A method for repairing reinforced concrete structures in construction engineering

A technology for reinforced concrete and construction engineering, which is applied in the field of repairing reinforced concrete structures in construction engineering. It can solve the problems of repairing mortar falling off, and the interface between the repairing mortar and old concrete cannot be firmly bonded, so as to disperse internal stress, inhibit crack expansion, and improve resistance. cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The invention creates the preparation of repair mortar: stir 70-80 parts of ordinary Portland cement, 20-30 parts of sulphoaluminate early-strength cement, and 120-180 parts of quartz sand aggregate in a mixer, and then add silica fume 5 -10 parts, 0.2-0.5 parts of polycarboxylate superplasticizer, 0.2-0.3 parts of hydroxycarboxylate retarder, 2-4 parts of silane-modified styrene-acrylic rubber powder, 0.05-0.1 parts of sulfate-based early strength agent, 0.05-0.15 parts of organosilicon defoamer, 10-15 parts of talcum powder, continue to stir evenly, and finally add 30-45 parts of water to obtain the repair mortar for reinforced concrete structure of construction engineering of the present invention.

[0013] The preparation process of the interface agent of the present invention is the same as the preparation process of the above-mentioned repair mortar, and only the quartz sand aggregate is not added during the initial stirring.

Embodiment 2-4

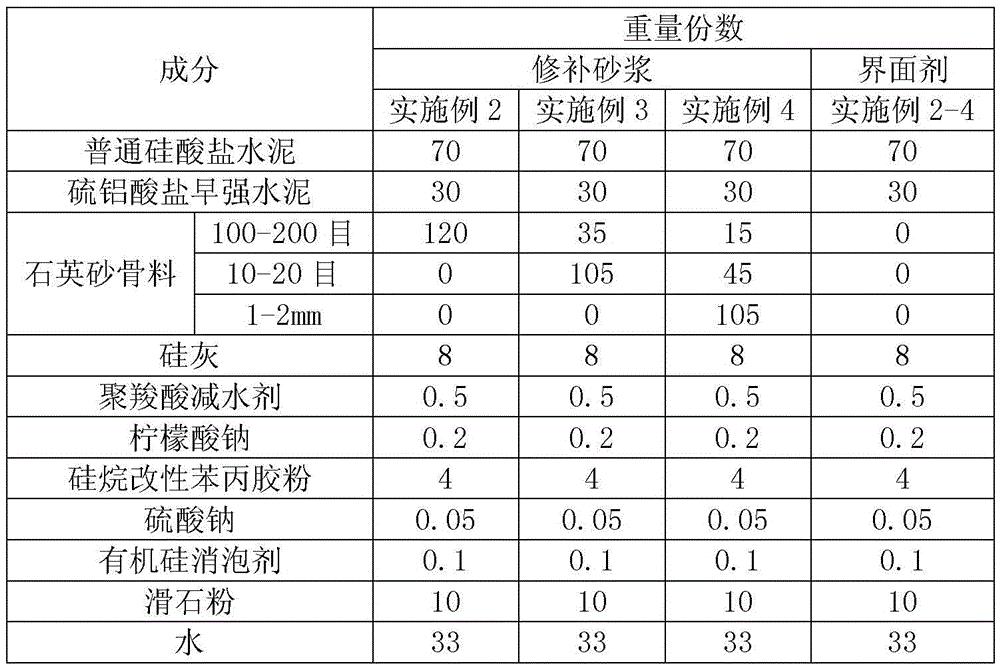

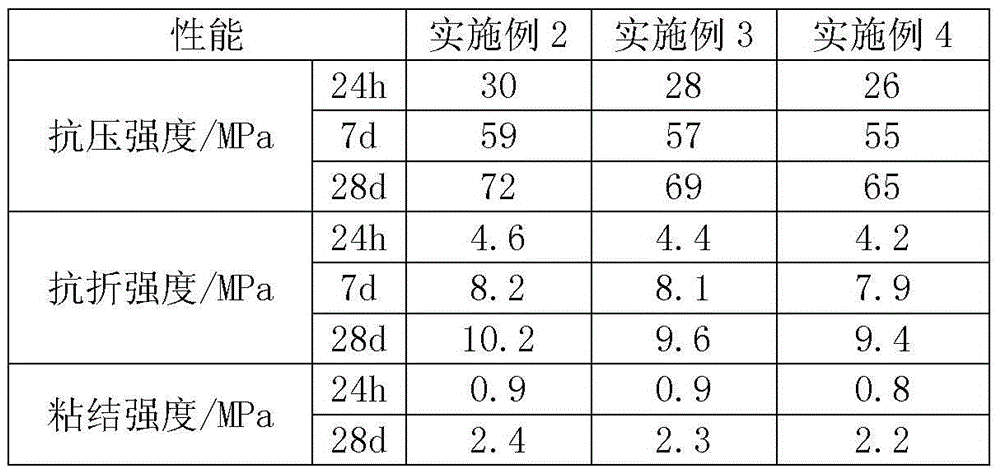

[0015] According to the parts by weight of the components in Table 1 below, the repair mortar and the interface agent shown in Examples 2-4 were respectively prepared using the same preparation steps as in Example 1. The performance indicators of the prepared repair mortar are shown in Table 2.

[0016] The composition of table 1 embodiment 2-4 repair mortar and interface agent

[0017]

[0018] Table 2 embodiment 2-4 repair mortar performance index

[0019]

Embodiment 5

[0021] Repair the concrete structural members with a crack width less than 0.3mm, clean the surface of the crack, and then directly brush the interface agent along the surface of the crack. Cover and seal with plastic cloth for 10-20 minutes, remove the plastic cloth, blow with an air gun until the surface of the interface agent is semi-dry, and then directly coat the interface agent with 3-5mm thick repair mortar for sealing treatment. The repair mortar uses the above-mentioned example 2 Made, wet curing for 5 days and then dry curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com