Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "No curl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for modifying flavored instant food by shiitake stem

The invention relates to a method for modifying flavored instant food by shiitake stem. The method includes soaking dried shitake stem in distilled water overnight; taking out the soaked shitake stem, slicing, placing slices in soak solution, regulating pH, adding cellulase for enzymolysis, and regulating pH; filtering after enzymatic deactivation, adding light soy sauce, white granulated sugar, thirteen spice, 2-4g of salt, monosodium glutamate and chili oil for curing overnight, drying at 80-90 DEG C, cooling to 50-60 DEG C for drying, adding soybean salad oil and spices, vacuum-packing and sterilizing. The shitake stem is modified by biological enzymatic analysis, so that the quality of the shiitake stem is improved, the shiitake stem is highly chewy and softer. By double mixing, the shiitake stem is brighter in color and more delicious and can arouse appetites of consumers better. By step drying, drying time can be shortened, and the finished food is ideal in red brown color without evident curls and air-dried skin. The shitake stem flavored instant food is highly chewy, rich in texture and delicious.

Owner:NANYANG ZHANGZHONGJING SUPER KITCHEN

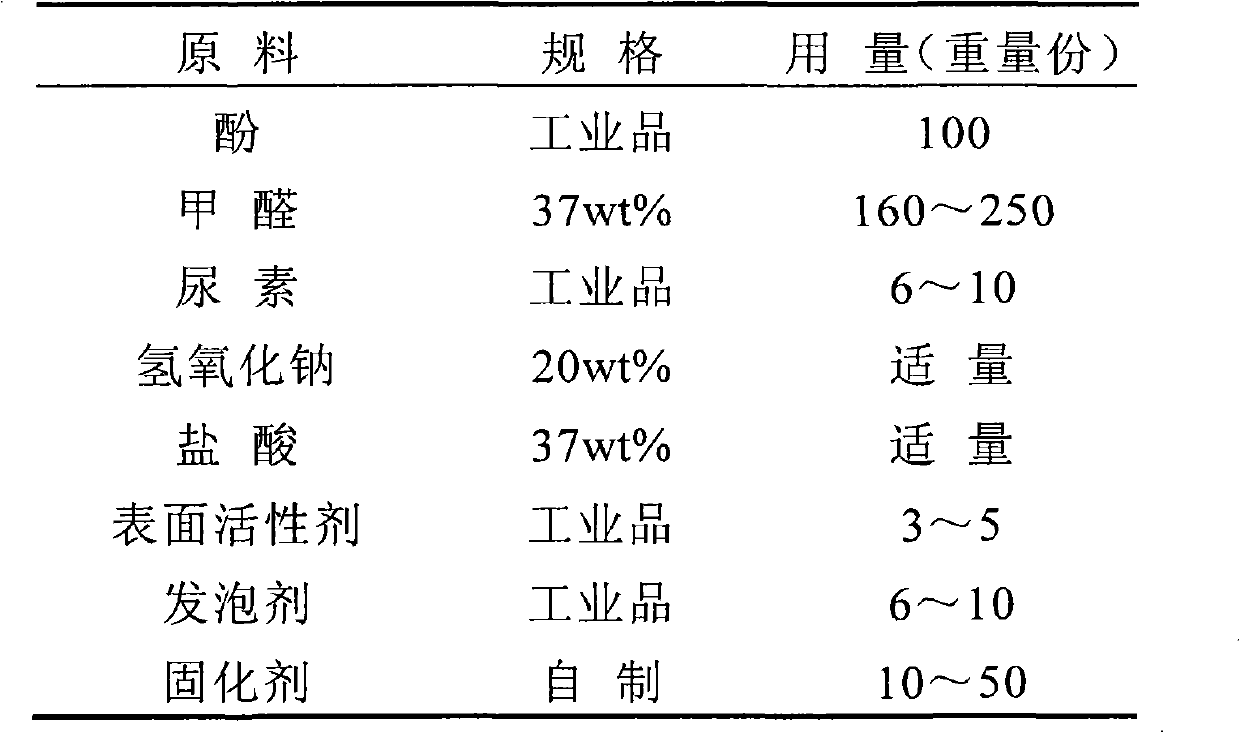

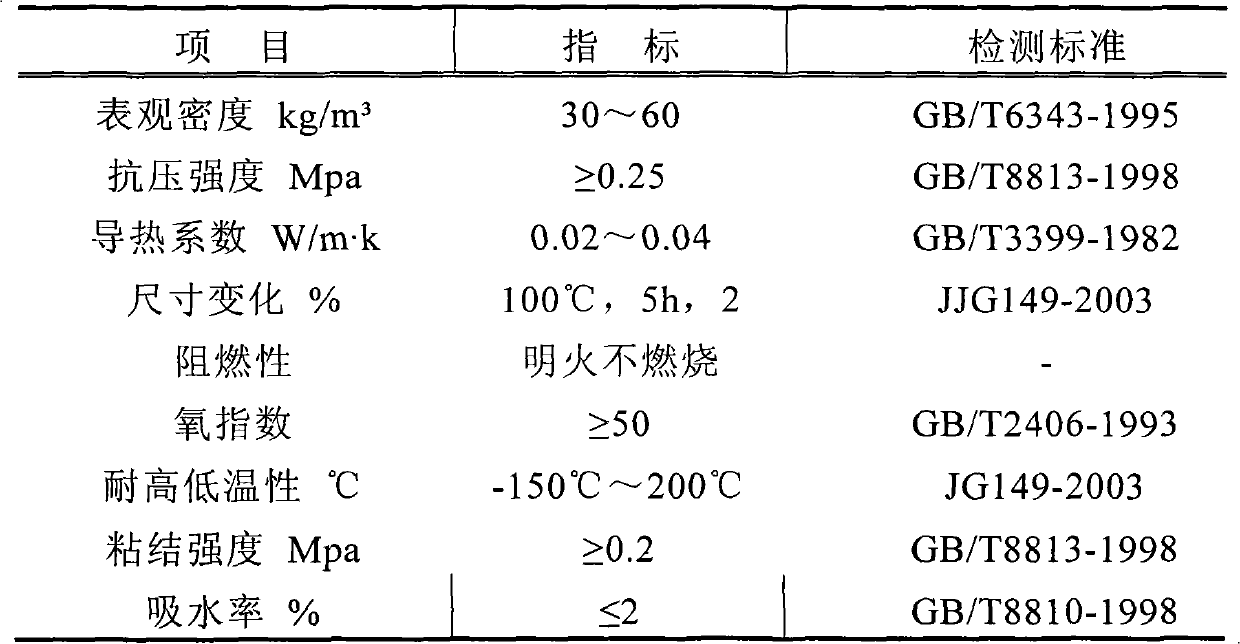

Preparation method of modified phenolic resin and application thereof

The invention discloses a preparation method of modified phenolic resin and an application thereof. The preparation method comprises the following steps of: firstly carrying out polycondensation on phenol, formaldehyde and urea under the conditions of a basic catalyst, the temperature of 85 to 95 DEG C and the pH value of 8 to 9, and regulating the pH value to 6.5 to 7.0 after the reaction is ended; then carrying out vacuum dehydration on polycondensation products under the vacuum condition, enabling the solid content to be 80 to 85 percent by weight, cooling to the room temperature, and regulating the viscosity to be 2.0 to 3.0Pa.s; and finally adding a surfactant and a foaming agent, stirring, discharging and packaging. Furthermore, a composite curing agent is also necessary to be mixed with the modified phenolic resin when in use according to the mass ratio of 100: 10 to 50. The prepared modified phenolic resin has the advantages of light weight, low toxicity, difficult combustion, low smoke, heat insulation, high temperature and low temperature resistance, and the like, can be widely used in the fields of building, transportation, shipping, chemical engineering, petroleum, and the like and has a certain social and economic benefits.

Owner:上海虞城新型建材有限公司 +1

Method for cleanly transferring single layer graphene by using PMMA

The invention discloses a method for cleanly transferring single layer graphene by using PMMA, and relates to a method for transferring the single layer graphene, aiming to solve the problems of an existing graphene transferring method that existing graphene grows unstably on a specific substrate such as a silicon wafer and the transferring is incomplete and curling easily occurs. The method disclosed by the invention is as follows: first, single layer graphene is grown on a copper foil substrate; second, then the copper foil substrate is coated with a PMMA glue in a suspending way, and then placed on a heating plate, heated, solidified, and trimmed; third, the copper foil is floated on the liquid-level of corrosive liquid, and fished out until the copper foil becomes transparent; fourth,standing in water is performed; fifth, the operation of the fourth step is repeated; sixth, the target substrate is picked up, blow-dried with nitrogen, and baked in an oven until the surface turns purple; seventh, PMMA is added dropwise, and standing is performed; and eighth, soaking in acetone, heating and washing are performed to complete the transfer of the single layer graphene. The method disclosed by the invention has broad prospects in the fields of optoelectronic devices and the like.

