Large-size composite material air inlet passage measuring rake

A composite material and air inlet technology, which is applied in the field of large-sized composite material air inlet measurement rake, can solve the problems of single measurement parameter, increased force of the rake body on the damping ring, and increased vibration stress, etc. Changes, overall structure weight reduction, high shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

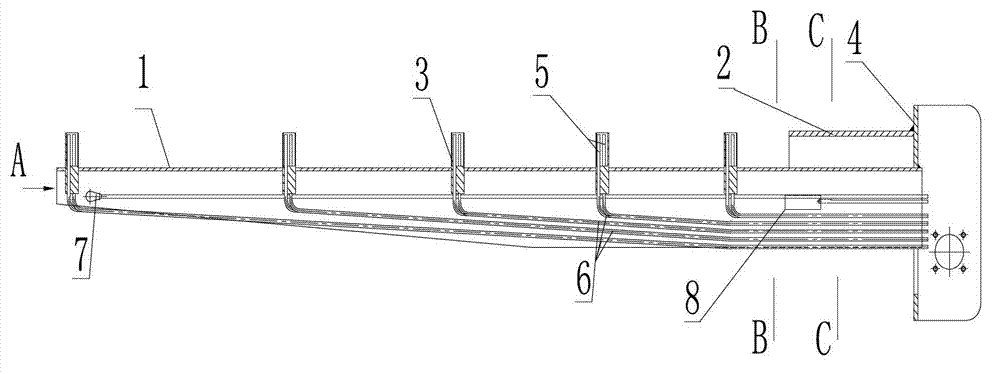

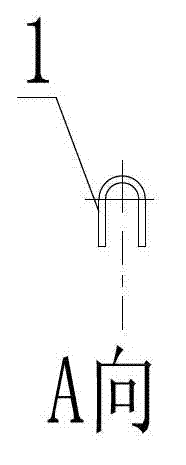

[0012] The invention provides a large-scale composite material air inlet measuring rake, such as figure 1 , figure 2 , image 3 , Figure 4 shown, including:

[0013] The skin skeleton 2 with a U-shaped cross section includes a front measurement section and a rear installation section. The root of the installation section of the skin skeleton 2 is connected to the mounting seat 9. The position is provided with a measuring point sheath 5, and a measuring element 7 is installed in the measuring point sheath 5, and the measuring element 7 is output to the mounting seat 9 through the conduit 4, and the shock-absorbing sheath 8 with a U-shaped cross section is set on the skin On the outside of the installation section of the skeleton 2, there is a gap between the shock-absorbing sheath 8 and the skin skeleton 2, the roots of the shock-absorbing sheath 8 are connected to the mounting seat 9, and the inner wall of the head of the measurement section of the skin skeleton 2 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com