Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156results about How to "Intensity unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

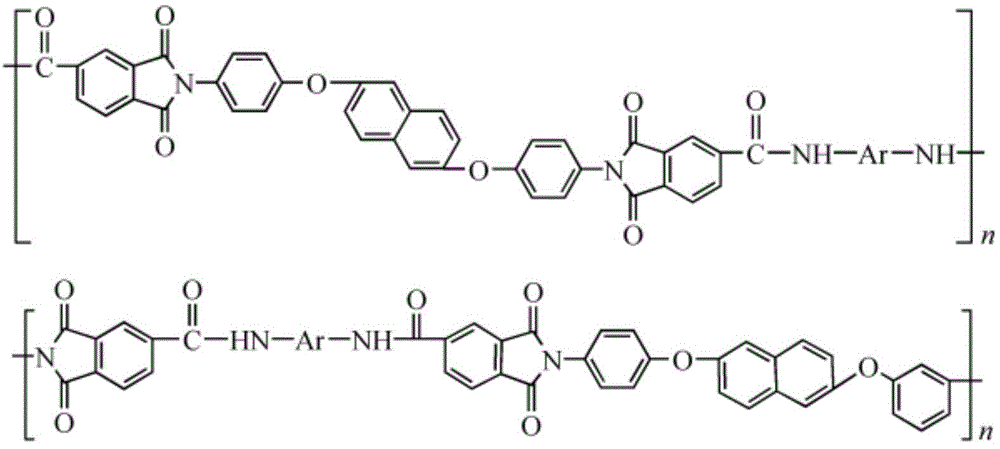

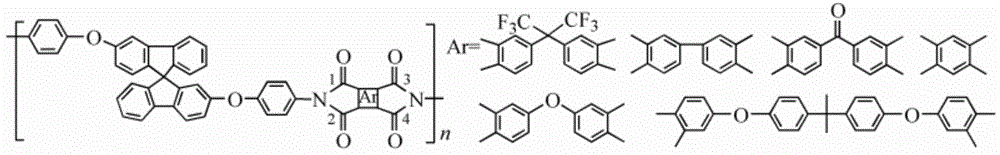

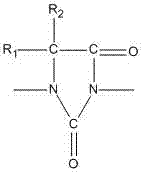

Low-melt-viscosity thermoplastic polyimide material and 3D printing moulding method thereof

ActiveCN103980489AOutstanding performanceHighlight application valueSolventUltimate tensile strength

The invention discloses a low-melt-viscosity thermoplastic polyimide material which is used for 3D printing. Molecular structure of the thermoplastic polyimide material is subjected to a modification process (such as introducing a special flexibility structure unit, a large side group or solvophilic group, a twisted and non-coplaner structure, characteristic atoms such as a heterocycle and a fluorine silicon and the like, and carrying out a main chain copolymerization reaction) to enable the polyimide material to be meltable and thus to have good processability a well processing performance. The polyimide material, after being mixed with a heat stabilizer and a reinforcing agent, is manufactured into a high-performance polyimide product in a manner of melting 3D printing technology. The polyimide material widens a selectable range of present 3D printing materials. With the high-performance and low-melt-viscosity thermoplastic polyimide as a 3D printing material, the high-performance polyimide product prepared from the polyimide material has excellent high temperature resistance performance, corrosion resistance performance and mechanical strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

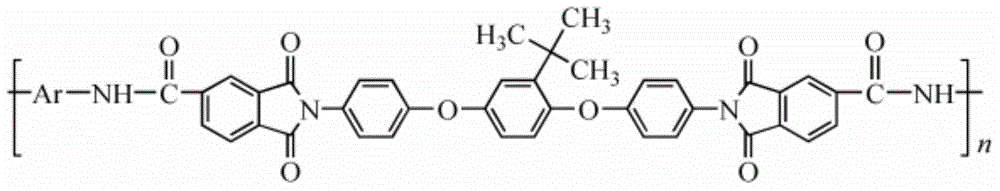

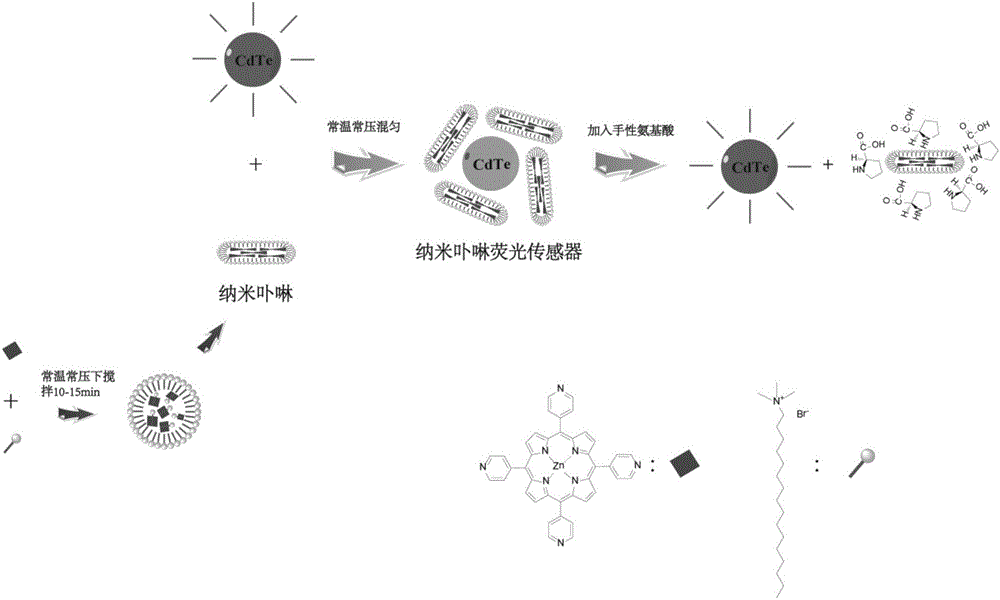

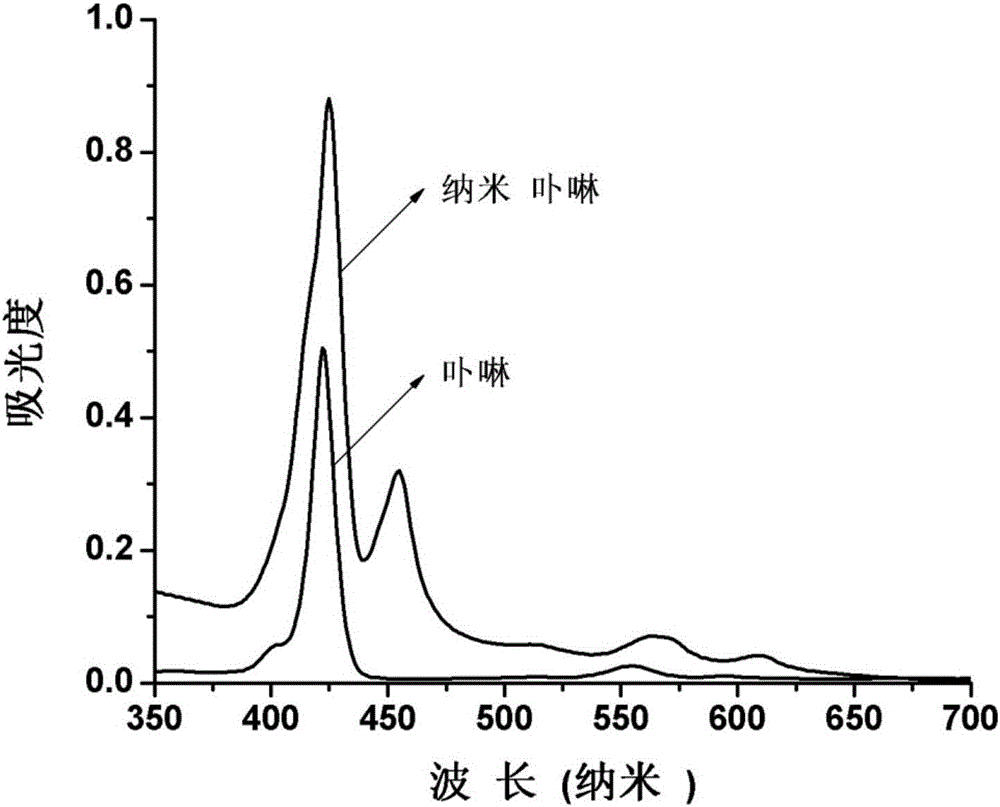

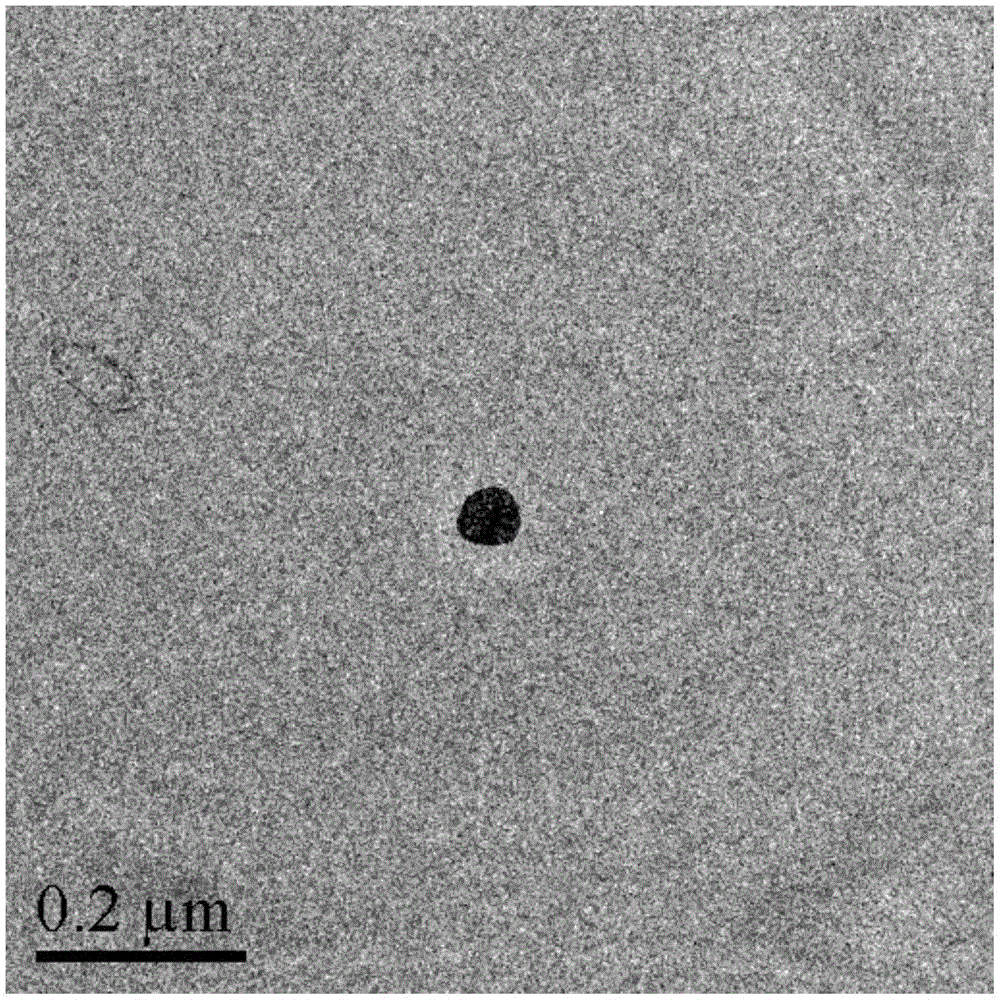

Method for recognizing quantitative chiral amino acid by using reversible nano porphyrin fluorescence sensor

ActiveCN106706591AHigh sensitivityRealize qualitative and quantitative detectionFluorescence/phosphorescenceMaterials preparationQuantum dot

The invention discloses a method for recognizing quantitative chiral amino acid by using a reversible nano porphyrin fluorescence sensor, and belongs to the technical field of nano material preparation and chemical analysis detection. The reversible nano porphyrin fluorescence sensor for specifically recognizing quantitative proline, lysine and serine chirality adopts a CdTe quantum dot as a fluorescence probe, and self-assembled porphyrin prepared from a tetra-(4-pyridyl) zinc porphyrin tetrahydrofuran solution and cetyl trimethyl ammonium bromide (CTAB) as a fluorescence quencher, and with the specific combination of the florescence probe and the fluorescence quencher, an openable / closeable nano porphyrin fluorescence sensor can be prepared. The reversible (opening-closing-opening) nano porphyrin fluorescence sensor can be prepared under the action of the openable / closeable nano porphyrin fluorescence sensor with the chiral proline, lysine and serine. Compared with a conventional chromatographic method for recognizing amino acid chirality by separating, the method disclosed by the invention has multiple advantages.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