Owner:HARBIN INST OF TECH

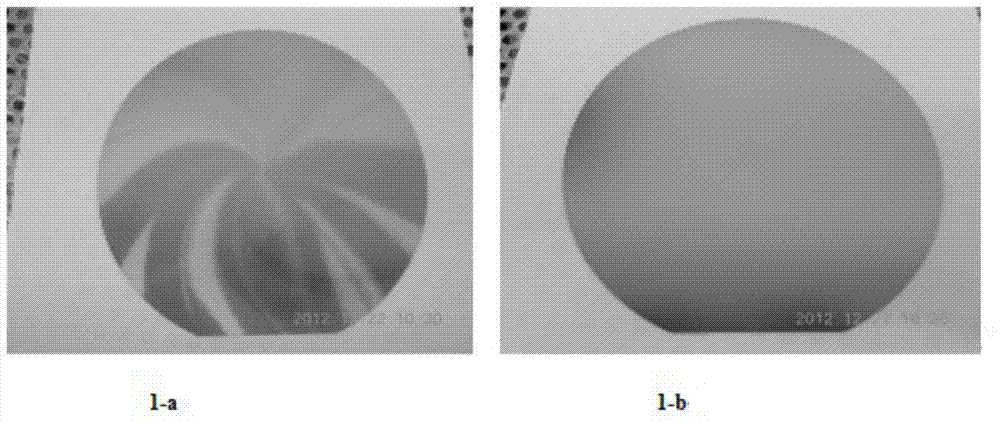

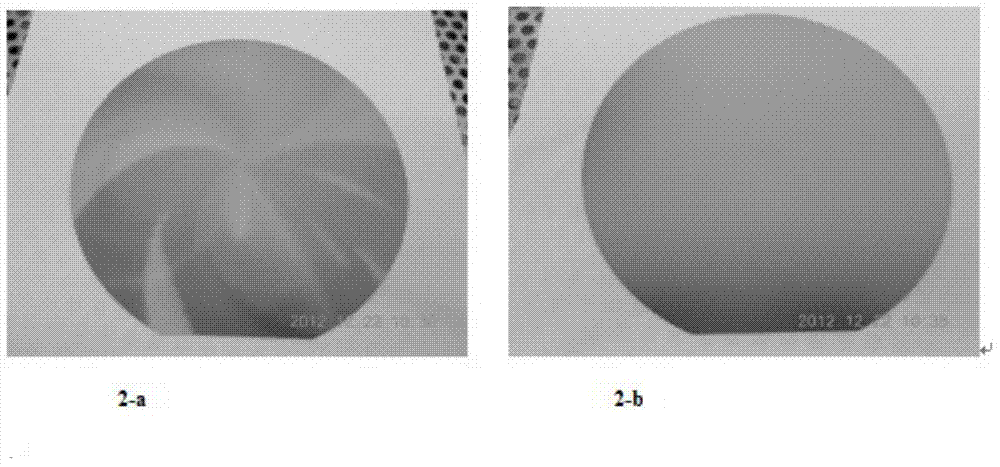

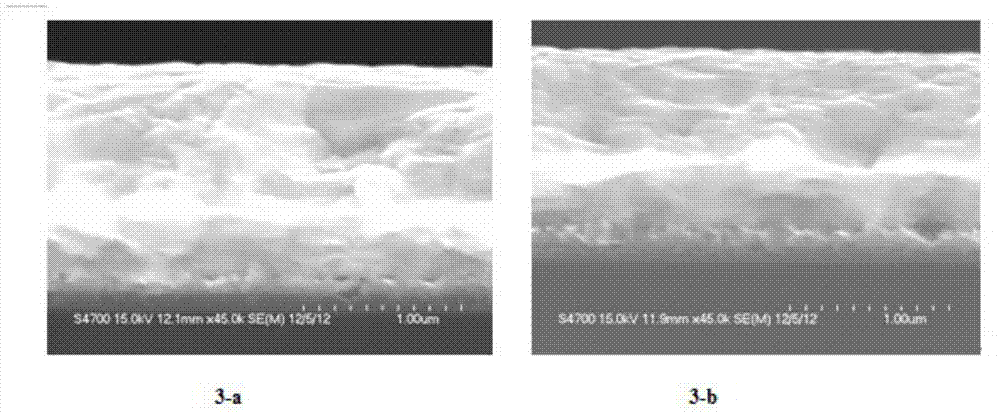

Method for improving appearance quality of rear surface of thin sheet

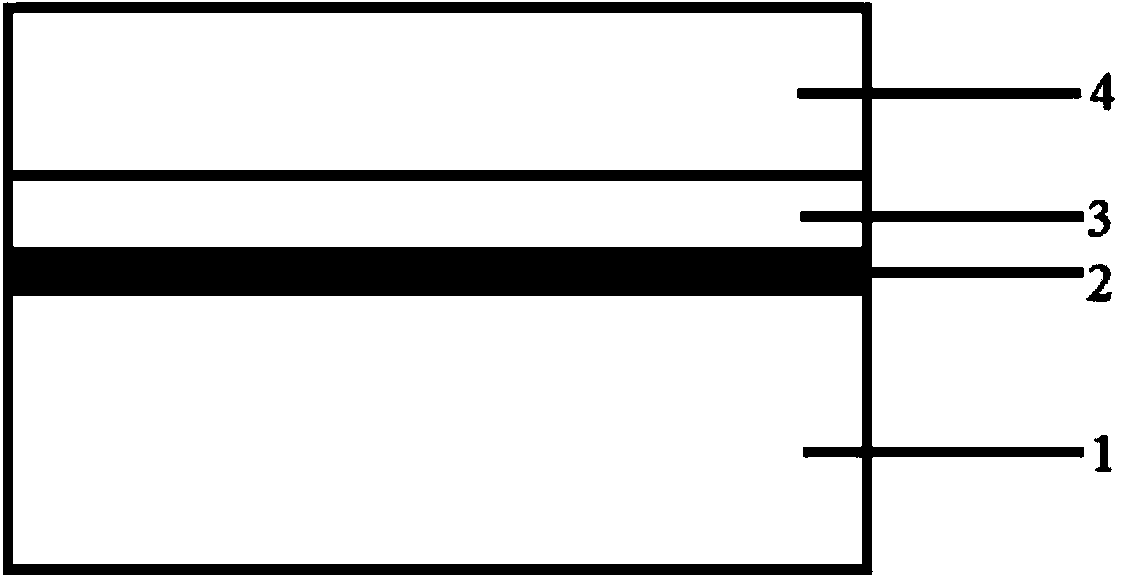

InactiveCN104752161AExcellent conditionNo curlSemiconductor/solid-state device manufacturingHydrofluoric acidAcetic acid

The invention relates to a method for improving appearance quality of a rear surface of a thin sheet. The method comprises the steps of adhering a film on the front surface; thinning the rear surface; corroding the rear surface through silicon; removing the film; washing the rear surface; metalizing the rear surface; the thinned sheet is corroded through corrosion liquid during performing the rear surface silicon corrosion process and the process of removing silicon dioxide before metalizing the rear surface, wherein the corrosion liquid in the rear surface silicon corrosion process is prepared from the following components in volume ratio: hydrofluoric acid, nitric acid and glacial acetic acid in volume ratio of 1: 7: 1; the corrosion liquid in the process of removing silicon dioxide before metalizing the rear surface is prepared from the following components in volume ratio: BOE and C2H6O2 in volume ratio of 1: 1.5. A wafer processed by the method has the advantages that the rear surface metal surface is free of curling, tilting and other phenomena after finishing the following rear surface metalizing process; the phenomenon of failure of the reliability of a semiconductor caused by the spalling of the rear surface metal layer can be avoided; meanwhile, the appearance condition is obviously superior to that of other wafers processed by other washing manner.

Owner:SUZHOU TONGGUAN MICROELECTRONICS

Preparation method of bisurface copper foil gunless base material

A process for preparing the non-adhesive substrate with dual surface copper foil players includes such steps as coating the additive compound for preventing ion immigration on the rough surface of copper foils, reaction between thermoplastic prepolymer resin and thermosetting master resin, and heating while pressing for iminating at 300 deg.C for 30 min.

Owner:SHENZHEN DANBOND TECH

Flexible printed wiring board and manufacturing method thereof

InactiveCN1947476AGood dimensional stabilityNo curlCircuit susbtrate materialsMultilayer circuit manufactureElectrical conductorEngineering

A flexible printed wiring board having a stable quality, not generating curls on a film even after circuit process on a conductor side, and a method of manufacturing such flexible printed wiring board are provided. The flexible printed wiring board is provided with a base layer, which is composed of at least one type of low thermal expansion polyimide resin, between a bottom layer contacting the conductor and a top layer on the opposite side to the conductor. The bottom layer and the top layer are composed of a thermoplastic polyimide rein having a larger thermal expansion coefficient than that of the base layer, and a thickness P1 of the bottom layer and a thickness P2 of the top layer satisfy a condition of P1 H05K 1 / 03 0 10 1 2005 / 3 / 9 1947476 2007 / 4 / 11 000000000 Nippon Steel Chemical Co. Japan Higasayama Ichiro Sato Seiji wangjian 11038 The Patent Agency of the Chinese Council for the Promotion of International Trade (CCPIT) No.1 Waidajie, Fuxingmen, Beijing 100086 Japan 2004 / 3 / 9 065854 / 2004 2006 / 9 / 8 PCT / JP2005 / 004100 2005 / 3 / 9 WO2005 / 086547 2005 / 9 / 15 Japanese

