High-dielectric grain boundary layer ceramic material and preparation method of grain boundary layer ceramic substrate

A ceramic material and high mesogen technology, applied in the field of capacitors, can solve problems such as poor product performance stability, cracking, and easy curling of ceramic substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

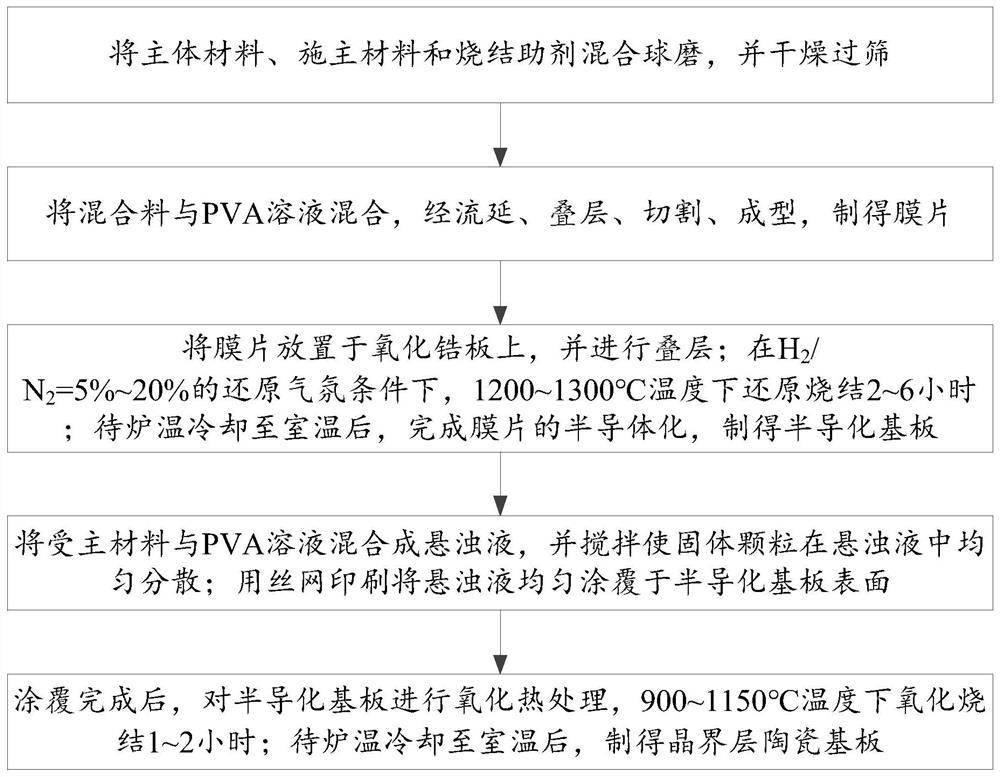

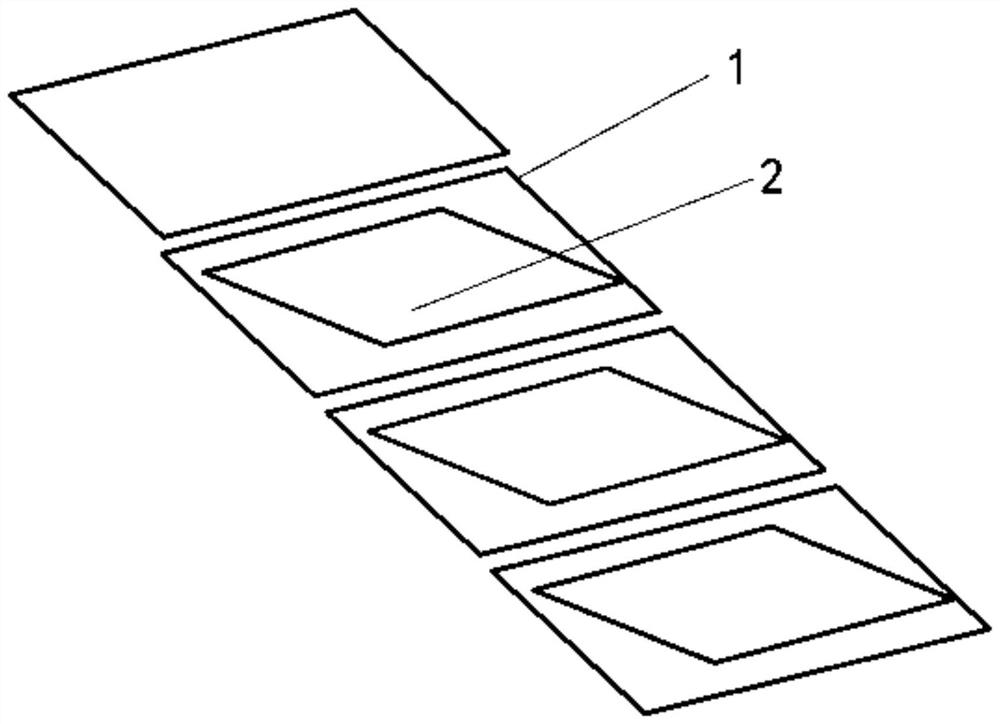

[0066] Such as figure 1 As shown, the present invention provides a method for preparing a ceramic substrate with a high-mesogenic grain boundary layer, which completes the preparation of a ceramic substrate with a grain boundary layer by secondary lamination and sintering, which are respectively reducing semiconductor sintering and oxidizing grain boundary layer insulation sintering, specifically including:

[0067] Step 1, mixing and ball-milling the main material, the donor material and the sintering aid, drying and sieving to prepare the mixture;

[0068] Specifically:

[0069] The strontium titanate main material and La 2 o 3 , Nb 2 o 5 , SiO 2 , Li 2 CO 3 Add it into the ball mill, mix and ball mill for 5-8 hours, dry the material after discharge, and pass through a 60-mesh sieve to obtain a particle size of d 50 <3μm mixture.

[0070] Step 2, mixing the mixture with the PVA solution, and then casting, laminating, cutting, and forming to obtain a membrane;

[00...

Embodiment

[0083] The present invention provides a high-mesogenic boundary layer ceramic material. The formula of the reduced sintered material is shown in Table 1, and the formula of the oxidized sintered coating material is shown in Table 2, and the unit is g:

[0084] Table 1

[0085] Sample serial number 1 2 3 4 5 6 SrTiO 3

900 900 900 900 900 900 La 2 o 3

3.3 3.3 3.3 3.3 3.3 3.3 Nb 2 o 5

4 4 4 4 4 4 Li 2 CO 3

/ 9.2 9.2 9.2 9.2 9.2 SiO 2

/ / 1.8 1.8 1.8 1.8 Sintering temperature 1450℃ 1250℃ 1250℃ 1250℃ 1250℃ 1250℃

[0086] Table 2

[0087]

[0088] The present invention provides a method for preparing a grain boundary layer ceramic substrate based on the ceramic material of the above-mentioned samples 1-6, comprising:

[0089] Step 1. Weigh the material with corresponding quality according to the formula in Table 1, grind it on a ball mill for 5 hours, discharge, dry, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com