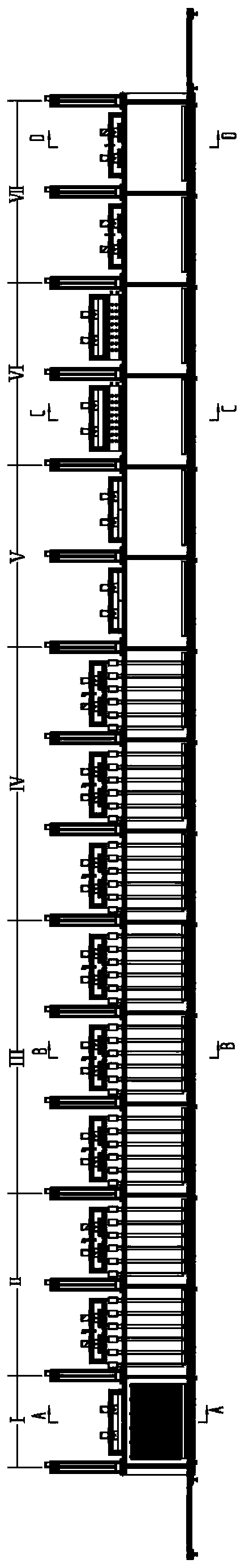

Continuous wood modification heat treatment process and system

A technology of wood modification and wood, which is applied in the direction of wood heat treatment, wood treatment, wood treatment details, etc., can solve the problems of insufficient wood use, high energy consumption of heat treatment, inconsistent carbonization degree, etc., to shorten the production cycle and improve Economic benefits, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