Owner:NIPPON STEEL CHEMICAL CO LTD

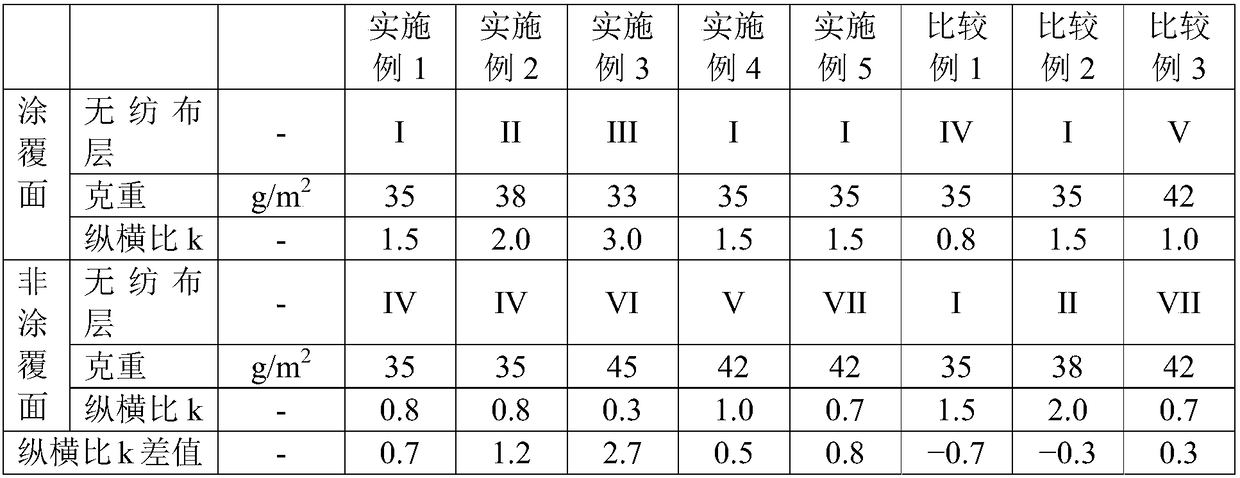

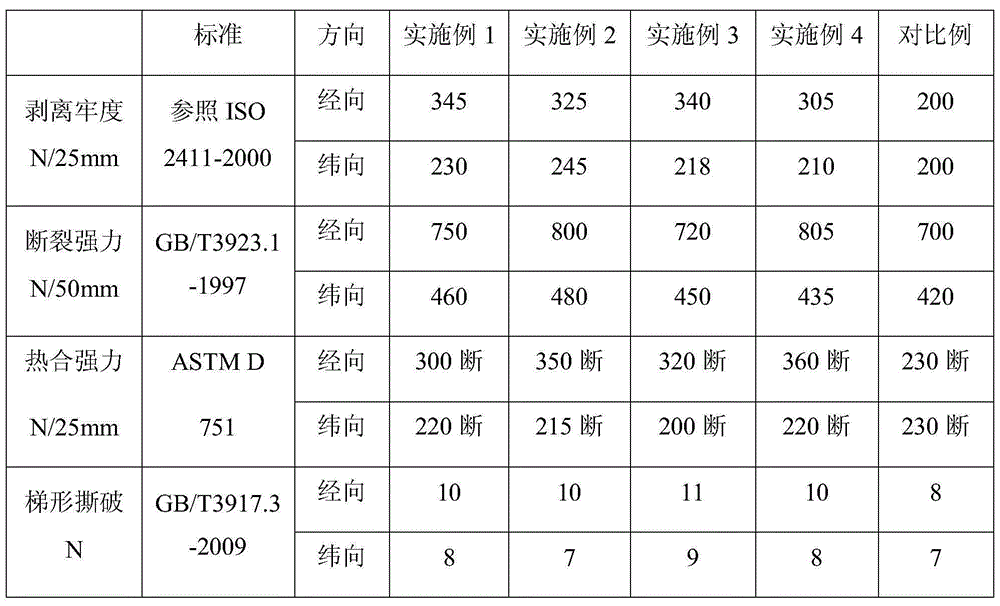

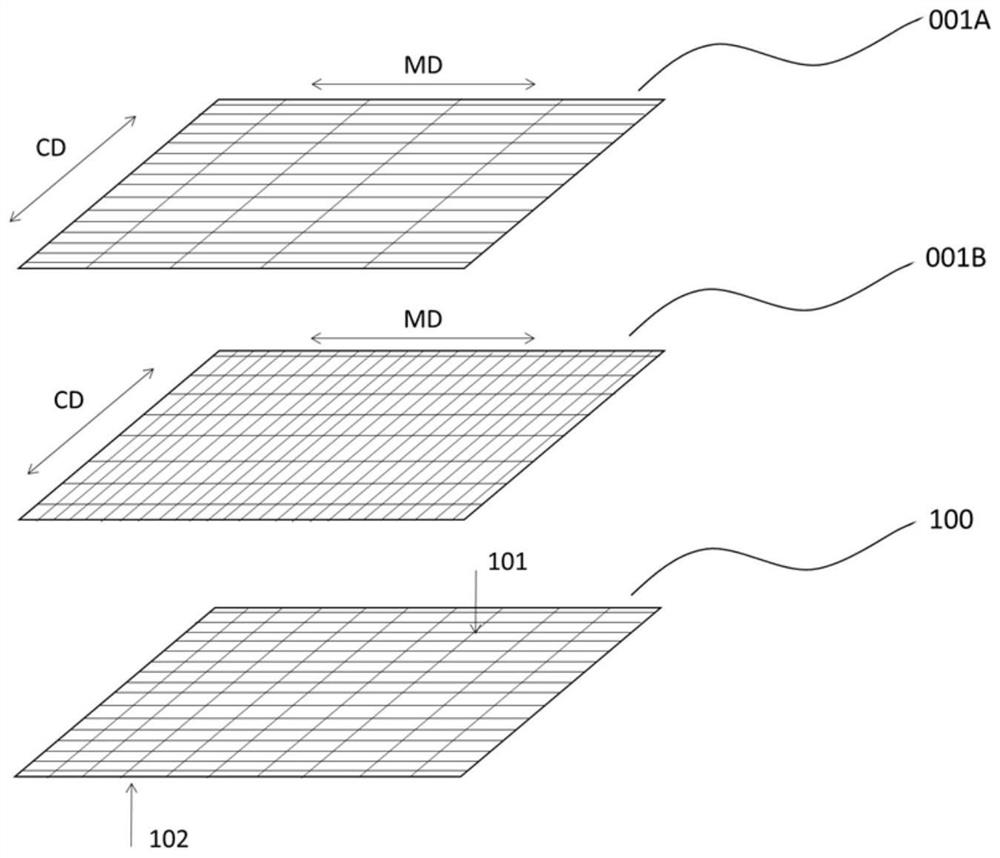

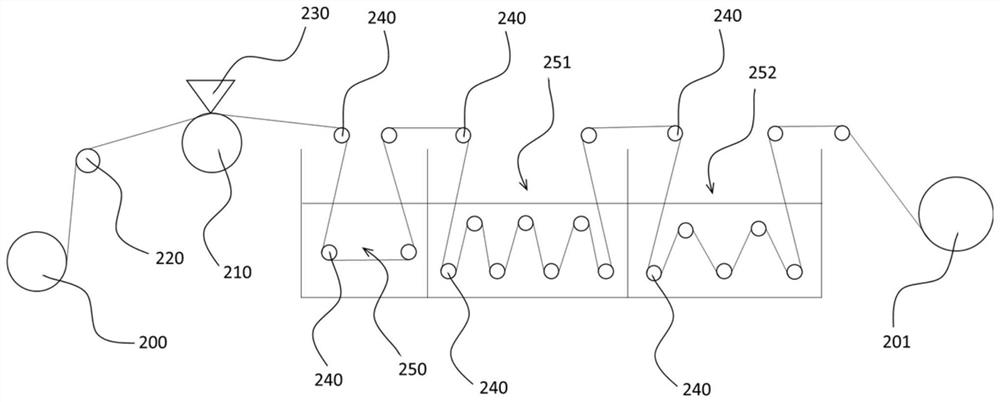

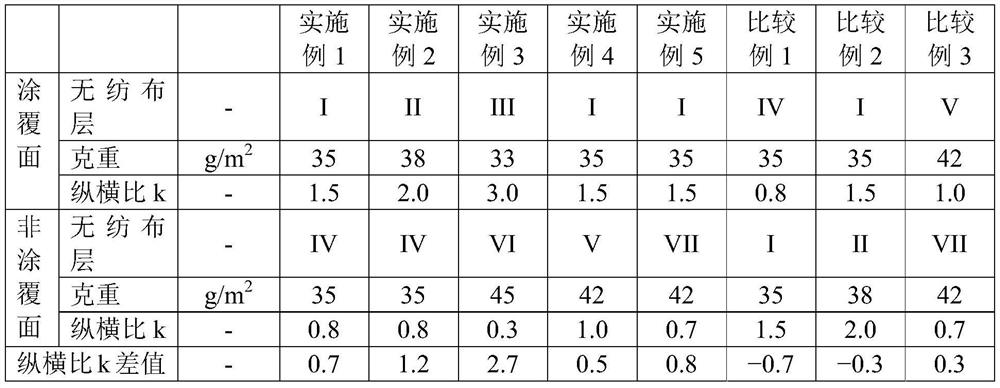

Semi-permeable membrane support material

ActiveCN109316974AImprove bindingSmall CD tensile strengthSemi-permeable membranesEngineeringUltimate tensile strength

The invention discloses a semi-permeable membrane support material. The semi-permeable membrane support material is a sheet-shaped material obtained by heating and pressurizing after laminating two layers of non-woven fabric with different aspect ratios k. A k value of the non-woven fabric layer adjacent to the coating surface side of the sheet-shaped material is greater than 1.5, and the k valueof the non-woven fabric layer adjacent to the non-coating surface side is less than 1.0. The support material does not generate crimping after hot-pressing while excellent performance of air permeability, tensile strength, no fluff and the like is guaranteed, after the coating surface thereof is coated with a polymer membrane at the same time, a crimping phenomenon does not occur, and a situationadverse to processing is effectively avoided from occurring in a production process.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

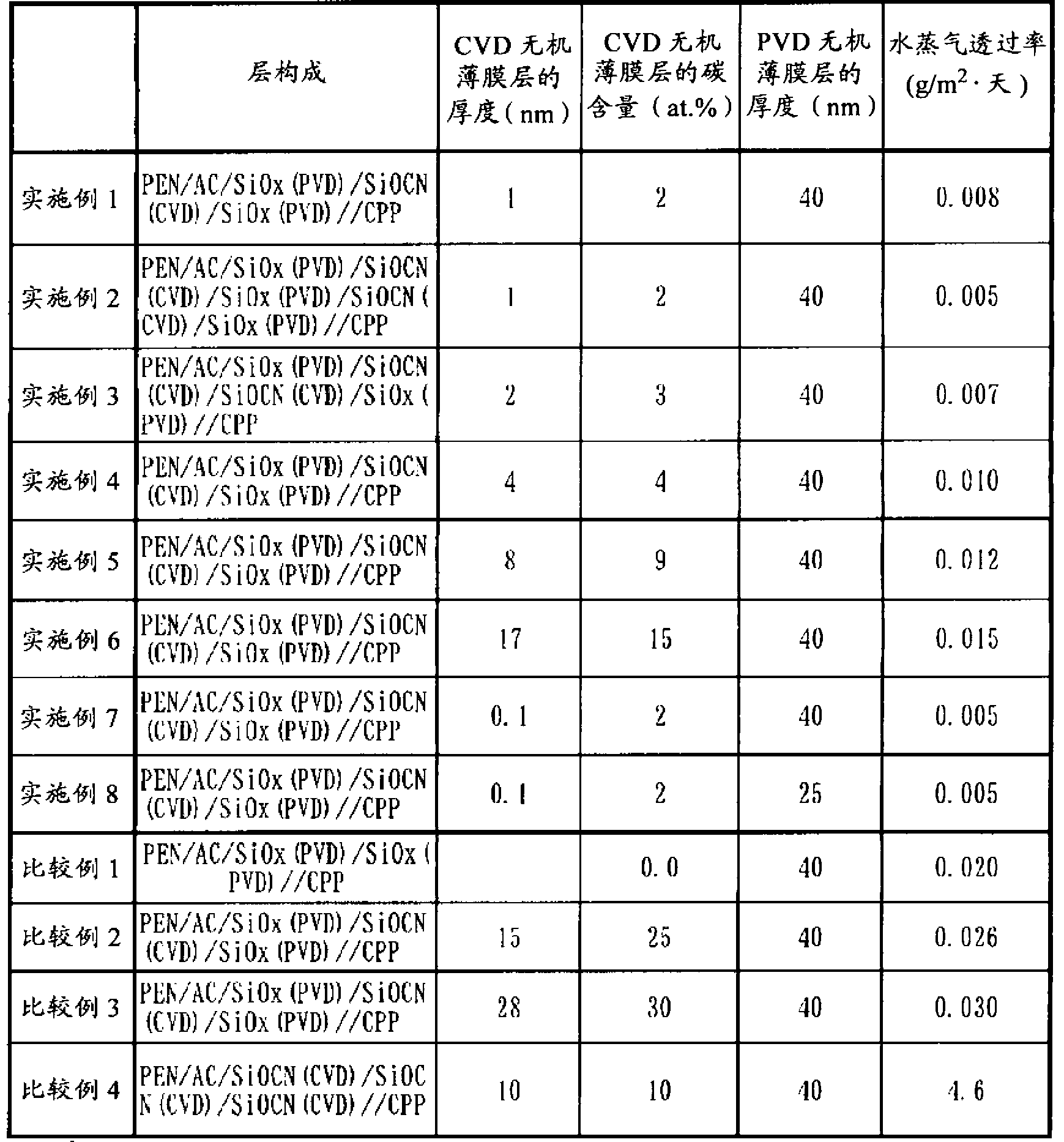

Gas-barrier laminate film

InactiveCN103189202AHigh bonding strengthNo curlSynthetic resin layered productsVacuum evaporation coatingAdhesion strengthMaterials science

