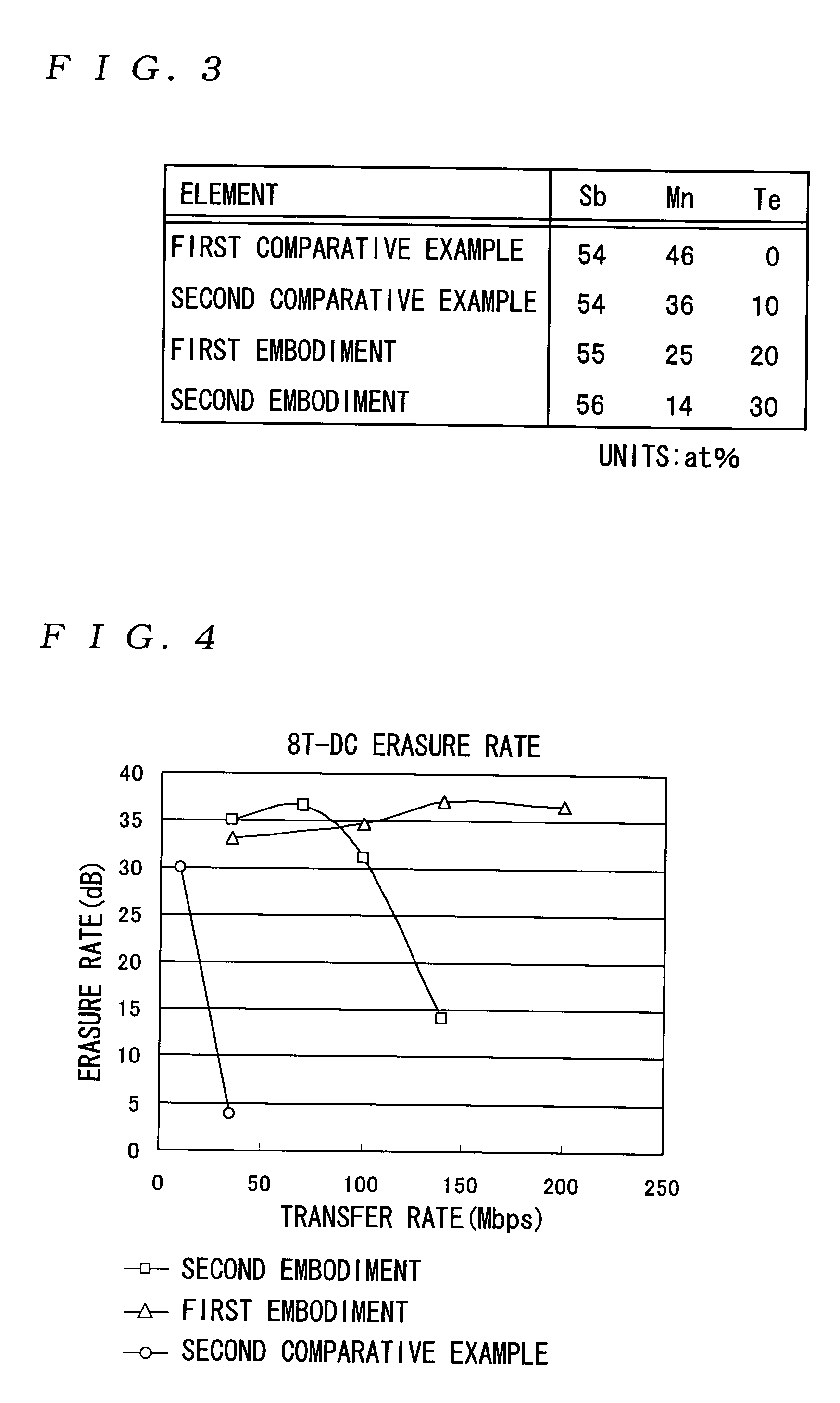

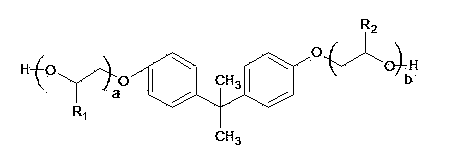

Sputtering target for phase-change memory, film for phase change memory formed by using the target, and method for producing the target

InactiveUS20050115829A1Improving rewriting propertyImprove crystallization speedCellsElectrical apparatusPhase-change memoryTe element

The present invention provides a sputtering target for a phase change memory and a phase change memory film formed with such a target, and the manufacturing method thereof, characterized in that the sputtering target is composed from elements of not less than a three component system and has as its principal component one or more components selected from stibium, tellurium and selenium, and the compositional deviation in relation to the intended composition is ±1.0 at % or less. This sputtering target for a phase change memory is capable of reducing, as much as possible, impurities that cause the reduction in the number of times rewriting can be conducted as a result of such impurities segregating and condensing in the vicinity of the boundary face of the memory point and non-memory point; in particular, impurity elements that affect the crystallization speed, reducing the compositional deviation of the target in relation to the intended composition, and improving the rewriting properties and crystallization speed of the phase change memory by suppressing the compositional segregation of the target.

