Alloy powder homogenizing treatment method for flux-cored wire

A technology of homogenization treatment and flux-cored welding wire, applied in welding medium, welding equipment, metal processing equipment, etc., can solve the problems of the influence of molten gold quality, component segregation, poor fluidity, etc., to achieve uneven segregation and overall fluidity. The effect of changing and overall fluidity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment is a method for homogenizing alloy powder for flux-cored welding wire, comprising the following steps:

[0019] S1, the particle size of the main raw material powder used maintains the original requirements, and the particle size of the secondary powder raw material that needs to be added in a small amount is required to be less than 100 mesh (fine powder), so as to be dispersed and mixed with the main raw material powder to form a powder raw material;

[0020] S2, the binder for granulation is a water glass solution diluted with water, depending on the viscosity of the water glass, it needs to be diluted with 20-70% water before use;

[0021] S3, put the binder and the powder raw material into the mixer for mixing, the weight percentage of the binder added to the powder raw material is less than 30%, so as to avoid the influence of too much binder on the welding quality;

[0022] S4, the binder and the powder raw materials are evenly mixed and taken out...

Embodiment 2

[0028] Ferro-niobium powder is added to the flux-cored welding wire containing niobium, high carbon and high chromium, and the standard particle size is changed from less than 50 mesh to fine powder less than 100 mesh, and it is granulated with some high-carbon ferrochrome powder. The ratio is as follows:

[0029] After mixing 1 kg of ferro-niobium fine powder with a particle size of less than 100 mesh, 1 kg of high-carbon ferrochrome powder and a small amount of arc stabilizer powder, granulating, sintering and crushing, sieve through a 50-mesh sieve;

[0030] After granulation, 2 kg of powder is mixed with 3 kg of high-carbon ferrochromium powder, and then coated with low-carbon steel skin to form a flux-cored welding wire. The powder is 50% of the flux-cored wire, and the wire diameter is 2.8mm.

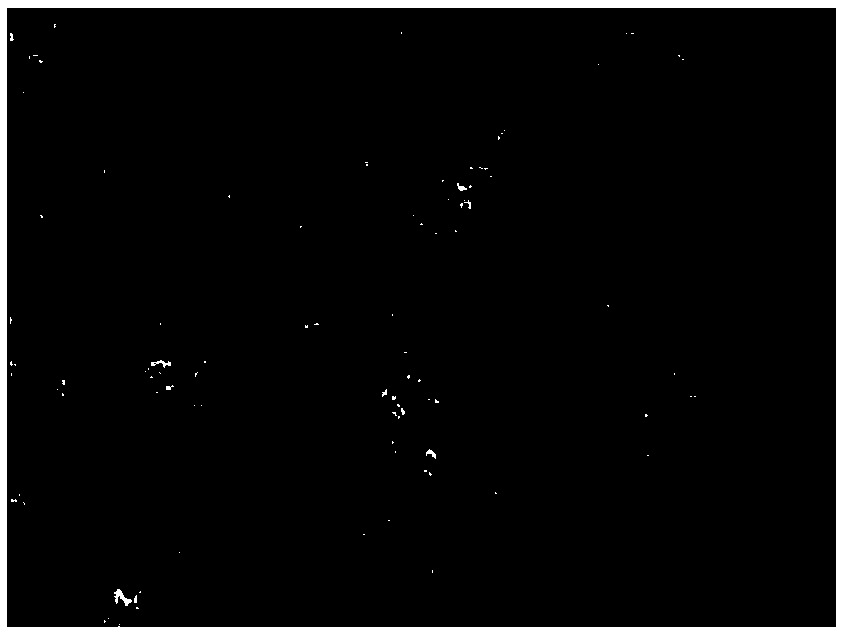

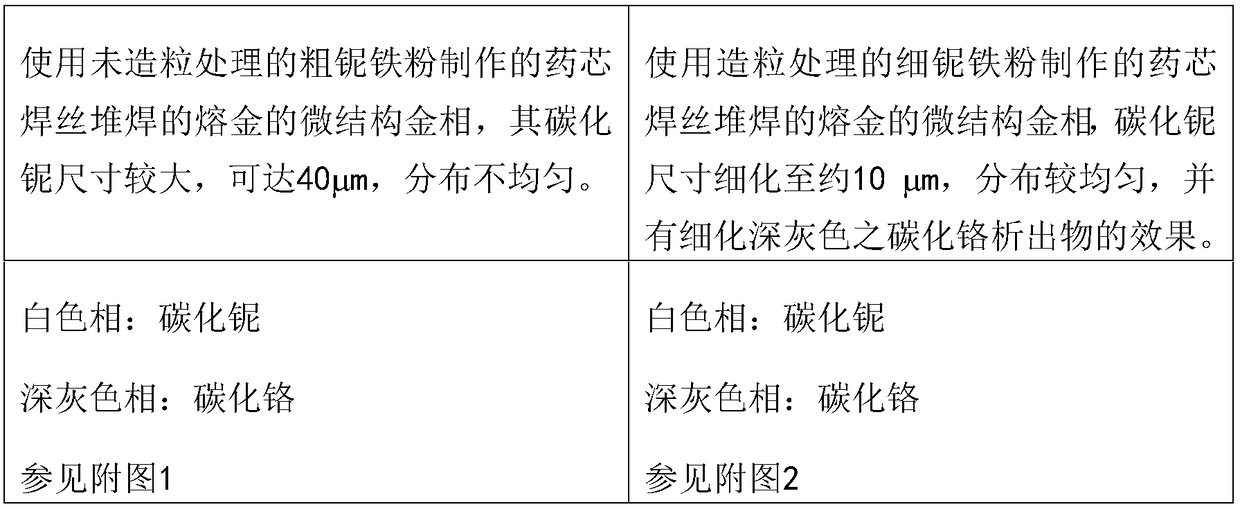

[0031] The produced welding wire was made of fully molten gold test piece with the same welding parameters to analyze its metallographic microstructure. The results are shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com