Owner:MITSUBISHI PLASTICS INC

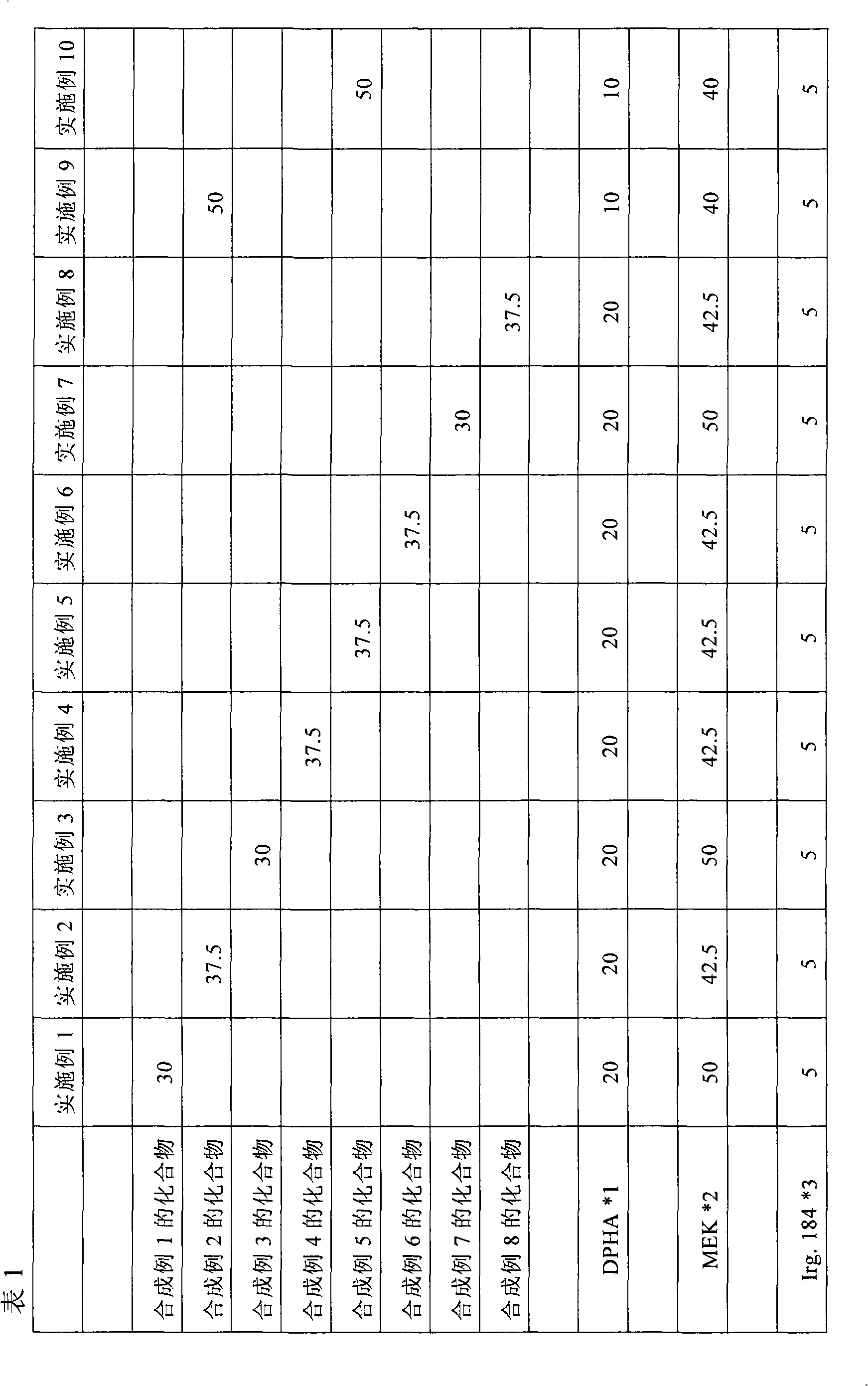

Resin composition

The present invention provides a resin composition which has low shrinkage ratio in solidifying and can obtain cured film with high hardness and no easy generation of crimp or crack, and a protecting coating using the resin composition. The resin composition comprises carbamate(methyl)acrylate obtained through the reaction between glycerin(methyl)acrylate (a) and alicyclic polyisocyanate compound, or carbamate(methyl)acrylate obtained through the reaction between glycerin(methyl)acrylate (a) and (methyl)acrylate (a-1) except for (a) and polyisocyanate compound (b), (methyl)acrylate and photopolymerization initiator.

Owner:NIPPON KAYAKU CO LTD

Composite thin film for medical wrist strap and preparation technology of composite thin film

ActiveCN104175672AImprove adhesionNo curlLamination ancillary operationsSynthetic resin layered productsComposite filmMicrometer

The invention discloses a composite thin film for a medical wrist strap. The composite thin film is characterized by comprising a protection layer, a composite adhesive layer and an identification layer in sequence, wherein the protection layer refers to an EVA (Ethylene-Vinyl Acetate) thin film, the composite adhesive in the composite adhesive layer refers to polyether composite adhesive, and the identification layer refers to thermosensitive paper with a layer of thermosensitive coating with thickness of 1-5 micrometers. The protection layer in the composite thin film is soft in texture and does not scratch any patient; the composite adhesive in the adhesive protection layer and the identification layer of the composite thin film is high in adhesion strength, the phenomena of cracking, curling and the like do not occur, and the preparation technology is simple in process, low in requirements for technological conditions, low in investment cost and suitable to large-scale production.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Flexible metal clad laminate

ActiveCN104245306AImprove welding resistanceNo curlSynthetic resin layered productsMetal layered productsMoisture absorptionHeat treated

Provided is a flexible metal clad laminate, in which a metal layer is formed on one surface or both surfaces of an insulating layer constituted by a plurality of polyimide-based resin layers, and the polyimide-based resin layers that are in contact with the metal layer have Storage Modulus of 1 X 108 Pa or more at 300 DEG C and 1 X 108 Pa or less at 350 DEG C, and has characteristics in that curling of a product does not occur, adhesive strength with a metal clad is favorable, a dimensional change after heat treatment is small, and particularly solder resistance after moisture absorption is excellent.

Owner:NEXFLEX CO LTD

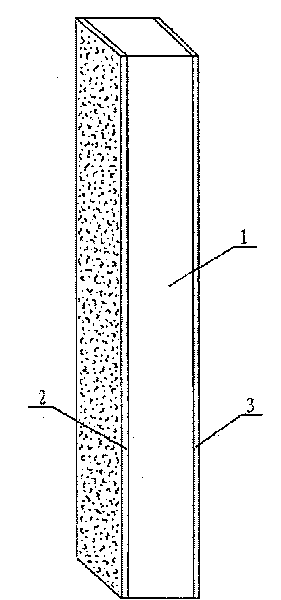

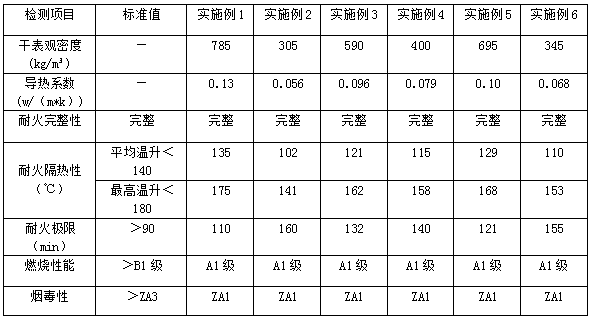

Preparation method of inorganic fireproof door core material

ActiveCN105481461ARapid hardening early strengthImprove fire performanceCeramicwareFoaming agentSulfate

The invention discloses a preparation method of an inorganic fireproof door core material, and belongs to the technical field of fireproof materials. The preparation method of the inorganic fireproof door core material is characterized by comprising the following steps that 1, cement slurry is prepared, wherein 1 part of sulfate aluminum cement, 0.002-0.01 part of water reducing agent, 0.002-0.01 part of basalt fiber and 0.3-0.4 part of water are mixed to be uniform for use; 2, a foam body is prepared, wherein a foaming agent is diluted, and the foam body is prepared; 3, the foam prepared in the second step and the cement slurry prepared in the first step are mixed according to the proportion of 2-6 mL / g, stirring is conducted to be uniform, the obtained mixture is poured into a mold, standard curing is conducted for 24 h, demolding is conducted, and then natural curing or standard curing is conducted for 7-28 days, and the inorganic fireproof door core material is obtained. When the inorganic fireproof door core material is subjected to a flame, dripping matter does not exist on the surface, the phenomena of curling and melting do not exist, and the inorganic fireproof door core material has the advantages of being good in use property and fireproof property and environmentally friendly.