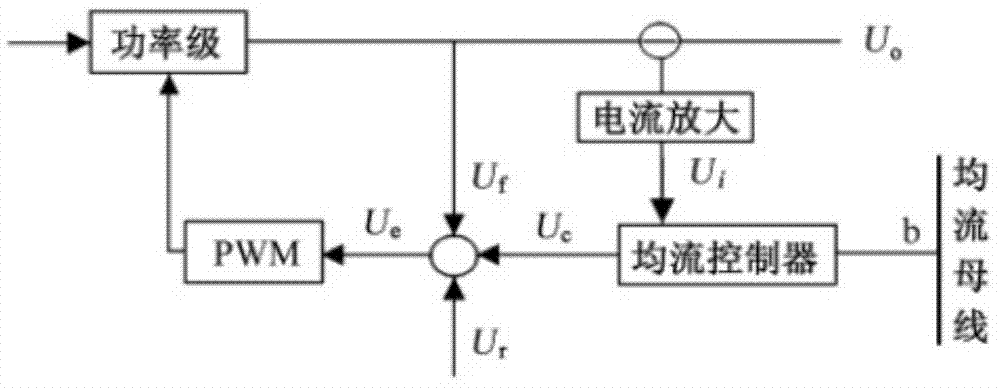

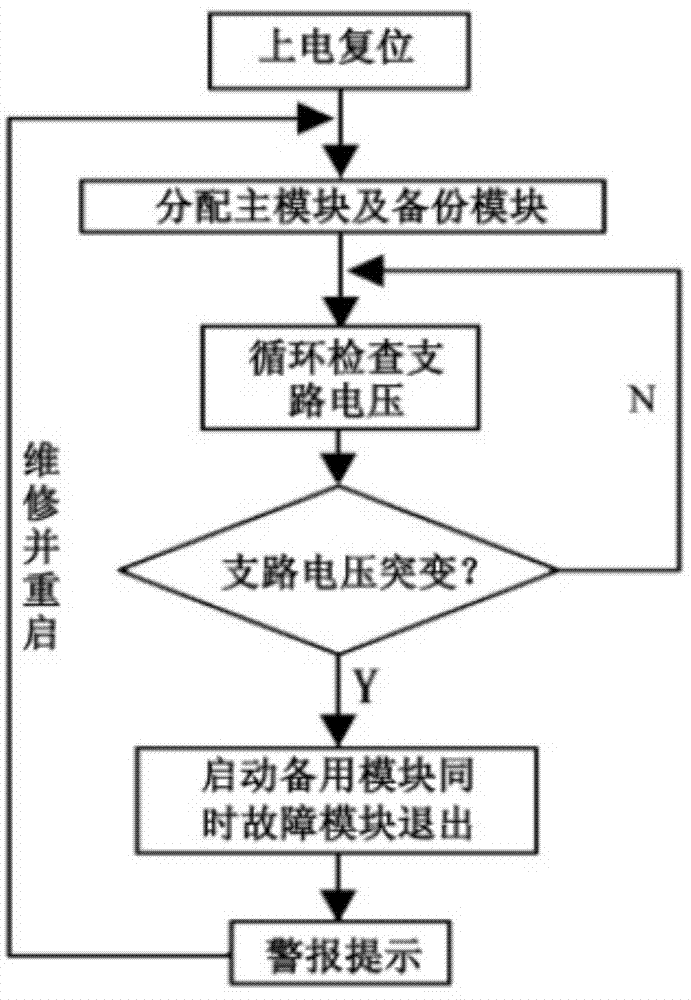

Current-sharing control method for parallel redundant power supply

InactiveCN103683479AOvercoming complexityOvercome stabilityEmergency power supply arrangementsComputer moduleEngineering

The invention discloses a current-sharing control method for a parallel redundant power supply. The current-sharing control method includes the steps: respectively connecting a current-sharing bus with a main module and a backup module of the power supply, and respectively comparing detection current outputted by the bus and the main module and the backup module of the power supply by a current-sharing controller when voltage at two ends of a resistor has voltage difference to obtain the voltage Uc of the current-sharing controller; comparing the voltage Uc of the current-sharing controller with reference voltage Ur to obtain output voltage Ur', comparing and amplifying the output voltage Ur' and feedback voltage Uf to obtain feedback voltage Ue, and adjusting and controlling the voltage of the main module and the backup module of the power supply by the aid of the feedback voltage Ue to realize current-sharing control for main circuit current. The shortcomings of complicated circuit and poor circuit stability of two previous current-sharing techniques are overcome, the intensity of output current of a power supply module is kept unchanged, and the current-sharing control method can effectively adapt to load change.

Owner:DALIAN UNIV

Preparation method of highly-compact nickel-aluminium-based self-lubricating material

The invention discloses a preparation method of a highly-compact nickel-aluminium-based self-lubricating material. The method adopts a combined technology of batch high-energy ball milling and powder metallurgy to prepare a material with a compactness of more than 98%. The invention is especially applicable to mechanical movement self-lubricating part materials working in a corrosive environment at a high temperature.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Rare-earth heat-resistant aluminum alloy guide wire material and preparation method thereof

InactiveCN110343912AHigh strengthImprove heat resistanceConductive materialMetal/alloy conductorsHeat resistanceRare earth

The invention provides a rare-earth heat-resistant aluminum alloy guide wire material and a preparation method thereof. The aluminum alloy guide wire material consists of the following elements in percentage by weight: 5.00%-15.00% of Ce, 0.15%-0.70% of Zr, 0.01%-0.50% of Y, 0.01%-5.00% of Fe, 0.10%-5.00% of Mg, 0.05%-8.00% of Si, 0.001%-5.00% of Cu, 0.001%-0.40% of Co, 0.001%-0.85% of B, 0.001%-0.2% of Ti, 0.001%-0.15% of V, 0.001%-0.12% of Cr, 0.001%-0.12% of Mn, 0.001%-0.15% of Ni and the balance of aluminum. The high-strength high-conductivity heat-resistant aluminum alloy has high conductivity and high heat resistance.

Owner:SHANGHAI JIAO TONG UNIV

Aluminous cement containing nano calcium carbonate and preparation method thereof

The invention relates to calcium aluminate cement containing nanometer-sized calcium carbonate and a preparation method thereof. The preparation method of the calcium aluminate cement containing nanometer-sized calcium carbonate is based on calcium aluminate used in prior refractory material by adding nano calcium carbonate powder and alumina micropowder. The invention solves the shortcoming of low mid-temperature strength in prior calcium aluminate, and particularly greatly improves the strength around 800 DEG C. The monolithic refractory containing the combined nanometer-sized calcium carbonate has a small change in cold strength under 800 DEG C and 1600 DEG C burning, and the strength of the cold state and the hot state is greatly increased compared with that of prior ordinary monolithic refractory containing the same quantity of CaO made by combining calcium aluminate cement. The invented nanometer-sized calcium aluminate cement containing calcium carbonate can be broadly used in producing refractory material such as refractory casting material, spray material, etc., and can greatly improve mid-temperature strength of material.

Owner:ZHENGZHOU UNIV

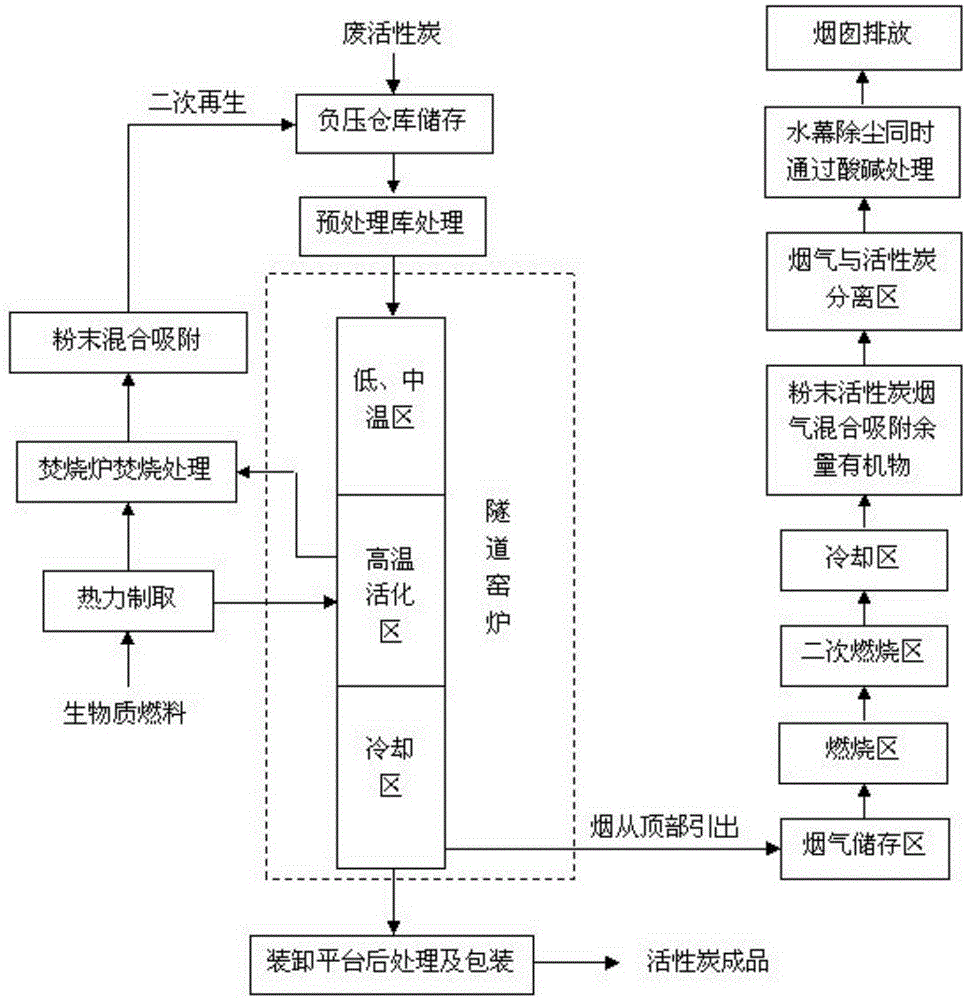

Spent activated carbon regeneration method

ActiveCN105289563AGuarantee product qualityReduce raw material lossOther chemical processesCombustible gas purificationChemistryActivated carbon

The invention discloses a spent activated carbon regeneration method, which comprises the steps of storage, pretreatment, heating power preparation, roasting, aftertreatment and packaging as well as preheating and the like. The optimal activated carbon regeneration processing steps are screened out through a large number of experiments. According to the regenerative activated carbon produced by the regeneration method, the adsorptive property of the regenerative activated carbon reaches 95 percent to 110 percent of original activated carbon, the intensity basically does not change, the regeneration rate can be kept above 90 percent and in a whole regeneration and activation process, biomass particle combustion furnace equipment is used, by combusting biomass fuel, sufficient heating power is provided for a high-temperature activation region in the middle of a tunnel kiln, so that the product quality of the regenerative activated carbon is facilitated, the raw material loss can be greatly reduced, and the economical and biological benefits are good. Meanwhile, the technology is scientific and reasonable, mature, safe and environment-friendly, and secondary pollution cannot be caused to the environment, the waste is turned into treasure, so resource waste and environment pollution can be reduced, and important economic value and social benefits are achieved.

Owner:江苏亚旗环保科技有限公司

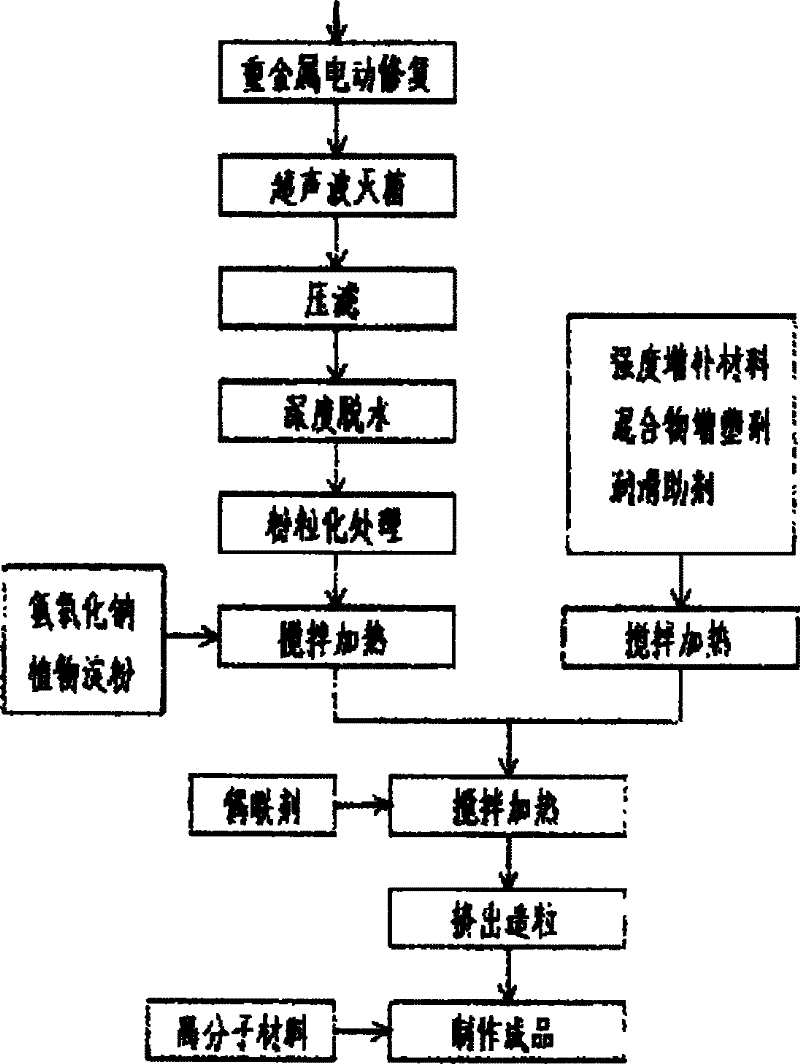

Easily degradable and environment friendly plastic and manufacturing method thereof

InactiveCN102226020ANo pollution in the processStable storageSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentPolyvinyl alcoholWater processing

The invention relates to a novel environment friendly plastic. The plastic is characterized in that: the plastic comprises a high-nutrient biodegradable material which comprises residual sludge particles, sodium hydroxide and plant starch, an intensity supplement material which comprises natural mineral powder, a natural fiber and polyvinyl alcohol, a mixture plasticizer which comprises alkyl sulfonate and glycol, a coupling agent which comprises macromolecular wax, calcium stearate and a stearic acid lubricant additive, and a polyethylene / polypropylene macromolecular synthetic material. The plastic is manufactured through the following steps: mixing and stirring above blended components; melting, extruding and granulating; and processing into products or films with various shapes through known methods such as blow molding, calendaring, vacuum molding and the like. The residual sludge after water processing can be effectively recycled, so the plastic has the advantages of safety and non-toxicity, thorough degradation in the soil moisture environment, controllable degradation time, no secondary pollution, high intensity, good plasticity and wide application scope.

