Method for preparing polyamide-based heat conduction composite material through melt blending

A thermally conductive composite material and melt blending technology, which is applied in the field of preparation of polymer-based composite materials, can solve the problem of low thermal conductivity of polymer materials, and achieve the advantages of improving dispersibility, improving thermal conductivity and mechanical properties, and improving thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

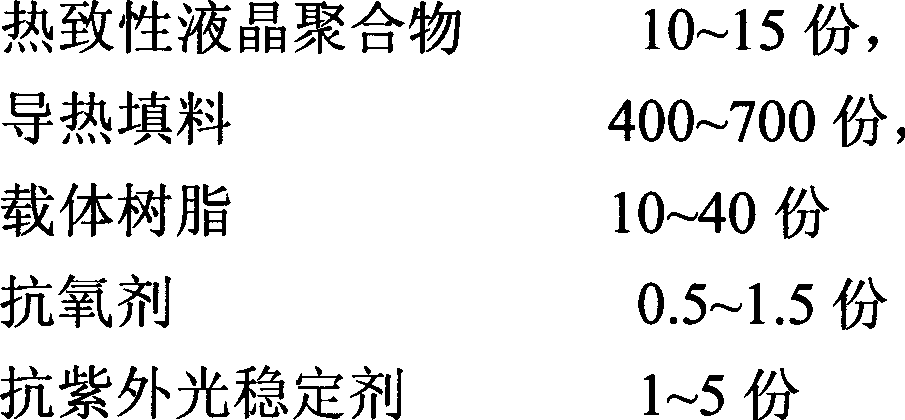

Method used

Image

Examples

Embodiment 1

[0016] Firstly, 400g of thermally conductive filler is surface treated with 0.5% coupling agent NDZ-311 in a high-speed mixer; then the carrier resin / thermally conductive filler / antioxidant / anti-ultraviolet light stabilizer with a mass ratio of 10:400:0.5:1 A twin-screw extruder is used to pelletize the multifunctional masterbatch together. The temperature of the extruder barrel is controlled at 120℃~140℃. Finally, the obtained multifunctional masterbatch is mixed with 100g polyamide 6 and 10g heat The homogenous liquid crystal polymer is mixed uniformly and dried together in a vacuum at 80°C for 4 hours. A twin-screw extruder is used to prepare a polyamide-based thermally conductive composite material. The temperature of the barrel is controlled at 210°C to 280°C and the vacuum device is kept open.

[0017] The thermal conductivity composite material prepared above was prepared by injection molding. The performance test results are as follows: the thermal conductivity is 6.5W / m·k...

Embodiment 2

[0019] First, use 1% coupling agent NDZ-311 for surface treatment of 400g of thermally conductive filler in a high-speed mixer; then, the mass ratio of carrier resin / thermally conductive filler / antioxidant / ultraviolet light stabilizer is 40:400:0.5:1 A twin-screw extruder is used to pelletize the multifunctional masterbatch together. The temperature of the extruder barrel is controlled at 120℃~140℃. Finally, the obtained multifunctional masterbatch is mixed with 100g polyamide 6 and 10g heat The homogenous liquid crystal polymer is uniformly mixed and dried together in a vacuum at 80°C for 4 hours. A twin-screw extruder is used to extrude the polyamide-based thermally conductive composite material. The temperature of the barrel is controlled at 210-280°C and the vacuum device is kept open.

[0020] The thermal conductivity composite material prepared above was injection molded and the performance test results are as follows: thermal conductivity is 5.7W / m·k, tensile strength 56.3M...

Embodiment 3

[0022] Firstly, 700 g of the thermally conductive filler is surface treated with 1.5% titanate coupling agent NDZ-311 in a high-speed mixer; then the mass ratio of the carrier resin / thermally conductive filler / antioxidant / antioxidant is 10:700:1:3. The ultraviolet light stabilizer is granulated together with a twin-screw extruder to make a multifunctional masterbatch. The temperature of the extruder barrel is controlled at 120℃~140℃; finally, the multifunctional masterbatch is mixed with 100g of polyamide 6 and 10g of thermotropic liquid crystal polymer is mixed uniformly, dried together at 80℃ for 4 hours, and extruded by twin screw extruder to prepare polyamide-based thermally conductive composite material. The temperature of the barrel is controlled at 210~280℃, and the vacuum device is kept on. .

[0023] The thermally conductive composite material prepared above was injection molded and the performance test results are as follows: thermal conductivity is 9.5W / m·k, tensile st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com