Modified gangue powder filled polyolefin flame retardant composite material and its preparation process

A flame retardant composite material and coal gangue powder technology are applied in the field of coal gangue modified and filled polyolefin flame retardant composite material and preparation, and can solve the problem of decreasing the filling amount of coal gangue powder, reducing the mechanical properties of polyolefin materials, increasing the preparation cost, etc. problems, to achieve the effect of improving flow processability, excellent flame retardant effect, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

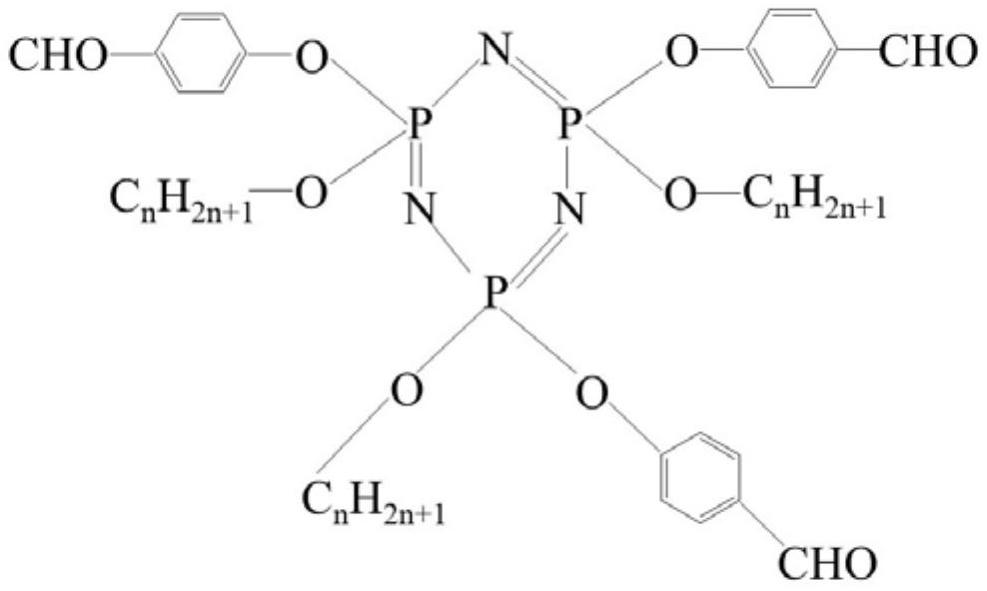

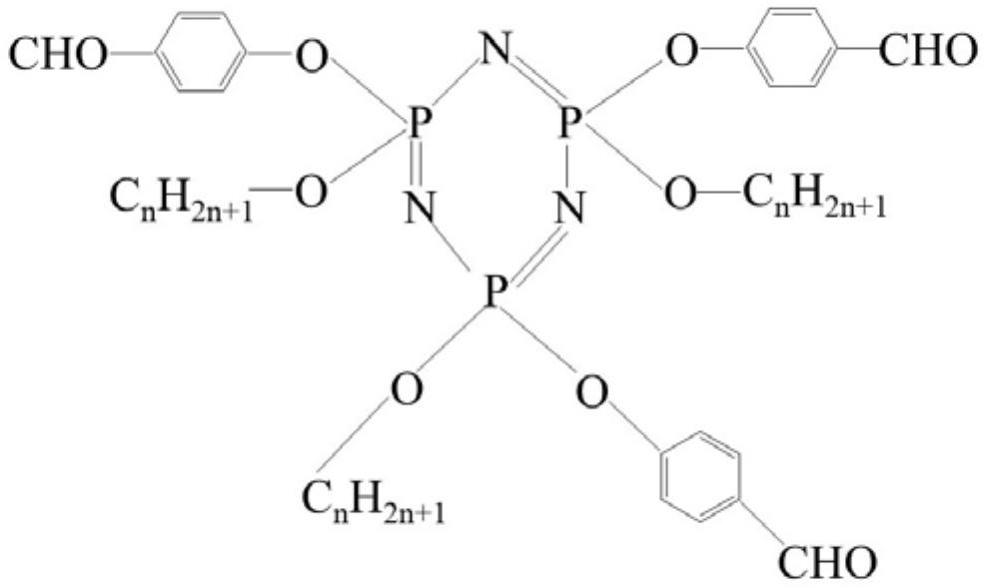

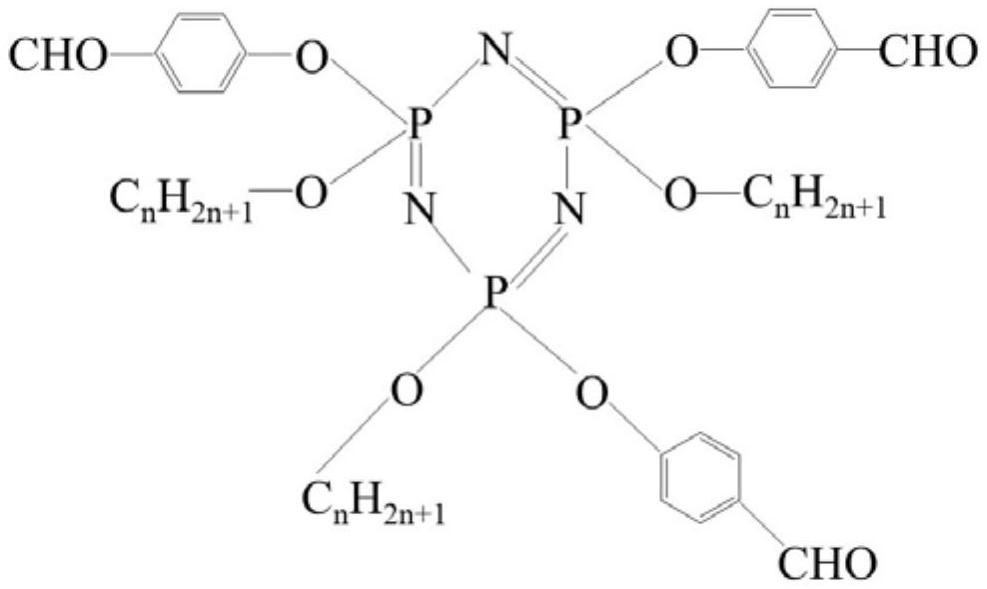

Image

Examples

Embodiment 1

[0025] At room temperature, dry the gangue powder at 110-120°C until the water content is <0.1%, and add HDCP and dried gangue powder into the high-speed mixer at a weight ratio of 1:100 at a speed of 1000r / min. Mix for 10 minutes to obtain modified gangue powder. Fill the modified coal gangue powder and polyolefin into the twin-screw extruder according to the weight ratio of 30:100. The main screw speed is 140rpm, the pump speed is 10rpm, and the temperature is 190-200°C. After melt blending and extrusion, cool Use a granulator to cut pellets, fill the pellets into the injection molding machine, the injection molding temperature is 190°C, the injection molding pressure is 40MPa, and the injection extrusion can prepare modified coal gangue powder filled polyolefin flame-retardant composite products, and its elastic modulus is improved. 20%, the strength can be increased by 10%, the toughness can be enhanced by 20%, the heat distortion temperature is 260°C, and the limiting oxy...

Embodiment 2