Owner:JX NIPPON MINING& METALS CORP

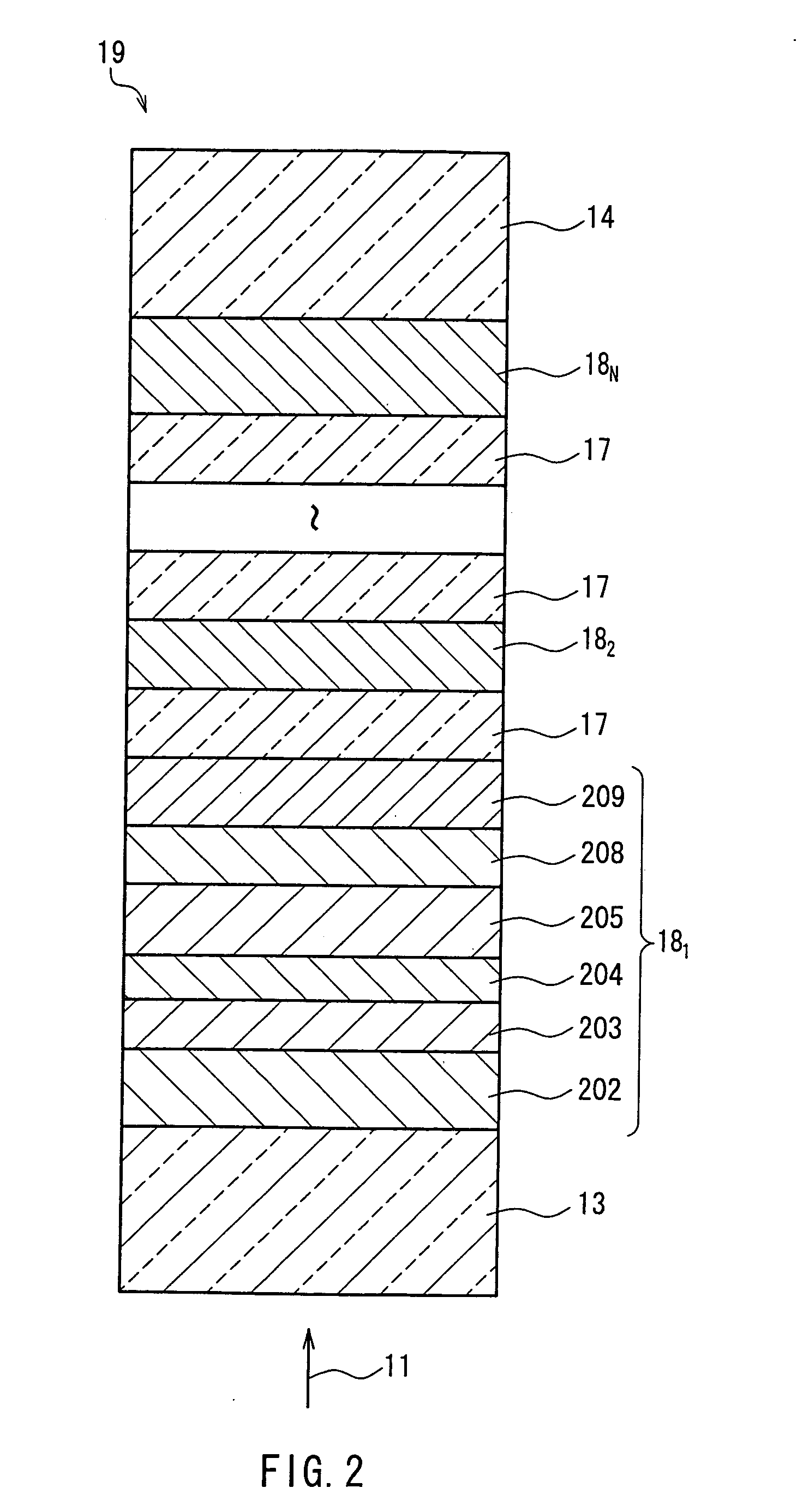

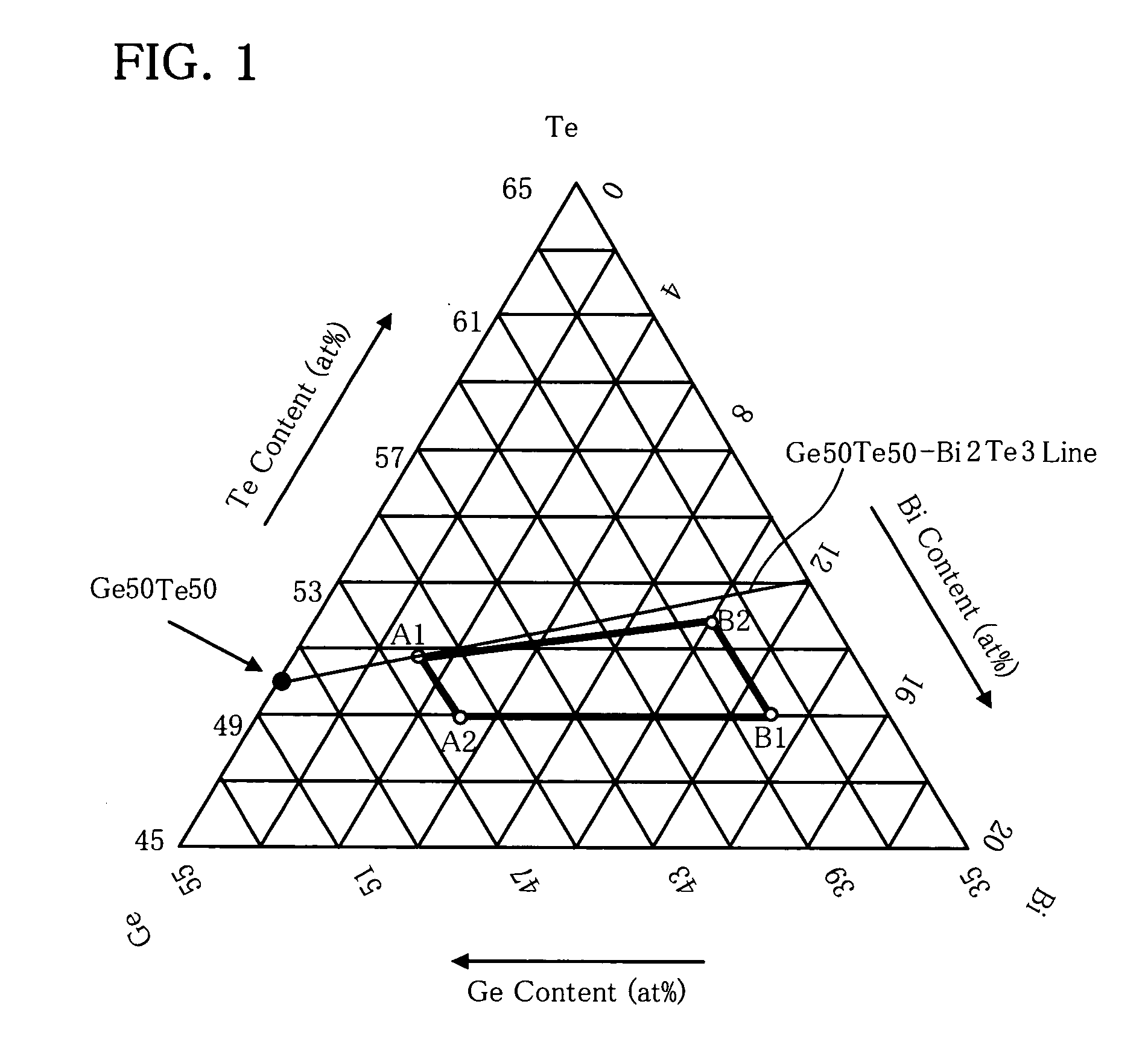

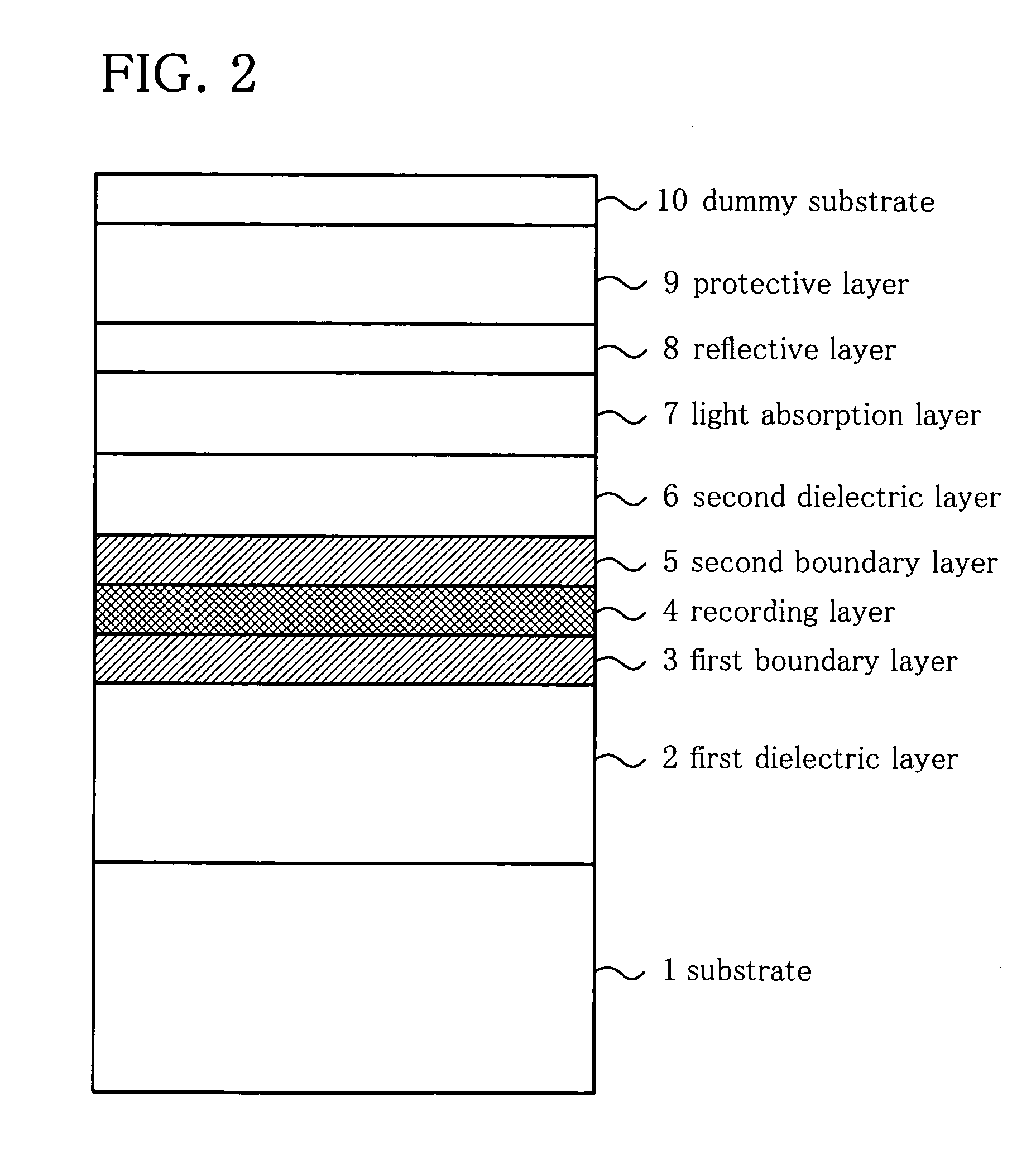

Information recording medium

InactiveUS20050227035A1Improve performanceExtended shelf lifeLayered productsPhotomechanical apparatusPhase changeRecording layer

In an information recording medium, a Bi—Ge—Te material is adopted as a phase-change recording layer material. A C—Ta—O material is used for at least any one of first and second boundary layers which are in contact with a recording layer.