Owner:JILIN LONGYUN CHEM IND

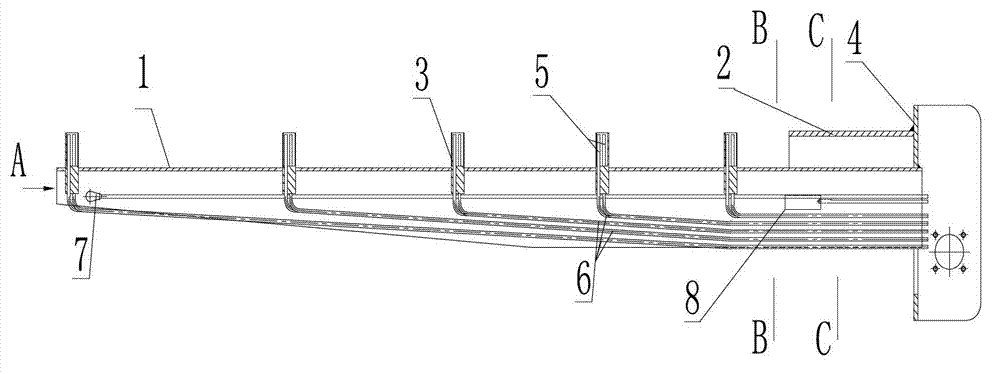

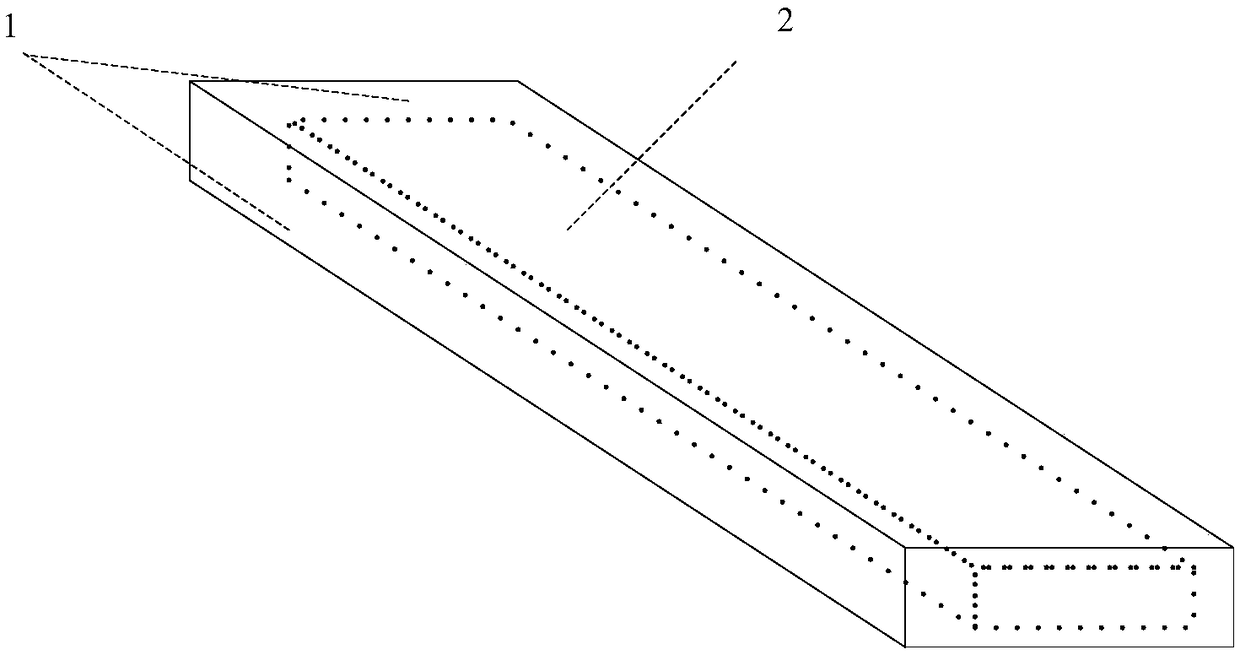

Large-size composite material air inlet passage measuring rake

InactiveCN103115747AOverall strength unchangedImprove shock absorptionAerodynamic testingEngineeringMechanical engineering

The invention provides a large-size composite material air inlet passage measuring rake. Aims of integrated collection and measurement of measuring parameters of an engine inlet flow field, and simple and fast installation and disassembly are achieved under the demands that rake body weight is greatly reduced, and stiffness and vibration intensity of the measuring rake are met. The technical scheme includes that the large-size composite material air inlet passage measuring rake is characterized in that a skin framework with a U-shaped cross section comprises a front measuring section and a back installation section, the root portion of installation section of the skin framework is connected on an installation seat, a measuring point protective sleeve is arranged on the windward side of measuring section of the skin framework in an equal-ring-surface mode, a measuring element is installed in the measuring point protective sleeve and is outputted to the installation seat through a guide pipe, a damping protective sleeve with a U-shaped cross section is sleeved on the outer side of the skin framework, a gap is arranged between the damping protective sleeve and the skin framework, and the damping protective sleeve is connected on the installation seat.

Owner:CHINESE FLIGHT TEST ESTAB

Disperse dye composition and preparing method thereof

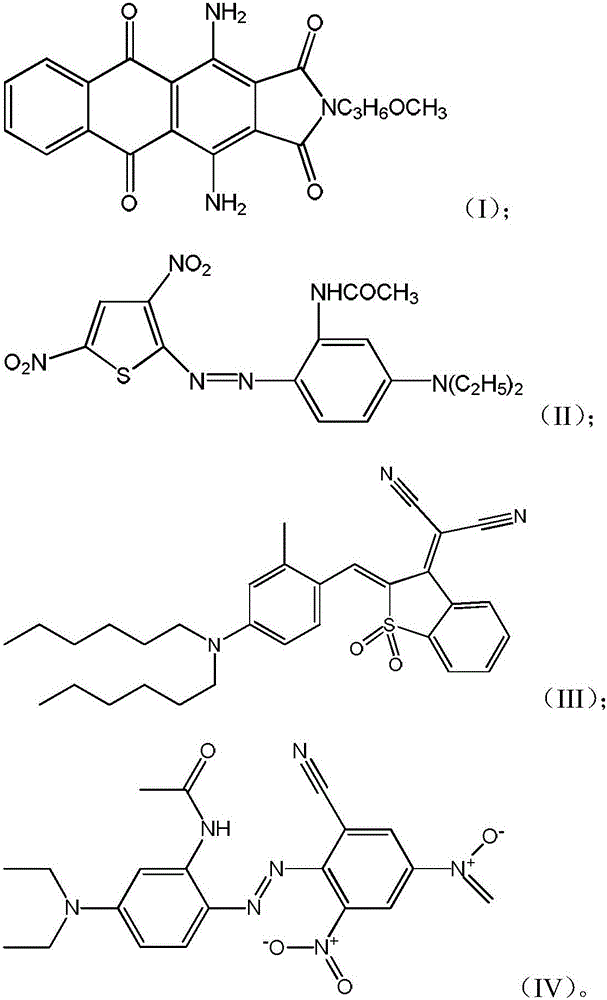

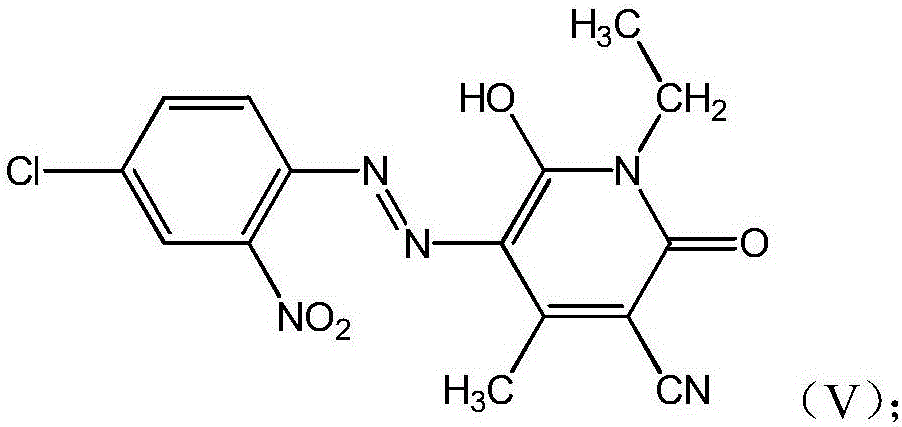

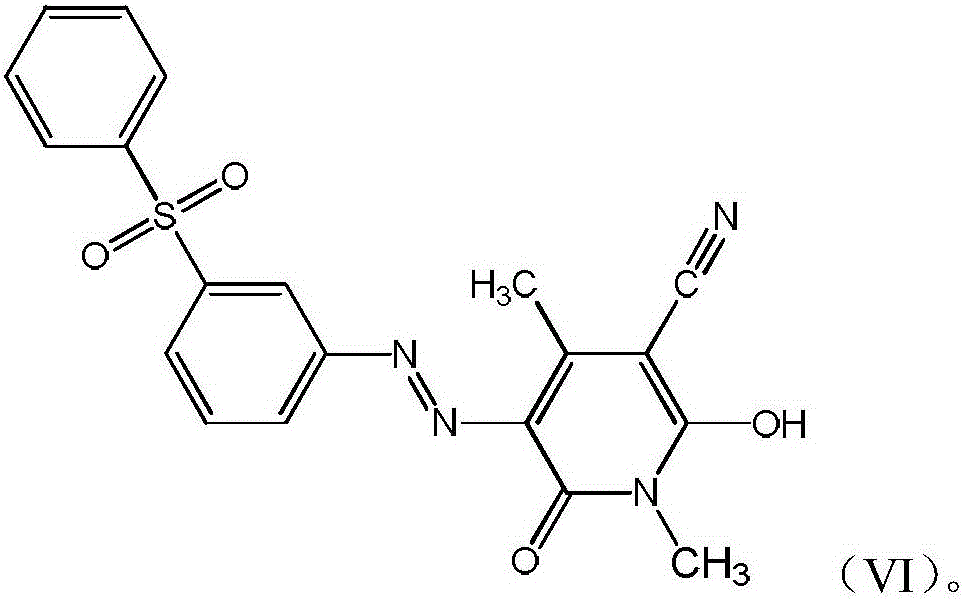

ActiveCN105860581AGood color fastness to lightGood color fastness to sublimationOrganic dyesMonomerDisperse dye

The invention discloses a disperse dye composition capable of improving strength and a preparing method thereof. The disperse dye composition comprises, by weight, 0.1-100 parts of C.I. disperse blue60, 0.1-50 parts of C.I. disperse green9, 0.1-50 parts of C.I. disperse blue354, 0.1-10 parts of C.I. disperse blue165 and 0.1-5 parts of disperse yellow. The preparing method of the disperse dye includes the following steps that 1, C.I. disperse blue60, C.I. disperse green9, C.I. disperse blue354, C.I. disperse blue165 and disperse yellow are taken according to the formula amount and mixed to obtain a mixed dye, wherein the disperse yellow is selected from C.I. disperse yellow211 and / or C.I. disperse yellow114; 2, water is added into the mixed dye obtained in the step 1, the weight dosage ratio of the mixed dye to the water is 1:(2-20), the mixture is mixed, and mixed slurry is obtained; 3, the mixed slurry obtained in the step 2 is sprayed and dried, and the disperse dye composition is obtained.

Owner:ZHEJIANG OUYA CHEM CO LTD

Near-eutectic type high-strength heat-resistant Al-Ce-series aluminum alloy and preparation method

The invention provides a near-eutectic type high-strength heat-resistant Al-Ce-series aluminum alloy and a preparation method. The near-eutectic type high-strength heat-resistant Al-Ce-series aluminumalloy is prepared from the following elements in percentage by weight: 5.00 percent to 15.00 percent of Ce, 0.01 percent to 5.00 percent of Fe, 0.10 percent to 1.20 percent of Mg, 0.05 percent to 1.00 percent of Si, 0.001 percent to 5.00 percent of Cu, 0.001 percent to 0.40 percent of Co, 0.001 percent to 0.85 percent of B, 0.001 percent to 0.20 percent of Ti, 0.001 percent to 0.15 percent of V,0.001 percent to 0.12 percent of Cr, 0.001 percent to 0.12 percent of Mn, 0.001 percent to 0.15 percent of Ni, and the balance aluminum. The near-eutectic type high-strength heat-resistant Al-Ce-series aluminum alloy provided by the invention has high strength and high heat resistance, the tensile strength at the room temperature reaches to more than 440MPa, and the tensile strength at 300 DEG C reaches to more than 250MPa; and the cost of raw materials for preparing the aluminum alloy is low, and a preparation process is simple.

Owner:SHANGHAI JIAO TONG UNIV

High volume stability marine concrete and its preparation method

The present invention relates to marine engineering concrete and its preparation process. The marine engineering concrete with high volume stability consists of fine synthetic fiber in 0.05-0.15 vol%, cementing material in 400-500 kg / cu m, crushed stone in 1000-1300 kg / cu m, sand in 600-1000 kg / cu m, and plasiticizer accounting for 0.5-2.0 wt% of the cementing material. The cementing material includes Portland cement, ground ore slag and silica fume. The marine engineering concrete with high volume stability has high anticorrosion capacity to sulfate and chloride in sea water, low hydration heat, high microscopic compatibility, high strength, low cost, greatly raised volume stability and durability and raised resistance to environment temperature and humidity change.

Owner:TONGJI UNIV

Internal conmbustion engine valve different lifting device and method thereof

The invention discloses a combustion air valve different raising device which improves the air channel and the flow inside the cylinder, which is a set of cam includes a symmetric jam and a non-symmetric jam or two non symmetric jams; or includes a symmetric jam and a non-symmetric jam or two non symmetric jams. The maximum raising point on the axial project is a non doubling position, above two non-symmetric jam is symmetric at axial projection; each group of jams has the same maximum raising. The invention also discloses the actualizing method with above device.

Owner:张士强

Preparation of multi-component titanium-based catalyst carrier

ActiveCN1895781AIntensity unchangedHigh mechanical strengthCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsTitanium dioxideTitanium

A process for preparing a multi-element carrier of Ti-base catalyst includes such steps as providing TiO2, proportionally adding Zr and / or RE, pore forming agent and adhesive, grinding while mixing, extruding to become strip, drying, cutting to become particles, and calcining. It has high stability, mechanical strength and O2-bearing power.