[0027]At room temperature, dry the gangue powder at 110-120°C until the water content is <0.1%, and add HDCP and dried gangue powder into the high-speed mixer at a weight ratio of 10:100 at a speed of 1300r / min. Mix for 20 minutes to obtain modified gangue powder. Fill the modified coal gangue powder and polyolefin into the twin-screw extruder at a weight ratio of 30:100, the main screw speed is 120rpm, the pump speed is 9rpm, and the temperature is 220-240°C. After melt blending and extrusion, cool Cut pellets with a granulator, fill the pellets into the injection molding machine, the injection molding temperature is 230°C, the injection molding pressure is 60MPa, and the injection extrusion can prepare modified coal gangue powder filled polyolefin flame-retardant composite products, and its elastic modulus is improved. 35%, the strength can be increased by 28%, the toughness can be enhanced by 45%, the heat distortion temperature is 280°C, and the limiting oxygen index is 33...

Embodiment 3

[0029] At room temperature, dry the gangue powder at 110-120°C until the water content is <0.1%, and add HDCP and dried gangue powder into the high-speed mixer at a weight ratio of 8:100 at a speed of 1200r / min, at a high speed Mix for 15 minutes to obtain modified gangue powder. Fill the modified coal gangue powder and polyolefin into the twin-screw extruder at a weight ratio of 30:100. The main screw speed is 100 rpm, the pump speed is 8 rpm, and the temperature is 210-220 ° C. After melt blending and extrusion, cool Use a granulator to cut pellets, fill the pellets into the injection molding machine, the injection molding temperature is 210°C, the injection molding pressure is 50MPa, and the injection extrusion can prepare modified coal gangue powder filled polyolefin flame-retardant composite products, and its elastic modulus is improved. 40%, the strength can be increased by 35%, the toughness can be enhanced by 55%, the heat distortion temperature is 290°C, and the limit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com