Owner:HITACHT MAXELL LTD

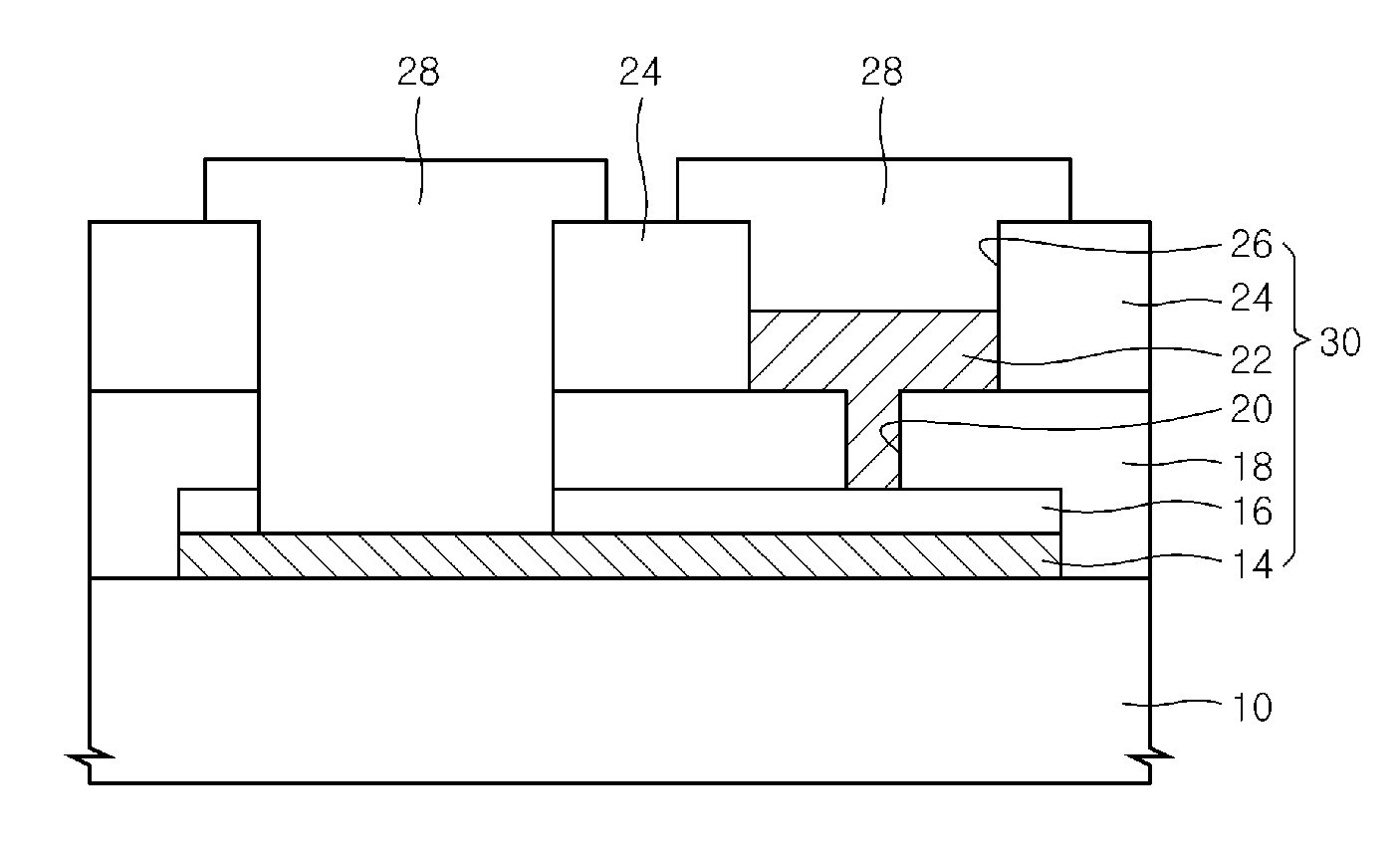

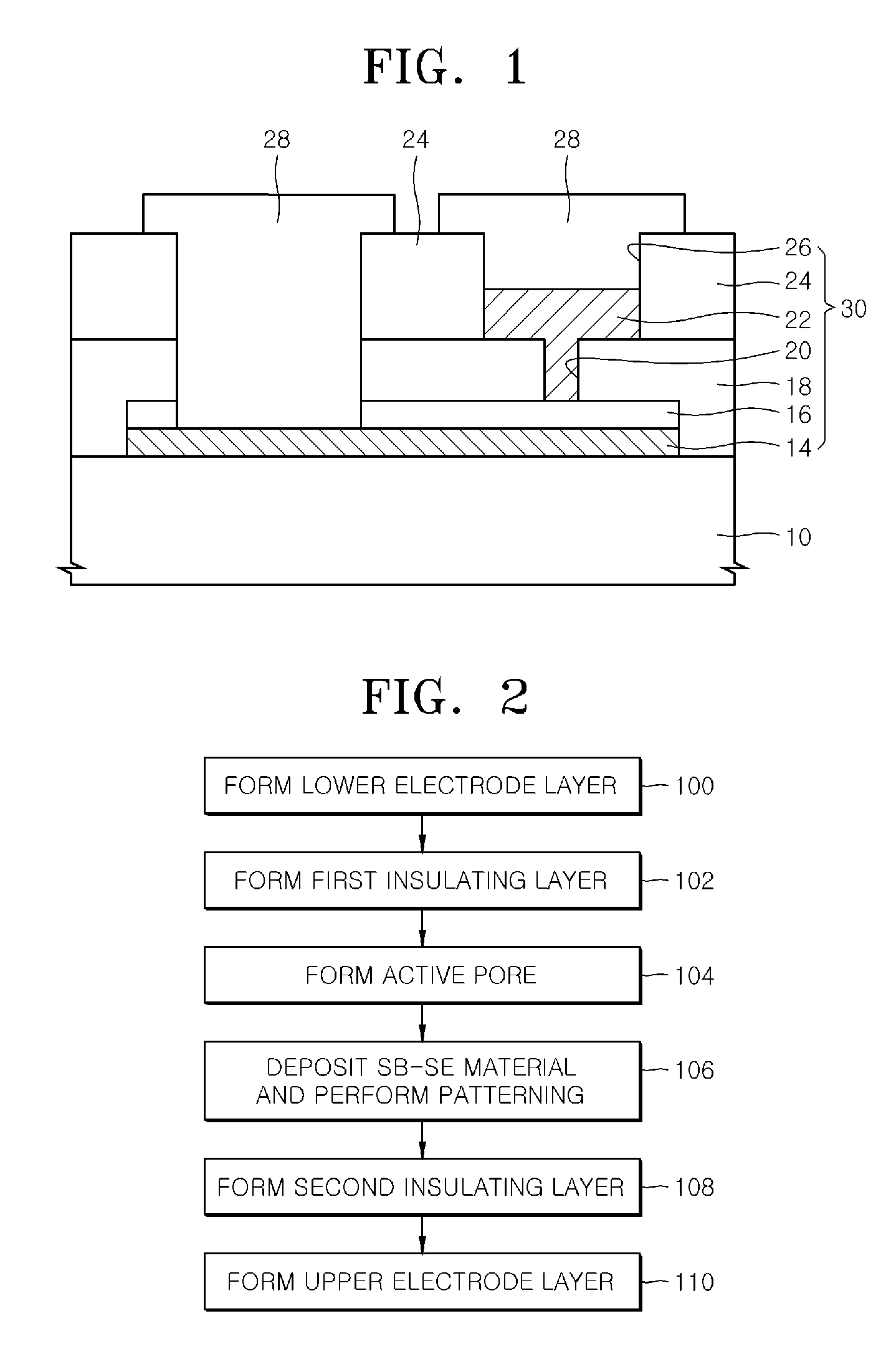

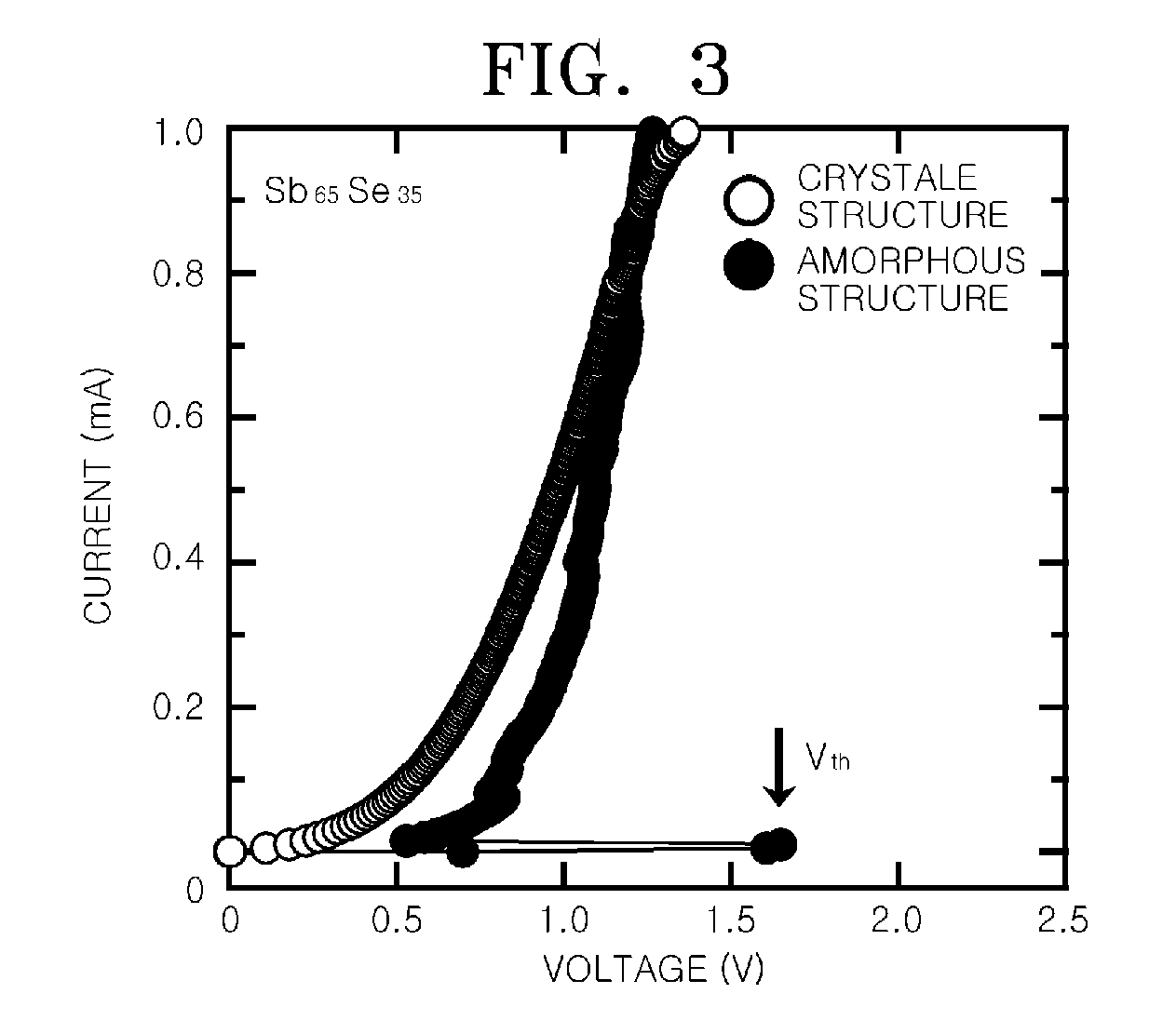

Phase-change memory device using Sb-Se metal alloy and method of fabricating the same

ActiveUS7547913B2Improve crystallization speedLow melting pointSemiconductor/solid-state device manufacturingSemiconductor devicesPhase-change memoryMetal alloy

Provided are a phase-change memory device using a phase-change material having a low melting point and a high crystallization speed, and a method of fabricating the same. The phase-change memory device includes an antimony (Sb)-selenium (Se) chalcogenide SbxSe100-x phase-change material layer contacting a heat-generating electrode layer exposed through a pore and filling the pore. Due to the use of SbxSe100-x in the phase-change material layer, a higher-speed, lower-power consumption phase-change memory device than a GST memory device can be manufactured.

Owner:ELECTRONICS & TELECOMM RES INST

Information recording medium and manufacturing method thereof

InactiveUS20060141202A1Reduce the amplitudeIncrease temperatureLayered productsSolid-state devicesAmorphous phaseOptoelectronics

An information recording medium, comprising: a recording layer which can phase-change reversibly between a crystal phase and an amorphous phase by using an optical means or an electric means, wherein the recording layer comprises at least Ge, Te, M1 (which is at least one element selected from the group consisting of Sc, Y, La, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, Yb and Lu), M2 (which is at least one element selected from the group consisting of Sb and Bi) and M3 (which is at least one element selected from the group consisting of Te and Bi).

Owner:PANASONIC CORP

Aliphatic-aromatic copolyester and preparation method thereof

The invention relates to a completely biodegradable and highly molecular-weight nanoparticle-containing aliphatic-aromatic copolyester and a preparation method thereof. The aliphatic-aromatic copolyester is prepared from the following poly-monomers: (A) alphatic binary acid or one or more of compounds of ester, acid anhydride and acyl halide; (B) aromatic binary acid, cyclo-alkane binary acid or one or more of ester, acid anhydride and acyl halide compounds; (C) dihydric alcohol, alkamine, aminothiol or one or more of derivatives with epoxy group and azacyclo; and (D) nanoparticles subjected to coupling agent surface treatment. The aliphatic-aromatic copolyester has excellent melt strength and tear-resistant anti-impact properties, the heat-resistant property and the aging-resistant property can be improved. Through addition of nanoparticles, the mechanical performance can be enhanced, the crystallization speed and crystallinity are quickened, and the heat-resistant property and the aging-resistant property are improved.

Owner:李宗华

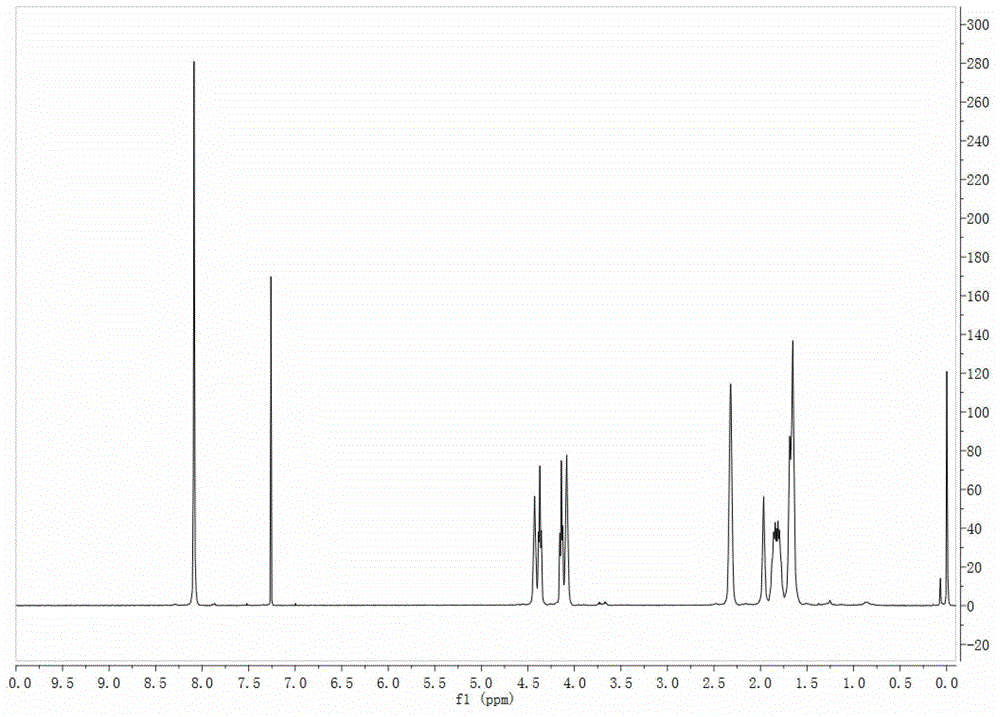

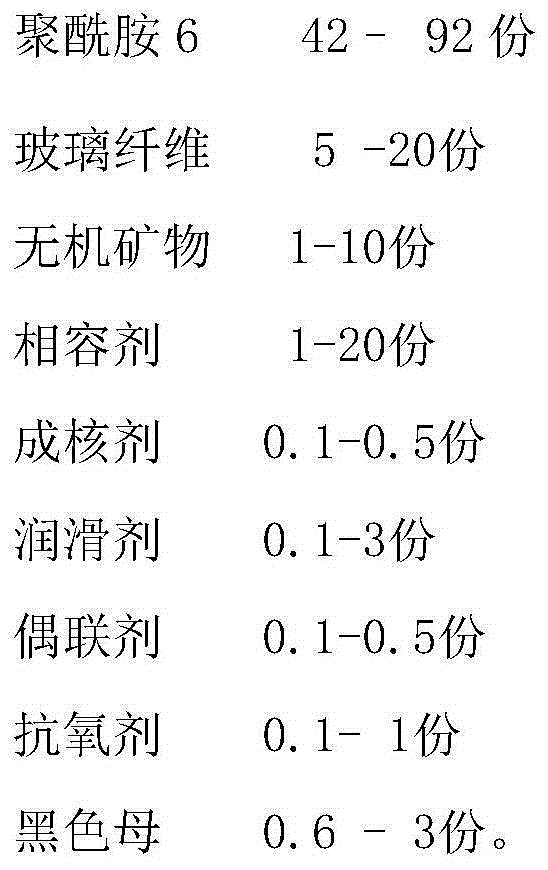

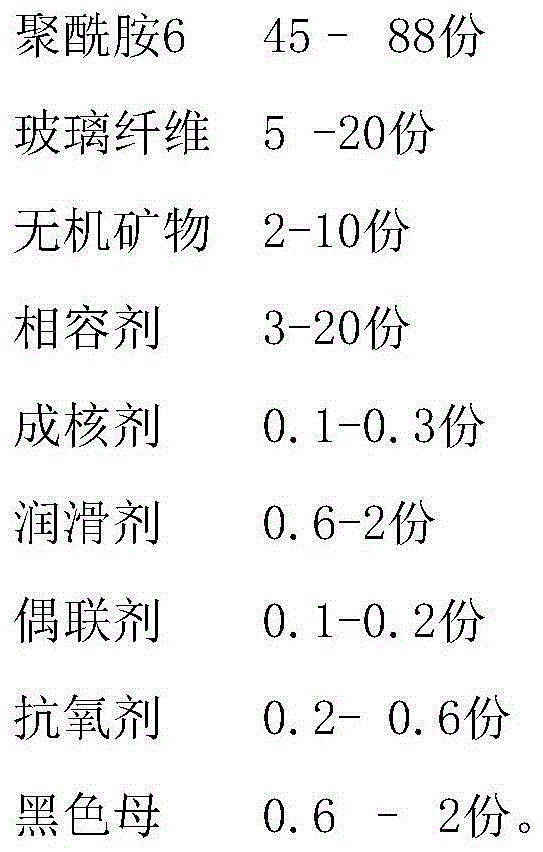

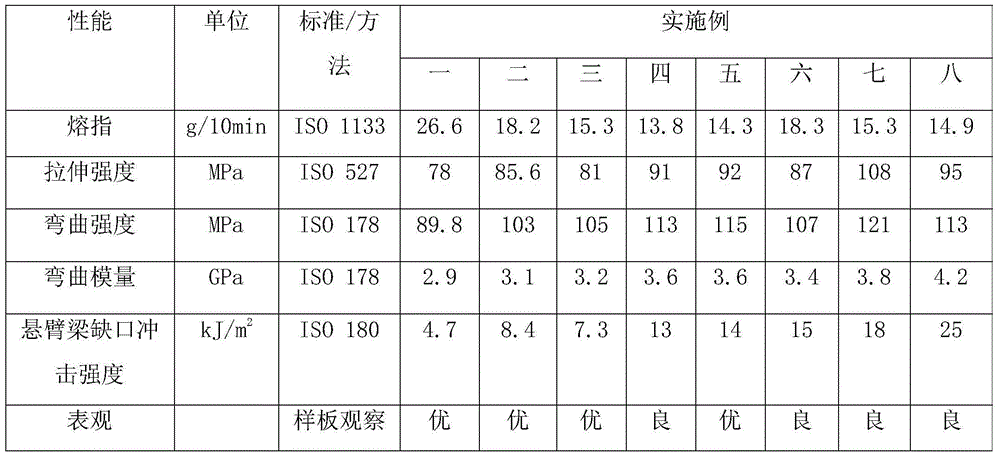

Polyamide 6 composite and preparation method thereof

The invention relates to a composite and a preparation method thereof, in particular to a polyamide 6 composite and a preparation method thereof. Non-alkali chopped fibers are selected to serve as a reinforcing agent of the pyamide 6 composite, and compatilizer is added to improve fatigue durability and low-temperature brittleness of glass fiber reinforcing materials. Coupling reagents, lubricating agents and inorganic minerals are added to improve the combination of the polyamide 6 composite and the glass fibers, and dispersion of the glass fibers in the polyamide 6 composite is enhanced, so that the glass fibers are not prone to being exposed outside the surface, and a good surface is achieved. The polyamide 6 composite and the eparation method thereof have the advantages that the polyamide 6 composite can be used for injection molding of automobile doors and window frame decoration strips.

