Apparatus and method for separating wet paint overspray

A filtering device and overspray technology, applied in separation methods, spray devices, chemical instruments and methods, etc., can solve problems such as difficulty in fluidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

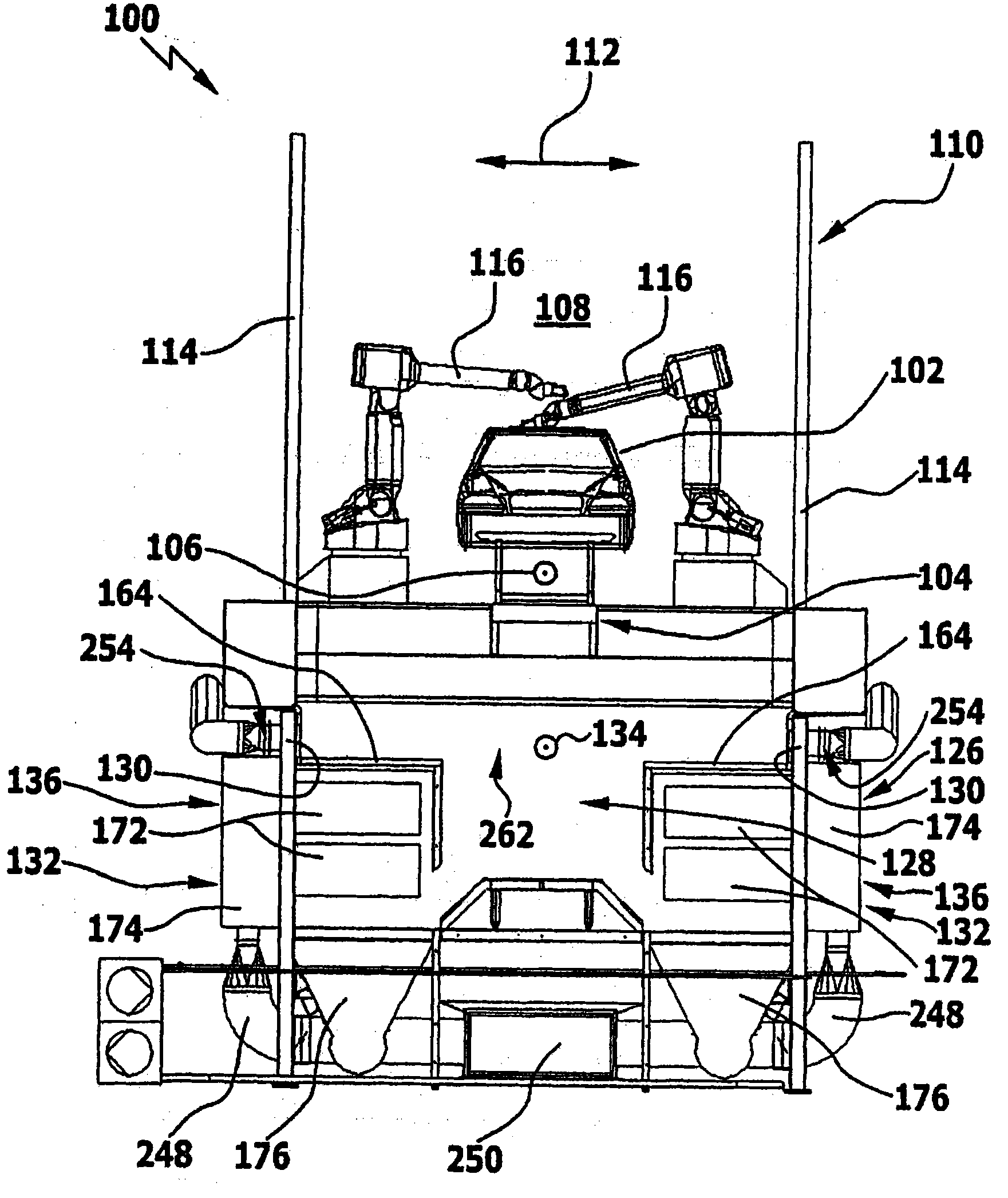

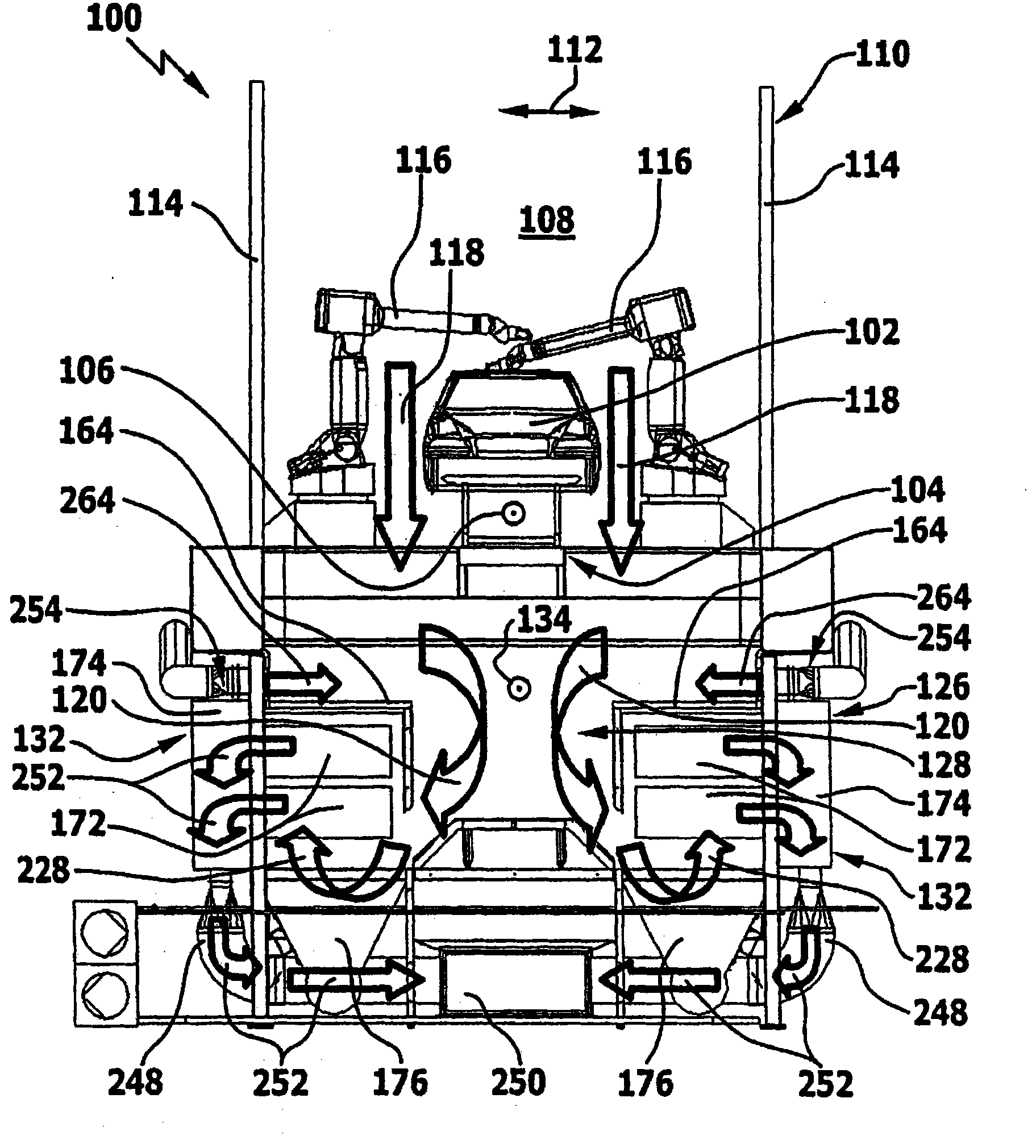

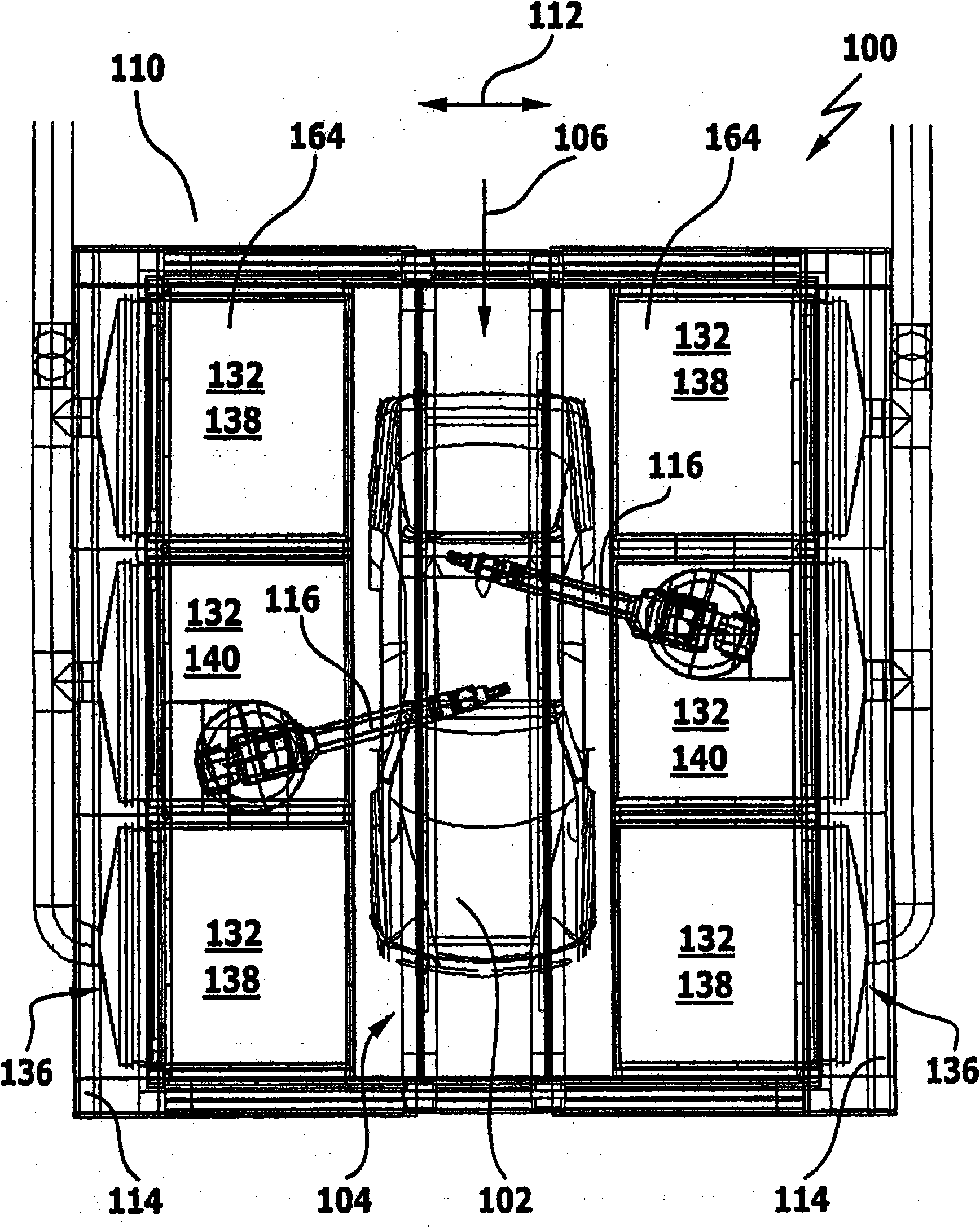

[0056] exist Figures 1 to 7 The device shown in , denoted as a whole by 100 , comprises a purely schematically shown conveying device 104 for painting a motor vehicle body 102 , by means of which the motor vehicle body 102 can be conveyed along a conveying direction 106 The movement passes through the painting area 108 of the spray booth indicated as a whole by 110 .

[0057] The painting area 108 is the interior of a paint spray booth 110 which is delimited by a chamber wall 114 towards both sides of the conveying device 104 in a horizontal transverse direction 112 extending perpendicularly to the conveying direction 106 corresponding to The longitudinal direction of the spray booth 110 .

[0058] Arranged in the paint booth 110 facing both sides of the conveying device 104 is a painting device 116 , for example in the form of a painting robot.

[0059] By means of a (only partly shown) circulating air circuit, an airflow is generated which passes substantially vertically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com