Owner:JIAHUA SPECIAL CEMENT

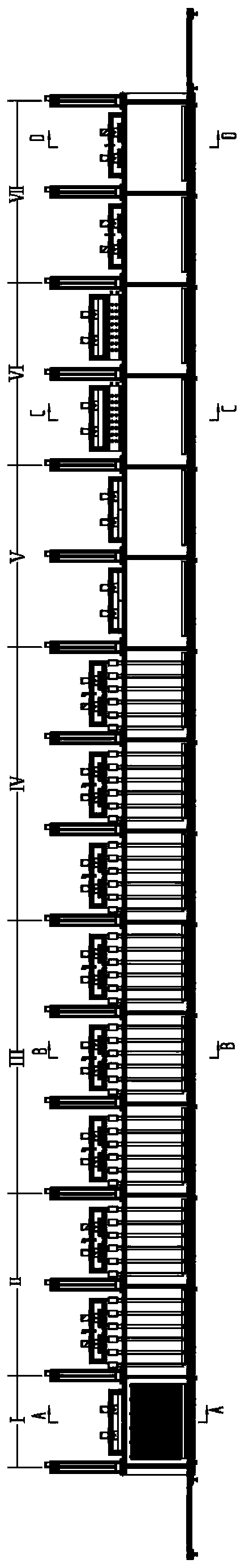

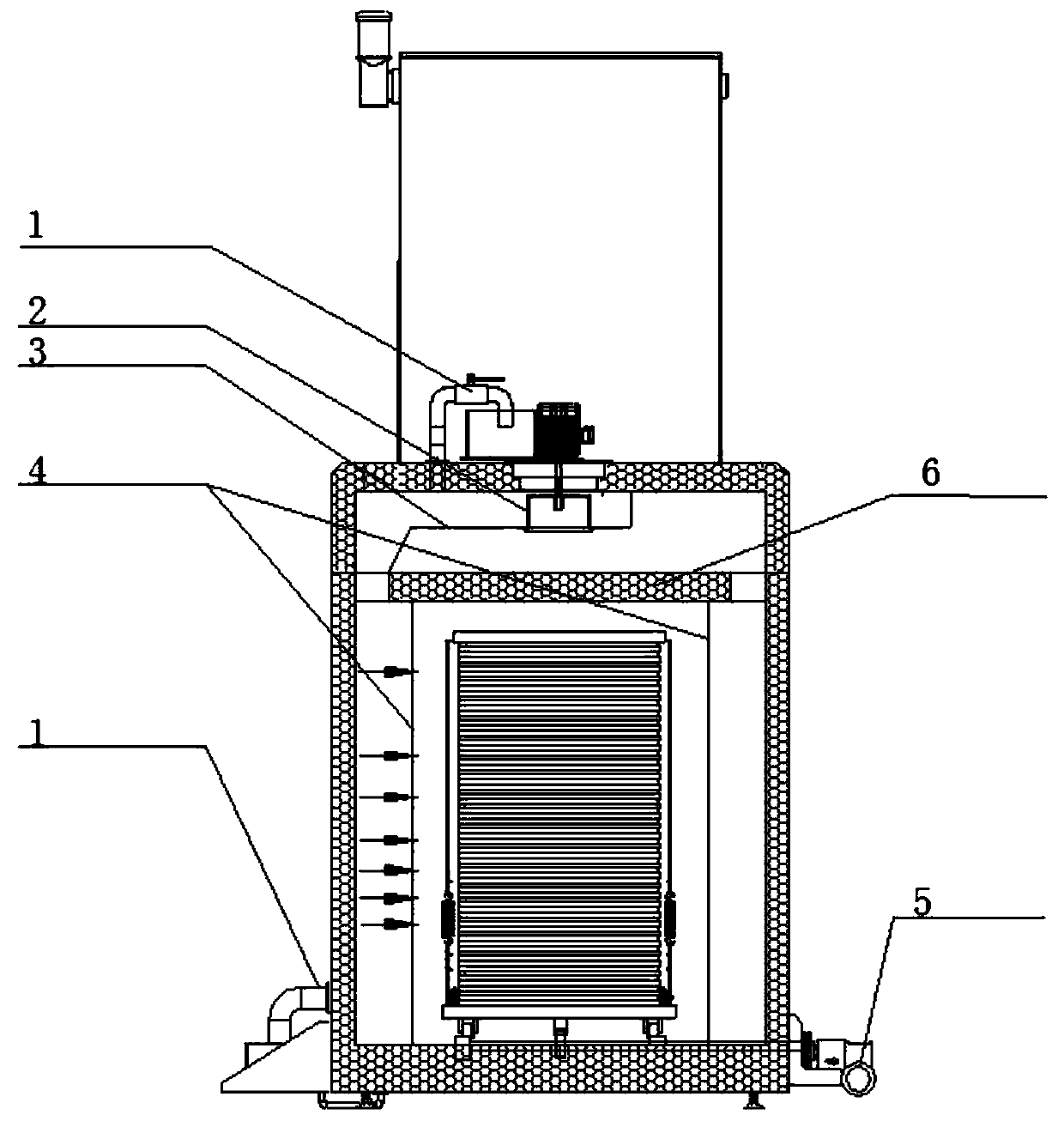

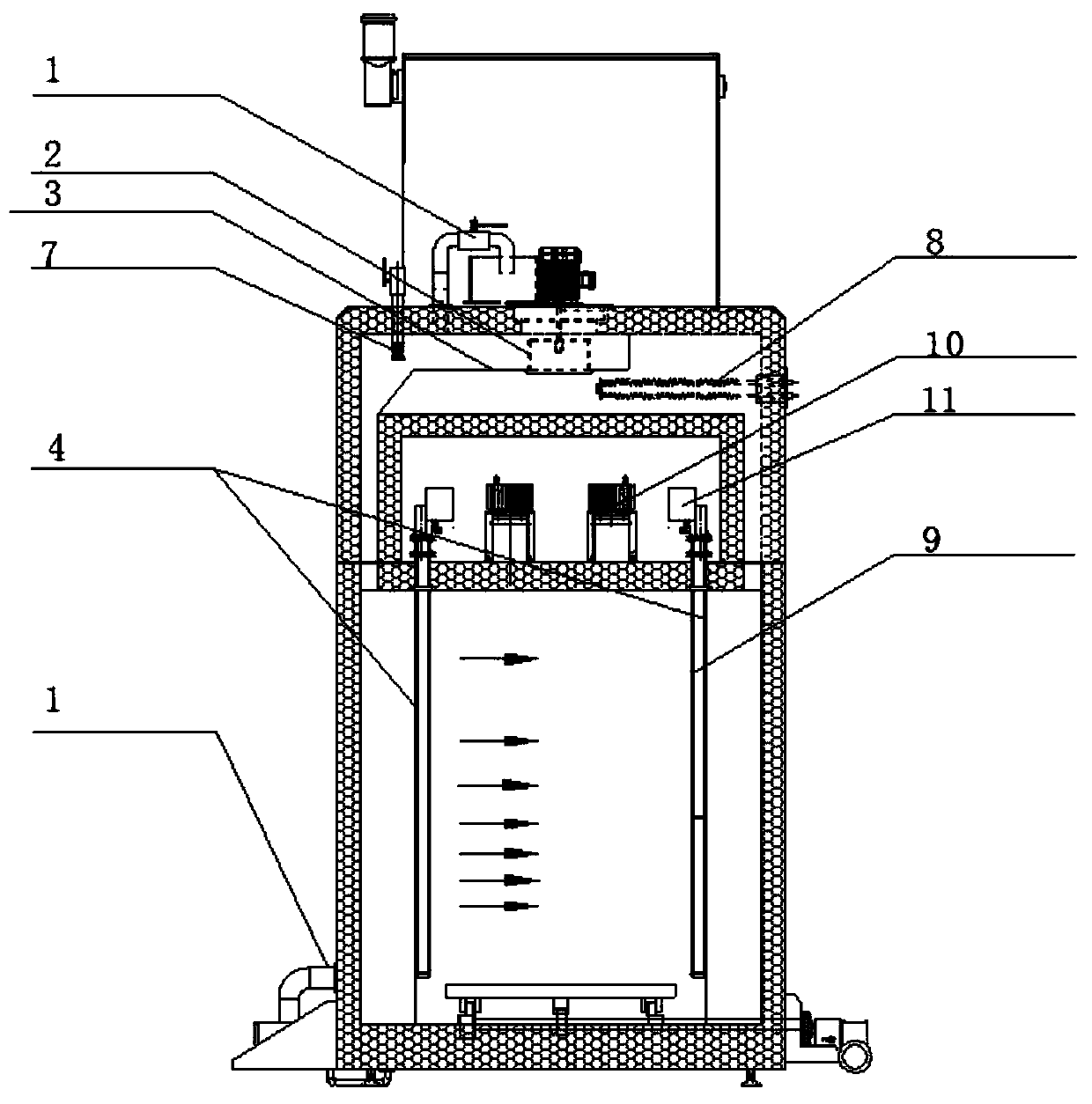

Continuous wood modification heat treatment process and system

ActiveCN110877391AReduce defects such as cracking and deformationImprove pass rateRadiation/waves wood treatmentPressure wood treatmentCarbonizationProcess engineering

The invention provides a continuous wood modification heat treatment process. The process comprises the following steps: stacking initial wood blanks on a trolley at intervals, applying pressure to the tops of the initial wood blanks to enable all the positions of the initial wood blanks to be stressed evenly and kept flat, and sequentially performing the following treatment steps of preheating treatment, heating treatment, drying treatment, carbonization treatment, slow cooling treatment, rapid cooling treatment and rewetting treatment. Each treatment step comprises a plurality of kilns, thekilns in the steps S2-S4 are arranged in an equal-gradient heating mode, and the kilns in the steps S5-S7 are arranged in an equal-gradient cooling mode. The invention provides a continuous wood modification heat treatment system. The continuous wood heat treatment system comprises a plurality of kilns, a trolley, a transmission device for driving the trolley to move, and a microwave and other heat source heating device. The process and the system provided by the invention provide high-quality wood which is low in energy consumption, short in production period, uniform and consistent in carbonization degree of the interior and the surface, high in strength and stable in performance, and the system is low in production cost and suitable for mass production.

Owner:湖南威达尔木业科技有限公司

Method for preparing anode foil of aluminum electrolytic capacitor by means of cold rolling machine

ActiveCN113458143AIncrease capacityLarge specific surface areaMetal rolling arrangementsMetallurgyWater boil

The invention discloses a method for preparing anode foil of an aluminum electrolytic capacitor by means of a cold rolling machine. The method comprises the following steps that 1, a solvent, a binder and a dispersing agent are added into an aluminum raw material and then are stirred; 2, the surface of an aluminum foil substrate is coated with aluminum raw material slurry and then is dried; 3, the dried and coated aluminum foil substrate is rolled; 4, a anode foil precursor is sintered; 5, water boiling treatment is performed on the sintered anode foil precursor; and 6, formation treatment is performed on the anode foil precursor after water boiling to obtain the anode foil of the aluminum electrolytic capacitor. The thickness of the powder layer in the anode foil of the aluminum electrolytic capacitor is controlled by introducing a cold rolling method, the problem that the thickness of a sintered film is not uniform after the aluminum foil substrate is coated is solved, the porosity of the sintered film on the surface of the aluminum foil substrate is adjusted through rolling, an oxide film with good quality is obtained in the later formation process, thus the capacitance of the anode foil of the aluminum electrolytic capacitor is improved, and the anode foil of the aluminum electrolytic capacitor, which can be used in a medium-high voltage environment, is obtained.

Owner:西安稀有金属材料研究院有限公司

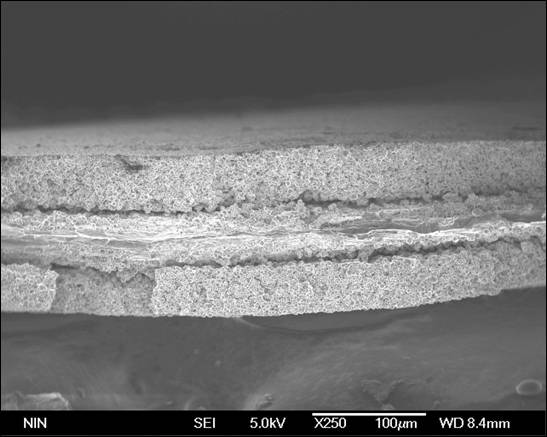

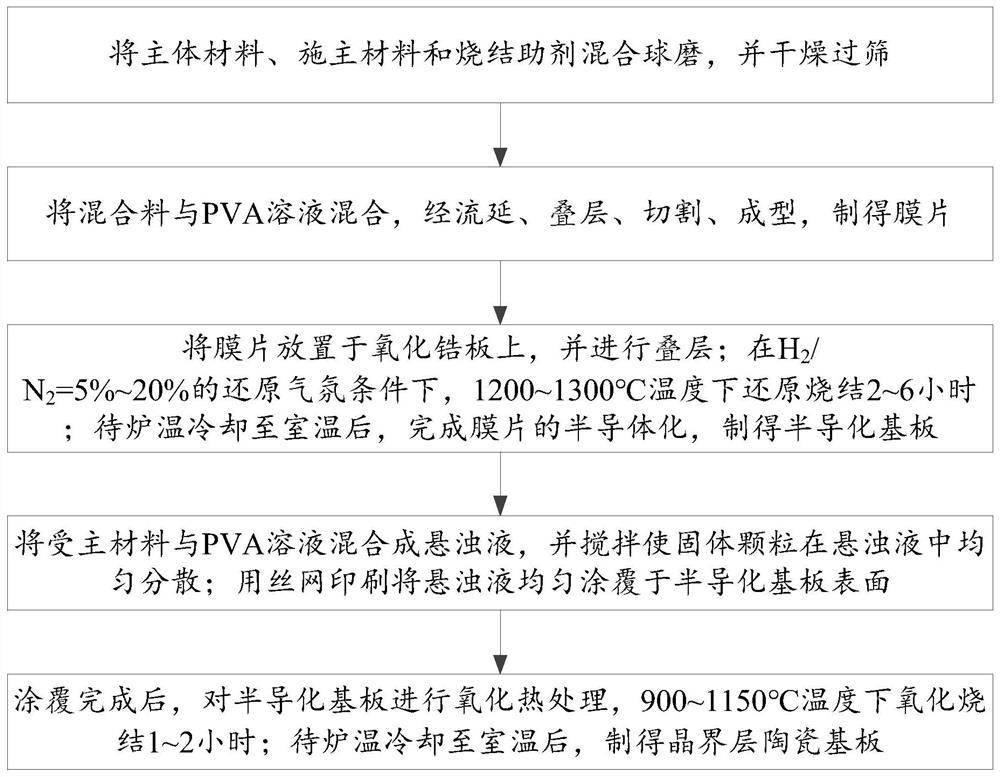

High-dielectric grain boundary layer ceramic material and preparation method of grain boundary layer ceramic substrate

ActiveCN112811901AReduced sintering temperatureVolatile fastStrontium titanateDielectric permittivity

The invention discloses a high-dielectric grain boundary layer ceramic material and a preparation method of a grain boundary layer ceramic substrate. The ceramic material comprises a main body material strontium titanate, a donor materials La2O3 and Nb2O5, a sintering aid SiO2 and Li2CO3, and an acceptor material which is one or more of Bi2O3, CuO and ZnO; the sintering aid is used for reducing the sintering temperature of the ceramic and promoting crystal grain development; and the acceptor material is used as a grain boundary insulation coating material for oxidation sintering. Based on the ceramic material, the preparation of the grain boundary layer ceramic substrate is completed through secondary sintering, namely reduction semiconductor sintering and oxidation grain boundary layer insulation sintering. The ceramic substrate is prepared by doping the sintering aid into the ceramic material and adopting a secondary sintering mode, so that on one hand, the energy is saved, and on the other hand, the larger particle size can be obtained at a lower sintering temperature, and the dielectric constant is favorably improved; and meanwhile, in the grain boundary insulation process, ZnO is added, and the insulation resistance and the insulation strength of the product are improved.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH +2

