Flexible metal clad laminate

A flexible metal and metal layer technology, applied in the direction of metal layered products, layered products, synthetic resin layered products, etc., can solve the problems of solder resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

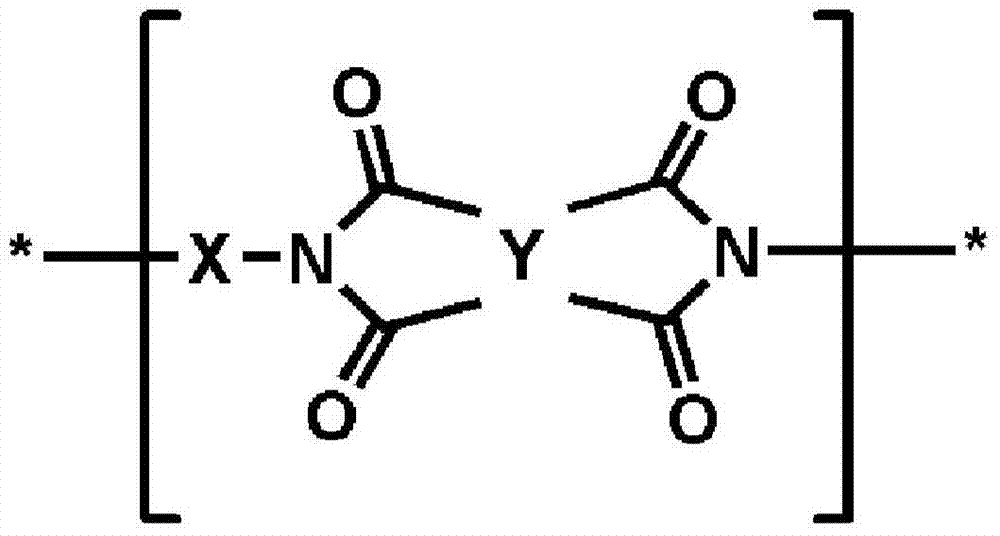

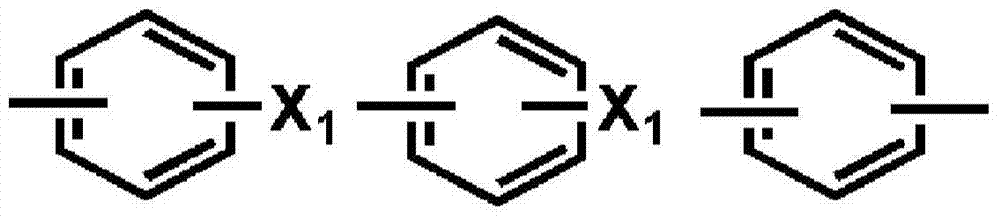

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] Under the same preparation conditions as in Synthesis Example 1, preparation was carried out according to the components and contents described in [Table 1].

[0096] Table 1

[0097] [Table 1]

[0098]

[0099] *E' at 300°C: Storage heat at 300°C

[0100] *E' at 350°C: Storage heat at 350°C

[0101] *CTE: Coefficient of linear thermal expansion measured in the range of 100°C to 200°C

[0102] *Tg: glass transition temperature

Embodiment 1

[0104] The polyamic acid solution prepared by [Synthesis Example 2] was applied on a 12 μm thick electrolytic copper foil (F2WS copper foil made of Furukawa circuit foil, roughness Rz = 2.0 μm), which was then heated at 140° C. dried to form a first polyimide precursor layer. The polyamic acid solution prepared by [Synthesis Example 1] was applied on one side of the first polyimide precursor layer, which was then dried at 140° C. to form a second polyimide precursor layer. After that, the polyamic acid solution prepared by [Synthesis Example 2] was applied on one side of the second polyimide precursor layer, and then dried at 140° C. to form a third polyimide precursor Floor. Under a nitrogen atmosphere, the fabricated laminate was heated from 150°C to 385°C for 9 minutes. After curing, the thickness of each of the first polyimide precursor layer, the second polyimide precursor layer and the third polyimide precursor layer reached 2.5 μm, 14 μm and 3 μm, respectively. The p...

Embodiment 2

[0106] By the same method as in Example 1, a flexible metal-clad laminate was produced according to the layer structure in [Table 2].

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com