Owner:NANJING JULONG SCI&TECH CO LTD

Intumescent flame retardant polybutylene succinate and preparation method thereof

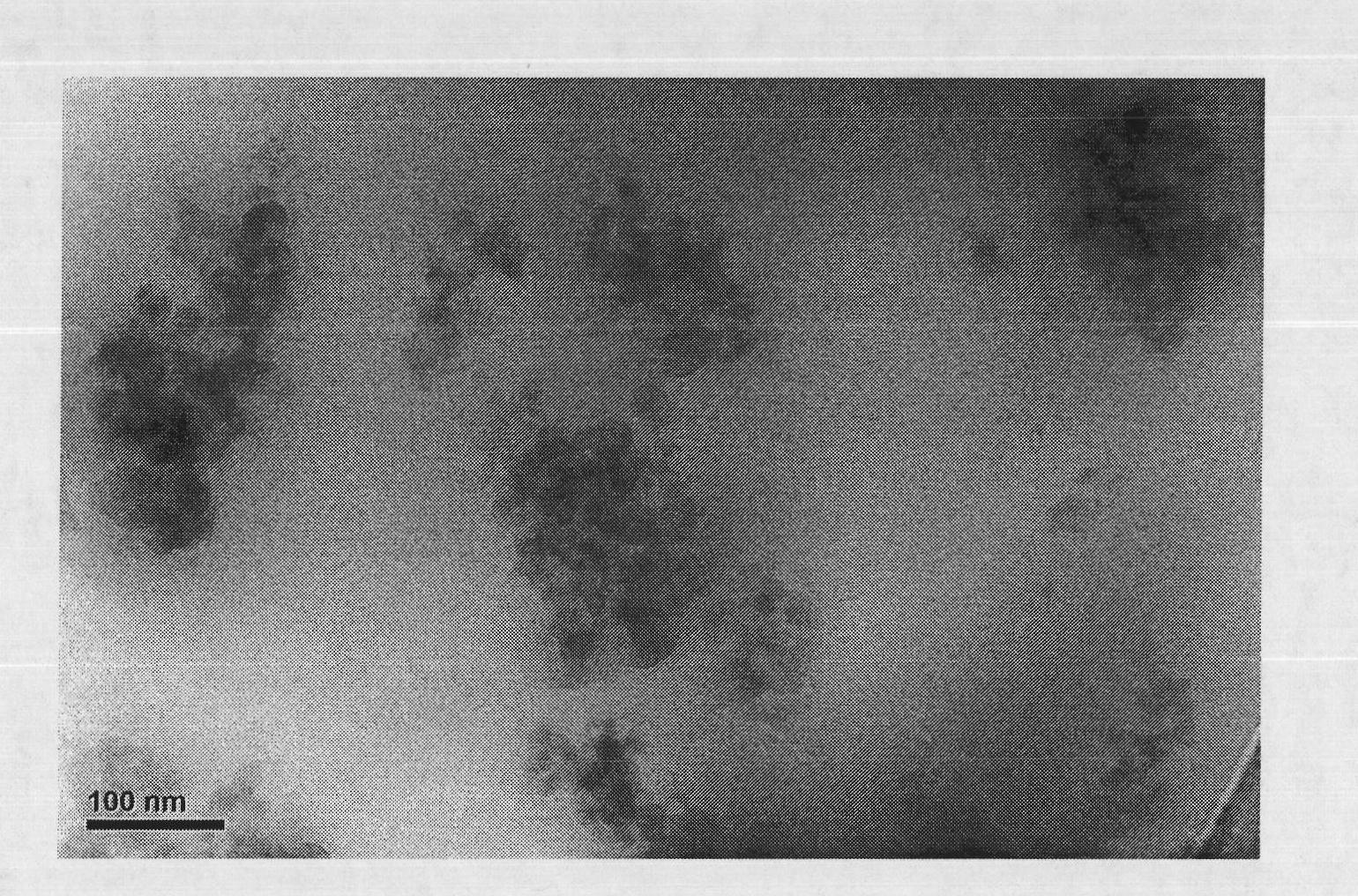

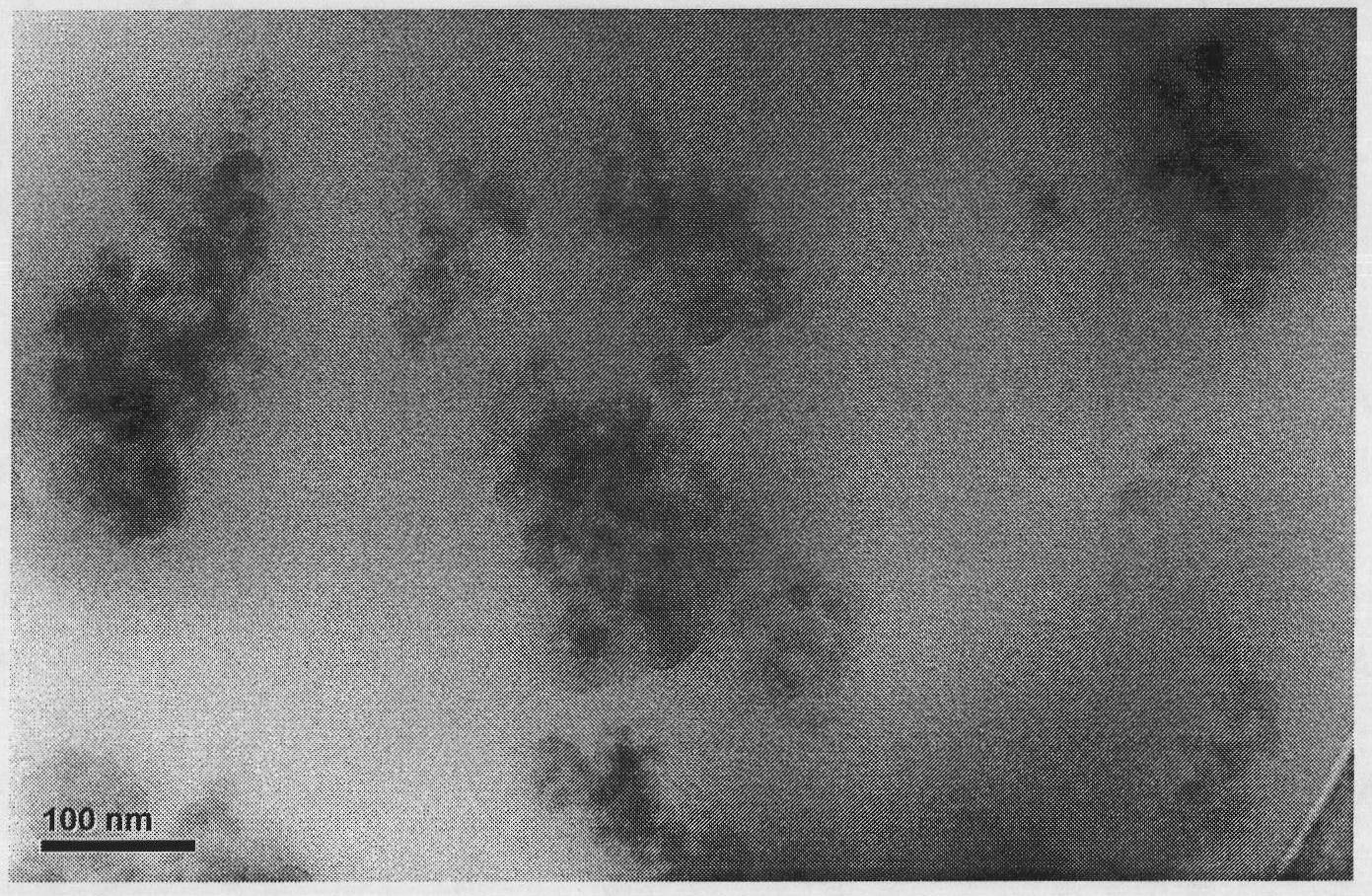

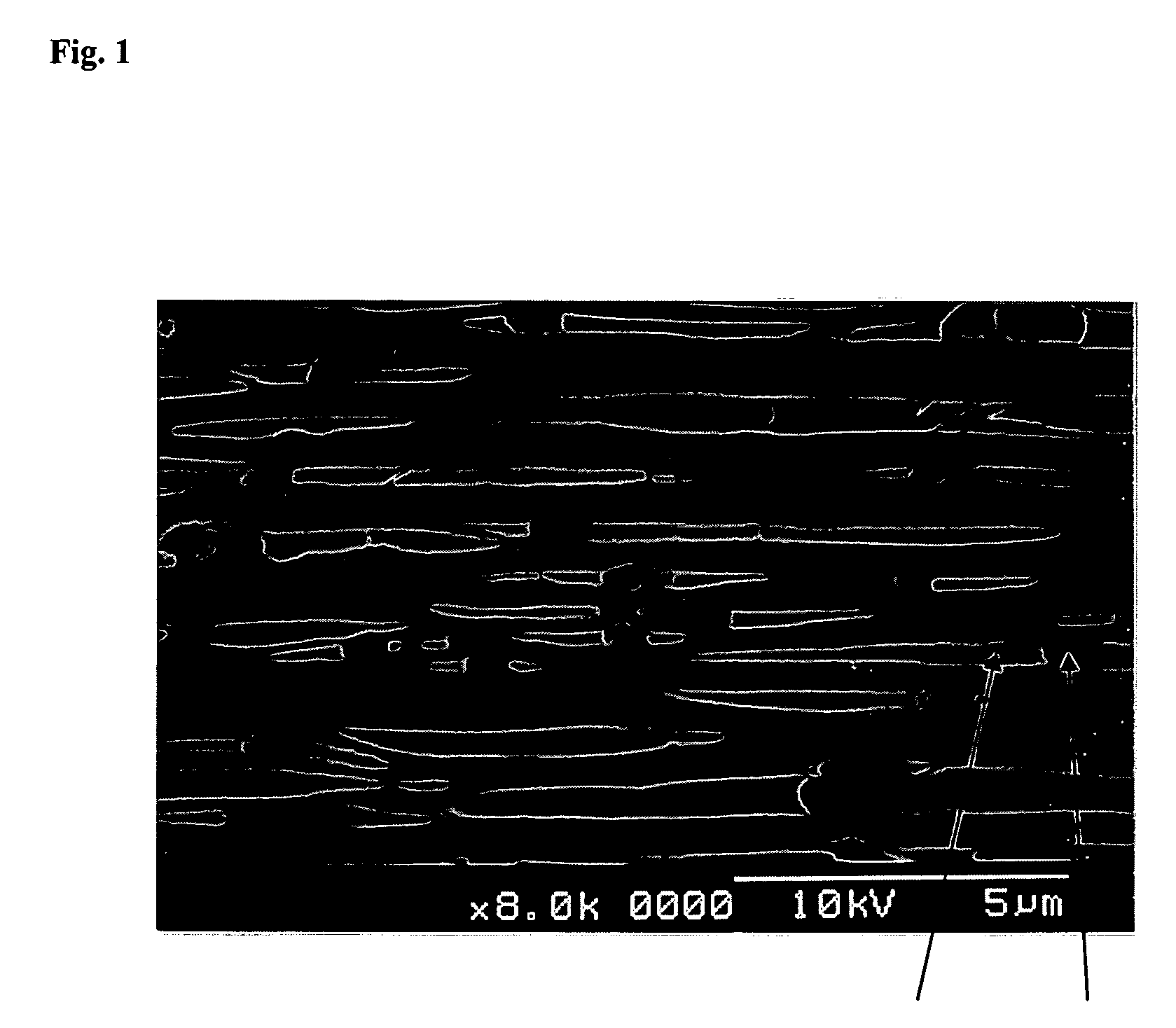

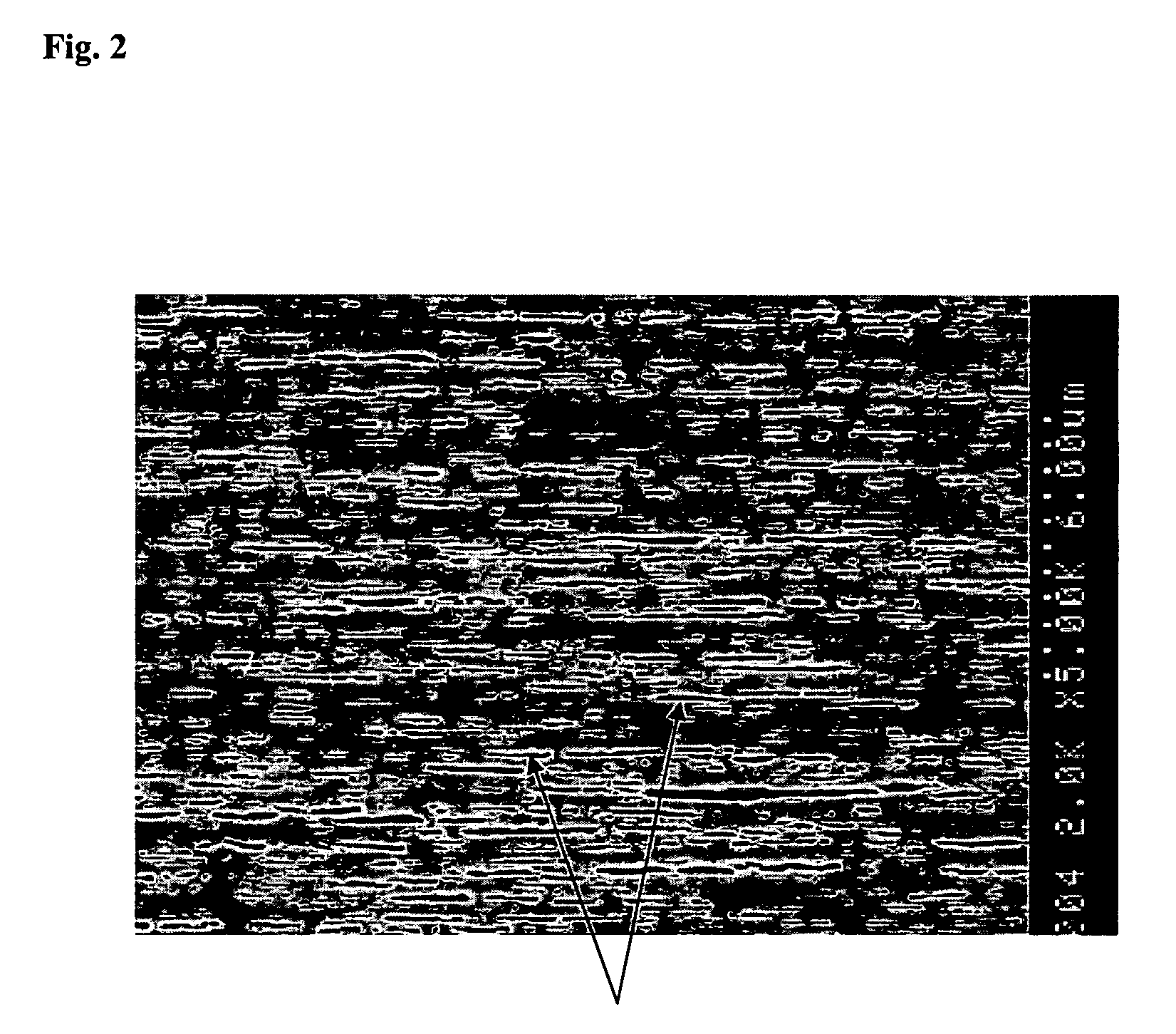

ActiveCN101781445AFast crystallizationImprove the perfection of crystal formChemistryTransmission electron microscopy

The invention discloses intumescent flame retardant polybutylene succinate and a preparation method thereof, which are characterized in that 80 to 85 percent of polybutylene succinate and 15 to 20 percent of intumescent flame retardant agent as well as 0 to 3 percent of synergist are added to an internal mixer to be cut, melt down and blended to obtain the product. Pictures of a high-resolution transmission electron microscope show that nano-grade dispersion is formed in the Polybutylene succinate basal body; the oxygen index reaches 40 and passes through the vertical burning test standard UL-94V0 grade; the initial thermal decomposition temperature is 321 DEG C, the maximum thermal decomposition temperature is 353 DEG C, and the residual quality score is 11.6 percent at the temperature of 700 DEG C; the pictures of the carbon layer shows that a compact intumescent carbon layer is formed, and a plurality of complete bubbles are formed. The intumescent flame retardant polybutylene succinate can be used for the foaming materials and the packing materials of the toy, household appliance, daily chemicals, food and medicines.

Owner:UNIV OF SCI & TECH OF CHINA

Water base dispersion of polyurethane resin, and water base adhesive and water base primer coating agent containing the same

InactiveUS20060148970A1Great easeMelted satisfactorilyPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsWater basedAdhesive

A polyurethane resin aqueous dispersion comprising: dispersion particles incorporating a self-emulsifying polyurethane resin (A) with an anionic group, and a hydrophobic resin (B) with a flow start temperature (X) of no more than 60° C. and a crystallization temperature (Y) within a range from 0 to 50° C.; and an aqueous medium.