Owner:中国中化股份有限公司 +1

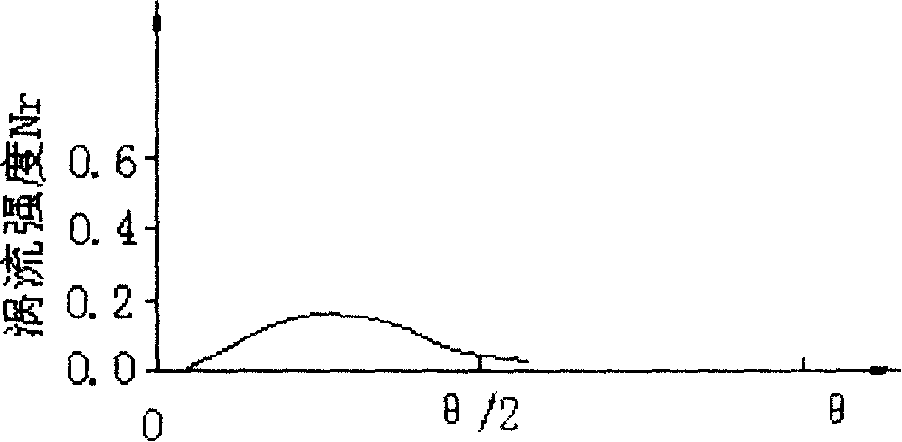

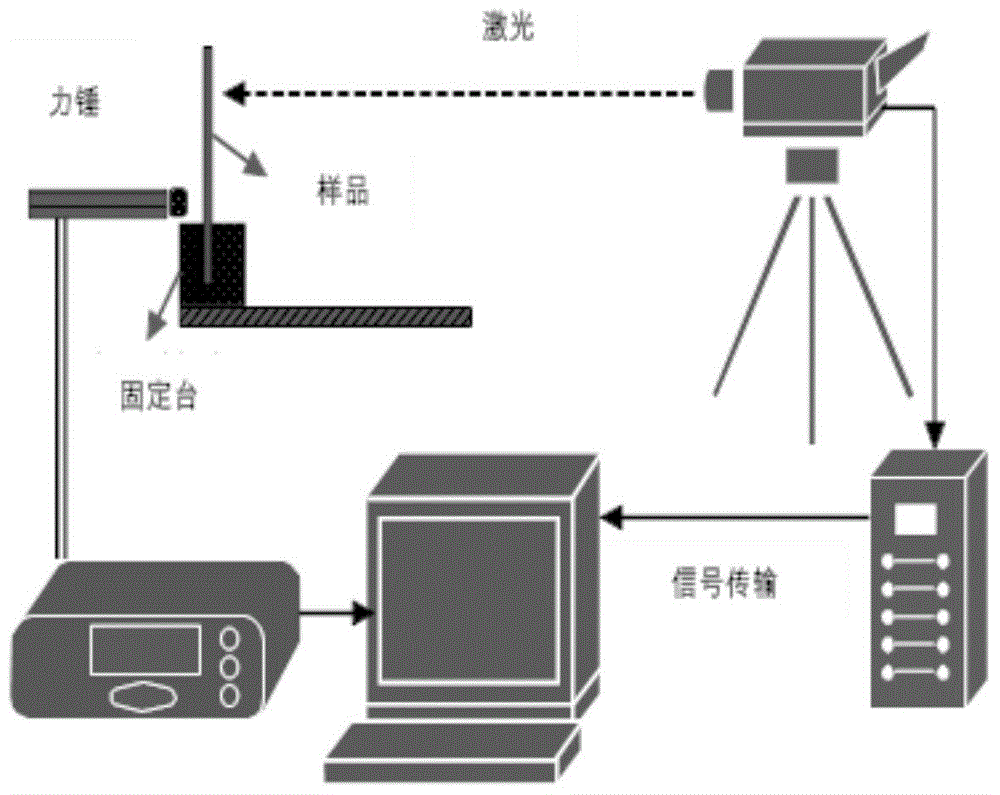

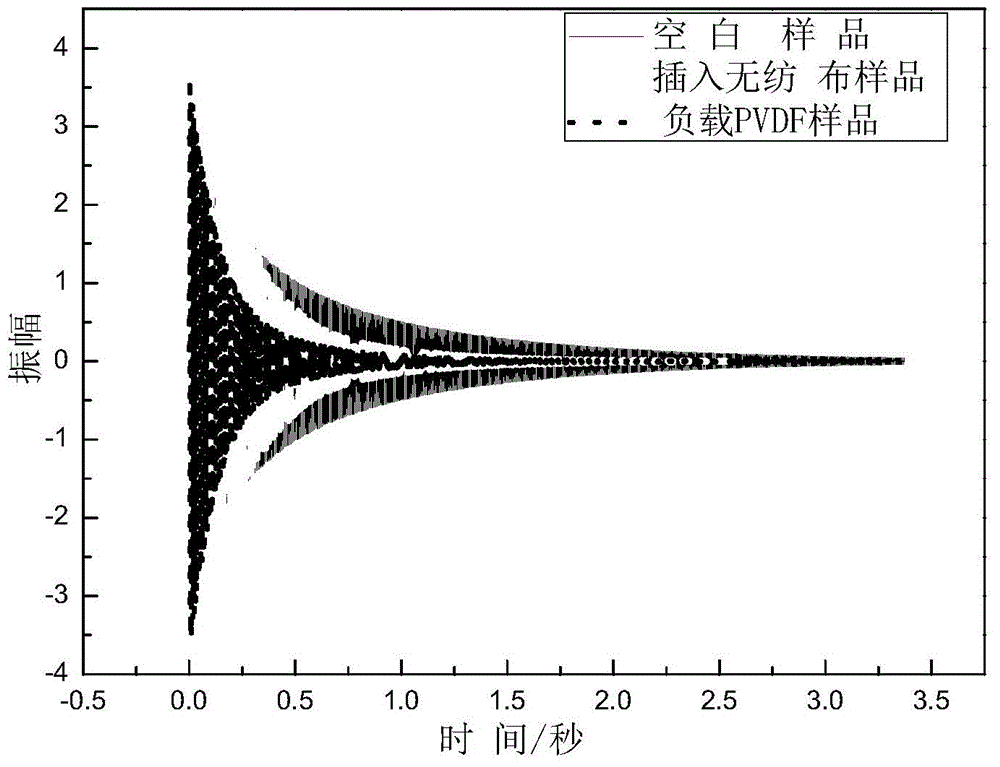

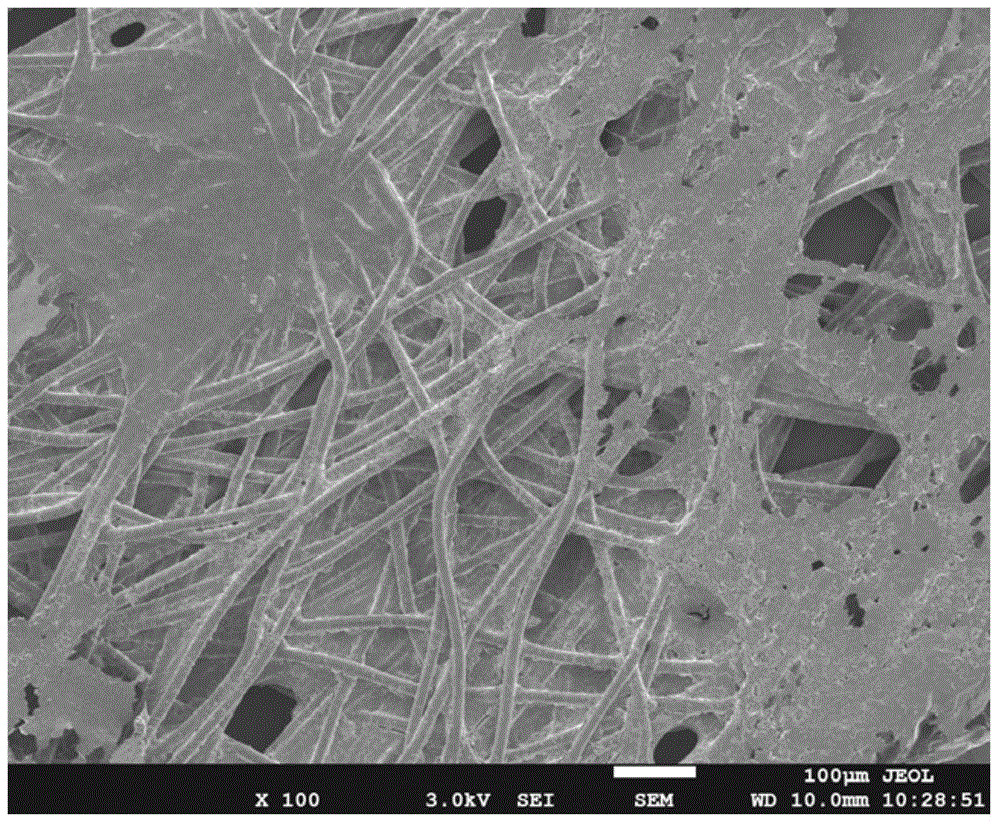

Composite damping layer toughened thin layer and preparation method thereof

InactiveCN104527173AImprove toughnessHigh strengthSynthetic resin layered productsLaminationFiberWeight gaining

The invention relates to a composite damping layer toughened thin layer and a preparation method thereof. The invention discloses a preparation method for a novel interlayer toughened layer with a damping vibration attenuation function and an application technology of the interlayer toughened layer in continuous carbon fiber reinforced laminated composite materials. A low surface density non-woven fabric with a network structure, a porous film or textile is adopted as the functional carrier to load polyvinylidene fluoride PVDF, then the composite toughened thin layer is placed at the interlayer of a conventional carbon fiber laminated composite material by an intercalation technology to conduct moulding solidification, thus obtaining the structural damping composite material with the toughness enhanced by more than 3 times. The method is easy to operate, and the obtained composite material not only has significantly improved toughness, no obvious loss of static mechanical properties, obviously increased vibration attenuation rate, but also causes little composite material weight gain.

Owner:倪楠楠

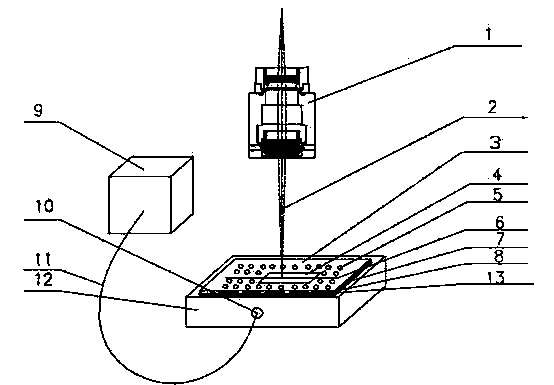

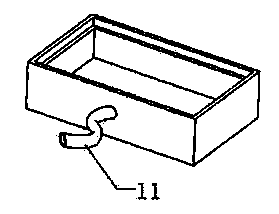

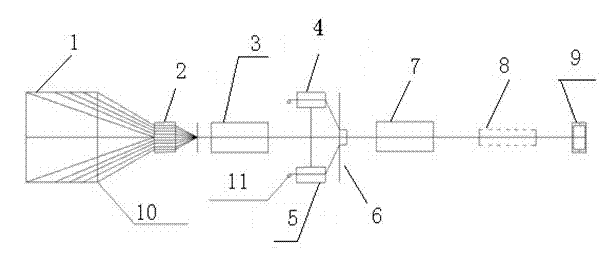

Sheet laser welding clamping system

ActiveCN103639602ASimple structureSimple assembly structureWelding/cutting auxillary devicesAuxillary welding devicesLaser processingEngineering

The invention relates to a sheet laser welding clamping system. The sheet laser welding clamping system is characterized by comprising a laser processing head, a clamp cavity base and a vacuum absorption system, the vacuum absorption system is connected with the clamp cavity base through a pipeline, an end cover is further arranged on the clamp cavity base, the clamp cavity base is made of high-strength steel materials, a cavity structure is arranged inside the clamp cavity base, a through hole is formed in the side wall of the clamp cavity base, and the through hole is connected with the vacuum absorption device through the pipeline. The sheet laser welding clamping system has the advantages that the whole structure is simple, operation is convenient, and the cost is low; the clamp cavity base is of a cavity structure, and is connected with the upper end cover in a welding mode, the sealing effect is achieved, and the assembling structure is simple; due to the fact that the vacuum absorption system is adopted in the sheet laser welding clamping system, the degree of intelligence is greatly improved, starting and shutdown of a vacuum generator are controlled through a vacuum switch, manual operation is easy, a large number of workloads for clamping are reduced, and working efficiency is improved.

Owner:NANJING ZHONGKE RAYCHAM TECH

Mixed neoprene sealant

The invention discloses a mixed neoprene sealant comprising the following raw materials by weight: 12-20 parts of neoprene, 9-15 parts of natural rubber, 6-10 parts of butadiene rubber, 15-20 parts of terpene resin, 110-140 parts of xylene, 3-9 parts of magnesium oxide, 70-80 parts of talcum powder and 8-13 parts of a thickening agent; the neoprene, natural rubber and butadiene rubber are mixed and then put in an open rubber mixing mill for mixing and blanking to obtain a thin sheet, the thin sheet is moved to part of xylene solution for soaking to obtain a rubber solution; the rubber solution is poured into a kneader for mixing evenly, then the terpene resin is added and mixed, part of the talcum powder is added and mixed evenly, then the rest of the talcum powder is added and mixed evenly, and the magnesium oxide and the thickening agent are added and mixed to obtain a mixed rubber solution; the thickness of the mixed rubber solution is adjusted to 0.2-0.45L / min by use of the rest of the xylene to obtain the mixed neoprene sealant. The mixed neoprene sealant ensures the adhesion ability and sealing effect, and has the advantages of easily obtained raw materials and simple production.

