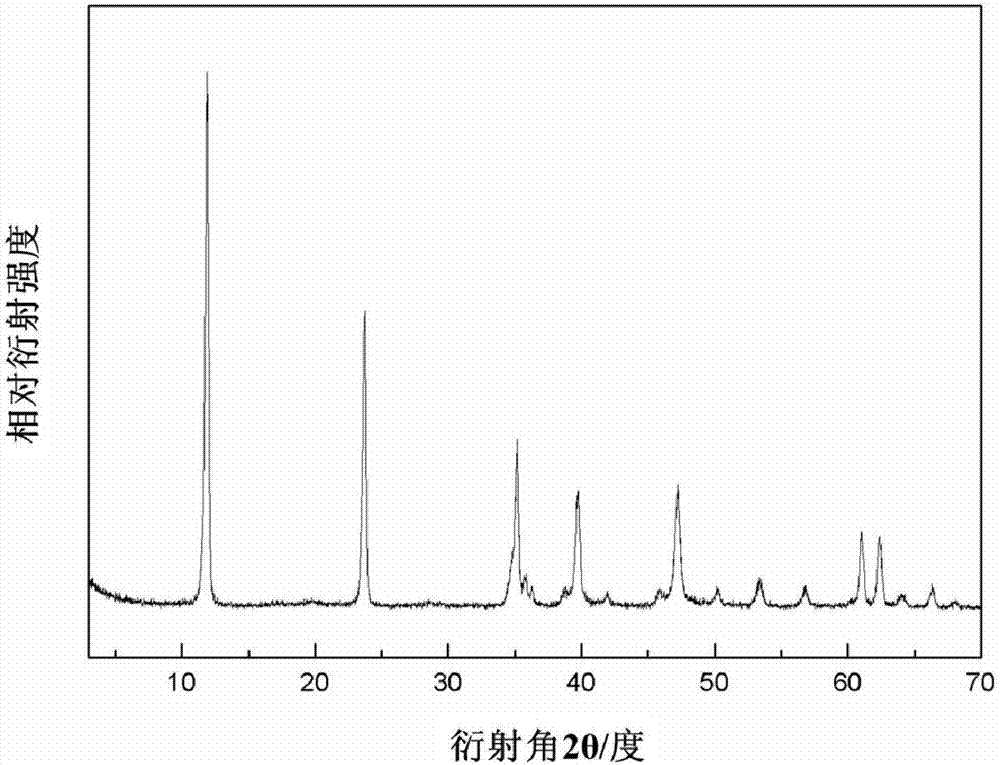

Method for preparing polypropylene/hydrotalcite nanometer composite material by using hydrotalcite as nucleating agent

A nanocomposite material, polypropylene technology, applied in the field of preparing polypropylene/hydrotalcite nanocomposite materials, can solve the problems of large shrinkage, shortened service life, and reduced dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

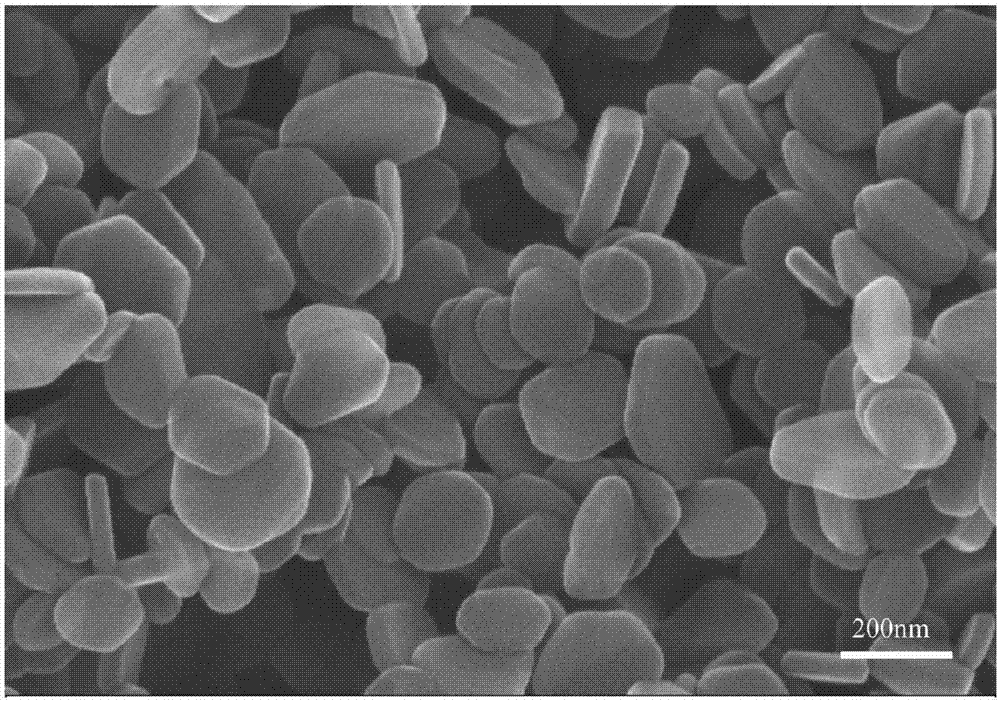

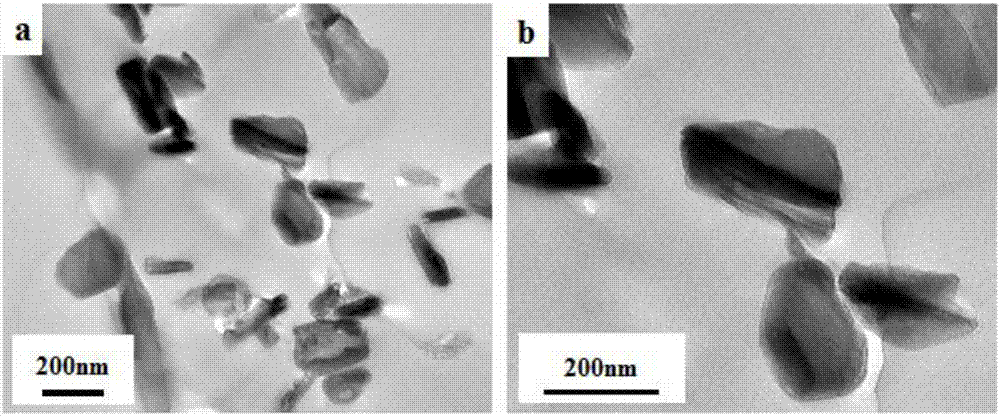

Embodiment 1

[0025] Step A: take by weighing 6.4102g Mg (NO 3 ) 2 ·6H 2 O and 4.6891g Al(NO 3 ) 3 9H 2 O (molar ratio Mg / Al=2) was dissolved in 50 mL to remove CO 2 deionized water to prepare the mixed salt solution.

[0026] Step B: Weigh 4.0g of sodium hydroxide and 2.65g of sodium carbonate and dissolve them in 50ml to remove CO 2 Deionized water, respectively made into a solution with a molar concentration of 2mol / L and a solution with a molar concentration of 0.5mol / L.

[0027] Step C: transfer the sodium carbonate solution obtained in step B to a round-bottomed flask, and drop the mixed salt solution of step A and the sodium hydroxide solution of step B into it at the same time, keep stirring and control the pH=10 or so, wait until After the salt solution is dripped, transfer the mixed solution to the pressure vessel, then seal the pressure vessel, place it in an oven at 150°C, take it out after 24 hours of reaction, and use ethanol / deionized water at a ratio of 1:1 to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com