Owner:DAINIPPON INK & CHEM INC

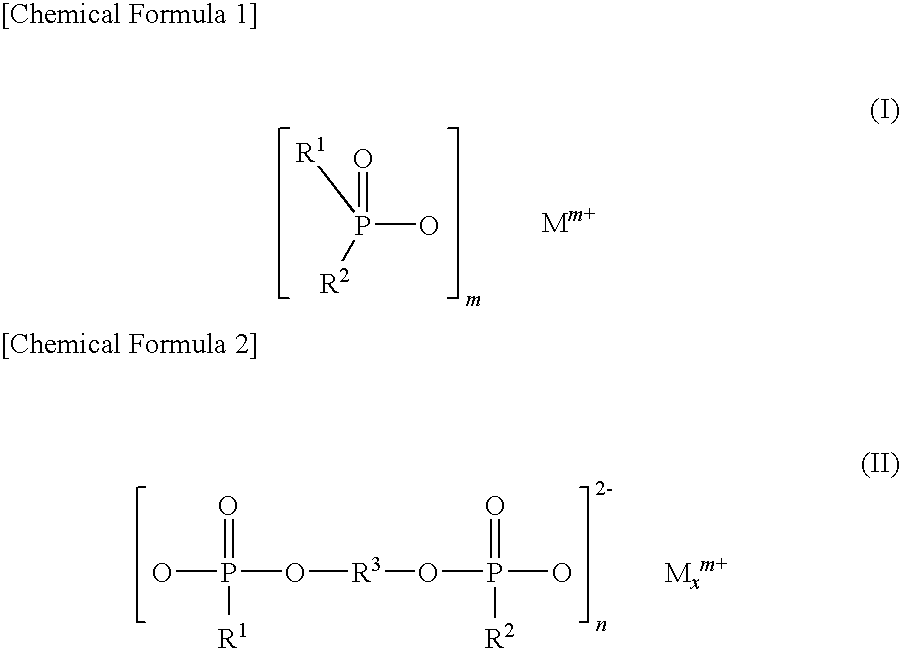

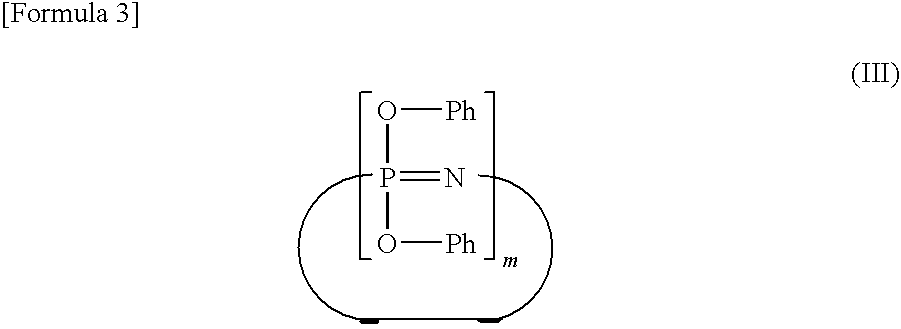

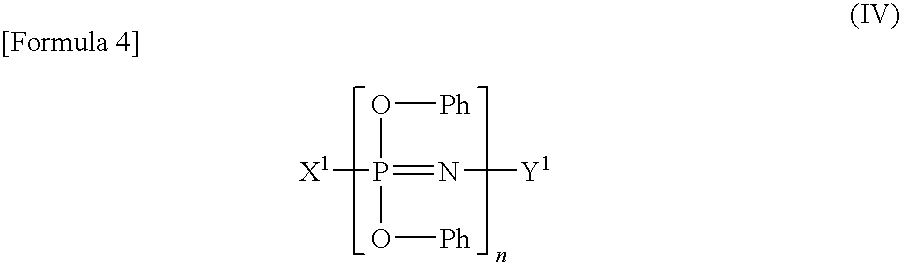

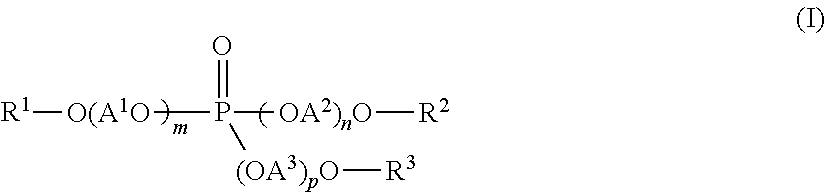

Process for production of polylactic acid resin composition

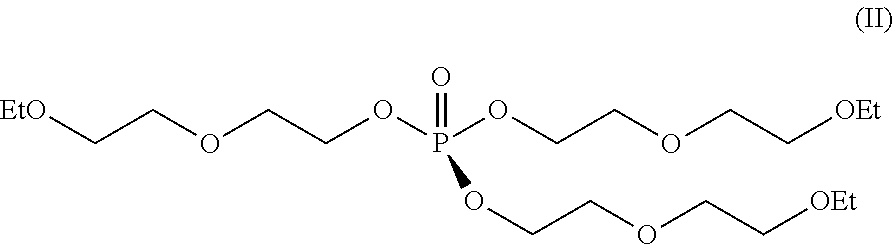

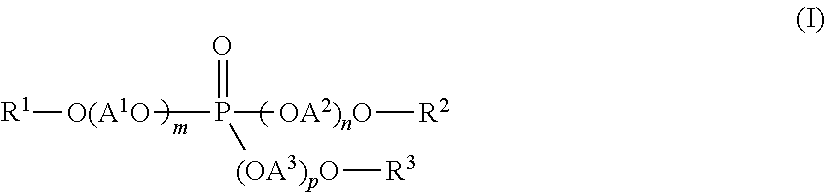

ActiveUS20120296017A1Improve crystallization speedImprove compatibilityGroup 5/15 element organic compoundsPhosphoric Acid EstersViscosity

A method for producing a polylactic acid resin composition, including the following steps (1) and (2): step (1): subjecting an organic crystal nucleating agent to a wet pulverization in the presence of a carboxylic acid ester having a weight-average molecular weight of from 150 to 600 and a viscosity at 23° C. of from 1 to 500 mP·s and / or a phosphoric ester having a weight-average molecular weight of from 150 to 600 and a viscosity at 23° C. of from 1 to 500 mPa·s to give a finely pulverized organic crystal nucleating agent composition; and step (2): melt-kneading a raw material for a polylactic acid resin composition comprising the finely pulverized organic crystal nucleating agent composition obtained in the step (1) and a polylactic acid resin. The polylactic acid resin composition obtainable by the method of the present invention can be suitably used in various industrial applications, such as daily sundries, household electric appliance parts, packaging materials for household electric appliance parts, and automobile parts.

Owner:KAO CORP

Polyamide resin

A polyamide resin composed of constitutional units derived from a diamine component 70 mol % or more of which is derived from p-xylylenediamine and constitutional unit derived from a dicarboxylic acid 70 mol % or more of which is derived from an aliphatic dicarboxylic acid having 6 to 18 carbon atoms. The polyamide resin has a number average molecular weight (Mn) of 10,000 to 50,000 and a degree of dispersion (weight average molecular weight / number average molecular weight=Mw / Mn) satisfying the following formula (1):1.5≦(Mw / Mn)≦6.0,wherein Mw and Mn are determined by gel permeation chromatography (GPC).

