Composite damping layer toughened thin layer and preparation method thereof

A composite damping and thin-layer technology, which is applied in the field of structural damping composite materials, can solve the problems of heat resistance, stiffness reduction, and poor processing technology, and achieve the effect of improving fracture toughness and damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

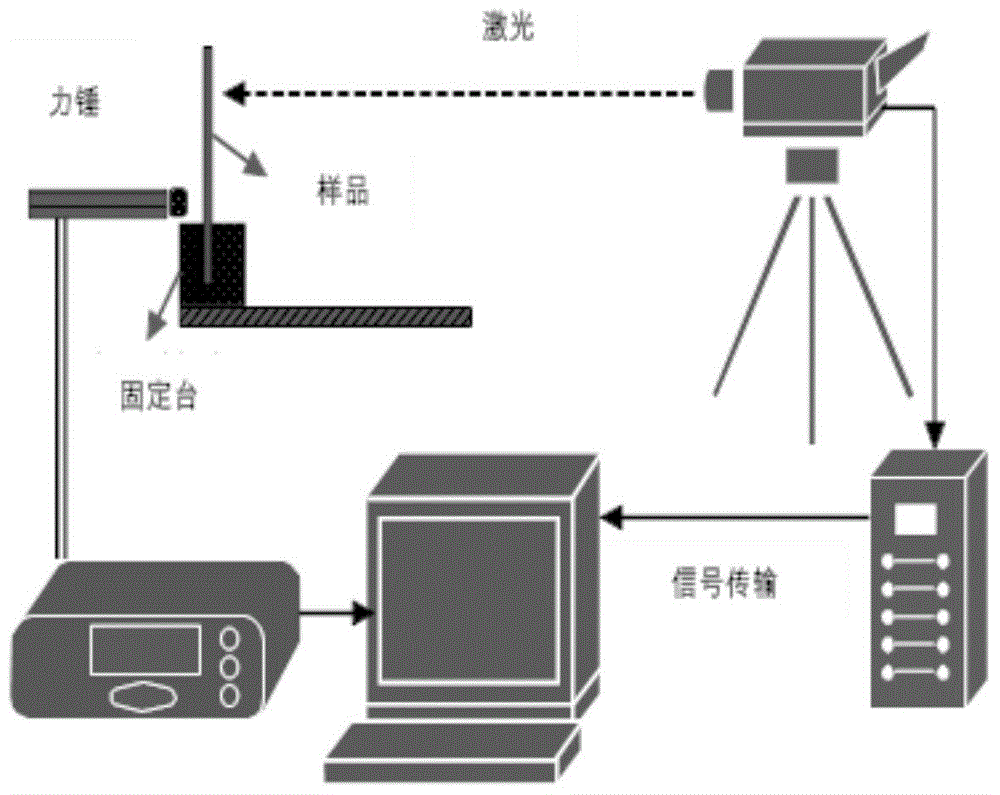

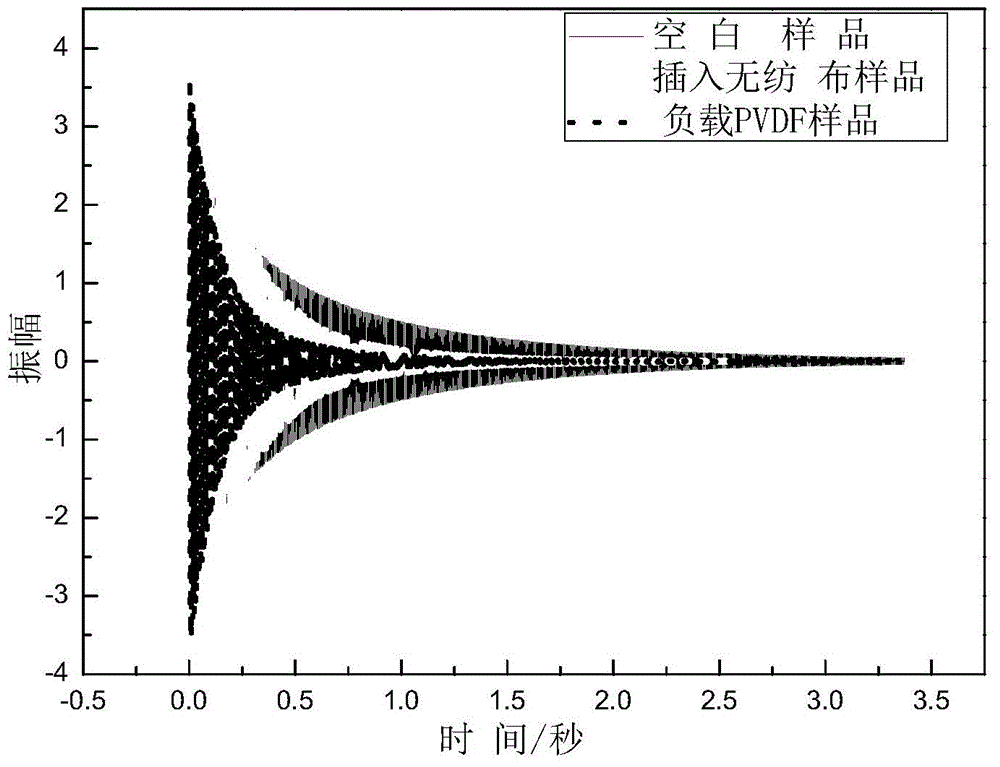

[0028] The implementation process of the technical solution of the present invention is as follows:

[0029] 1. Disperse PVDF in dimethylformamide DMF or dimethylacetamide DMAc to form a dispersion with a concentration of 5-30%;

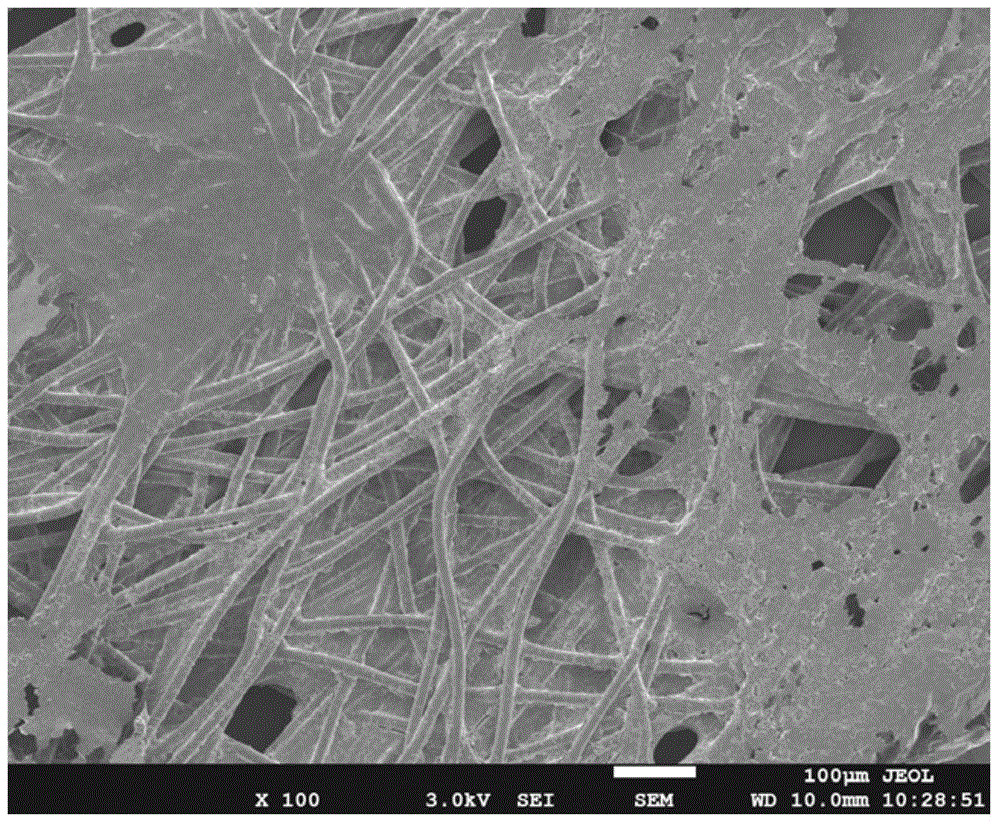

[0030] 2. Set the thickness to 80μm and surface density to 40g / m 2 Aramid non-woven fabric with a thickness of 53μm and a surface density of 20g / m 2 Nylon non-woven fabric with a thickness of 25μm and a surface density of 8g / m 2 Polyether ether ketone non-woven fabric or thickness of 75μm, surface density of 26g / m 2 Polyimide non-woven fabric with a thickness of 15μm and a surface density of 7g / m 2 Polyethersulfone non-woven fabric with a thickness of 30μm and an area density of 16g / m 2 The aramid non-woven fabric is immersed in the PVDF dispersion liquid obtained in the above step 1, the liquid surface is pulled out and dried or dried, and the above steps are repeated to impregnate once again to obtain a polymer non-woven fabric evenly loaded wi...

Embodiment 2

[0037] The implementation process of the technical solution of the present invention is as follows:

[0038] 1. Disperse PVDF in dimethylformamide DMF or dimethylacetamide DMAc to form a dispersion with a concentration of 5-30%;

[0039] 2. The thickness is about 20μm, the surface density is 14g / m 2 Polyaryletherketone porous film (porosity about 40%) or thickness of 8μm, surface density of 6g / m 2 Polyimide porous film or thickness of about 25μm, surface density of 11g / m 2 Polyetherimide porous film or thickness of about 15um, area density of 9g / m2 The polyether ether ketone porous film is immersed in the PVDF dispersion described in step 1, pulled out of the liquid surface and dried, repeating the above steps and then dipped twice to obtain a polymer porous film evenly loaded with PVDF;

[0040] 3. Lay the polymer porous films obtained by the above loading one by one between the layers of continuous carbon fiber reinforced satin weave or plain weave or unidirectional or a m...

Embodiment 3

[0045] The implementation process of the technical solution of the present invention is as follows:

[0046] 1. Disperse PVDF in dimethylformamide DMF or dimethylacetamide DMAc to form a dispersion with a concentration of 5-30%;

[0047] 2. Load the above dispersion liquid through the carrier under negative pressure to a thickness of 35 μm and a surface density of 14 g / m 2 Nylon fabric with a thickness of 25μm and an area density of 11g / m 2 Polyether ether ketone fabric or thickness of 45μm, area density of 18g / m 2 on the polyimide fabric;

[0048] 3. Place the above-mentioned PVDF-loaded fabrics one by one between the layers of continuous carbon fiber reinforced epoxy resin prepreg for lamination, carbon fiber T800, 12K or CCF300, 3K, epoxy resin QY9611 (product of Beijing Aeronautical Manufacturing Engineering Research Institute) ) or epoxy resin 5228 (product of Beijing Institute of Aeronautical Materials), to obtain a toughened-damping composite material prefabricated b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com