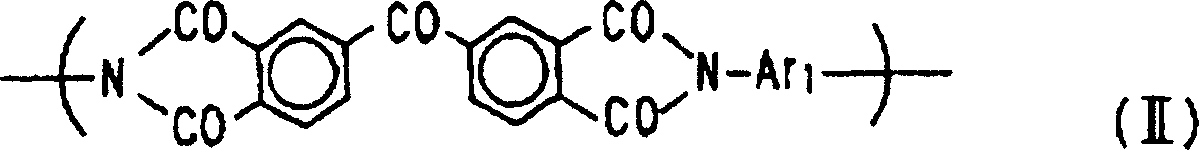

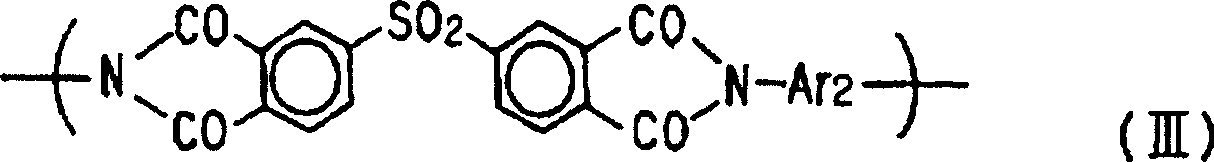

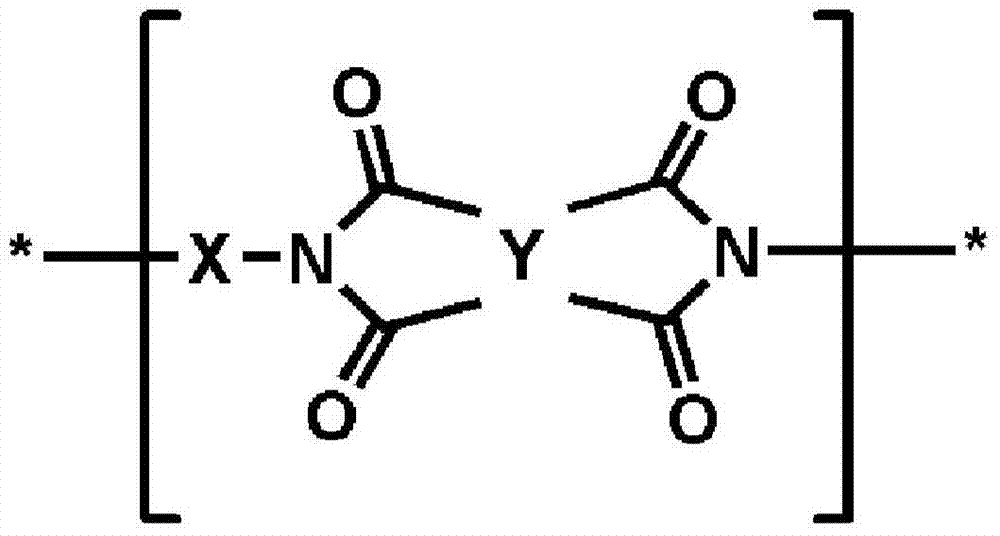

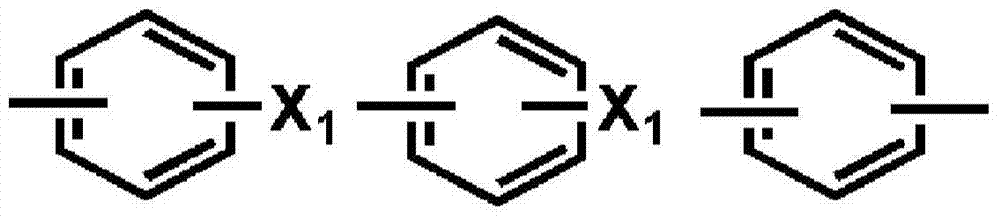

Flexible copper-polyimide laminate and manufacturing method thereof

InactiveCN101010191ANo curlGood dimensional stabilitySynthetic resin layered productsPrinted circuit aspectsFolding endurancePolymer science

The present invention provides a flexible copper-polyimide laminate including a linear random block polyimide layer formed on the at least one side thereof, the linear random block polyimide layer comprising 0.25 to 90.25 mol.% of a repeating unit l represented by the formula 1, 0.25 to 90.25 mol.% of a repeating unit m represented by the formula 2, 0.25 to 90.25 mol.% of a repeating unit n represented by the formula 3, and 0.25 to 90.25 mol.% of a repeating unit o represented by the formula 4. The flexible copper-polyimide laminate having a polyimide layer is free from curls and excellent in dimensional stability, tensile property, folding endurance and resistance to flexural fatigue with low moisture content.