Owner:MITSUBISHI GAS CHEM CO INC

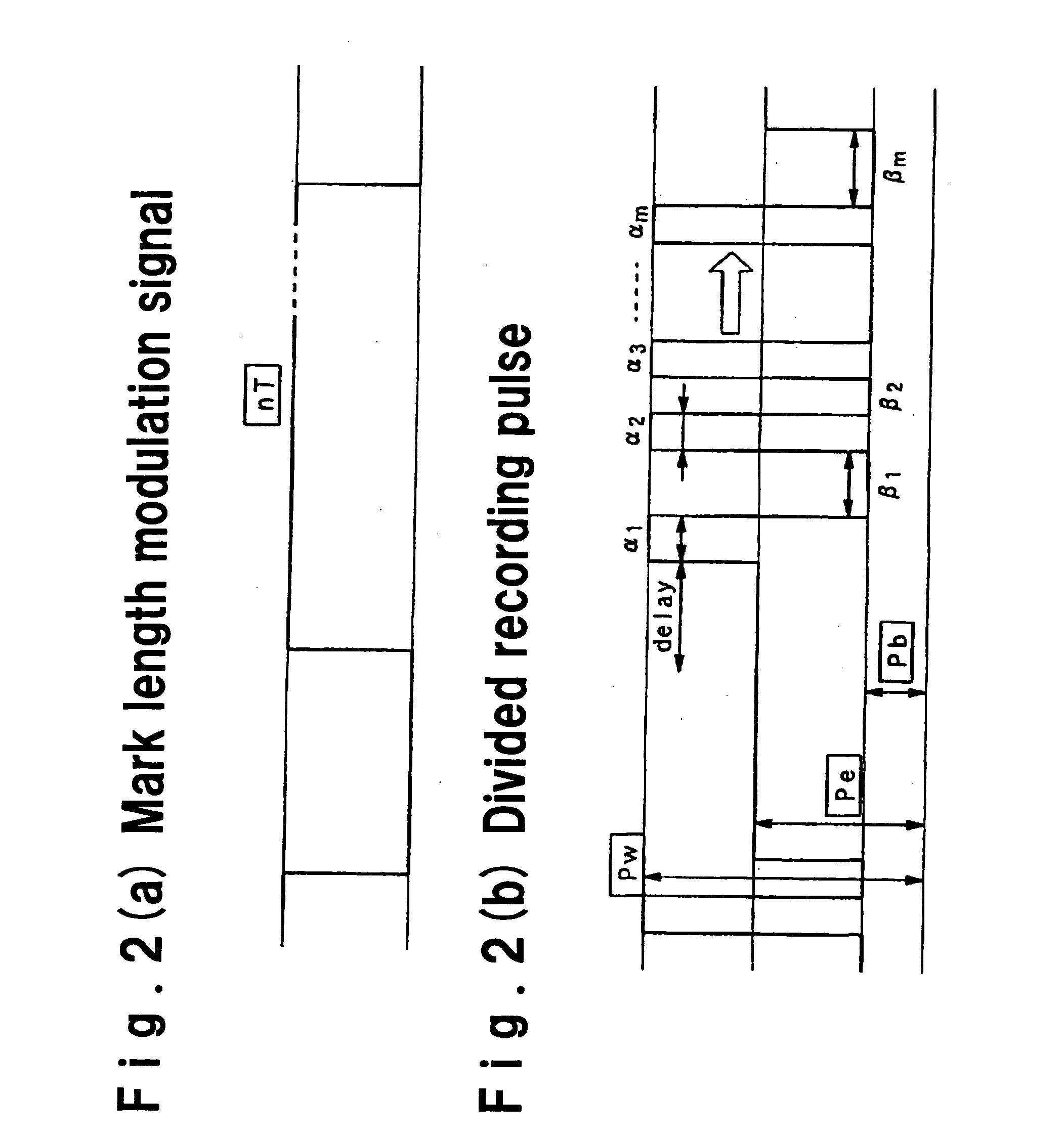

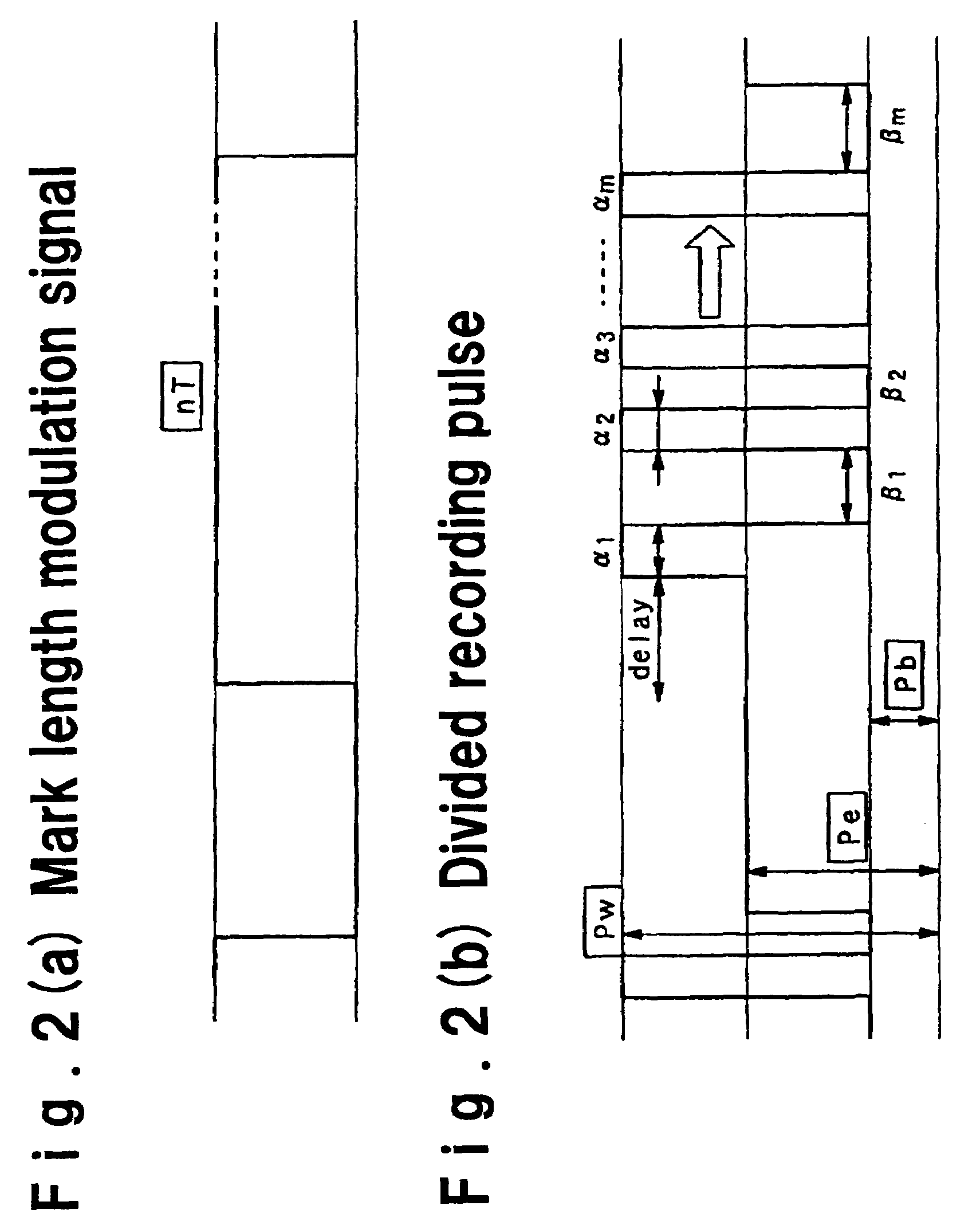

Phase-change recording material and information recording medium

ActiveUS20050175822A1Excellent signal characteristicGood storage stabilityElectrical apparatusLayered productsPhase changeHigh velocity

A phase-change recording material on which high velocity recording / erasing is possible, which provides excellent recording signal characteristics, which provides a high storage stability of the recording signals, with which the change in the reflectivity of the recorded signals is small even after a long term storage, and which provides excellent recording signal characteristics even if overwriting is carried out again, and an information recording medium employing the above material, are provided. It is characterized by containing as the main component a composition represented by Gex(InwSn1-w)yTezSb1-x-y-z (wherein the Sb content is higher than any one of the Ge content, the In content, the Sn content and the Te content, and x, y, z and w representing atomicity ratios satisfy (i) 0≦x≦0.3, (ii) 0.07≦y-z, (iii) wxy-z≦0.1, (iv) 0<z, (v) (1−w)xy≦0.35 and (vi) 0.35≦1-x-y-z).

Owner:CMC MAGNETICS CORPORATION

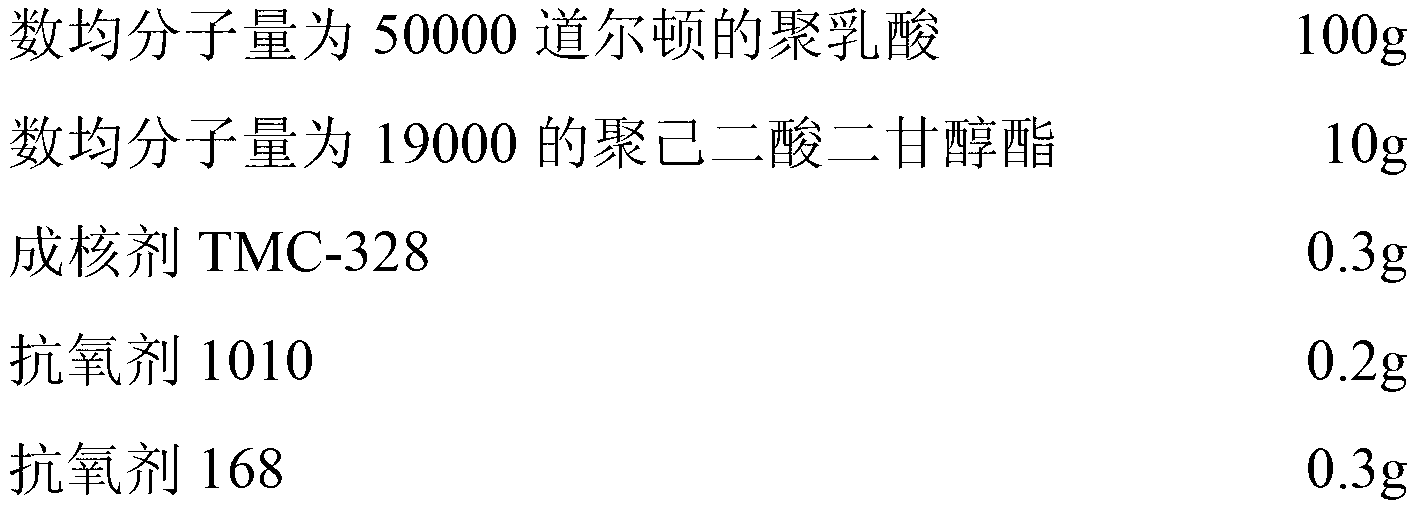

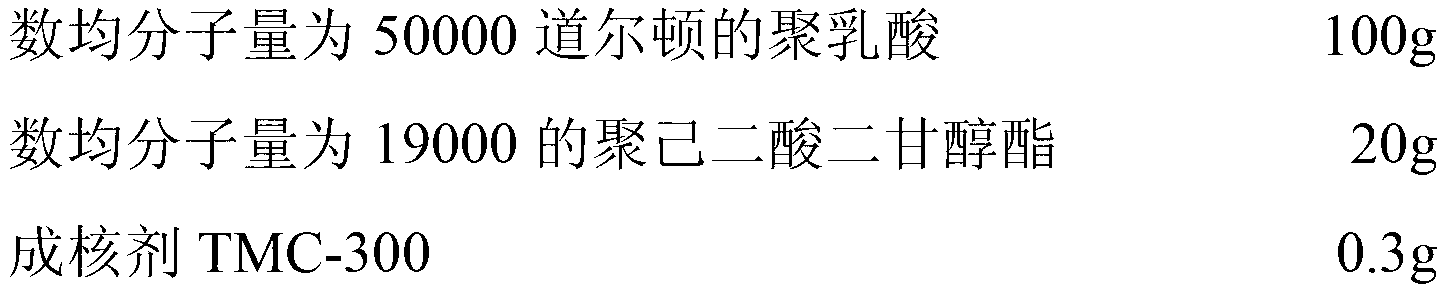

Completely-biodegradable plasticizing polylactic resin and method for preparing same

InactiveCN103160087AGood flexibilityImprove impact resistanceUltimate tensile strengthPolymer chemistry

