Frame type glass door without screw fixing

A frame type, screwless technology, applied in the installation of window glass, door leaf and other directions, can solve the problems of glass door shape, cutting, punching, difficult bending process, safety accidents, etc., to ensure smoothness and smoothness, The assembly process is simple and the overall strength remains unchanged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in conjunction with accompanying drawings:

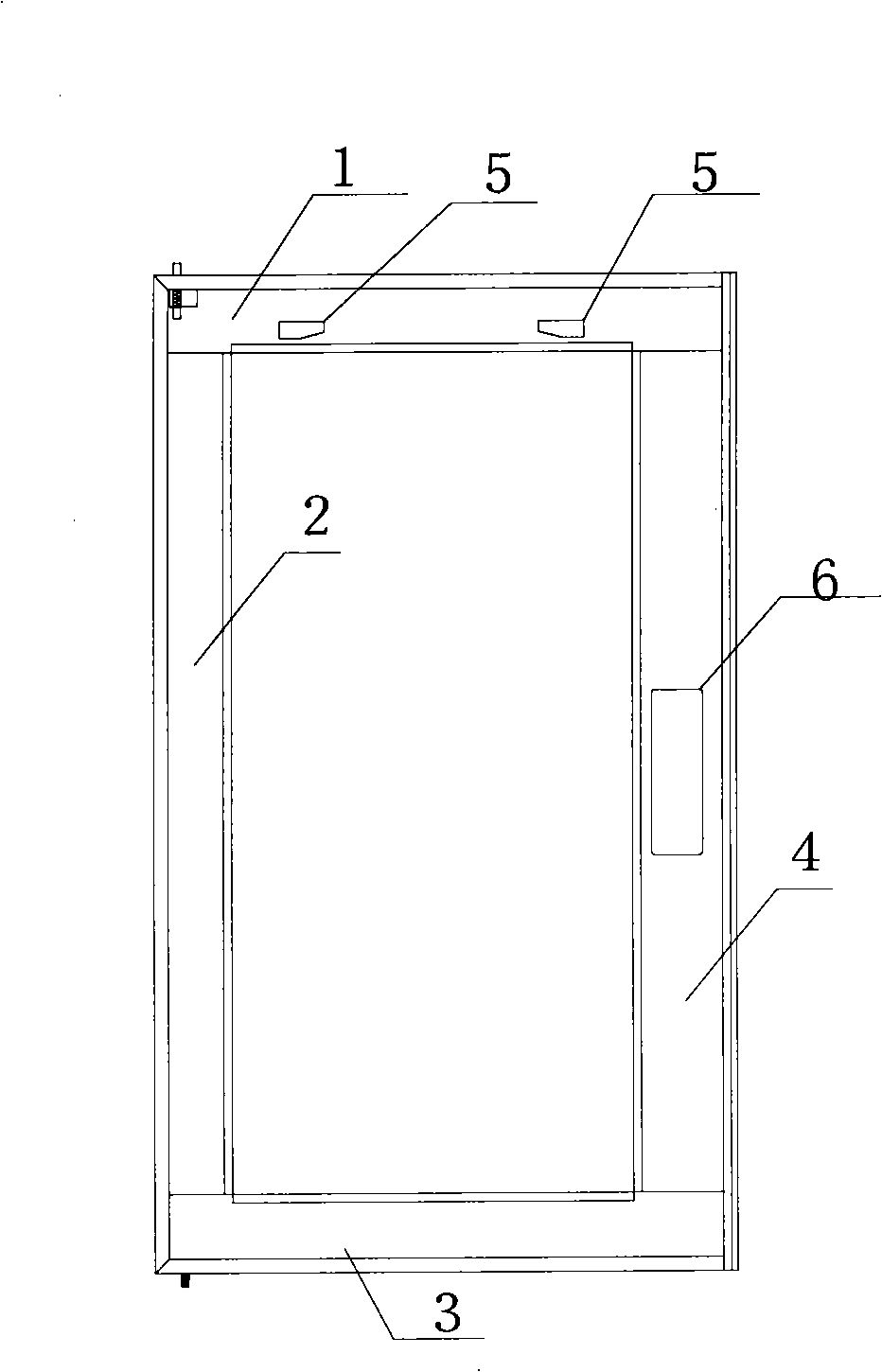

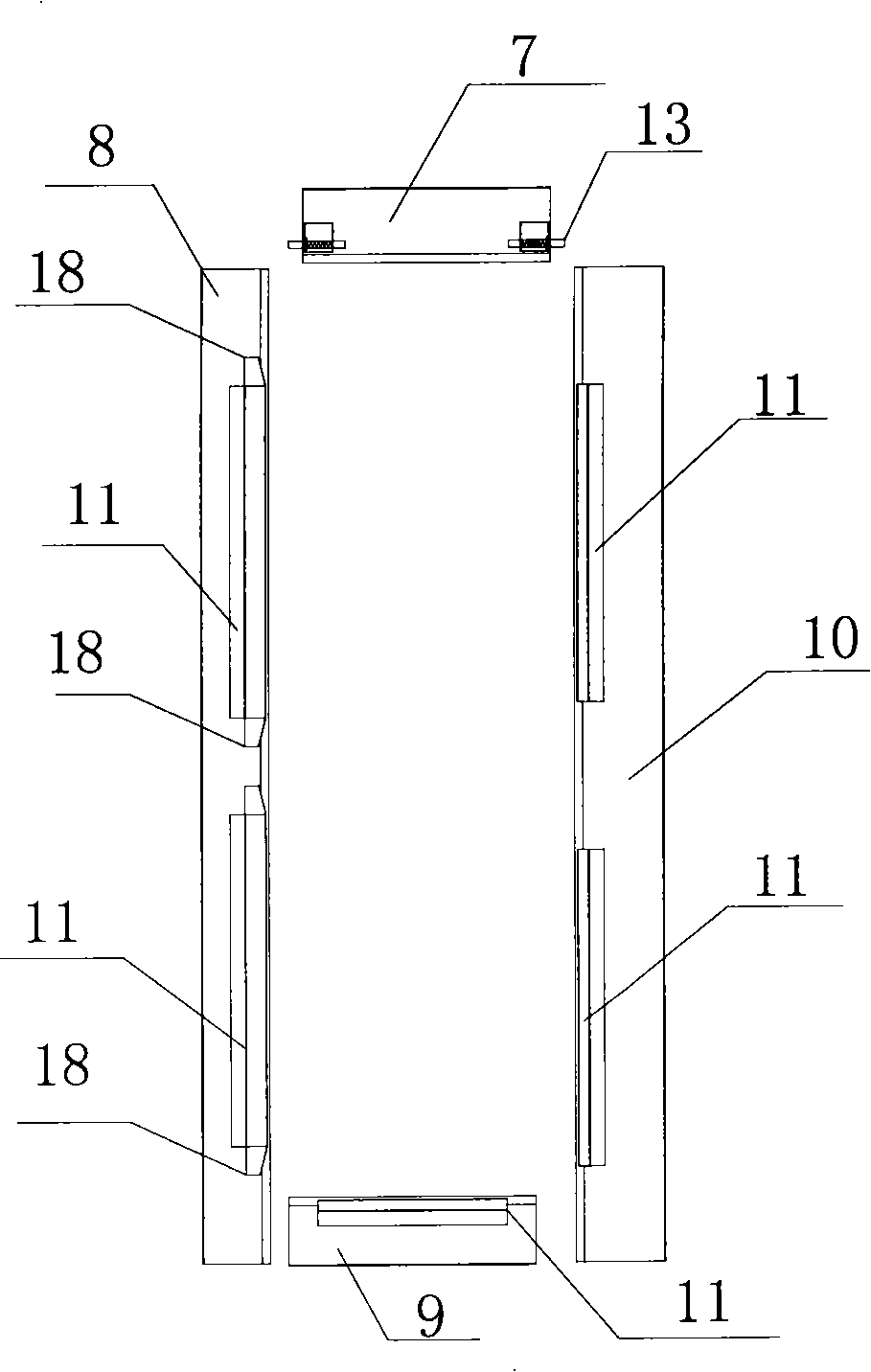

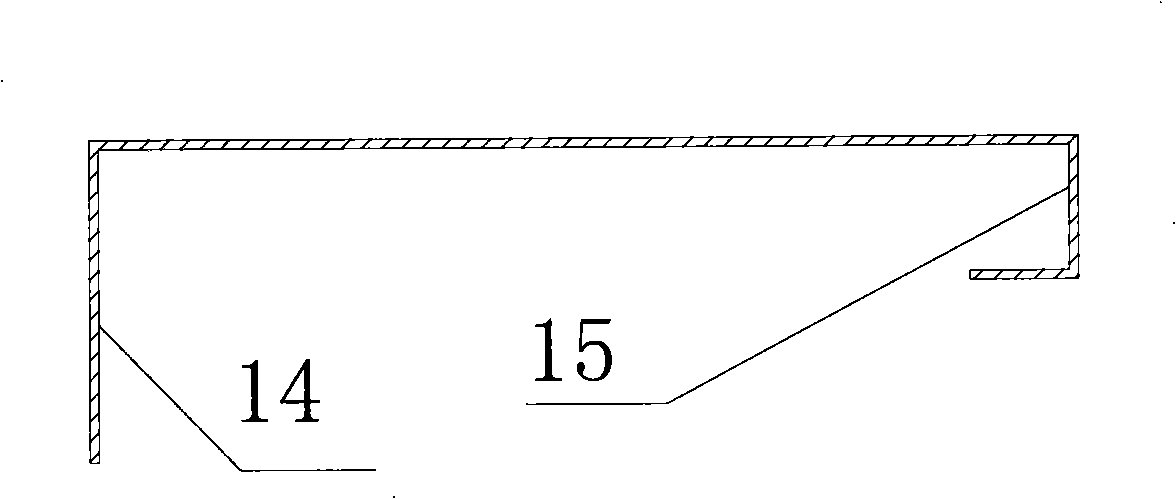

[0028] A frame-type glass door without screws fixed by the present invention is mainly used in steel office cabinets, and is composed of two doors combined; only the structure of one of the doors is given here and explained in conjunction with the accompanying drawings The door frame of the glass door is composed of four outer sealing plates 1, 3, 2, 4 and corresponding inner sealing plates 7, 9, 8, 10; the outer door frame is formed by welding the four outer sealing plates, and the four inner sealing plates The sealing plates are respectively combined with the corresponding outer sealing plates to form an integral door frame; Figure 4 As shown: the outer side of the outer sealing plate 1, 2, 3, 4 has the outer groove 16 formed by the plate upward and then inward twice at 88°; the inner side has the plate upward and then outward twice at 90° The inner side groove 17 that li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com