Owner:KOLON IND INC

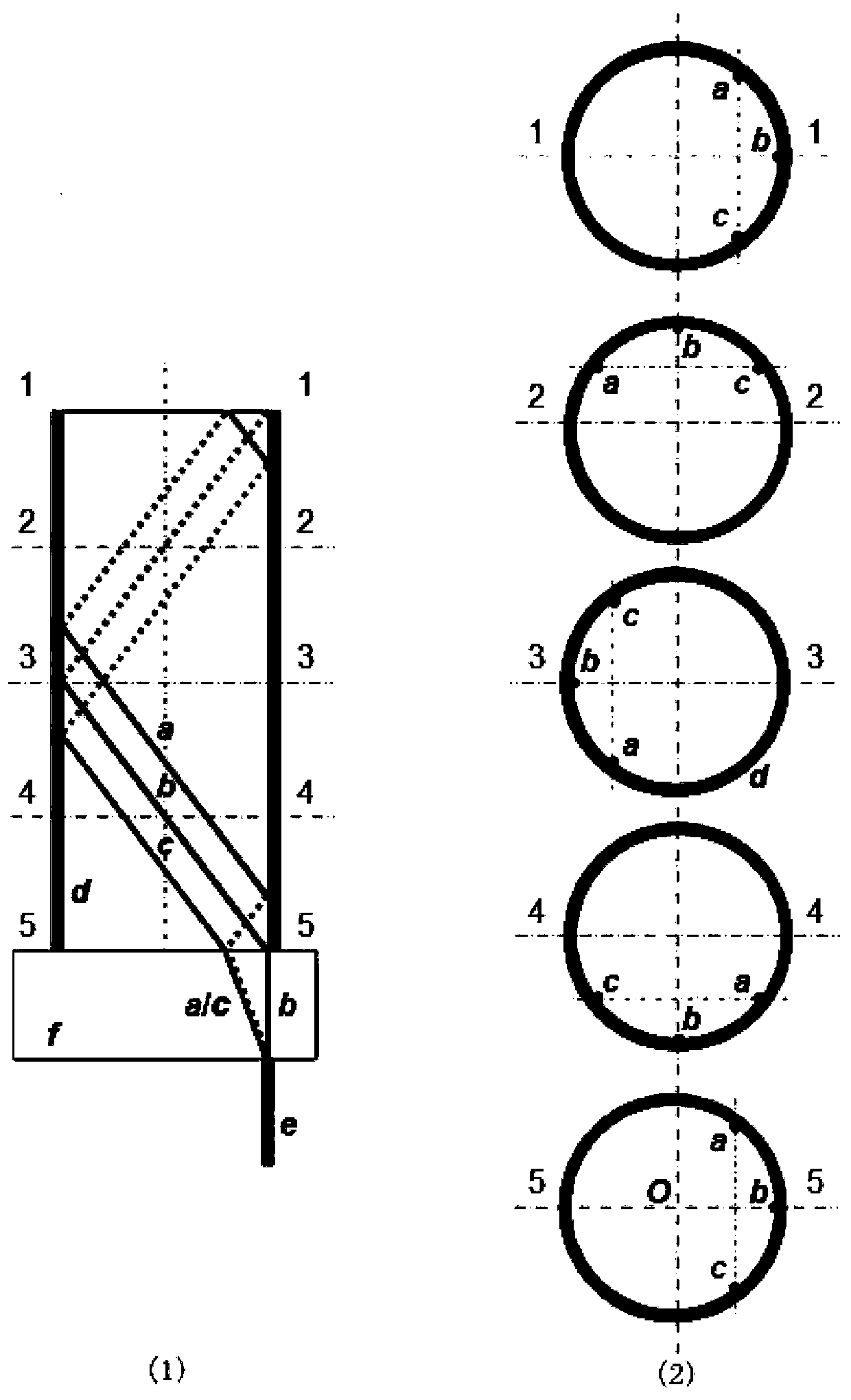

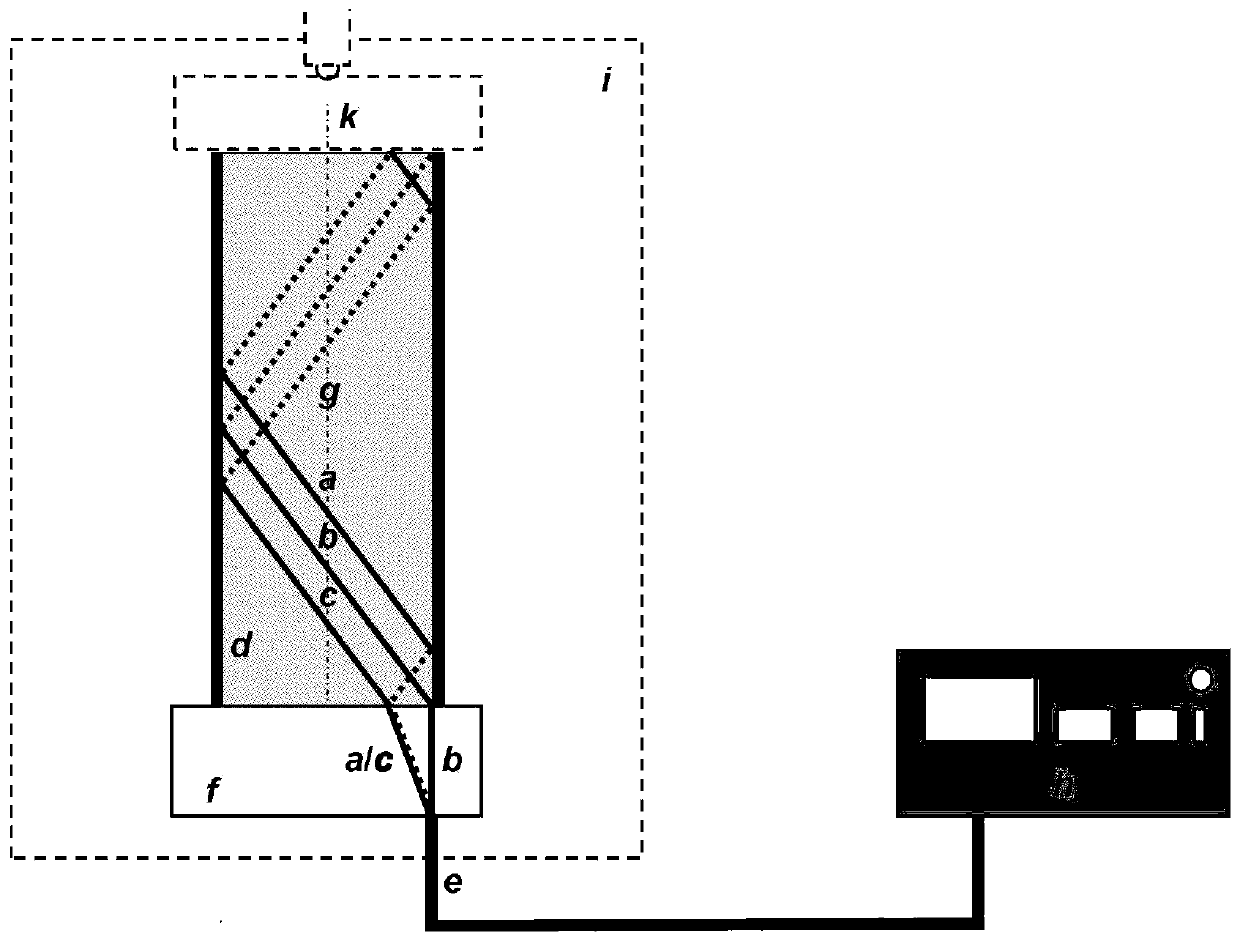

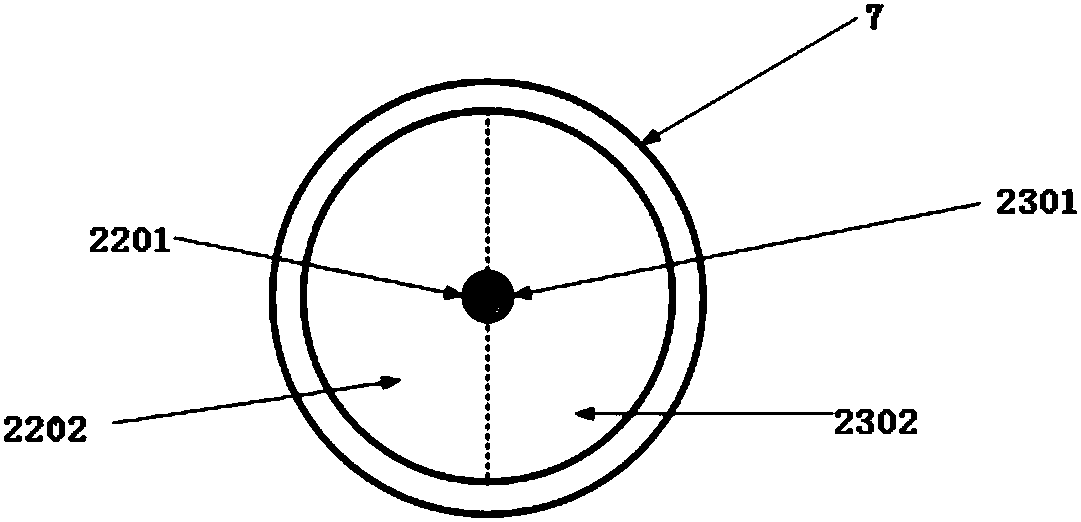

Moisture content measuring system based on parallel spiral telescopic time domain reflection probe

ActiveCN111122619ASolve the control puzzleImprove consistencyMaterial analysis using wave/particle radiationConvertersMoisture

The invention discloses a moisture content measuring system based on a parallel spiral telescopic time domain reflection probe. The system comprises a time domain reflection probe, an insulation converter, a flexible cylinder and a time domain reflection signal generation collector. The time domain reflection probe comprises a positive electrode probe and at least one negative electrode probe. Thepositive electrode probe and the negative electrode probe are spirally arranged on the inner side wall of the flexible cylinder in parallel. The arranged time domain reflection probe at least accounts for 90% of the height of the flexible cylinder, and the positive electrode probe and the negative electrode probe penetrate through the insulation converter and are connected with the time domain reflection signal generator through coaxial cables. The scheme can be used for nondestructive real-time measurement of the moisture content of frozen soil, natural gas hydrate-containing soil, sandy soil, silt, clay, loess, special soil, rock and other samples in a triaxial shear test. The system not only guarantees the measurement effect of the moisture content of the sample, but also avoids the influence on the triaxial shear test data of the sample, and has a wide application prospect in the triaxial shear test of unsaturated soil and natural gas hydrate-containing soil samples.

Owner:QINGDAO INST OF MARINE GEOLOGY

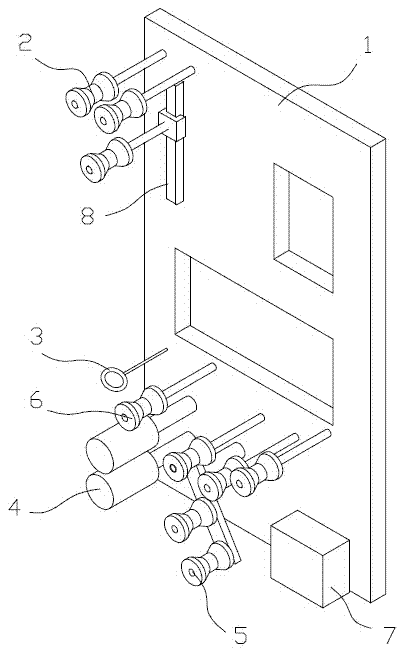

Zipper feeding device

Owner:江阴市汇通包装机械有限公司

Durable fireproof material

The invention discloses a durable fireproof material. The fireproof material components include: 4-8 parts by mass of dichloromethane, 10-13 parts by mass of sodium lauryl sulfate, resin, 9-13 parts by mass of sodium silicate, 3-8 parts by mass of lithium dihydrogen phosphate airgel. The material of the invention has good aging resistance and weather resistance.

Owner:蒲雪萍

Composite pnenolic aldehyde foam heat-insulating board for building and forming method thereof

InactiveCN101148515BImprove brittlenessHigh compressive strengthClimate change adaptationSynthetic resin layered productsEpoxyFire retardant

The heat insulating composite foamed phenolic plate for building includes one heat insulating foamed phenolic plate produced with foamed phenolic resin 100 weight portions, polyurethane 10-25 weight portions, epoxy resin 0.5-5 weight portions, fire retardant 10-20 weight portions, surfactant 0.5-2 weight portions, polyglycol 5-15 weight portions, glass fiber 0.5-2 weight portions, foam homogenizing agent 5-10 weight portions, foaming agent 5-10 weight portions and acid curing agent 5-10 weight portions; and one sprayed layer in the surface of the heat insulating foamed phenolic plate and comprising cement 100-150 weight portions, water 80-100 weight portions, emulsion of acrylate copolymer 90-110 weight portions, hydroxyethyl cellulose 3-6 weight portions and defoaming agent 0.5-2 weight portions. The heat insulating composite foamed phenolic plate has high toughness, less pulverizing, high strength and good construction performance.

Owner:郎云峰

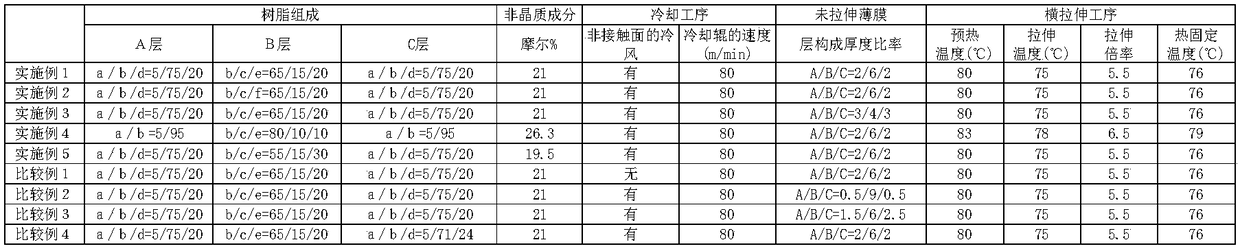

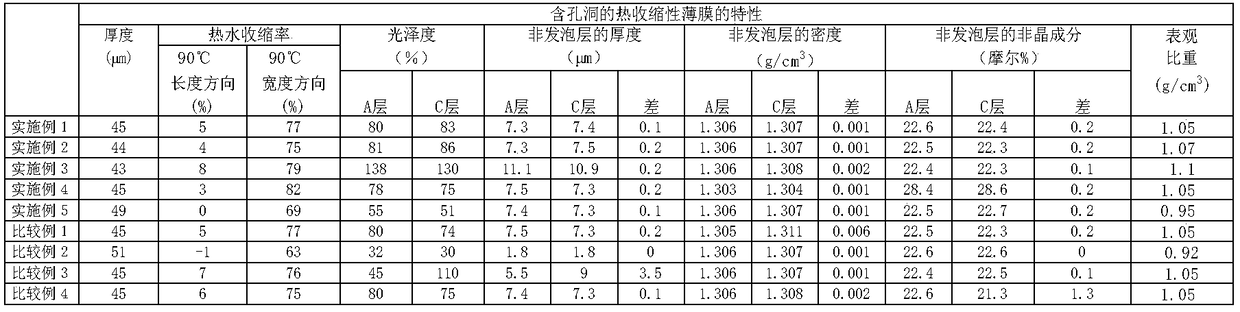

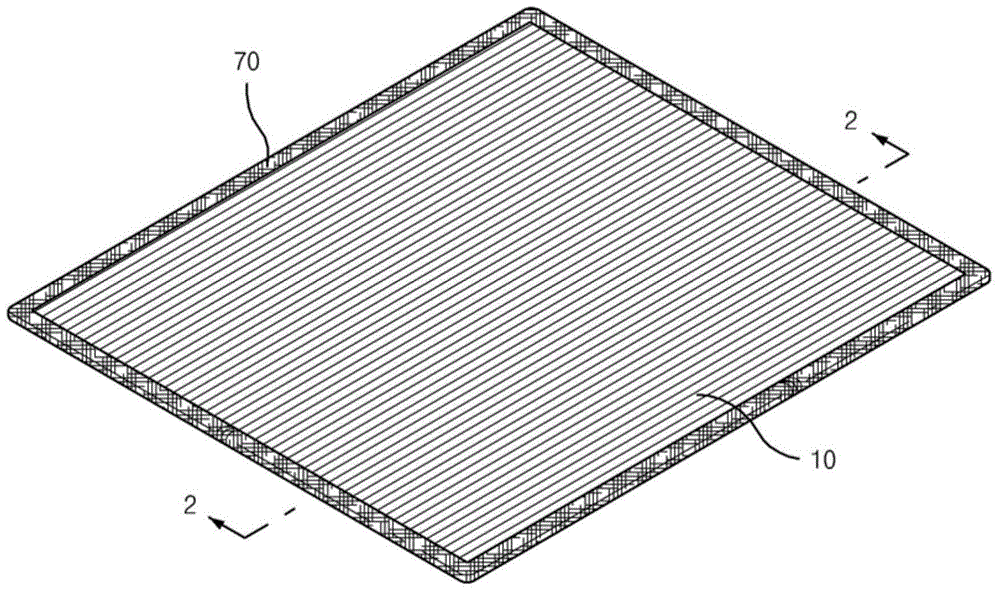

Void-containing heat-shrinkable polyester-based film

ActiveCN108883570AImprove shrinkageGood shrinkage processabilityFlexible coversWrappersPolyesterPolymer science

To provide a void-containing heat-shrinkable polyester-based film which, even when produced at a heightened productivity, can have satisfactory shrink finishing and printability. A void-containing heat-shrinkable polyester-based film that has a multilayer structure comprising a foamed layer and non-foamed layers disposed as outside layers respectively on both sides of the foamed layer, wherein thetwo outside films are equal in thickness, density, and the number of moles of an amorphous component. Due to this, the polyester-based film has specific heat shrinkability and a specific gloss.

Owner:TOYOBO CO LTD

Cleaning wiper for glass

InactiveCN104023612AEase frictionEasy to cleanCarpet cleanersKitchenware cleanersTarget surfaceEngineering

The present invention relates to a cleaning wiper for glass, with which moisture, stains, water marks, hand stains, grease, and the like on glass products (hereinafter referred to as cleaning target surfaces) such as liquid crystal and glass can be wiped with convenience.

Owner:CLEMBON

A kind of preparation method of double-sided copper foil adhesive-free substrate

The invention discloses a method for preparing a double-sided copper foil adhesive-free base material, especially for preparing a condensation thermoplastic double-sided copper foil adhesive-free base material, which is prepared by anti-ion migration additive compound on the roughened surface of the copper foil. Treatment and coating, and then through the reaction of thermoplastic prepolymer resin and thermosetting pre-main resin, compound heating, pressurization, and imidization at 300 ° C for 30 minutes to obtain ultra-thin double-sided copper insulating layer Double-sided copper foil adhesive-free substrate. The method of the invention has simple process and low cost, and the volume resistivity of the prepared insulating layer is 1×1014Ω·cm, which can meet the requirements of multilayer flexible circuit board products.

