High-rigidity and high-toughness polypropylene composite material and preparation method thereof

A technology for composite materials and polypropylene, applied in the field of high-rigidity and high-toughness polypropylene composite materials and its preparation, can solve the problems of high crystallinity, poor dimensional stability, and low weather resistance of polypropylene, so as to increase the content of β crystals and improve Effect of impact strength and dispersibility enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

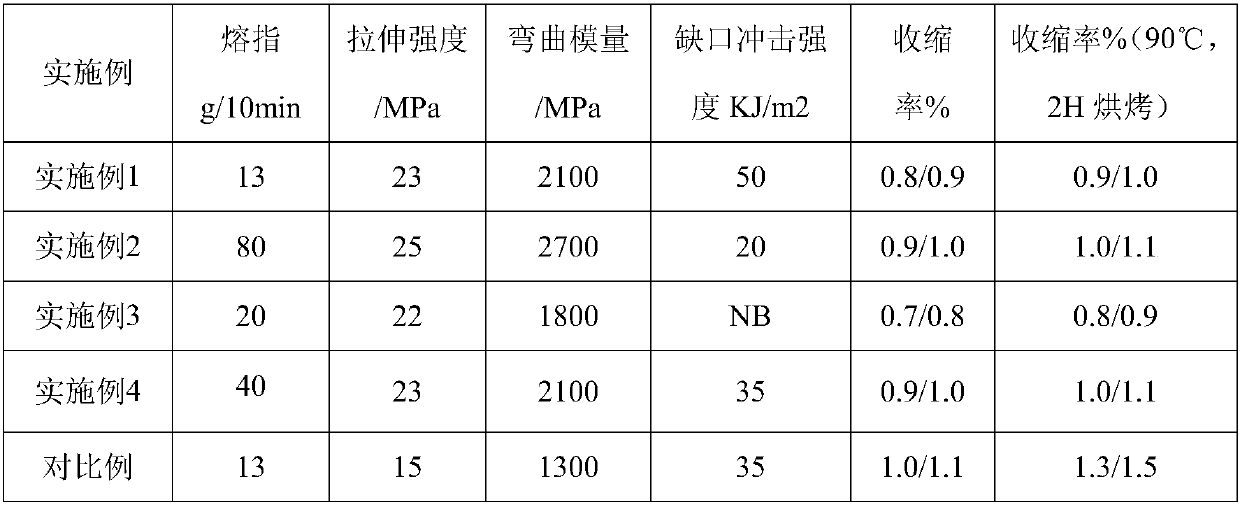

Examples

Embodiment 1

[0038] Weigh 40 parts of dry copolymerized polypropylene PP-K9026, 20 parts of talc powder AH51210, 10 parts of reinforcing agent, 24 parts of toughening agent POE 8200, 3 parts of compatibilizer POE-G, and 0.2 parts of nucleating agent according to the weight ratio Masterbatch (Y 2 o 3 : TMB-5=1:1), 0.1 part of antioxidant 1010, 0.1 part of antioxidant DSTDP, 0.2 part of lubricant EBS, 0.3 part of coupling agent KH550, 0.1 part of light stabilizer V703, add the above materials into high-speed mixing Mix evenly in the extruder, then put the evenly mixed mixture into the extruder, and cut into pellets after cooling with water. Among them, the processing temperature of the extruder is 180°C, 190°C, 195°C, 195°C, 200°C, 205°C from the feeding port to the die port, the main engine speed is 180rpm, and the vacuum degree is -0.03MPa.

Embodiment 2

[0040] Weigh 63 parts of dry copolymerized polypropylene PP-BX3920, 10 parts of magnesium sulfate whisker WS-1S2, 10 parts of reinforcing agent, 15 parts of toughening agent EPDM, 2 parts of compatibilizer PP-G, 0.4 parts by weight Part nucleation masterbatch (Y 2 o 3 : TMB-5=1:3), 0.1 part of antioxidant, 0.1 part of antioxidant DSTDP, 0.2 part of antioxidant 168, 0.2 part of lubricant calcium stearate, 0.3 part of coupling agent KH550, 0.3 part of light stabilizer For agent V703, add the above materials into a high-speed mixer and mix them evenly, then add the evenly mixed mixture into the extruder, and cut into pellets after water cooling. Among them, the processing temperature of the extruder is 180°C, 190°C, 195°C, 195°C, 200°C, 205°C from the feeding port to the die port, the speed of the main machine is 200rpm, and the vacuum degree is -0.05MPa.

Embodiment 3

[0042] Weigh 80 parts of dry copolymerized polypropylene PP-K9026, 5 parts of talc powder AH51210, 5 parts of reinforcing agent, 8 parts of toughening agent POE 8200, 2 parts of compatibilizer POE-G, and 1 part of nucleating agent according to the weight ratio Masterbatch (Y 2 o 3 : TMB-5=1:1), 0.1 part of antioxidant 1010, 0.1 part of antioxidant DSTDP, 0.2 part of antioxidant 168, 0.2 part of lubricant EBS, 0.3 part of coupling agent KH550, 0.3 part of light stabilizer V703 , Add the above materials into a high-speed mixer and mix them evenly, then add the evenly mixed mixture into the extruder, and cut into pellets after water cooling. Among them, the processing temperature of the extruder is 180°C, 190°C, 195°C, 195°C, 200°C, 205°C from the feeding port to the die port, the main engine speed is 350rpm, and the vacuum degree is -0.05MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com