Polyester elastomer for blow molding and preparation method thereof

A polyester elastomer and elastomer technology, applied in the field of polyester elastomers, can solve the problems of poor rheology and difficult processing, and achieve the effects of good appearance quality, easy processing, and changing the degree of softness and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

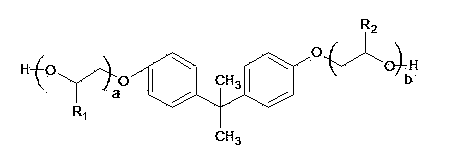

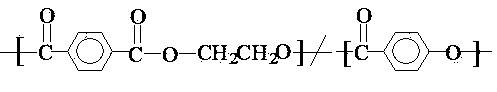

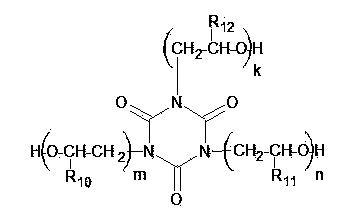

[0052] Add 30g DMT, 25g BDO and 25g PTMEG (Mn=1000), 0.25g polyether diol containing aromatic ring (where R1=R2=H, a=b=1), and add 20mg tetratitanate Butyl ester and 10mg antioxidant 1010, heat up at 170-180°C under normal pressure for transesterification reaction, remove by-product methanol, generate mixed glycol terephthalate and its oligomers, the amount of methanol to be left is When the theoretical amount is 95%, the transesterification reaction is ended; after the transesterification reaction product is pressed, it is transferred to a high vacuum (100-200Pa) stage for co-polycondensation reaction, and the temperature rises to 230-250°C, and the polycondensation is controlled by the stirring power value At the end of the reaction, nitrogen gas was filled, and the vacuum was eliminated to obtain polyester elastomer; the intrinsic viscosity of the polyester elastomer was 1.2 dL / g, and the obtained 50g polyester elastomer, 2g polyester liquid crystal macromolecular compound, ...

Embodiment 2

[0054] Add 50g DMT, 40g BDO and 56g PTMEG (Mn=1000), 2.5g polyether diol containing aromatic ring (wherein R1=H, R2=CH 3 , a=b=1) At the same time, add 50mg tetrabutyl titanate and 40mg antioxidant 1010, raise the temperature at 160-180°C to carry out transesterification reaction under normal pressure, remove the by-product methanol, and generate terephthalic acid mixed glycol Esters and their oligomers, when the amount of methanol remaining is 95% of the theoretical amount, the transesterification reaction is ended; after the product of the transesterification reaction is pressed, it is transferred to a high vacuum (100-200Pa) stage for co-condensation reaction, the temperature Rise to 230-250°C, control the end point of the polycondensation reaction by the numerical value of the stirring power, fill with nitrogen, and eliminate the vacuum to obtain a polyester elastomer; the intrinsic viscosity of the polyester elastomer is 0.82dL / g, and the obtained 50g polyester elastomer ...

Embodiment 3

[0056] In the flask, add 35g DMT, 20g BDO and 48g PTMEG (Mn=2000), 3g polyether glycol containing aromatic ring (wherein R1=H, R2=CH 3 , a=b=1), add 50mg tetrabutyl titanate and 15mg antioxidant 1010 at the same time, carry out the transesterification reaction under normal pressure at 170-180°C, remove the by-product methanol, and generate terephthalic acid Alcohol esters and its oligomers, when the amount of methanol left over is 95% of the theoretical amount, the transesterification reaction is terminated; after the product of the transesterification reaction is pressed, it is transferred to a high vacuum (60Pa) stage for co-condensation reaction, and the temperature rises to 230-250°C, control the end point of the polycondensation reaction by the numerical value of the stirring power, fill with nitrogen, and eliminate the vacuum to obtain a polyester elastomer; the intrinsic viscosity of the polyester elastomer is 1.5dL / g, and the obtained 50g polyester elastomer, Add 4g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com