Owner:SHENZHEN DANBOND TECH

A high-barrier high-temperature-resistant packaging film that does not roll after sterilization

ActiveCN106739340BImprove barrier propertiesPuncture resistantSynthetic resin layered productsDomestic containersPuncture resistancePolyamide

The invention discloses a high-barrier high-temperature-resistant packaging film capable of avoiding curling after sterilization. The packaging film comprises an upper film and a lower film, wherein physical crosslinking treatment is performed on the upper film to enable the melting point to reach 180-190 DEG C; the upper film comprises a CPP (chlorinated polypropylene) layer, and a first bonding layer, a first PA (polyamide) layer, an ink layer, a second bonding layer and a PE (polyethylene) layer which are sequentially arranged on the lower surface of the CPP layer; the lower film comprises a CPP layer, a third bonding layer and a nine-layer coextrusion layer; and in a heat sealing process of the upper film and the lower film, the PE layer of the upper film and the nine-layer coextrusion layer of the lower film are combined through heat sealing. Through the physical crosslinking treatment on the surface of the upper film, the melting point of the upper film can reach 180 DEG C or so; in the current sterilization and disinfection environment, the smoothness of the film can be kept, and the film can not curl; since the nine-layer coextrusion layer is used and multiple PE layers are arranged in the nine-layer coextrusion layer, the controllable thickness of each layer is realized on the premise of keeping an overlaying function, thereby realizing controllable cost; and since an EVOH (ethylene vinyl alcohol) layer and a PA layer are arranged, the EVOH layer has very strong barrier property, and the PA layer has puncture resistance.

Owner:浙江明凯新材料股份有限公司

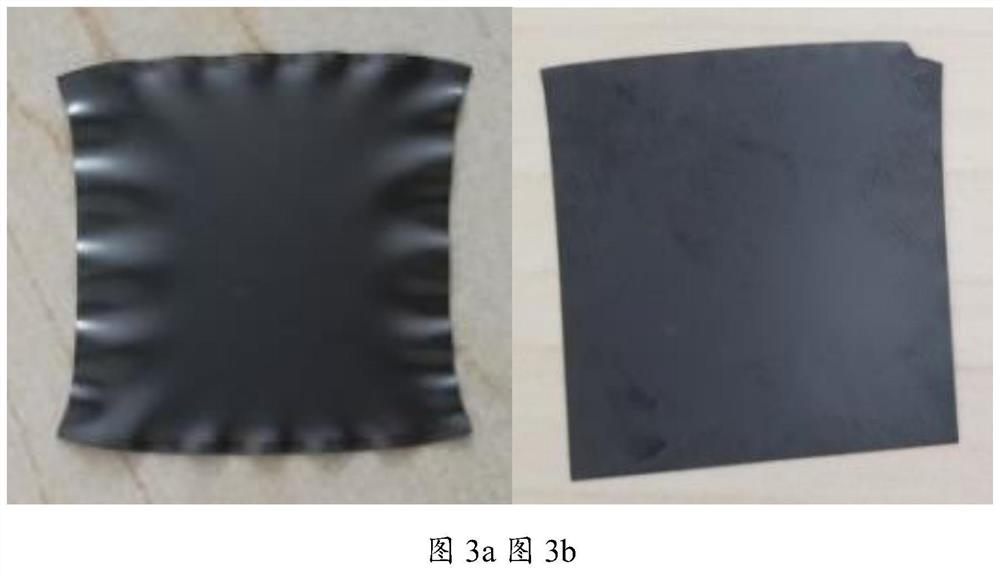

Method for improving single-face TPU compound fabric flatness

ActiveCN105088597ANo curlFlatness does not occurLamination ancillary operationsLaminationEngineeringMoisture

The invention provides a method for improving the single-face TPU compound fabric flatness for the technical problems that a sample wafer rolls up after being be cut and sampled, and is easy to blend and the next working procedure is not easy to carry out. The technical scheme adopted in the invention is as follows: the method for improving the single-face TPU compound fabric flatness is characterized in that following steps are added between a priming step and a TPU laminating step in the production process of a TPU compound fabric: step (1) coiling treatment; step (2) curing treatment; and step (3) TPU laminating pretreatment. By adopting the technical scheme, after the treatments such as curing and pre-humidification are adopted, a force generated when a coating fabric extends outside and droops after absorbing moisture and shrinkage of a TPU film can form a balanced force, so that the TPU compound fabric can not generate coiling or irregular phenomena, the subsequent working procedures are easy to perform, and meanwhile, the fitting fastness and other performances of the TPU products can not be influenced.

Owner:CTA HI TECH TEXTILES

A kind of preparation method of inorganic fireproof door core material

ActiveCN105481461BRapid hardening early strengthNo melting phenomenonCeramicwareFoaming agentSulfate

The invention discloses a preparation method of an inorganic fireproof door core material, and belongs to the technical field of fireproof materials. The preparation method of the inorganic fireproof door core material is characterized by comprising the following steps that 1, cement slurry is prepared, wherein 1 part of sulfate aluminum cement, 0.002-0.01 part of water reducing agent, 0.002-0.01 part of basalt fiber and 0.3-0.4 part of water are mixed to be uniform for use; 2, a foam body is prepared, wherein a foaming agent is diluted, and the foam body is prepared; 3, the foam prepared in the second step and the cement slurry prepared in the first step are mixed according to the proportion of 2-6 mL / g, stirring is conducted to be uniform, the obtained mixture is poured into a mold, standard curing is conducted for 24 h, demolding is conducted, and then natural curing or standard curing is conducted for 7-28 days, and the inorganic fireproof door core material is obtained. When the inorganic fireproof door core material is subjected to a flame, dripping matter does not exist on the surface, the phenomena of curling and melting do not exist, and the inorganic fireproof door core material has the advantages of being good in use property and fireproof property and environmentally friendly.

Owner:JIAHUA SPECIAL CEMENT

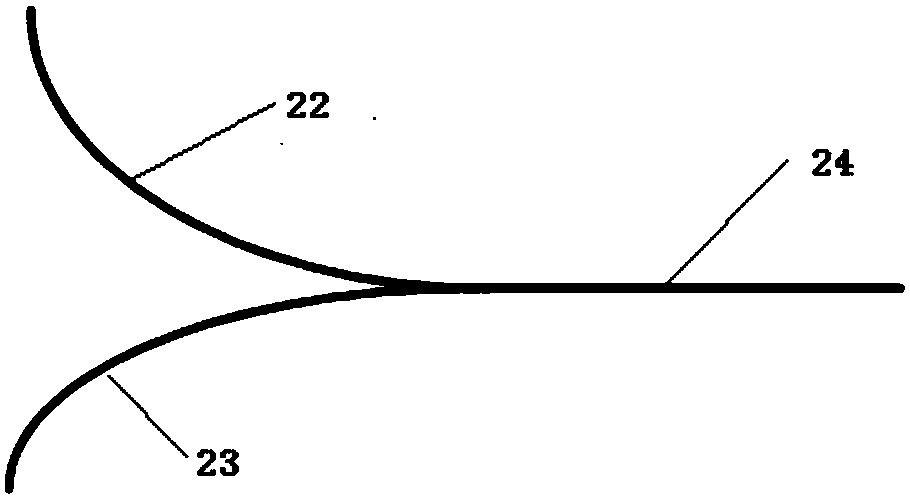

Device and method used for manufacturing high precision low loss optical fiber Y-branch splitter

The invention relates to a device and method used for manufacturing a high precision low loss optical fiber Y-branch splitter. The device is characterized by comprising a computer, a data connecting line, a program control high precision movable platform, a high strength connecting line, a pulley, a fixing frame, a quartz capillary tube, a heavy object clamp, a combustion nozzle, a nozzle supporting rod, a support base, a support rod, a support lower clamp, a support upper clamp, a Y-shaped rubber pipe, a first mass flow controller, a first mass flowmeter, an oxygen tank, a second mass flow controller, a second mass flowmeter and a hydrogen tank, the computer is connected with the program control high precision movable platform through the data connecting line, an optical fiber to be fusedis placed in the quartz capillary tube, and the program control high precision movable platform is connected with one end of the optical fiber to be fused placed in the quartz capillary pipe throughthe high strength connecting line, the pulley and the fixing frame in sequence. Fusing conditions of different optical fibers can be satisfied, Y-branch splitters with different coupling degrees can be manufactured, and the practicality difficulty is small.

Owner:JIANGSU STERLITE TONGGUANG FIBER

Cleaning agent of regenerated spinning polyester short fiber production raw material and preparation method thereof

InactiveCN101608148ALow impurity contentImprove cleanlinessInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsDodecylsulfonic acidTriethanolamine

The invention relates to a cleaning agent of regenerated spinning polyester short fiber production raw material and a preparation method thereof. The cleaning agent comprises the components in percentage by weight: 42-46 percent of calcium chloride, 4-9 percent of sodium hydroxide, 4-5.8 percent of trimeric sodium phosphate, 4-5 percent of sodium carbonate, 5.5-6 percent of liquid soluble silicate, 1.5-2 percent of trolamine, 0.5-1 percent of dodecyl sodium sulfate and 30-35 percent of water. The cleaning agent has high density, low use temperature, strong detergency, little damage to the surface of the raw material, high cleanliness of the cleaned raw material, simple preparation method and low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

Preparation method of anti-curling and easy-to-strip release paper for leather

ActiveCN106320085AModerate peel strengthGood release effectWater-repelling agents additionNon-macromolecular organic additionUltrasonic dispersionMoisture

The invention discloses a preparation method of anti-curling and easy-to-strip release paper for leather and belongs to the technical field of preparation of release paper. According to the method, firstly, fresh leaves of pittosporum tobira are made into granules and then mixed with a glutaraldehyde water solution for fixation, the mixture and n-hexane are stirred and heated and then are evaporated to be dried, a pittosporum tobira leaf wax concentrated solution is obtained and subjected to pulping, grinding and ultrasonic dispersion treatment with populus euphratica wood-pulp boards and deionized water, modified wood pulp dispersion size is prepared and subjected to papermaking and squeezing treatment, dried modified paper is obtained, a coating liquid is prepared from polyvinyl alcohol as a main raw material, the modified paper is coated with the coating liquid, and the anti-curling and easy-to-strip release paper for leather can be obtained after the paper is dried and cooled. A preparation process is simple, the prepared release paper for leather is moderate in strength and good in release property and doesn't easily curl in the moisture environment or under the wet condition, and a prepared leather product has good surface gloss, touches well and has broad application space.

Owner:肇庆凯盛电子科技有限公司

A semi-permeable membrane support material

ActiveCN109316974BImprove bindingSmall CD tensile strengthSemi-permeable membranesNonwoven fabricUltimate tensile strength

The invention discloses a semi-permeable membrane support material, which is a sheet material obtained by laminating two layers of non-woven fabrics with different aspect ratio k and then subjected to heat and pressure treatment, and the non-woven fabric on the side of the sheet material near the coated surface The k value of the layer is greater than 1.5, and the k value of the nonwoven layer near the non-coated side is less than 1.0. While ensuring excellent air permeability, tensile strength, and lint-free properties, the support material will not curl after hot pressing. At the same time, after coating the polymer film on its coating surface, it will not curl, effectively avoiding Unfavorable conditions occur during the production process.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com