Owner:TIANCHANG YONG TAI SEALING MATERIAL

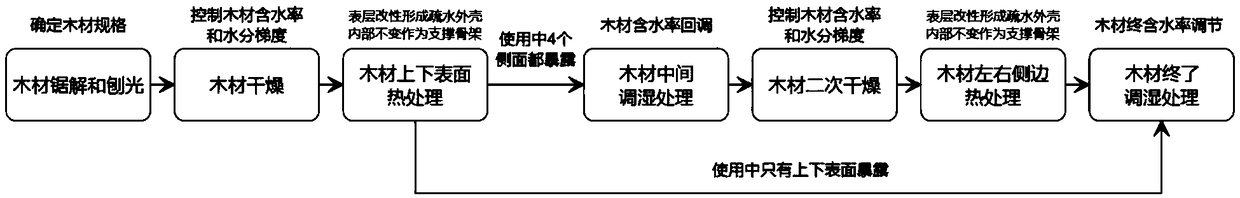

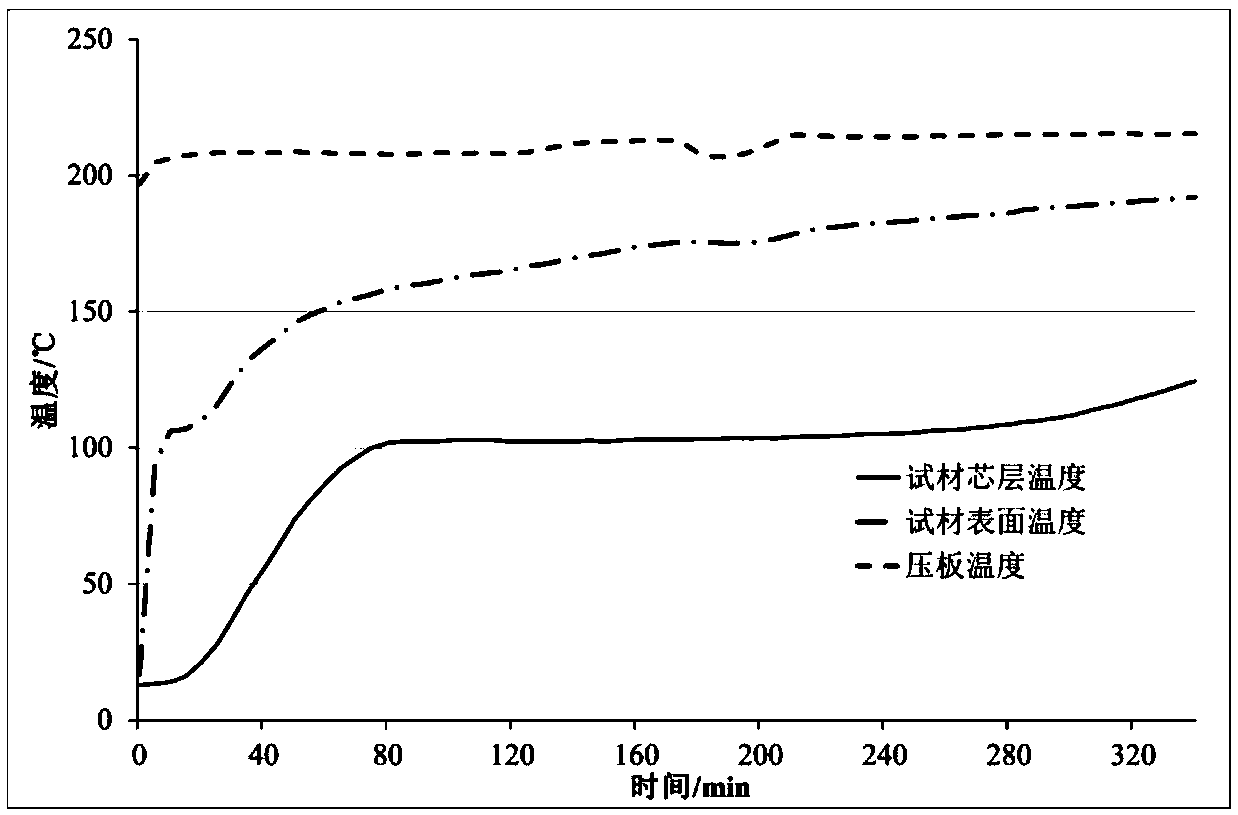

Novel wooden structural material with stable durability and preparation method of novel wooden structural material

ActiveCN108638277AOvercome the disadvantage of significant decrease in strengthImprove stabilityPlywood pressesWood compressionSurface layerUltimate tensile strength

The invention discloses a novel wooden structural material with stable durability and a preparation method of the novel wooden structural material and belongs to the technical field of wood protectionand modification. The novel wooden structural material with the stable durability comprises a protective outer shell formed through surface layer heat modification and a core layer. The core layer isa supporting skeleton with a temperature stagnant zone formed through process controlling in the preparing process. The preparation method of the novel wooden structural material with the stable durability comprises the steps that firstly, a wood is sawed and planed, then, the wood is dried, the moisture content of the wood is controlled, by means of a process method, a moisture gradient is formed between the wood surface layer and the core layer, a plate type hot press is used for carrying out heating treatment on the wood surface, the temperature of the core layer is controlled in the heating process, and finally, wet-conditioning treatment is carried out on the wood. The novel wooden structural material with the stable durability and the preparation method of the novel wooden structural material have the main beneficial effects that by means of scientific control over the initial moisture content level and the internal moisture content gradient of the wood and by adjusting the temperature rising rate of the wood surface layer and the core layer, the temperature stagnation area not formed through a conventional process is formed on the core layer, and the mechanical strength ofthe novel wooden structural material is not affected while the size stability of the wood is improved.

Owner:NANJING FORESTRY UNIV

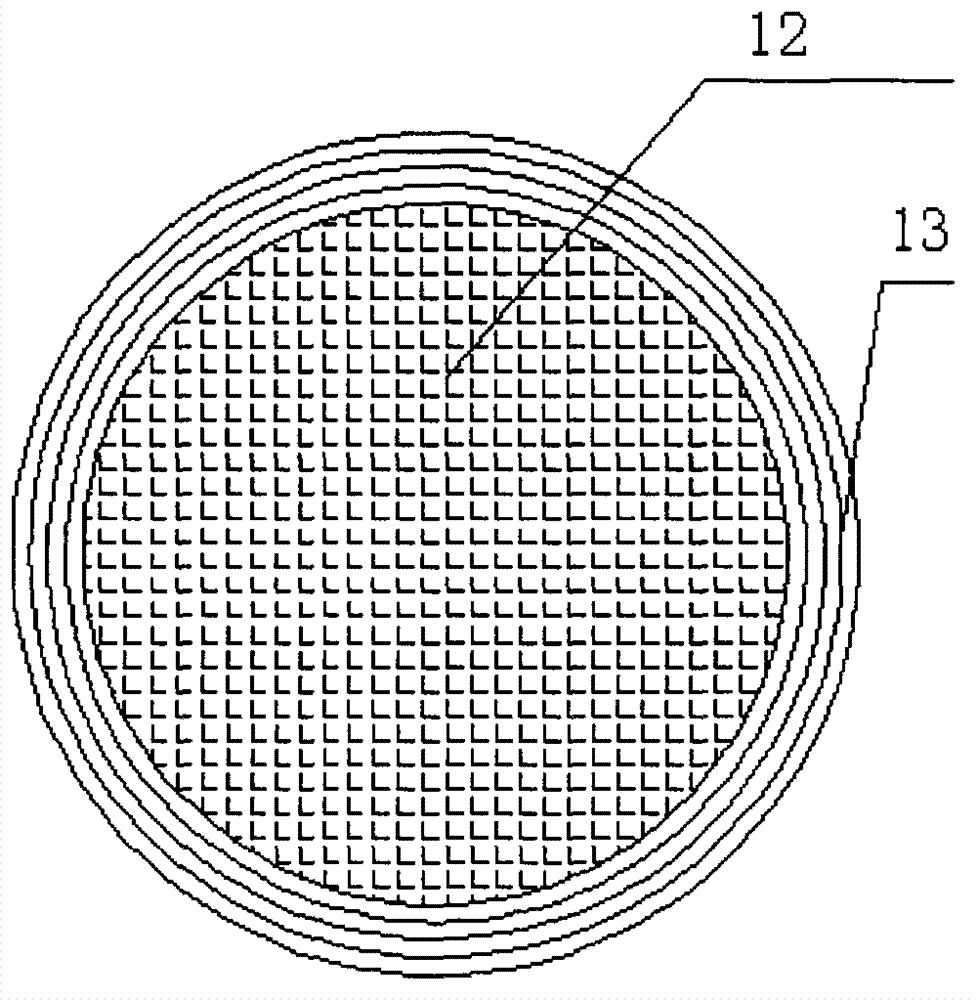

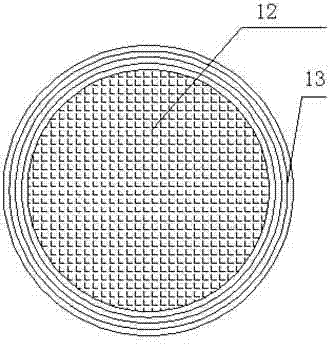

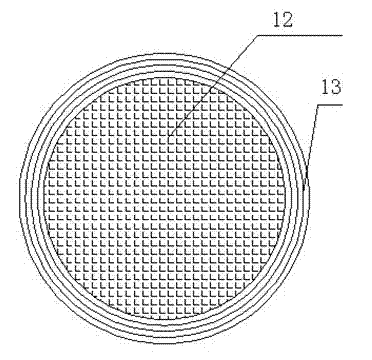

Carbon fiber composite material cable core

InactiveCN103310878ALow viscosity requirementImprove high temperature resistancePlastic/resin/waxes insulatorsInsulated cablesFiberEpoxy

The invention relates to a carbon fiber composite material cable core, which comprises a load bearing core (12) and a protection layer (13), wherein the protection layer (13) is covered outside the load bearing core (12) through a winding process, the load bearing core (12) is a high-temperature-resistance mechanical property epoxy resin and carbon fiber compound, and the protection layer (13) is a compound of high-temperature-resistance and weather-resistance epoxy resin compositions and glass fibers. The carbon fiber composite material cable core adopts the blending epoxy resin of the hydantoin epoxy resin and low-viscosity epoxy resin as resin substrates, the requirement of glass fibers on the low viscosity of the resin can be met, and the cable core can also have excellent high-temperature-resistance performance.

Owner:喻聪

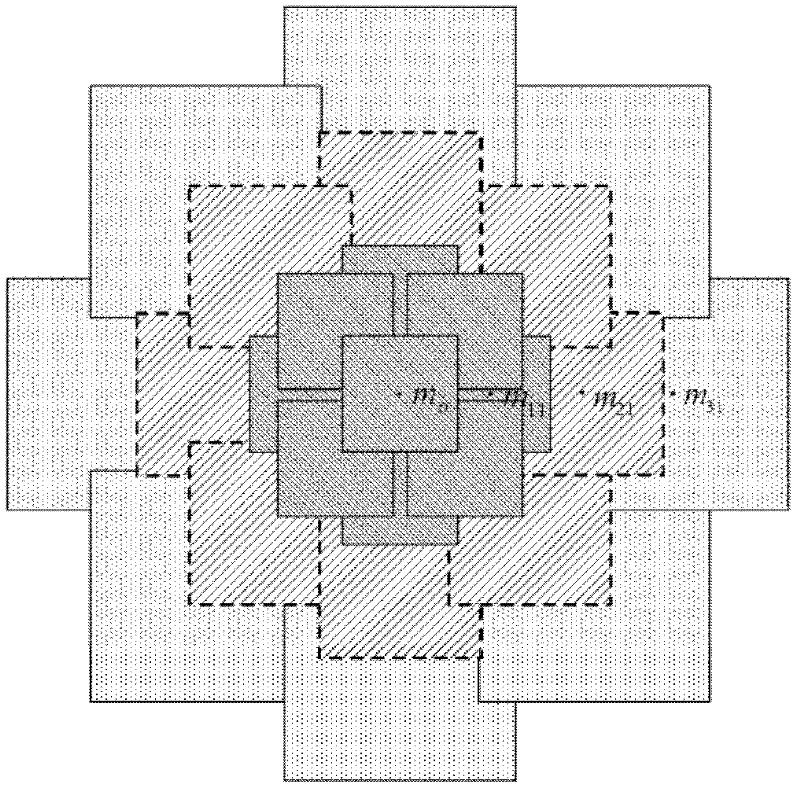

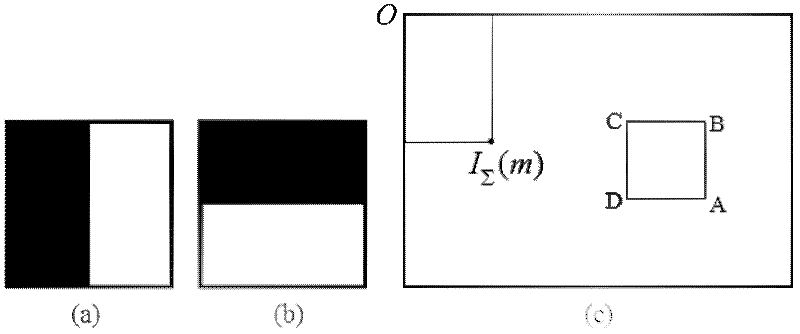

Descriptor constructing method suitable for dense matching of wide baseline image

InactiveCN102306383AImprove featuresImprove robustnessImage analysisCharacter and pattern recognitionPattern recognitionHaar wavelet

The invention discloses a descriptor constructing method suitable for dense matching of a wide baseline image. A descriptor constructed by the method provided by the invention comprises a sub descriptor constructed based on Haar wavelet response and a sub descriptor constructed based on a model with a constant color ratio. The descriptor constructed by the method provided by the invention not only enhances the description and matching speed of a traditional DAISY descriptor, but also enhances the independence and the robustness of the traditional descriptor by combining gray information and color information of an image. According to the invention, the model with a constant color ratio is constructed and the model can be used for constructing a sub descriptor with a constant color. The model is kept constant in the change of a view point, an illumination direction, illumination intensity and an illumination color.

