Spent activated carbon regeneration method

A treatment method, activated carbon technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve problems such as damage, and achieve the effects of mature technology, reduction of raw material loss, and scientific and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

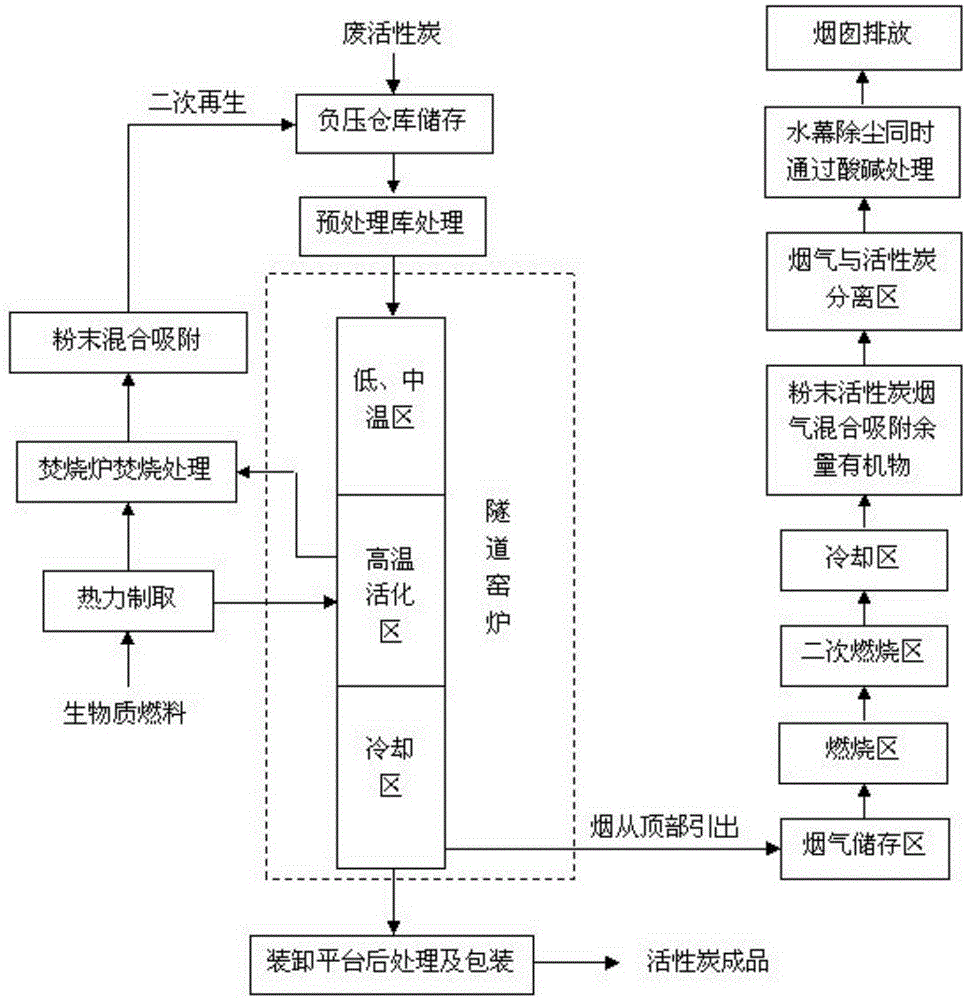

[0028] Such as figure 1 shown. A kind of waste activated carbon regeneration process described in the present embodiment, comprises the following steps successively:

[0029] (1) storage

[0030] Put the bagged waste activated carbon material into the standard raw material warehouse for airtight storage by means of a movable conveyor belt or manual handling, and the storage time is 3 weeks; There is a slight negative pressure inside; there is an air suction port and an exhaust fan above the standard raw material warehouse, and the exhaust fan draws the exhaust gas from the warehouse to the waste gas collection warehouse through the air suction port; there is a certain slope at the bottom of the standard raw material warehouse. Ditch and leachate collection tank;

[0031] (2) Pretreatment

[0032] Move the bagged waste activated carbon material stored and placed in the above step (1) into the micro-negative pressure pretreatment warehouse, manually open the bag, fill the wa...

Embodiment 2

[0048] A kind of waste activated carbon regeneration process described in the present embodiment, comprises the following steps successively:

[0049] (1) storage

[0050] Put the bagged waste activated carbon material into the standard raw material warehouse for airtight storage by means of a movable conveyor belt or manual handling, and the storage time is 3 weeks; There is a slight negative pressure inside; there is an air suction port and an exhaust fan above the standard raw material warehouse, and the exhaust fan draws the exhaust gas from the warehouse to the waste gas collection warehouse through the air suction port; there is a certain slope at the bottom of the standard raw material warehouse. Ditch and leachate collection tank;

[0051] (2) Pretreatment

[0052] Move the bagged waste activated carbon material stored and placed in the above step (1) into the micro-negative pressure pretreatment warehouse, manually open the bag, fill the waste activated carbon into ...

Embodiment 3

[0068] A kind of waste activated carbon regeneration process described in the present embodiment, comprises the following steps successively:

[0069] (1) storage

[0070] Put the bagged waste activated carbon material into the standard raw material warehouse for airtight storage by means of a movable conveyor belt or manual handling, and the storage time is 2 weeks; There is a slight negative pressure inside; there is an air suction port and an exhaust fan above the standard raw material warehouse, and the exhaust fan draws the exhaust gas from the warehouse to the waste gas collection warehouse through the air suction port; there is a certain slope at the bottom of the standard raw material warehouse. Ditch and leachate collection tank;

[0071] (2) Pretreatment

[0072] Move the bagged waste activated carbon material stored and placed in the above step (1) into the micro-negative pressure pretreatment warehouse, manually open the bag, fill the waste activated carbon into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com