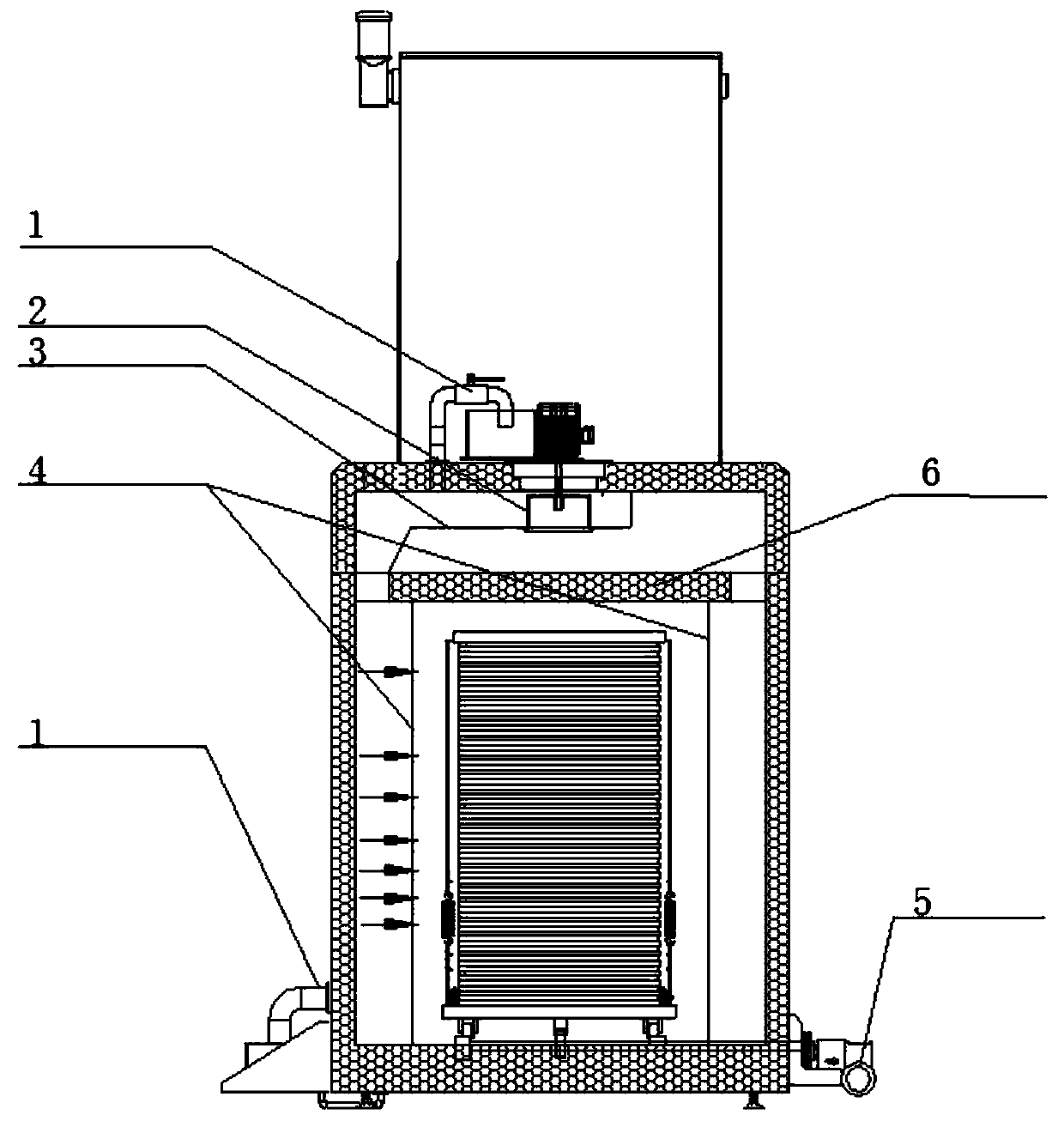

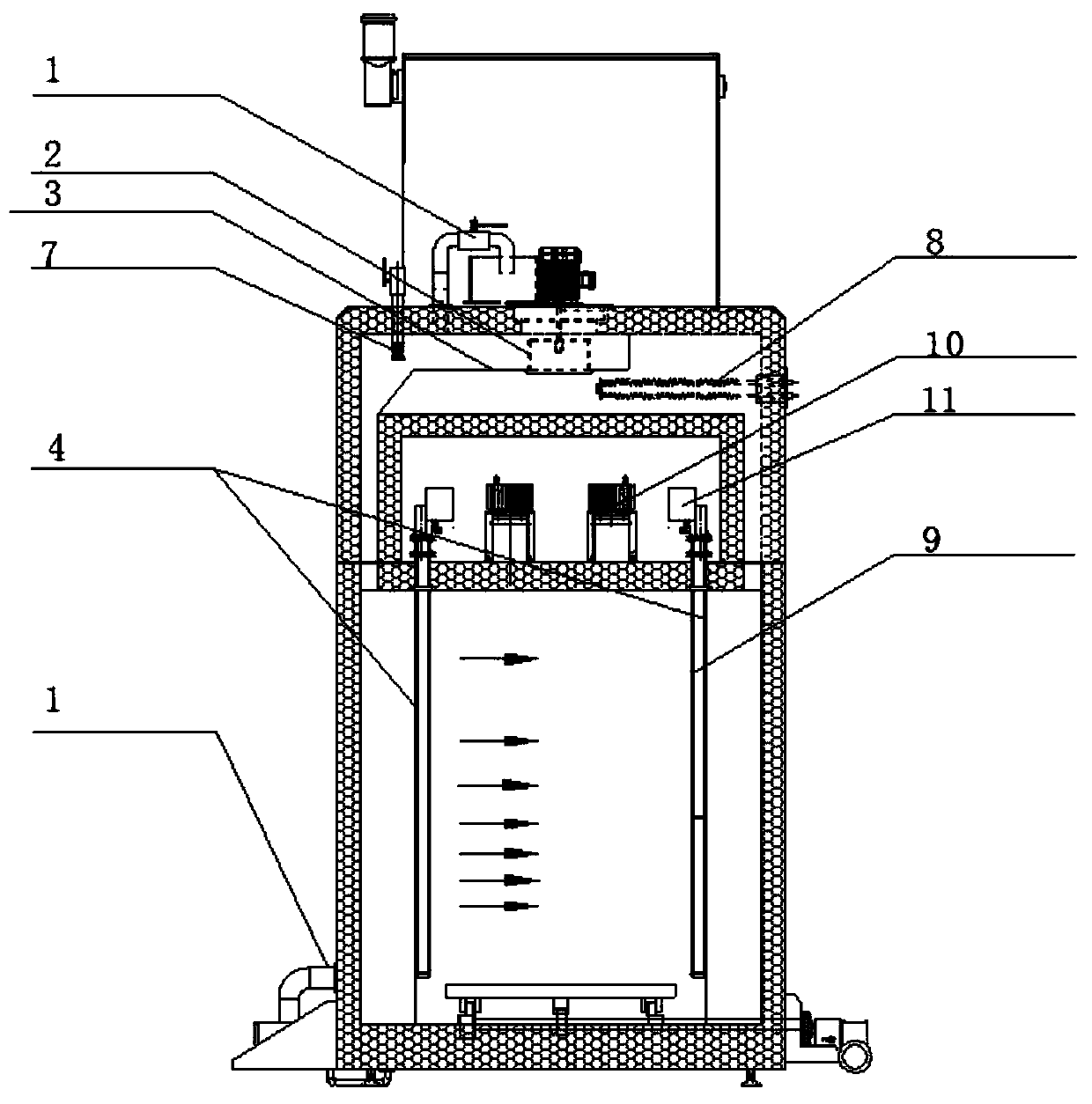

Method used

Image

Examples

Embodiment 1

[0093] Take the oak wood floor blank as an example:

[0094] A continuous wood modification heat treatment process. The initial wood blanks are stacked on the trolley at intervals, and pressure is applied on the top to keep the blanks balanced and flat. The following processing steps are followed in sequence:

[0095] S1. Preheating treatment: move the trolley carrying the initial wood blank to the preheating kiln, and the preheating temperature is 30°C;

[0096] S2. Heating treatment: move the initial wood blank after S1 treatment to the heating kiln. The heating treatment includes two heating kilns with temperatures of 80°C and 100°C respectively; in S2 treatment, the microwave power accounts for the total heating power The ratio is 30%, the water vapor flow rate is 2m3 / h, and the humidity is 50%.

[0097] S3. Drying treatment: Drying treatment includes two steps. The first step is to move the initial wood blank after S1 treatment to the first drying kiln, and the drying tr...

Embodiment 2

[0110] Take oak wood floor blank as an example:

[0111] A continuous wood modification heat treatment process. The initial wood blanks are stacked on the trolley at intervals, and pressure is applied on the top to keep the blanks balanced and flat. The following processing steps are followed in sequence:

[0112] S1. Preheating treatment: move the trolley carrying the initial wood blank to the preheating kiln, and the preheating temperature is 50°C;