Owner:BEIJING JIAOTONG UNIV

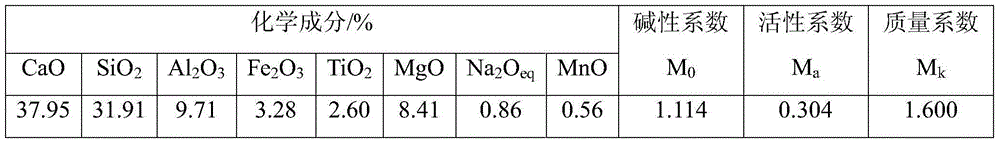

Cable core of carbon fiber composites

ActiveCN103093888AImprove mechanical propertiesExtend working lifeInsulated cablesInsulated conductorsGlass fiberEpoxy

The invention relates to a cable core of carbon fiber composites. The cable core of the carbon fiber composites comprises a bearing core (12) and a protective layer (13), and the protective layer (13) covers the outer portion of the bearing core (12) through a winding process. The cable core is characterized in that the bearing core (12) is the composite of epoxy resin and carbon fibers, wherein the epoxy resin is heat resisting and high in mechanical property, and the protective layer (13) is the composite of epoxy resin and glass fibers, wherein the epoxy resin is high temperature resisting and weather resisting. Due to the fact that the bearing core and the protective layer are chosen to be different epoxy resin systems, the high mechanical property of the epoxy resin system of the bearing core cannot be influenced by the epoxy resin system of the outer protective layer, the good weather resisting property of the outer protective layer protects the bearing core from being damaged by outer environment, and the combination property of the cable core is greatly improved.

Owner:CHANGJI POWER SUPPLY COMPANY STATE GRID XINJIANGELECTRIC POWER +1

Manufacture method of cable core

InactiveCN103093897AImprove mechanical propertiesExtend working lifeCable/conductor manufactureGlass fiberEpoxy

The invention relates to a manufacture method of a cable core. The manufacture cost of the cable core comprises the following steps: carbon fibers are led out of a creel, gum dipping is carried out to the carbon fibers after entering a first gum dipping area, and used epoxy resin is epoxy resin with heat-resisting high mechanical property; the carbon fibers after gum dipping enter a first curing oven to be precured, carbon fiber composite core are manufactured, the diameter of each carbon fiber composite core is 5mm to 12mm, and a curing degree reaches more than 85% by adjusting temperature; glass fibers on two sides are led out and respectively enter a second gum dipping area and a third gum dipping area, and used epoxy resin is high temperature resistant and weather resistant; the glass fibers after gum dipping pass through a winding area and are wound and cover the outer layers of the carbon fiber cores, the thickness of single side is 0.5mm to 2mm, and winding speed is synchronous with pultrusion speed by being controlled by a servo motor; and the carbon fiber composite cores and the glass fiber protective layers pass through the second curing oven after being compounded, and are fully cured by adjusting temperature. Composite material cable core products pass through a dragger and are wound up on the position of a winding disc.

Owner:STATE GRID CORP OF CHINA +1

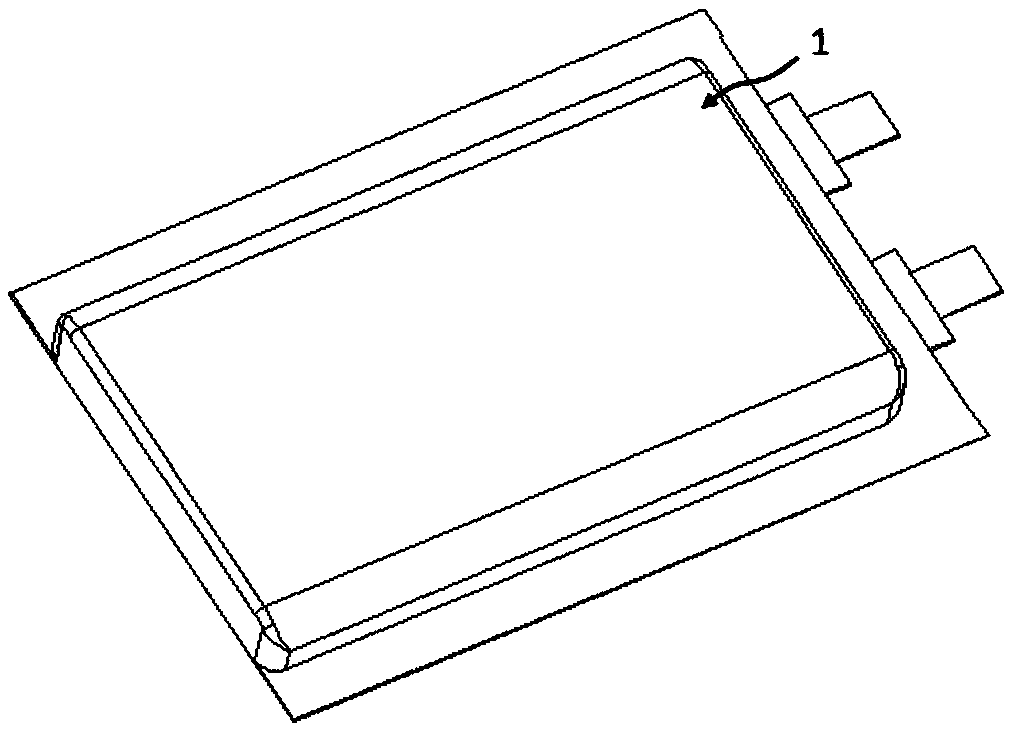

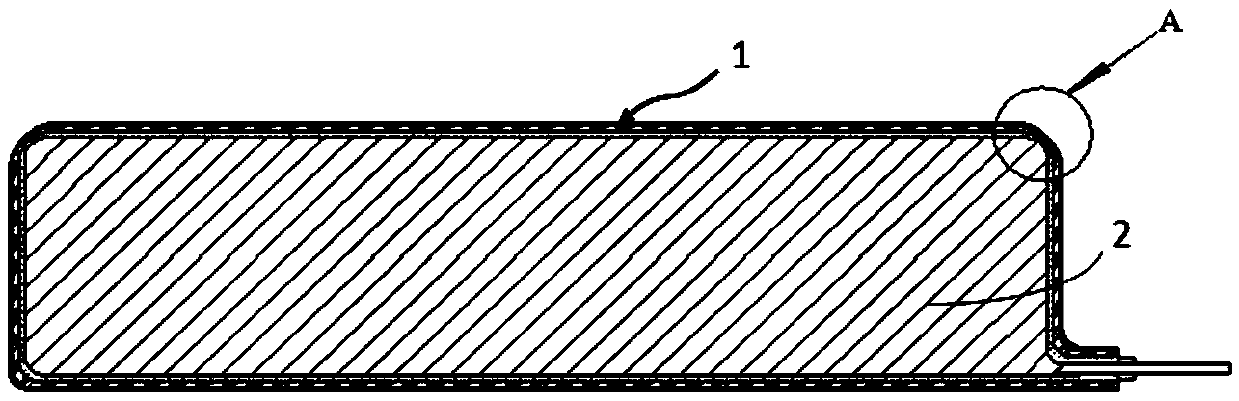

Lithium-ion battery packaging housing and lithium ion battery comprising same

InactiveCN105514307AReduce thicknessConstant thicknessSecondary cellsCell sealing materialsMetal coatingPunching

The invention relates to the field of lithium ion batteries, in particular to a lithium ion battery packaging housing, a preparation method and a lithium ion battery comprising the lithium ion battery packaging housing. A naked battery core of the lithium-ion battery is wrapped by the packaging housing, a sealing housing layer, a metal coating layer and a plastic coating layer are sequentially arranged from interior to exterior, the sealing housing layer wraps the naked battery core of the lithium-ion battery and is sealed, and then the metal coating layer and the plastic coating layer are sequentially arranged on the outer surface of the sealing housing layer. The materials of all the layers of the structure of the packaging housing are machined on the exterior of the lithium ion battery in the product manufacturing or packaging process, and packaging defects caused in a punching procedure are avoided when the thickness and the strength of folding positions and corners of the product are kept constant, so that the product packaging reliability is greatly improved, the housing does not have tensile deformation or wrinkling, appearance defects are avoided, the product appearance is improved, and the battery energy density is increased.

Owner:NINGDE AMPEREX TECH

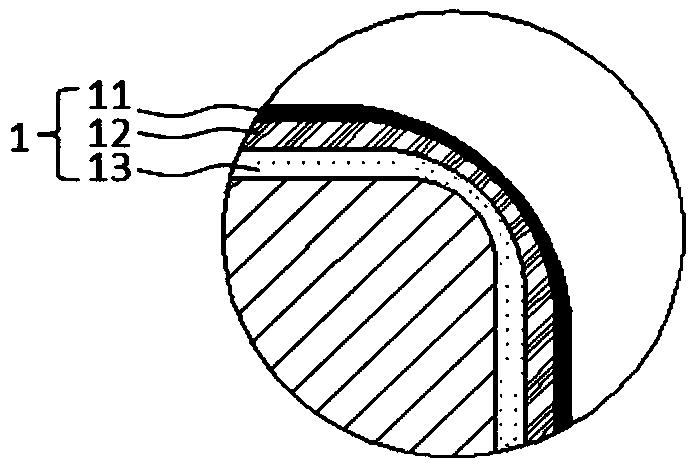

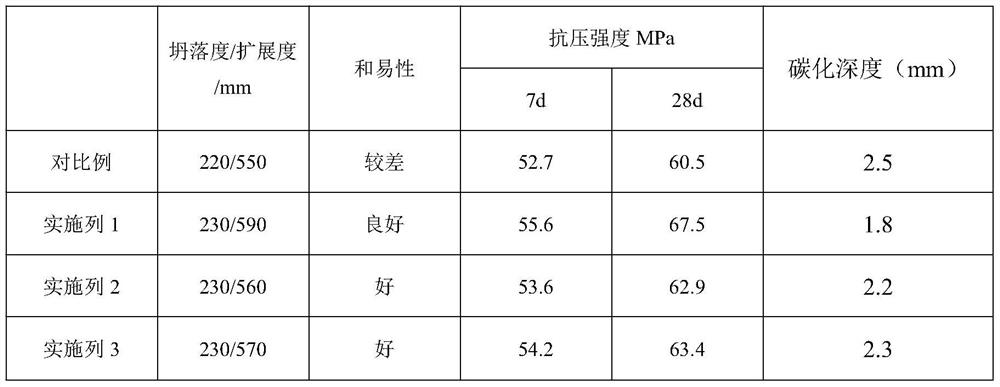

Machine-made sand concrete using synergist and preparation method of machine-made sand concrete

InactiveCN111943605AReduce porosityPromotes the hydration processNatural sandGeotechnical engineering

The invention discloses machine-made sand concrete using a synergist and a preparation method of the machine-made sand concrete. The concrete comprises the following components and a formula: 395-435parts of cement; 0-30 parts of fly ash; 0-30 parts of mineral powder; 900.15-920.55 part of machine-made sand; 864.85-884.45 parts of broken stone; 9.1-9.9 parts of an additive; 2.73-2.97 parts of a synergistic agent; and 153-170 parts of water. The synergist component comprises a reinforcing agent, a dispersing agent, nano calcium carbonate, a foaming agent, a foam stabilizer and water. Accordingto the invention, the inherent advantages of the machine-made sand are brought into full play, and the problem of shortage of natural sand resources is effectively relieved; use amount of cement in the same grade of machine-made sand concrete can be reduced and the strength of the machine-made sand concrete is not changed or even higher, the durability of the machine-made sand concrete is improved, the cost of the machine-made sand concrete is reduced, and the cracking risk of the concrete can be reduced.

Owner:中建西部建设贵州有限公司 +1

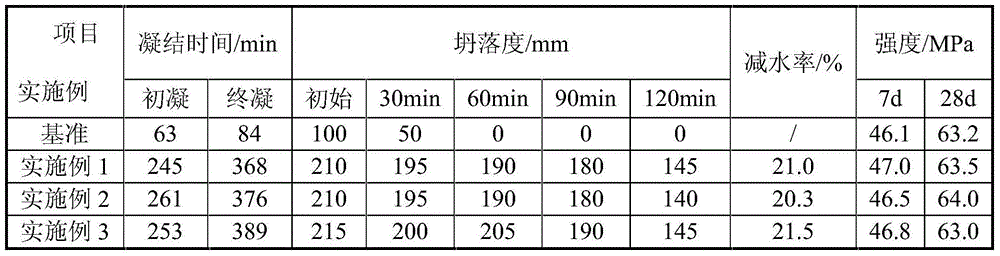

Alkali slag concrete water reducing agent

The invention discloses an alkali slag concrete water reducing agent which comprises following components, by mass: 11-23 parts of nitrates, 15-25 parts of a [beta]-naphthalenesulfonate-formaldehyde condensate, 3-5 parts of a lignosulfonate and 1-2 parts of a dodecyl benzene sulfonate. An alkali slag concrete is a WG-slag concrete and herein the WG represents for water glass; the [beta]-naphthalenesulfonate-formaldehyde condensate is [beta]-sodium naphthalenesulfonate-formaldehyde condensate; the lignosulfonate is calcium lignosulfonate; the dodecyl benzene sulfonate is sodium dodecyl benzene sulfonate; and the nitrates is a mixture composed of 1-3 parts of barium nitrate and 10-20 parts of lead nitrate. The water reducing agent can account for more than 20% of the WG-slag concrete, is good in adaptation with the WG-slag concrete, can effectively reduce an initial viscosity of newly-mixed WG-slag concrete, can improve a flowability and a workability of the concrete, can reduce a usage amount of the WG-slag concrete and can enhance the strength of the concrete.

