Method for nucleation growth of polycrystal perovskite thin film by perovskite quantum dots and related photoelectric device

A technology for growing polycrystalline and optoelectronic devices, which is applied in the fields of electric solid-state devices, photovoltaic power generation, electrical components, etc., can solve the problems of perovskite lattice structure mismatch, unpredictable final morphology, poor compatibility, etc., and achieve Ease of nucleation and crystal growth, enhanced crystallinity, and improved performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

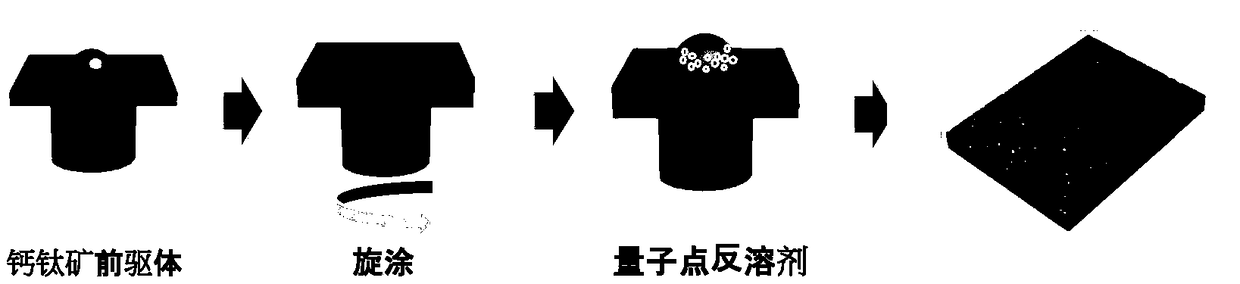

Method used

Image

Examples

Embodiment 1

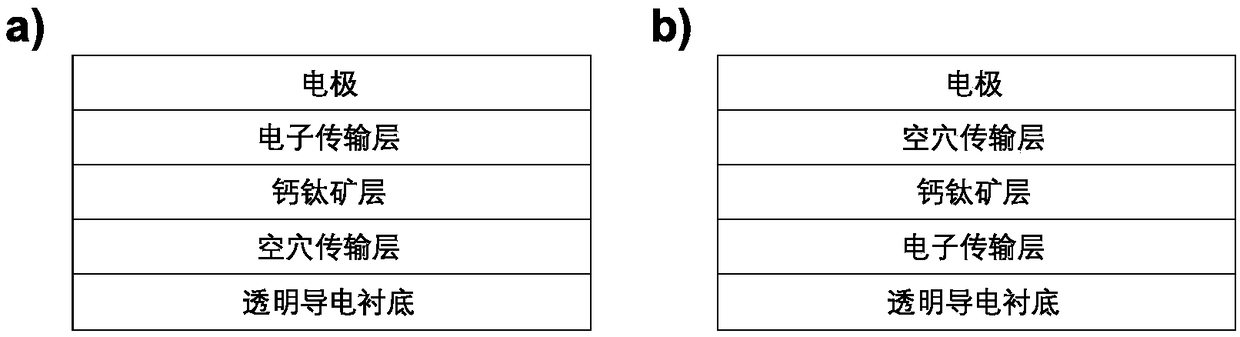

[0025] use figure 2 For the battery structure of a, the glass substrate coated with fluorine-doped tin oxide (FTO) was ultrasonically washed with deionized water, absolute ethanol, and acetone in sequence, and then a NiO hole transport layer with a thickness of 20 nm was thermally sprayed on the glass substrate. Using CH 3 NH 3 I and PbI 2 (molar ratio 1:1) configure the precursor solution of perovskite. Oleylamine and oleic acid were selected as coating agents and stabilizers to form CH with a size of 10nm 3 NH 3 PbBr 3 Quantum dots are dispersed in chlorobenzene solution to form a uniform and stable solution with a concentration of 0.005mg / ml. The perovskite precursor solution was spin-coated on the NiO hole transport layer, and then the quantum dot solution with a concentration of 0.005mg / ml was spin-coated, and then heated at 120°C for 10 minutes to obtain a CH with a thickness of 400nm. 3 NH 3 PB 3 perovskite layer.

[0026] A chlorobenzene solution of [6,6]-ph...

Embodiment 2

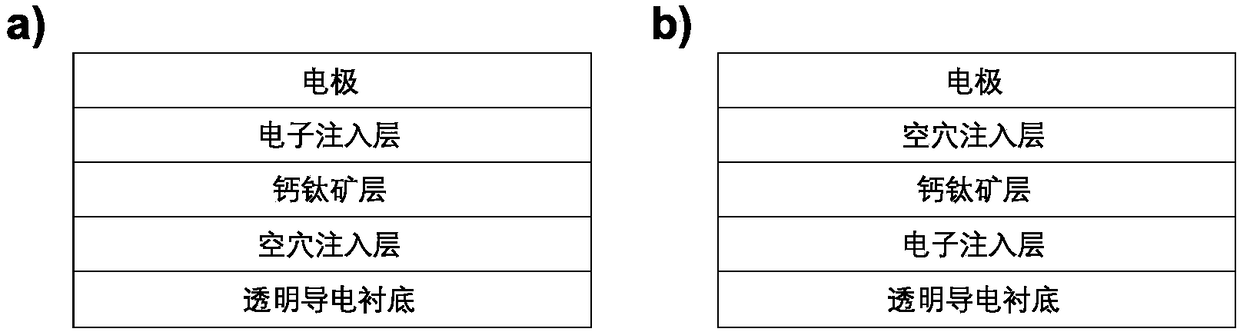

[0029] use image 3 The light-emitting diode structure of a, after washing the glass substrate coated with indium tin oxide (ITO) with deionized water, absolute ethanol, and acetone ultrasonically, spin-coat a layer of poly-3,4-ethylene with a thickness of 15 nm on the substrate. Dioxythiophene: Hole injection layer of polystyrene sulfonate. Using CH 3 NH 3 Br and PbBr 2 (molar ratio 1:1) configure the precursor solution of perovskite.

[0030] Hexylamine and octanoic acid were selected as capping agents and stabilizers to form CH with a size of 5nm 3 NH 3 PB 3Quantum dots are dispersed in toluene solution to form a uniform and stable solution with a concentration of 0.5 mg / ml. The perovskite precursor solution was spin-coated on the hole injection layer, and then the quantum dot solution with a concentration of 0.5mg / ml was spin-coated, and then heated at 100°C for 20 minutes to obtain a CH with a thickness of 300nm. 3 NH 3 PbBr 3 perovskite layer.

[0031] Spin-co...

Embodiment 3

[0034] use figure 2 For the battery structure of b, the glass substrate coated with indium tin oxide (ITO) was washed with deionized water, absolute ethanol, and acetone in sequence, and then a layer of 30nm thick C was prepared on the substrate by electron beam thermal evaporation. 60 electron transport layer. Using HC (NH 2 ) 2 I and PbI 2 (molar ratio 1:1) configure the precursor solution of perovskite.

[0035] Amylamine was chosen as capping agent and stabilizer to form CH with a size of 50nm 3 NH 3 PbCl 3 Quantum dots are dispersed in ether solution to form a uniform and stable solution with a concentration of 5 mg / ml. The perovskite precursor solution was spin-coated on C 60 On the electron transport layer, then dropwise add a quantum dot solution with a concentration of 5mg / ml, and then heat at 150°C for 10 minutes to obtain HC (NH 2 ) 2 PB 3 perovskite layer.

[0036] The CuSCN solution was spin-coated, and after curing, a hole transport layer with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com