[0113] S2, heating treatment: move the initial wood blank after S1 treatment to the heating kiln, the heating treatment includes 2 heating kilns, the temperature is 60°C and 80°C respectively; in S2 treatment, the proportion of microwave power is 35% , the water vapor flow rate is 5m3 / h, and the humidity is 100%.

[0114] S3. Drying treatment: Drying treatment includes two steps. The first step is to move the initial wood blank after S1 treatment to the first drying kiln, and the drying treatment temperature is 100°C. The init...

Embodiment 3

[0126] Take the oak wood floor blank as an example:

[0127] A continuous wood modification heat treatment process. The initial wood blanks are stacked on the trolley at intervals, and pressure is applied on the top to keep the blanks balanced and flat. The following processing steps are followed in sequence:

[0128] S1. Preheating treatment: move the trolley carrying the initial wood blank to the preheating kiln, and the preheating temperature is 40°C;

[0129] S2, heating treatment: move the initial wood blank after S1 treatment to the heating kiln, the heating treatment includes 2 heating kilns, the temperature is 70°C and 90°C respectively; in S2 treatment, the microwave power accounts for 38% , the water vapor flow rate is 4m3 / h, and the humidity is 100%.

[0130]S3. Drying treatment: Drying treatment includes two steps. The first step is to move the initial wood blank after S1 treatment to the first drying kiln, and the drying treatment temperature is 110°C. The initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com