Owner:重庆富普新材料有限公司

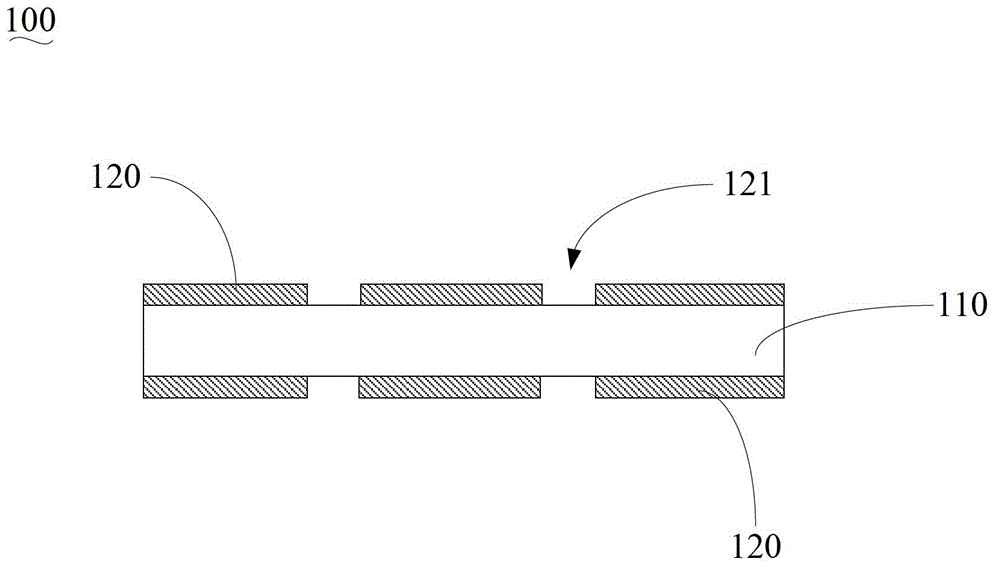

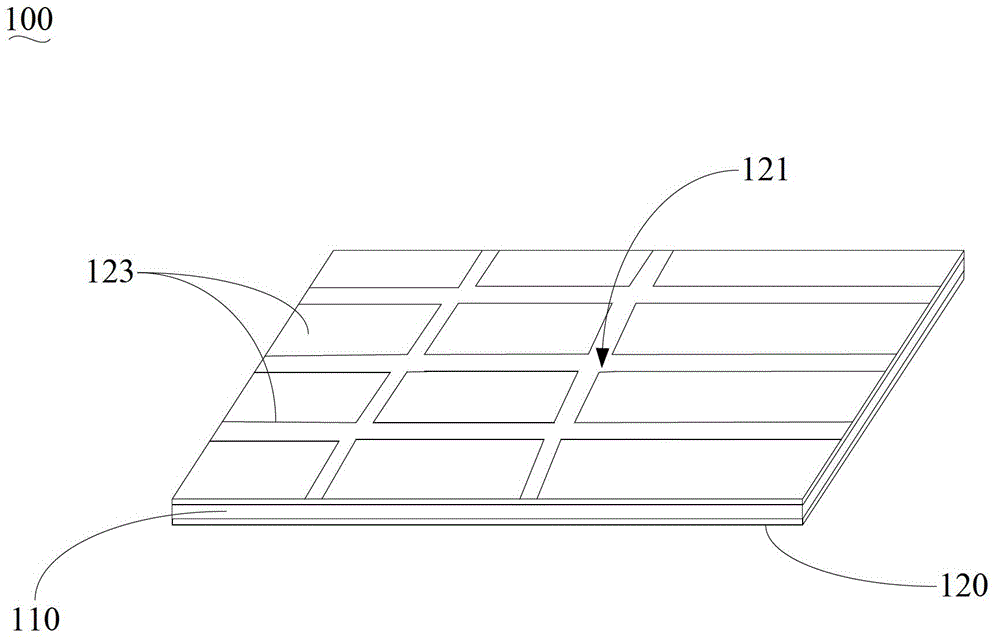

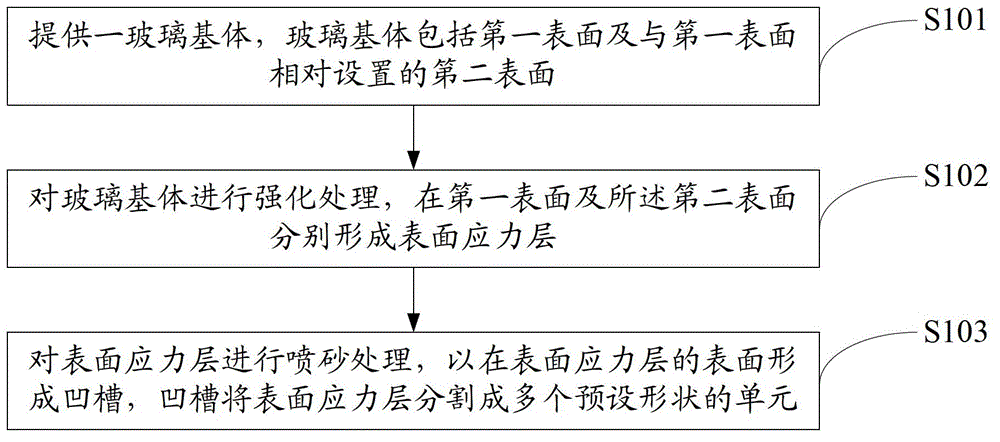

Panel glass, preparation method thereof, preparation method of touch screen adopting panel glass

InactiveCN103336610AIncrease productivityIntensity unchangedInput/output processes for data processingSurface stressSand blasting

A preparation method of a touch screen comprises the following steps: strengthening a basal body of a whole piece of glass; forming a light shield layer and a conductive circuit on the strengthened glass basal body, followed by sand blasting processing, forming a groove on the surface with a stress layer; cutting the glass basal body along the groove to obtain a plurality of touch screens with pre-arranged shape. According to the invention, the surface stress layer at the position of the groove is removed, so that the cutting can not damage the stress layer of the glass, which maintains the strength of the glass to be approximately constant. Due to the adoption of the preparation method, after the completion of primary reinforcement, the touch screens can be obtained through cutting, and as a result, the production efficiency is greatly improved. The invention also provides another preparation method for the touch screen, and a panel glass and a preparation method thereof.

Owner:NANCHANG O FILM OPTICAL TECH

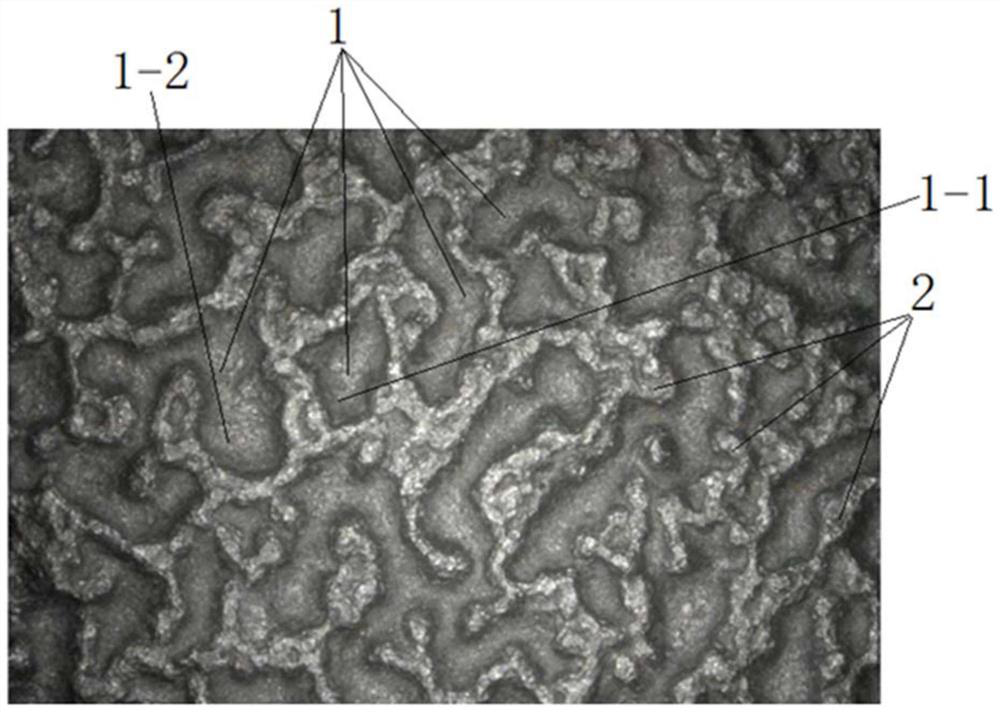

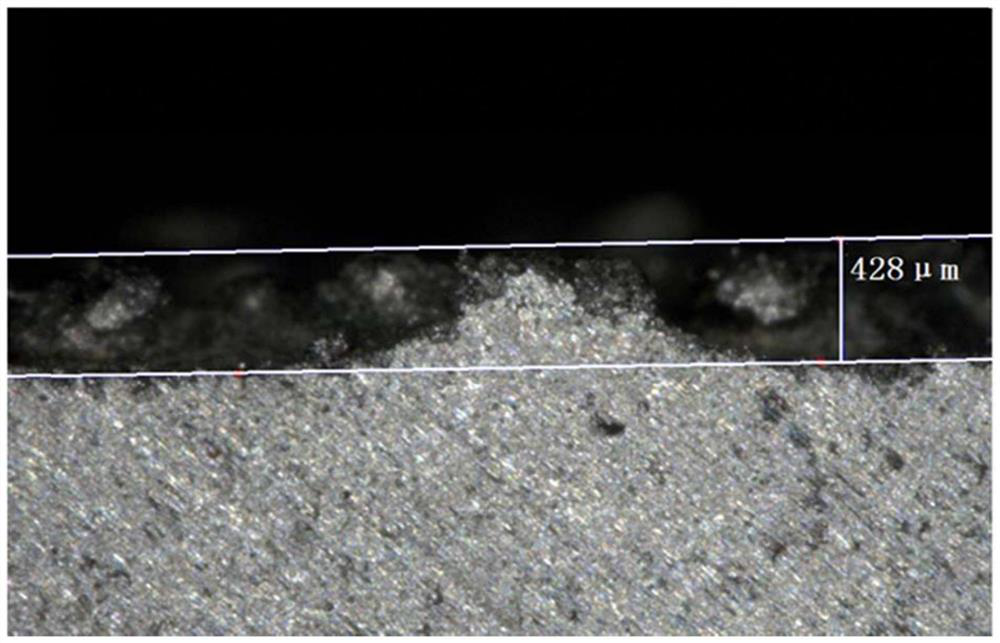

Cylinder liner and preparation process thereof

ActiveCN111664019AEasy to fillIncrease binding rateCasingsMoulding toolsMechanical engineeringAluminium alloy

The invention discloses a cylinder liner and a preparation process thereof. On the outer ring surface of the cylinder liner, there are randomly distributed recesses and protruding ribs dividing adjacent recesses, and the protruding ribs enclose a recess portion. The recess portion comprises meshes, the outer ring surface of the cylinder liner has closed meshes with the number of at least 10% of the total number of the meshes, and the remaining meshes are intermittent meshes. Through the special structure of the outer ring surface of the cylinder liner, it can be ensured that the aluminum alloyliquid can easily fill the surface during the casting process of the aluminum alloy liquid. After testing, the combination rate of the cylinder liner provided by the invention and the aluminum alloyliquid reaches 90% or more, and the combination rate of the outer round burr-shaped cylinder liner and the aluminum alloy liquid is less than 50%.

Owner:ZYNP GRP

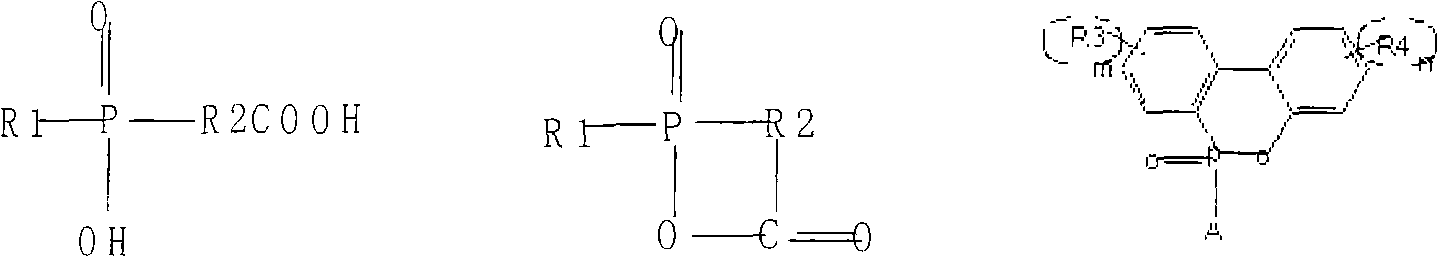

Preparation method of flame retarding phosphorus-copolyester with better color phase

The invention discloses a preparation method of flame retarding phosphorus-copolyester with better color phase. 4000-12000ppm of phosphorus- copolymerization flame retardant, which is calculated by phosphorus element, and 10-150ppm of three-valued phosphorus stabilizer, which is calculated by phosphorus element, are added during the preparation reaction. The hue value of the flame retarding phosphorus-copolyester prepared by the method is as follows: b is equal to minus 2 to 6, and L is equal to 60 to 90. The whiteness and the brightness of fabrics are good, and the fire resistance is excellent so as to reach M1 grade.

