A kind of preparation method of inorganic fireproof door core material

A fireproof door core, inorganic technology, applied in the field of fireproof materials, can solve problems such as poor practical performance and poor environmental protection of fireproof door core materials, and achieve the effects of good fire resistance, high elastic modulus, and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

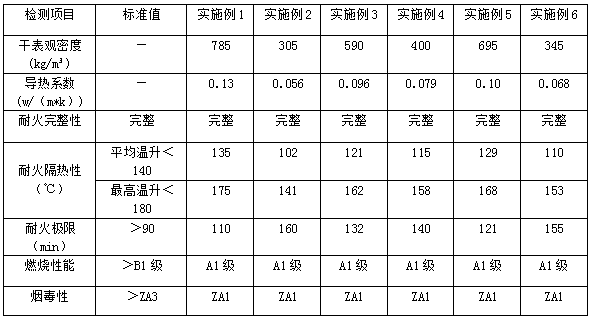

Examples

Embodiment 1

[0026] A preparation method of an inorganic fireproof door core material, comprising the following steps:

[0027] (1) Preparation of cement paste

[0028] Mix 1 part of sulphoaluminate cement, 0.002 part of water reducer, 0.002 part of basalt fiber, and 0.3 part of water and set aside;

[0029] (2) Foam preparation

[0030] After diluting the blowing agent, it is made into a foam;

[0031] (3) Mix the foam prepared in step (2) with the cement slurry prepared in step (1) at a ratio of 2mL / g, mix well and pour into the mold, demould after standard curing for 24 hours, and then carry out natural curing or standard curing 7 days will do.

Embodiment 2

[0033] A preparation method of an inorganic fireproof door core material, comprising the following steps:

[0034] (1) Preparation of cement paste

[0035] Mix 1 part of sulphoaluminate cement, 0.01 part of water reducer, 0.01 part of basalt fiber, and 0.4 part of water and set aside;

[0036] (2) Foam preparation

[0037] After diluting the blowing agent, it is made into a foam;

[0038] (3) Mix the foam prepared in step (2) with the cement slurry prepared in step (1) at a ratio of 6mL / g, mix well and pour into the mold, demould after standard curing for 24 hours, and then carry out natural curing or standard curing 28 days is enough.

[0039] In the step (1) of this embodiment, the water-reducing agent is a polycarboxylate water-reducer, its pH is 6.5-8.0, and the water-reducing rate is 20-40%. The water-reducing efficiency of the polycarboxylate water-reducer is high. The compatibility of aluminate cement is good; the length of basalt fiber in this implementation is 3mm...

Embodiment 3

[0041] A preparation method of an inorganic fireproof door core material, comprising the following steps:

[0042] (1) Preparation of cement paste

[0043] Mix 1 part of sulphoaluminate cement, 0.008 part of water reducer, 0.005 part of basalt fiber, and 0.32 part of water and set aside;

[0044] (2) Foam preparation

[0045] After diluting the foaming agent, use foaming and diluent to make a foam, and the foam is paste after making;

[0046] (3) Mix the foam prepared in step (2) with the cement slurry prepared in step (1) at a ratio of 4mL / g, mix well and pour into the mold, demould after standard curing for 24 hours, and then carry out natural curing or standard curing 10 days will do.

[0047] In the step (1) of this embodiment, the water-reducing agent is a polycarboxylate water-reducer, its pH is 6.5-8.0, and the water-reducing rate is 20-40%. The water-reducing efficiency of the polycarboxylate water-reducer is high. Aluminate cement has good compatibility; the basal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com