Cylinder liner and preparation process thereof

A preparation process and cylinder liner technology, applied in the field of cylinder liner manufacturing, can solve problems such as poor bonding of cylinder liners and aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

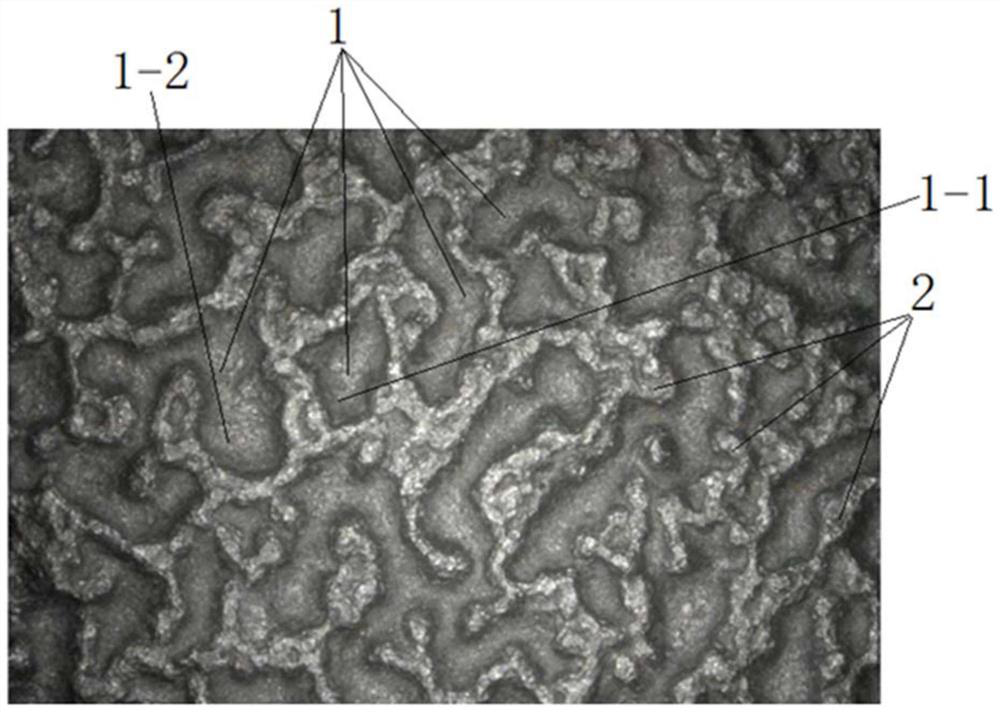

[0057] This embodiment provides a cylinder liner, such as figure 1 As shown, the outer surface of the cylinder liner is randomly distributed with depressions 1 and raised ribs 2 dividing adjacent depressions 1. The raised ribs 2 are enclosed to form depressions 1. The depressions 1 include mesh holes, and the outer There are closed meshes 1-1 accounting for at least 10% of the total meshes on the circular surface, and the remaining meshes are discontinuous meshes 1-2. Preferably, there are closed mesh holes 1-1 on the outer surface of the cylinder liner, accounting for 20-50% of the total mesh holes, and the remaining mesh holes are intermittent mesh holes.

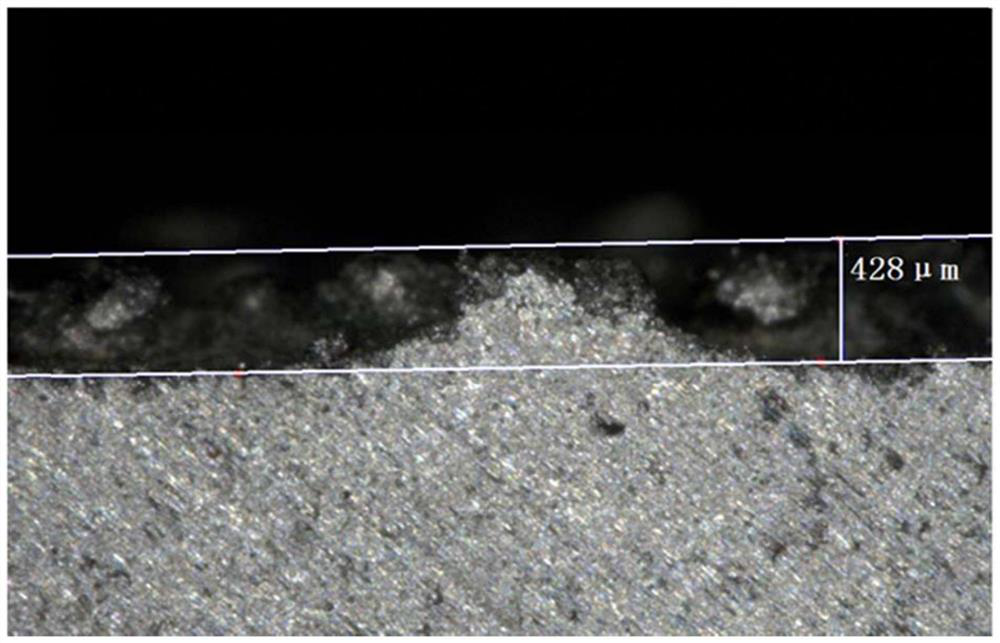

[0058] Further, the mesh diameter of the recessed portion 1 is 0.5-4.0 mm, and the mesh depth is 0.1-0.6 mm. Preferably, as Figure 2-7 shown, the mesh depth is 0.2-0.4mm, more specifically, as image 3 shown, the mesh depth is 428 μm; as Figure 5 shown, the mesh depth is 328 μm; as Figure 7 As shown, the mesh dept...

Embodiment 2

[0064] The present embodiment provides a cylinder liner and a preparation process thereof. The preparation process of the low-circumferential as-cast honeycomb-like or hill-like cylinder liner adopts a centrifugal casting process, which specifically includes the following steps:

[0065] (1) Smelting raw materials: adjust the chemical composition of molten iron, specifically: weigh the specified raw materials in proportion, use an intermediate frequency induction furnace to smelt at 1550 ° C, and season according to the following weight raw material requirements: carbon: 3.3%; sulfur: <0.1% ; Silicon: 2.4%; Phosphorus: ≤0.4%; Manganese: 0.8%; Chromium: 0.25%; Copper: 1%, the balance is iron, and molten iron is obtained;

[0066] (2) tapping inoculation: the above-mentioned molten iron is inoculated by tapping, the tapping temperature is 1500 ° C, the inoculation adopts downstream inoculation, the inoculation amount is 0.5wt%, and the inoculant is silicon strontium zirconium;

...

Embodiment 3

[0073] The present embodiment provides a cylinder liner and a preparation process thereof. The preparation process of the low-circumferential as-cast honeycomb-like or hill-like cylinder liner adopts a centrifugal casting process, which specifically includes the following steps:

[0074] (1) Smelting raw materials: adjust the chemical composition of molten iron, specifically: weigh the specified raw materials in proportion, use an intermediate frequency induction furnace to smelt at 1480 ° C, and season according to the following weight raw material requirements: carbon: 3.5%; sulfur: <0.1% ; Silicon: 2.0%; Phosphorus: ≤0.4%; Manganese: 1.0%; Chromium: 0.1%; Copper: 1.5%, the balance is iron, and molten iron is obtained;

[0075] (2) tapping inoculation: the above-mentioned molten iron is tapped and inoculated, the tapping temperature is 1480 ° C, the inoculation adopts downstream inoculation, the inoculation amount is 0.7wt%, and the inoculant is silicon strontium zirconium; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com