The invention provides a completely-biodegradable plasticizing polylactic resin and a method for preparing the polylactic resin and belongs to the field of modification of polymer materials. The polylactic resin is prepared from polylactic acid, a plasticizing modifying agent, a nucleating agent and an oxidation resisting agent at the mass ratio of 100:(10-40):(0.3-1):(0.3-1). The melt flow rate of the polylactic resin provided by the invention can be controlled at 5-30g / 10min, the tensile elongation at break is 480%, the impact strength is 30.0KJ / m<2>, the purposes of plasticizing and toughening the polylactic acid are achieved, the resin has good transparency and complete biodegradability and the application space of the polylactic acid is extended.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

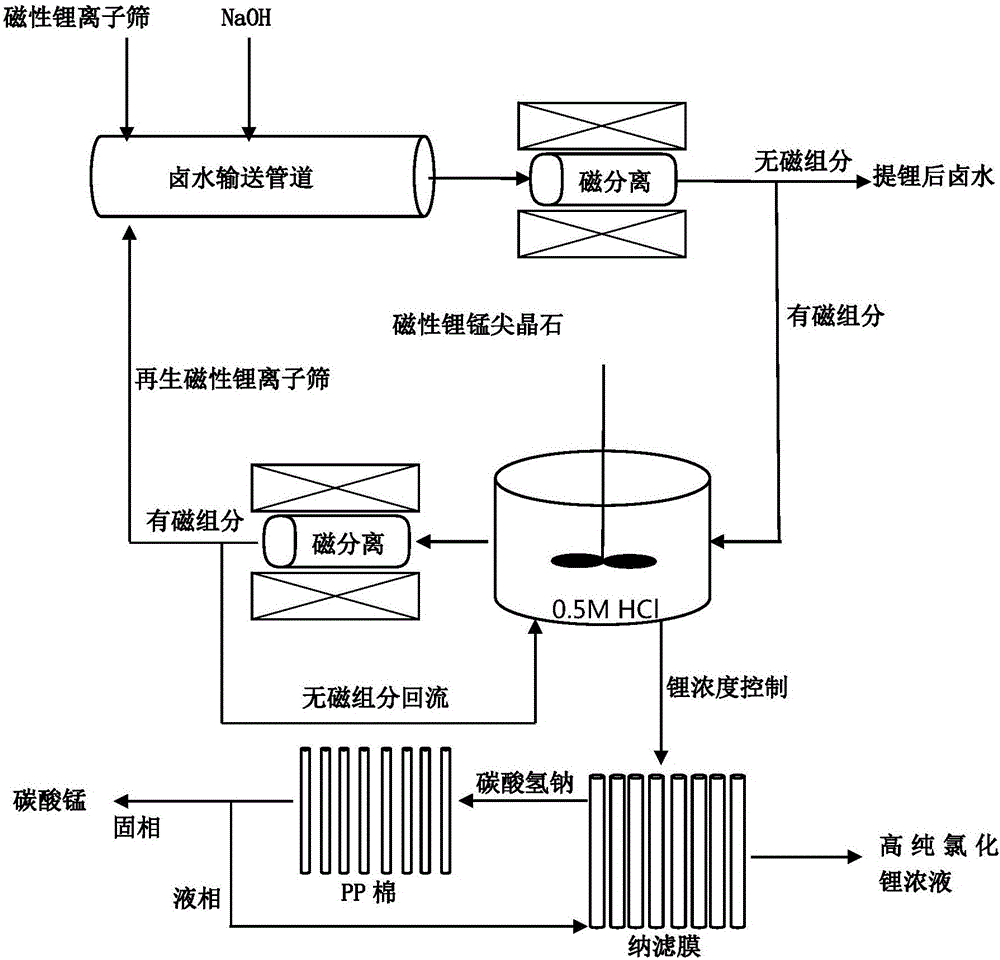

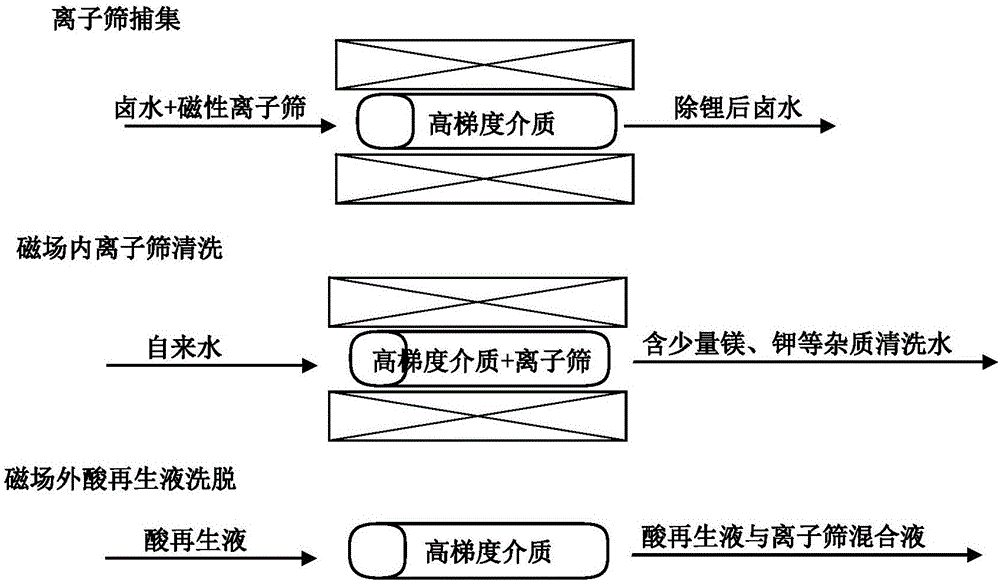

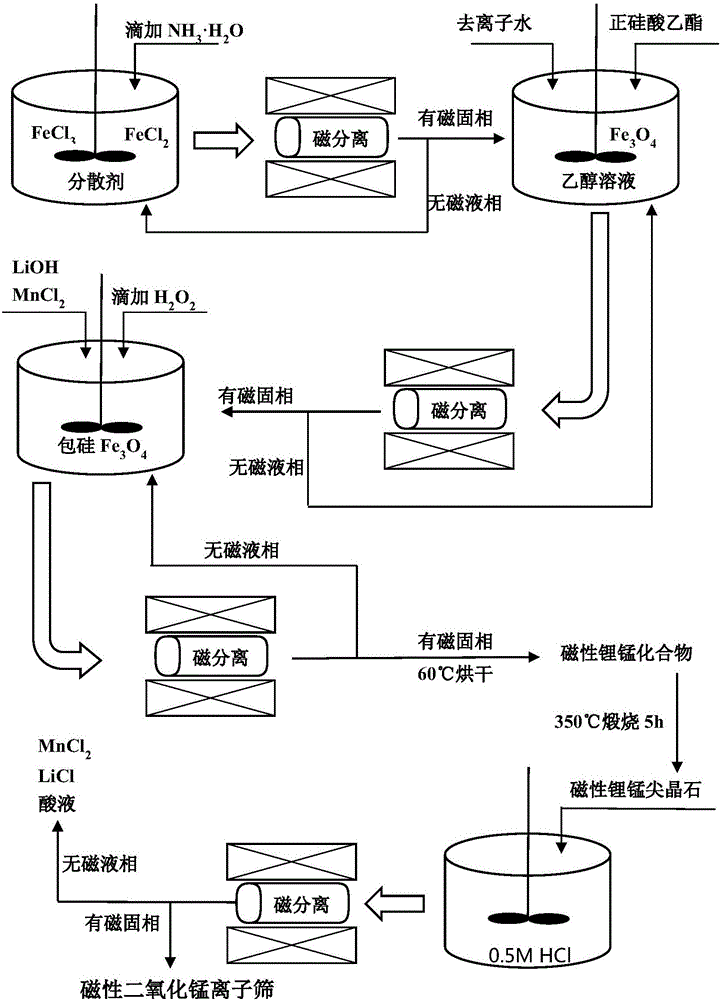

Method for extracting lithium from bittern and preparing high-purity lithium concentrate

ActiveCN106345394AEfficient separationEasy to separateOther chemical processesIron compoundsSodium bicarbonateDesorption

The invention discloses a method for extracting lithium from bittern and preparing a high-purity lithium concentrate. The method is characterized by comprising the following steps: adding a 0.5-20kg / t magnetic lithium ion sieve into a bittern conveying pipeline, and adjusting the pH value to be higher than or equal to 5.0; separating the magnetic lithium ion sieve from the bittern by a magnetic separation system; feeding the magnetic lithium ion sieve into a desorption activation link; performing magnetic separation of the ion sieve and the desorption liquid again; feeding the magnetic lithium ion sieve into the raw bittern, and extracting lithium again; circulating the desorption liquid repeatedly until the lithium concentration is higher than or equal to 3g / l, and enabling the desorption liquid to pass through a nanofiltration membrane, wherein the filtered part of the nanofiltration membrane is the high-purity concentrate with purity of higher than or equal to 99%, and a lithium carbonate product is directly prepared; repeatedly circulating the intercepted part of the nanofiltration membrane by a nanofiltration link until the manganese-lithium ratio is greater than 2:1; adding sodium bicarbonate to prepare a manganese carbonate product; separating with PP cotton; and returning the lithium liquid to feed water to the nanofiltration membrane. In the invention, high-purity lithium concentrate can be prepared by use of the magnetic lithium ion sieve and by combining the magnetic separation and membrane separation technology; and in the process, the lithium concentration links such as solarization and reverse osmosis are not needed.

Owner:衢州永正锂业科技有限公司

Modified nano silica reinforcing and toughening polylactic acid composite material and preparation method thereof

The invention provides a modified nano silica reinforcing and toughening polylactic acid composite material and a preparation method thereof. The modified nano silica reinforcing and toughening polylactic acid composite material is prepared by mixing and extruding the following raw materials: 70-90 parts of polylactic acid, 10-30 parts of poly propylene carbonate 1,4-butylene terephthalate, 0.3-0.9 parts of polystyrene-grafted nano silica, and 0.1-0.5 parts of an anti-oxidant. According to the invention, polystyrene-grafted nano silica, PLA and PBC are subjected to melt blending in an extruder to prepare the reinforcing and toughening polylactic acid composite material, strength and toughness of the composite material can be increased, and crystallization performance of PLA and PBC can be greatly increased.

Owner:HEFEI GENIUS NEW MATERIALS

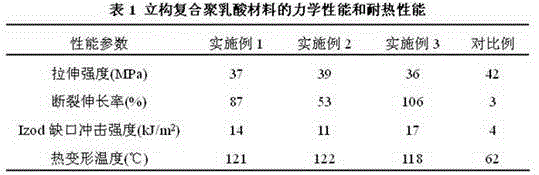

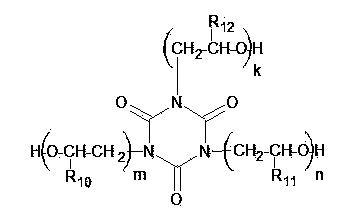

Composite polylactic acid material for 3D printing and preparation method thereof

ActiveCN106046726AImprove crystallization speedImprove heat resistanceAdditive manufacturing apparatusPolymer scienceUracil

The invention relates to a composite polylactic acid material for 3D printing. The high-toughness high-heat-resistance steric composite polylactic acid material suitable for 3D printing is prepared by melt blending of , by weight, 58-85% of PLLA and PDLA mixture, 0.2-2% of uracil derivative nucleating agent, 5-10% of polyethylene glycol and 10-30% of hydroxyalkanoate copolymer. The material can effectively increase crystallization speed and improve heat resistance of the polylactic acid steric composite, meets the requirement of 3D printing forming, remarkably improves impact strength of steric composite polylactic acid, remarkably increases breaking elongation and effectively solves the problem that 3D printing polylactic acid products are hard and fragile.

Owner:山西阳宸中北科技有限公司

Phase-change recording material and information recording medium

ActiveUS7105217B2Good signalGood storage stabilityElectrical apparatusLayered productsEngineeringComputer science

A phase-change recording material on which high velocity recording / erasing is possible, which provides excellent recording signal characteristics, which provides a high storage stability of the recording signals, with which the change in the reflectivity of the recorded signals is small even after a long term storage, and which provides excellent recording signal characteristics even if overwriting is carried out again, and an information recording medium employing the above material, are provided.It is characterized by containing as the main component a composition represented by Gex(InwSn1-w)yTezSb1-x-y-z (wherein the Sb content is higher than any one of the Ge content, the In content, the Sn content and the Te content, and x, y, z and w representing atomicity ratios satisfy (i) 0≦x≦0.3, (ii) 0.07≦y-z, (iii) wxy-z≦0.1, (iv) 0<z, (v) (1−w)xy≦0.35 and (vi) 0.35≦1-x-y-z).

