Machine-made sand concrete using synergist and preparation method of machine-made sand concrete

A machine-made sand and concrete technology, which is applied in the field of machine-made sand concrete, can solve the problems of slow increase in construction pumping strength, easy segregation and bleeding of the mixture, and difficult loss of slump, so as to improve resource utilization and conversion efficiency and improve water quality. Chemical process, solve the effect of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

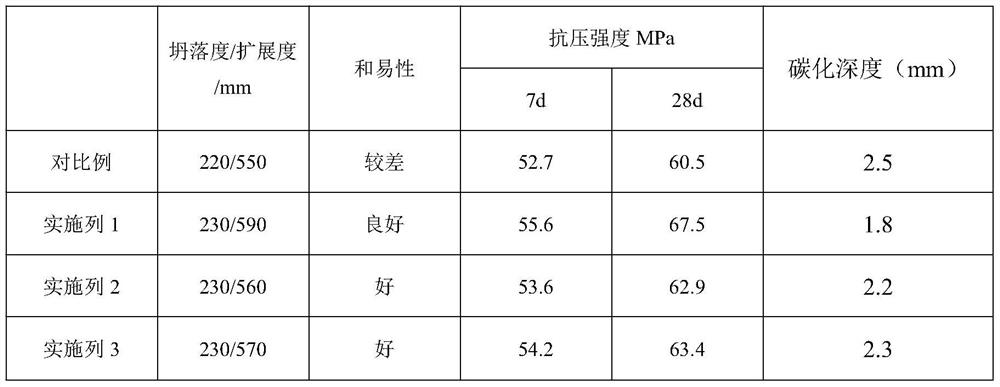

Examples

Embodiment 1

[0022] (1) The machine-made sand concrete synergist is taken by weighing the raw materials according to the mass percentage of each raw material, and 0.3% nanometer CaCO 3 Added into 16% hexenyl bis stearamide and dispersed ultrasonically to prepare nano-CaCO 3 Dispersions.

[0023] (2) Mix 19% of triethylenetetramine, 0.2% of potassium glycinate of coconut oil fatty acid, 0.09% of alkanolamide, and 64.41% of water, stir at 40°C for 1.5h, and then add the above-mentioned nano-CaCO 3 The dispersion liquid was stirred continuously for 0.5h to obtain the machine-made sand concrete synergist.

[0024] (3) Prepare concrete according to the ingredients in Table 2 by using the secondary feeding method, pour the weighed machine-made sand, gravel, and 60% water into the mixer and stir for 60 seconds, then add cement, fly ash, mineral powder and the remaining 40% The water, synergist, and water reducing agent were stirred for 1-2 minutes to obtain machine-made sand concrete, and the c...

Embodiment 2

[0026] (1) The machine-made sand concrete synergist is taken by weighing the raw materials according to the mass percentage of each raw material, and 0.4% nanometer CaCO 3 Add it to 18% monoglyceride stearate and disperse it ultrasonically to make nano-CaCO 3 Dispersions;

[0027] (2) Mix 20% triglycerol, 0.3% sodium coconut oil fatty acid alanine, 0.1% lauryl dimethylamine oxide, and 61.2% water, stir at 50°C for 2h, and then add the above-mentioned nano-CaCO 3 Dispersion liquid, continue to stir for 1h, obtain machine-made sand concrete synergist;

[0028] (3) Prepare concrete according to the ingredients in Table 2 by using the secondary feeding method, pour the weighed machine-made sand, gravel, and 60% water into the mixer and stir for 60 seconds, then add cement, fly ash, mineral powder and the remaining 40% The water, synergist, and water reducer are stirred for 1-2 minutes to obtain machine-made sand concrete.

Embodiment 3

[0030] (1) The machine-made sand concrete synergist is weighed according to the mass percentage of each raw material, and 0.5% nanometer CaCO 3 Add it to 20% glyceryl tristearate and disperse it ultrasonically to make nano-CaCO 3 Dispersions;

[0031] (2) Mix 25% of triethylenetetramine, 0.6% of coconut oil fatty acid sodium alanine, 0.3% of lauryl dimethyl amine oxide, and 53.65% of water, stir at 60°C for 2.5h, and then add the above nano CaCO 3 Dispersion liquid, continue to stir for 1.5h, obtain machine-made sand concrete synergist;

[0032] (3) Prepare concrete according to the ingredients in Table 2 by using the secondary feeding method, pour the weighed machine-made sand, gravel, and 60% water into the mixer and stir for 60 seconds, then add cement, fly ash, mineral powder and the remaining 40% The water, synergist, and water reducer are stirred for 1-2 minutes to obtain machine-made sand concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com