A method for preparing polyamide-based thermally conductive composite materials by melt blending

A heat-conducting composite material and melt-blending technology, which is applied in the field of preparation of polymer-based composite materials, can solve the problems of low thermal conductivity of polymer materials, improve dispersion, improve thermal conductivity and mechanical properties, and improve thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

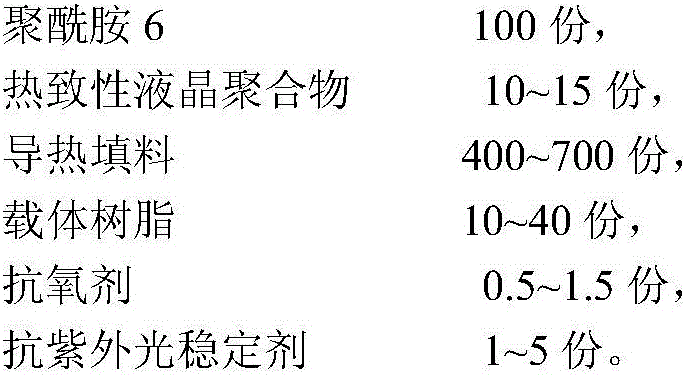

Method used

Image

Examples

Embodiment 1

[0016] First, 400g of thermally conductive filler is surface-treated in a high-speed mixer with 0.5% coupling agent NDZ-311; then the mass ratio of carrier resin / thermally conductive filler / antioxidant / anti-ultraviolet light is stabilized The multi-functional masterbatch is granulated together with the twin-screw extruder, and the temperature of the barrel of the extruder is controlled at 120°C to 140°C; finally, the multifunctional masterbatch is mixed with 100g of polyamide 6 and 10g of hot water Mix the non-tropic liquid crystal polymers evenly, and dry them in a vacuum at 80°C for 4 hours, and then extrude them with a twin-screw extruder to prepare polyamide-based thermally conductive composite materials. The temperature of the barrel is controlled at 210°C to 280°C, and the vacuum device is kept on.

[0017] The thermal conductive composite material prepared above was prepared by injection molding, and the performance test results are as follows: thermal conductivity is 6....

Embodiment 2

[0019] First, 400g of thermally conductive filler is surface-treated in a high-speed mixer with 1% coupling agent NDZ-311; then the carrier resin / thermally conductive filler / antioxidant / anti-ultraviolet light stabilized The multi-functional masterbatch is granulated together with the twin-screw extruder, and the temperature of the barrel of the extruder is controlled at 120°C to 140°C; finally, the multifunctional masterbatch is mixed with 100g of polyamide 6 and 10g of hot water Mix the non-tropic liquid crystal polymers evenly, and dry them in vacuum at 80°C for 4 hours, and then extrude them with a twin-screw extruder to prepare polyamide-based heat-conducting composite materials. The temperature of the barrel is controlled at 210-280°C, and the vacuum device is kept open.

[0020] The heat-conducting composite material prepared above was prepared by injection molding, and the performance test results are as follows: thermal conductivity is 5.7W / m·k, tensile strength is 56.3...

Embodiment 3

[0022] First, 700g of thermally conductive filler is surface-treated with 1.5% titanate coupling agent NDZ-311 in a high-speed mixer; The UV stabilizer is granulated together with a twin-screw extruder to make a multifunctional masterbatch, and the temperature of the barrel of the extruder is controlled at 120°C to 140°C; finally, the prepared multifunctional masterbatch is mixed with 100g of polyamide 6 and Mix 10g of thermotropic liquid crystal polymers evenly, and dry them together in vacuum at 80°C for 4 hours, and then extrude them with a twin-screw extruder to prepare polyamide-based thermally conductive composite materials. The temperature of the barrel is controlled at 210-280°C, and the vacuum device is kept open .

[0023] The thermal conductive composite material prepared above was prepared by injection molding, and the performance test results are as follows: the thermal conductivity is 9.5W / m·k, the tensile strength is 69.4MPa, the bending strength is 64.7MPa, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com