Owner:CMC MAGNETICS CORPORATION

Method for accelerating crystallization of polylactic acid resin

ActiveCN103396659AImprove crystallization propertiesIncreased crystallinity and crystallization speedPolyvinylidene fluoridePolylactic acid

The invention relates to the technical field of polylactic acid modification and aims to provide a method for accelerating crystallization of polylactic acid resin. The method comprises the specific steps of: adding a semi-crystalline polylactic acid resin and a polymer-type crystallization promoter into a mixing apparatus; then mixing well in the mixing apparatus; and extruding for granulation, so as to obtain a rapid crystallization modification polylactic acid resin. The method employs organic high-molecular polymer-type crystallization promoter to improve crystallization performance of the polylactic acid, and the promoter has good compatibility with polylactic acid, improves nucleation effect, accelerates crystallization of polylactic acid, and improves processability and thermal behavior of the polylactic acid. Furthermore, a commercialized semi-crystalline polymer polyvinylidene fluoride having similar melting point as polylactic acid is used as the crystallization promoter for polylactic acid, and a melt blending method can be employed. The method provided by the invention has simple process, low cost and can realize large-scale industrialized production.

Owner:ZHEJIANG UNIV

Transparent crystalline electrically-conductive thin film, method of production thereof, transparent electrically-conductive film, and touch panel

ActiveUS20090117405A1Improve crystallization speedLower performance requirementsConductive materialVacuum evaporation coatingHigh resistanceIndium

A transparent crystalline electrically-conductive thin film of the present invention comprises an indium tin oxide as a main component, wherein the indium tin oxide contains 9% by weight or less of tin oxide based on the total amount of indium oxide and tin oxide, wherein the transparent crystalline electrically-conductive thin film contains 0.45 atomic % or less of nitrogen. The transparent crystalline electrically-conductive thin film of the present invention has a high resistance value and good reliability in a high-temperature, high-humidity environment.

Owner:NITTO DENKO CORP

High-temperature-resistant tough degradable temporary plugging agent and preparation method thereof

PendingCN111690391AMaintain molecular weightReduce thermal degradationDrilling compositionElastomerPolyester

The invention relates to a high-temperature-resistant tough degradable temporary plugging agent and a preparation method thereof. The temporary plugging agent is prepared from the following componentsand raw materials in parts by weight: 80 to 90 parts of polyglycolic acid, 10 to 20 parts of polyester elastomer, 1 to 5 parts of plasticizer, 2 to 8 parts of compatilizer, 0.5 to 3 parts of antioxidant, 0.5 to 3 parts of nucleating agent, 0.2 to 1 part of crystallization promoter, 0.4 to 2 parts of hydrolysis regulator, 5 to 15 parts of lubricant and 0.5 to 2 parts of heat stabilizer. The temporary plugging agent has good high-temperature resistance and toughness, can still keep enough mechanical strength under the high-temperature condition, can be automatically degraded and easily removedafter being used, does not influence an underground reservoir, can effectively improve the construction efficiency of underground temporary plugging steering fracturing, and reduces the construction cost.

Owner:北京金圣奥能源技术有限公司

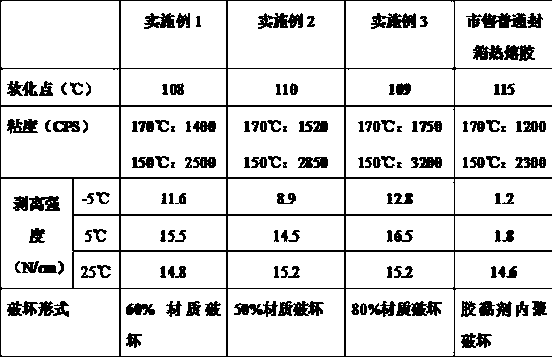

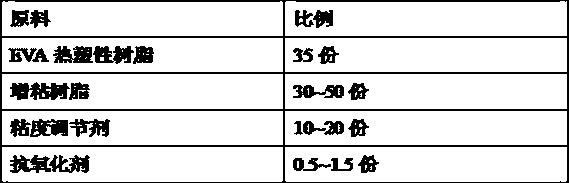

Hot melt adhesive for packaging

InactiveCN108395854AGood compatibilityImprove low temperature bonding performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesHigh surfacePackaging industry

The invention discloses a hot melt adhesive for packaging, and belongs to the field of adhesives. The hot melt adhesive is prepared at least from the following raw materials in parts by mass: 35 partsof ethylene-vinyl acetate (EVA) resin, 30-50 parts of tackifying resin, 10-20 parts of a viscosity regulator and 0.5-1.5 parts of an antioxidant. The hot melt adhesive provided by the invention has the advantages of environmental friendliness, no toxicity, no heavy metals, fast curing speed, excellent low-temperature resistance, high bonding strength to a carton with high surface paper strength (the wax picking degree of the carton surface paper reaches 20A or above), and the like. The hot melt adhesive solves the problems that cartons are open on a production line and in a warehouse when a conventional EVA hot melt adhesive is applied to the binding of cartons with high surface paper strength, and thus can be widely applied in the automatic packaging industry for food, beverages, beer and other industries.

Owner:朱俊帆

Low-warpage heat-resistant nylon composition and preparation method thereof

The invention discloses a low-warpage heat-resistant nylon composition and a preparation method thereof. The low-warpage heat-resistant nylon composition is prepared by the following steps: stirring 40-68 parts of nylon, 5-10 parts of poly-1,4-cyclohexane dimethylene terephthalate, 20-45 parts of glass fibers, 0-5 parts of a flexibilizer, 0.4-1.5 parts of a heat-resistant additive and 0.5-2 parts of processing aids in high-speed mixer for 3-5 minutes, performing melt extrusion on the mixture by virtue of a twin-screw extruder, and granulating to obtain the product. The low-warpage heat-resistant nylon composition disclosed by the invention has the balanced mechanical property and low warping property after high-temperature heat treatment, and the application range of the nylon material is widened.

Owner:HEFEI GENIUS NEW MATERIALS

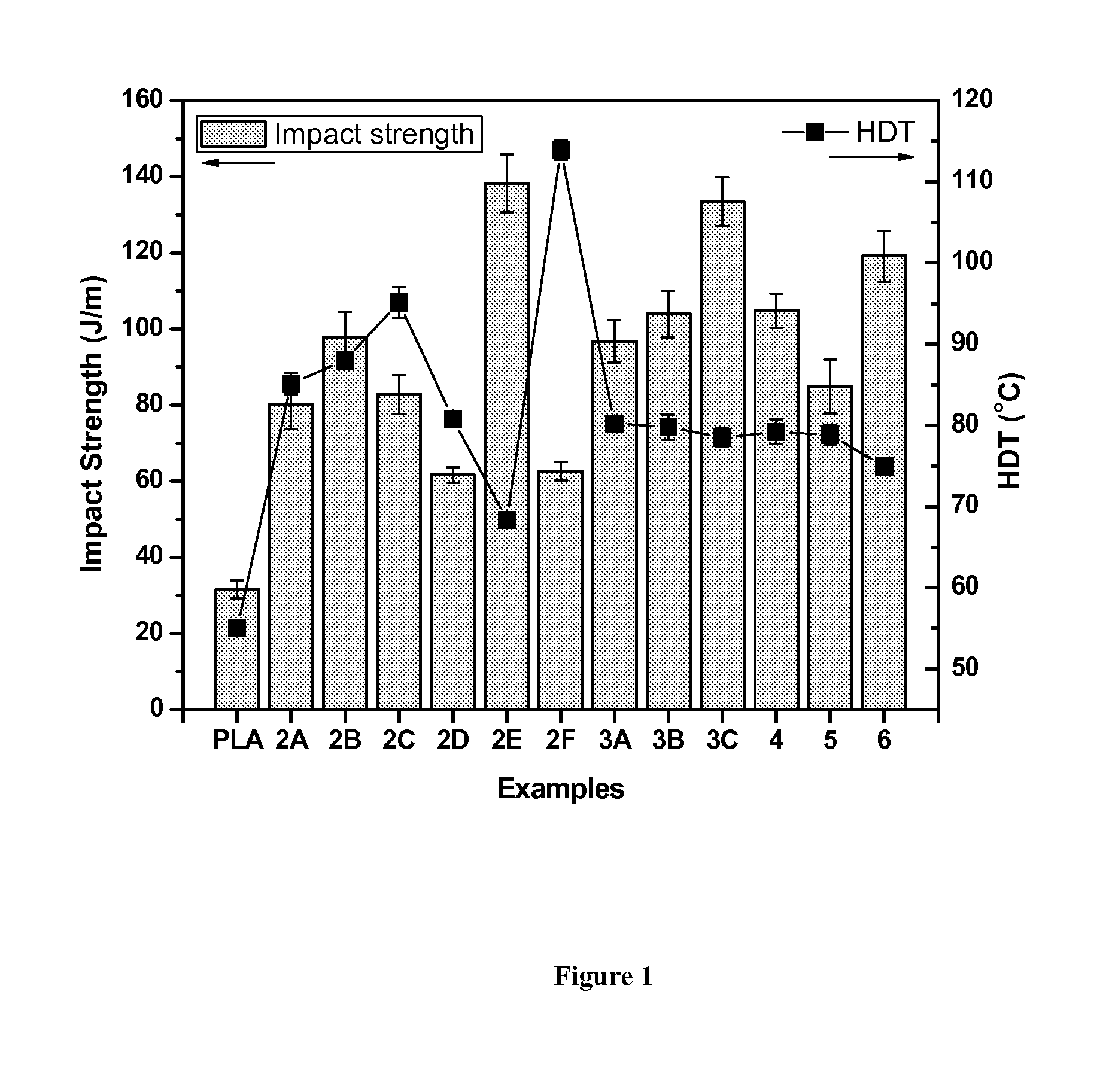

Poly (lactic acid)-based biocomposite materials having improved toughness and heat distortion temperature and methods of making and using thereof

InactiveUS20150361258A1Improve toughnessHigh impact strengthWood treatment detailsHeat deflection temperaturePolyolefin

Super tough poly (lactic acid) (PLA)-based blends showing non break impact behavior have been developed. The blend contains a PLA resin, (b) a thermoplastic elastomeric block copolymer, and (c) a functionalized polyolefin copolymer. The blend is used as matrix to incorporate one or more additives, such as fillers (e.g., natural fibers and / or mineral fillers), nucleating agents, and / or chain extenders to form composites. In some embodiments, the blend is the continuous phase and the one or more additives are the dispersed phase. The composites exhibit improved impact strength and heat distortion temperature compared to neat or virgin PLA. For example, in some embodiments, the impact strength of the composite is from about 60 J / m to about 140 J / m and / or the HDT of the composite ranges from about 60 to about 115° C.

Owner:UNIVERSITY OF GUELPH

Optical recording medium

InactiveUS20040053166A1Improve thermal stabilityReliably crystallizedPhotomechanical apparatusOptical overwritingSoft x rayX-ray

Owner:TDK CORPARATION

Polyester elastomer for blow molding and preparation method thereof

The invention discloses a polyester elastomer for blow molding and preparation method thereof, and the polyester elastomer comprises the following components by weight percent: 88.0-96.9% of thermoplastic polyester elastomer, 3.0-10.0% of polyester liquid crystal macromolecular compounds, and 0.1-2.0% of isocyanurate compounds. The preparation method comprises the following steps: obtaining thermoplastic polyester elastomers by esterification reaction or transesterification reaction and condensation polymerization; adding polyester liquid crystal macromolecular compound and isocyanurate compound for reaction; obtaining the product. According to the invention, thermoplastic polyester elastomers are added with polyester liquid crystal macromolecular compounds and isocyanurate compounds, and the melt index of the obtained polyester elastomer for blow molding is between 0.5-1.5, and the product has higher melt-strength with good appearance quality, easier processing process and excellent mechanical properties.

Owner:KINGFA SCI & TECH CO LTD +1

Biaxially oriented white polypropylene film for thermal transfer recording and receiving sheet for thermal transfer recording therefrom

InactiveUS20070154662A1High productivityExcellent processibilitySynthetic resin layered productsThermographyPolypropylenePolymer chemistry

A biaxially oriented white polypropylene film for thermal transfer recording including a film containing polypropylene resin having a β-crystal ratio of about 30% or more and a melting temperature of about 140 to about 172° C., and which has substantially non-nucleus voids, a void ratio of about 30 to about 80% and a sum of strengths of longitudinal direction and of transverse direction of the film at 2% elongation (F2 value) being in the range of about 10 to about 70 MPa and a surface glossiness being in the range of about 10 to about 145%.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com