Motor train unit grinder which does not generate metal inserts and has good shaping effect

A grinding wheel and EMU technology, which is applied in the field of transportation, can solve the problems of poor metal inlay and shape modification, and achieve the effects of preventing metal inlay, increasing cleaning effect, and high friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Weigh 28 kilograms of modified phenolic resins respectively; 48 kilograms of reduced iron powder; 22 kilograms of copper fibers; 8 kilograms of steel fibers; 6 kilograms of potassium feldspars; 9 kilograms of graphite; 8 kilograms of cryolite; 2 kg of barium sulfate; 4 kg of boron nitride; then, the above-mentioned weighed raw materials were put into a high-speed mixer, mixed for 1 minute at a speed of 50 rpm, and then mixed for 5 minutes at a speed of 500 rpm to obtain a premix.

[0063] (2) Put the premix in an oven and dry at 80°C for 5 minutes to obtain a dried semi-finished product;

[0064] (3) Take 1.56 kg of the semi-finished product dried above and put it into a molding equipment preheated at 160-165°C, add a grinding steel back, pressurize 40 tons on a four-column hydraulic press, hold the pressure for 40 minutes, unload the mold, and obtain Semi-finished grinders;

[0065] (4) Then, put the obtained semi-finished grinding wheel into an oven, and process ...

Embodiment 2

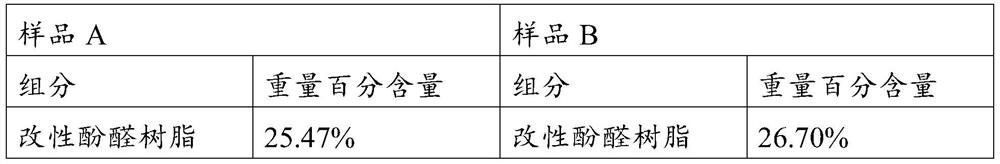

[0069] Milling sub-sample A and sample B were prepared as shown in Table 1 below, wherein sample C used the milling sub-sample prepared in Example 1.

[0070] Table 1:

[0071]

[0072]

[0073] Sample A and Sample B were prepared according to the method described in Example 1.

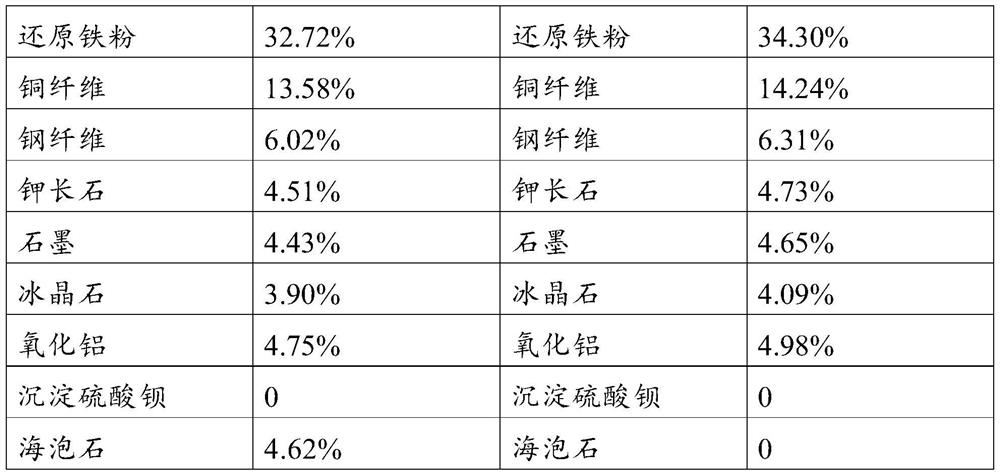

[0074] The physical properties of samples A, B and C were tested according to the standard method, and the friction performance of the grinding wheel was tested on a 1:3 scaled down brake dynamic test bench. The performance test results of samples A, B and C in the laboratory were compared with field use See Table 2 and Table 3 below for comparison.

[0075] Table 2: Physical and mechanical properties of three grinding sub-samples A, B, and C

[0076]

[0077] Table 3: Friction properties of three abrasive sub-samples A, B, and C

[0078]

[0079]

[0080] It can be seen from Table 2 that sample A is well used in the field; compared with sample A, the physical properties of sample B ...

Embodiment 3

[0083] Using the method of Example 1, according to the formulation of Table 4 below, the abrasives were prepared, and the properties of the prepared abrasives were shown in Table 5.

[0084] Table 4:

[0085]

[0086] Table 5: Physical properties of samples D and E

[0087]

[0088]

[0089] Table 6: Friction properties of samples D and E

[0090]

[0091] It can be seen from Tables 4 to 6 that after changing the formula ratio, the physical properties and friction properties of samples D and E all meet the site requirements, and no metal inlays are produced. However, the binder content of sample D is lower than that of sample C with the optimal ratio, and the wear amount of the friction test increases, and the service life decreases; the ratio of binder and cryolite in sample E is higher than that of C, which makes the internal adhesion of the friction body As the force increases, the amount of wear in the friction test becomes smaller, and the life span is impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com