Owner:TORAY IND INC

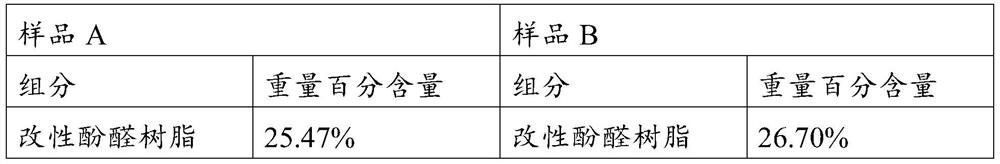

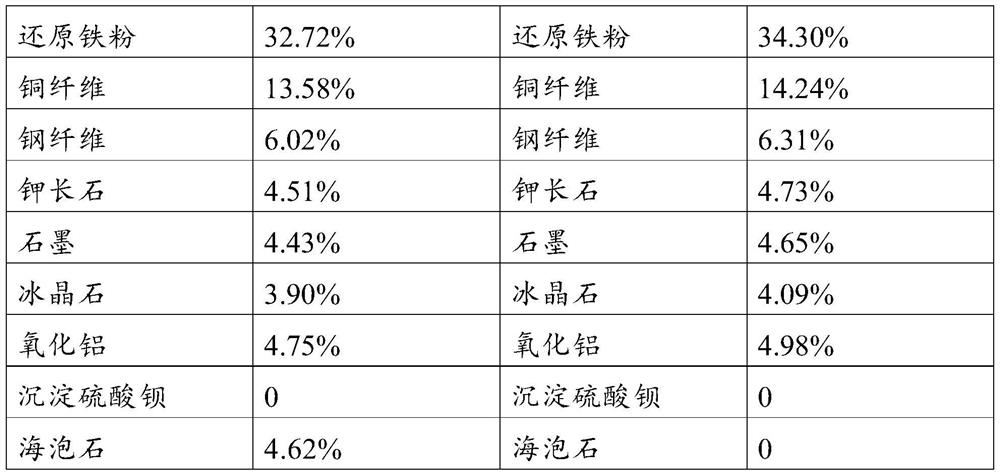

Motor train unit grinder which does not generate metal inserts and has good shaping effect

ActiveCN111875923AIncrease coefficient of frictionCoefficient of frictionVehicle cleaningBoron nitrideMaterials science

The invention provides a motor train unit grinding element which does not generate metal inserts and is good in shaping effect. The motor train unit grinder comprises the following components in percentage by weight: 10-30% of modified phenolic resin, 30-40% of reduced iron powder, 10-20% of copper fiber, 3-8% of steel fiber, 3-8% of potassium feldspar, 4-9% of graphite, 3-8% of cryolite, 2-4% ofaluminum oxide, 1-3% of precipitated barium sulfate and 2-5% of boron nitride, wherein the motor train unit grinder does not comprise sepiolite. The invention further provides a preparation method ofthe motor train unit grinding body and application of the motor train unit grinding body in railway transportation.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

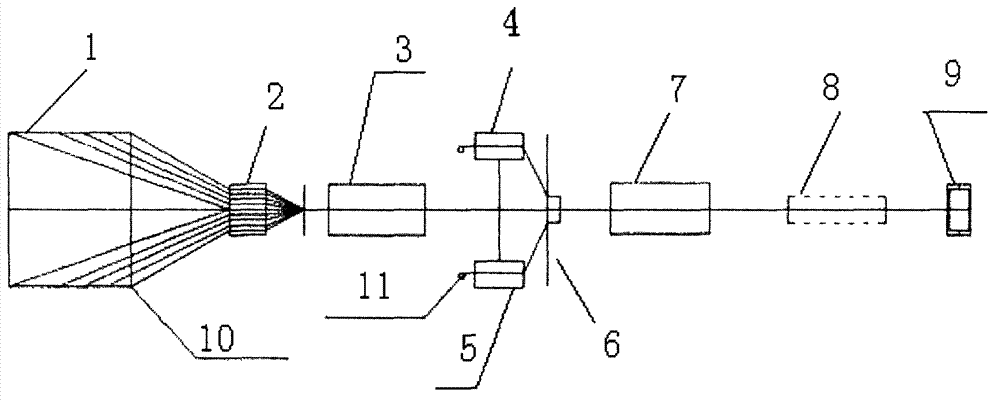

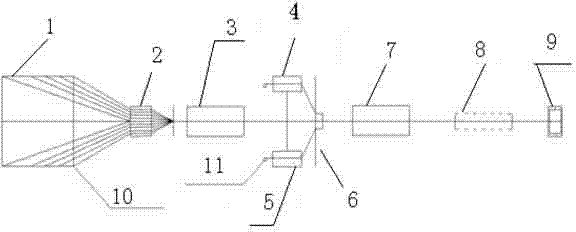

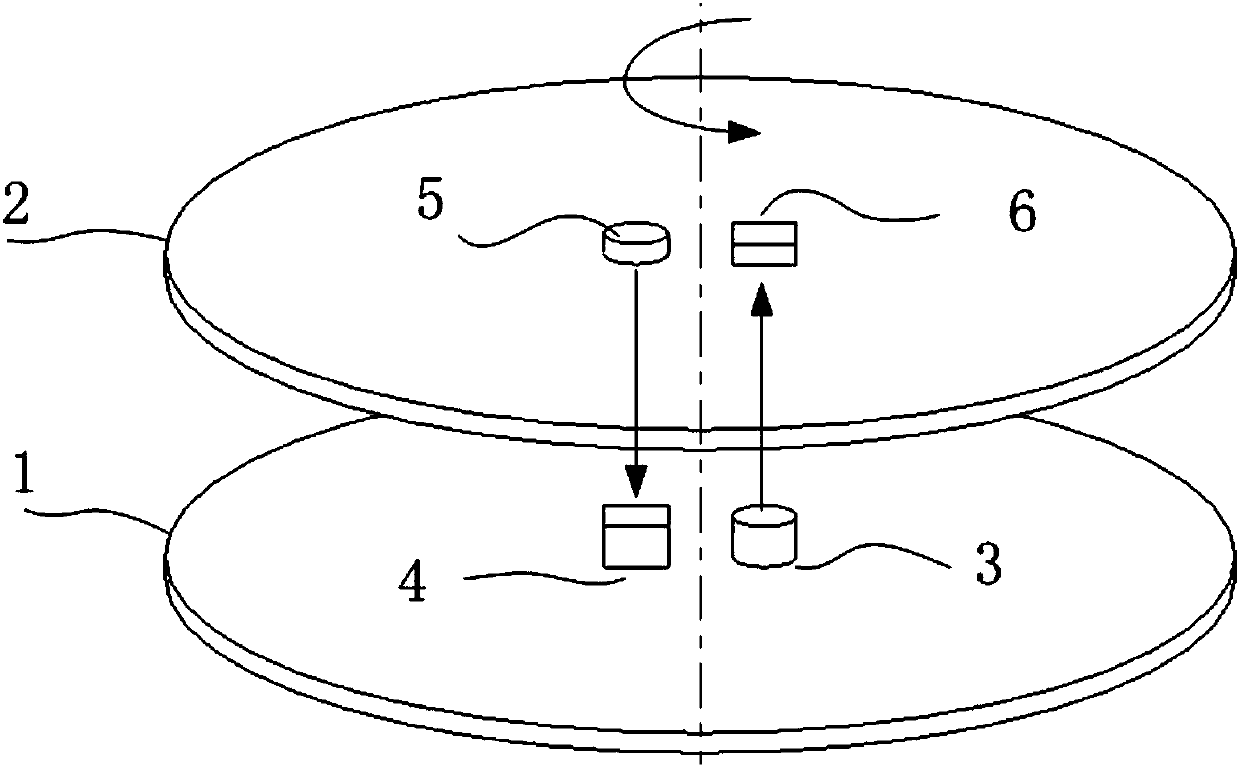

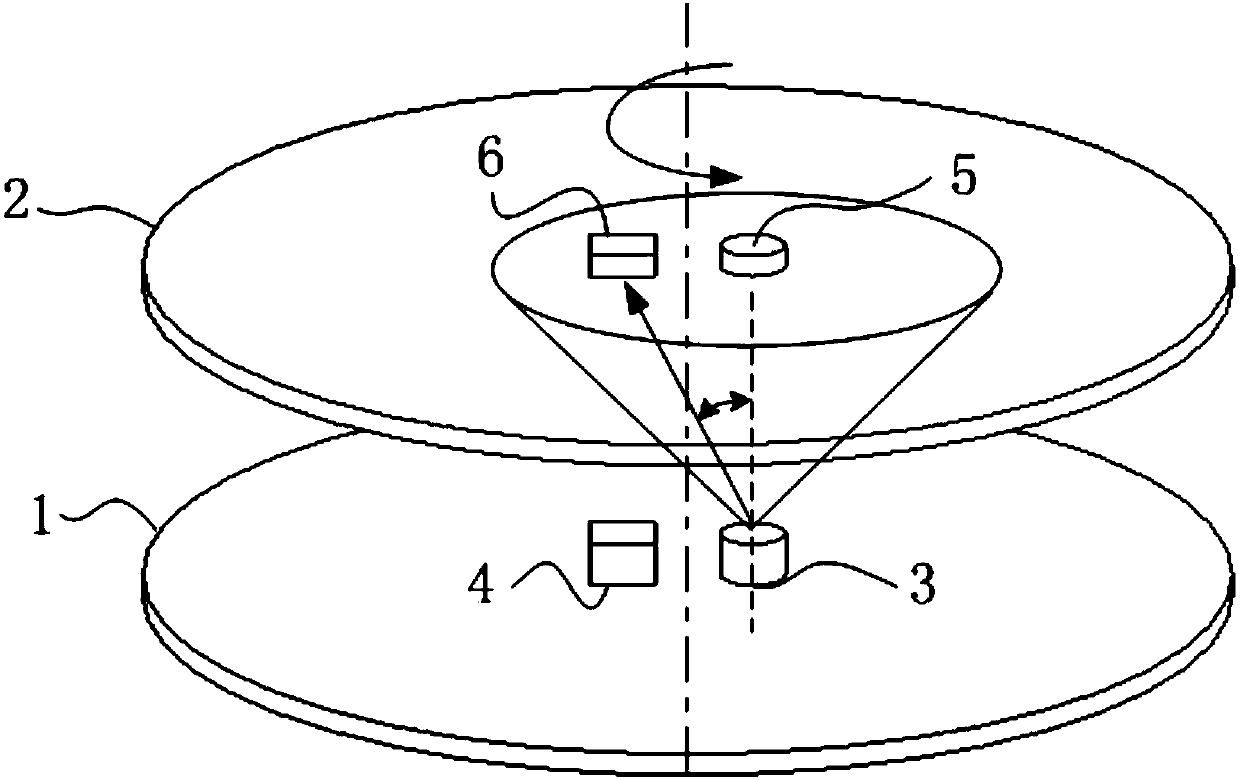

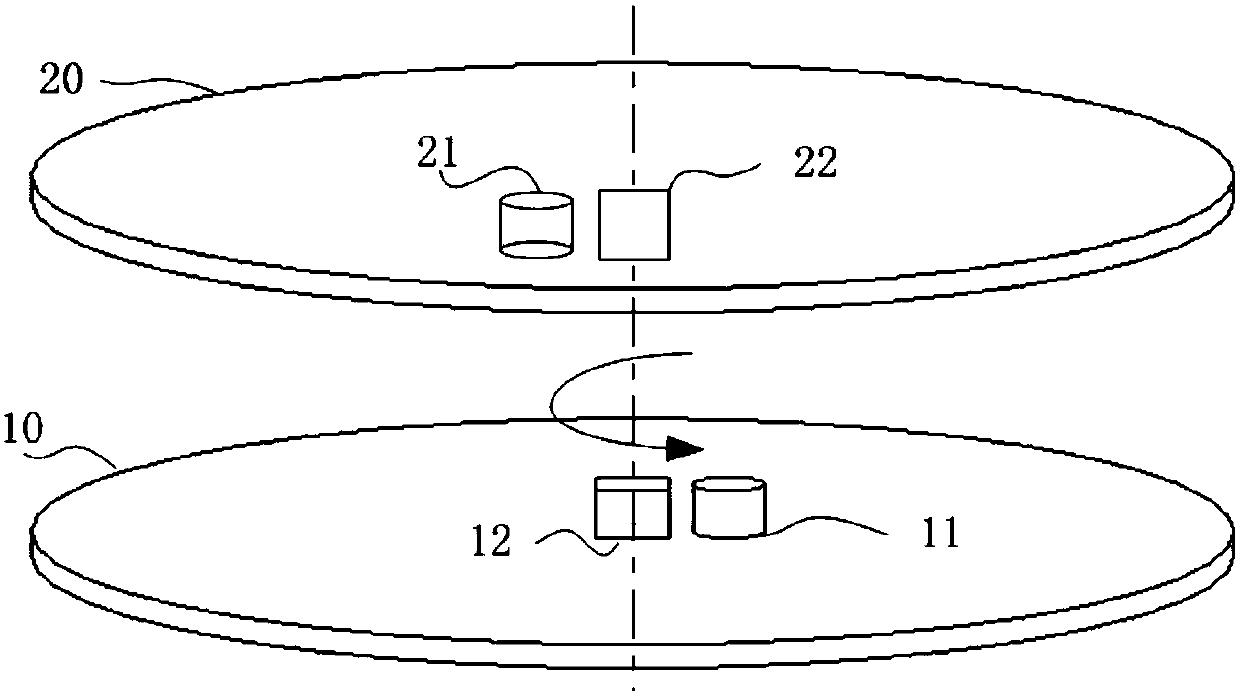

Full-duplex signal transmission device based on optical communication

PendingCN109932703AIntensity unchangedReduce bit error rateWave based measurement systemsOptical communicationLength wave

The specific embodiment of the invention provides a full-duplex signal transmission device based on optical communication. The device comprises a component 10 and a component 20, wherein components rotate relative to each other about the same rotation axis. The component 10 is provided with a light emitter 11 and a light receiver 12. The component 20 is provided with a light emitter 21 and a lightreceiver 22. The light emitter 11 and the light receiver 22 use spectral communication of a first wavelength. The light emitter 21 and the light receiver 12 use spectral communication of a second wavelength. The photosensitive surface of the light receiver 12 of the component 10 and the photosensitive surface of the light receiver 22 of the component 20 are arranged at the relative rotation centers of the components 10 and 20. According to the invention, the photosensitive surfaces of two light receivers are arranged at the relative rotation centers of two components respectively, which keepsthe intensity of the signals received by the light receivers unchanged; the bit error rate is reduced; and the transmission quality and efficiency are improved.

Owner:保定市天河电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com