Easily degradable and environment friendly plastic and manufacturing method thereof

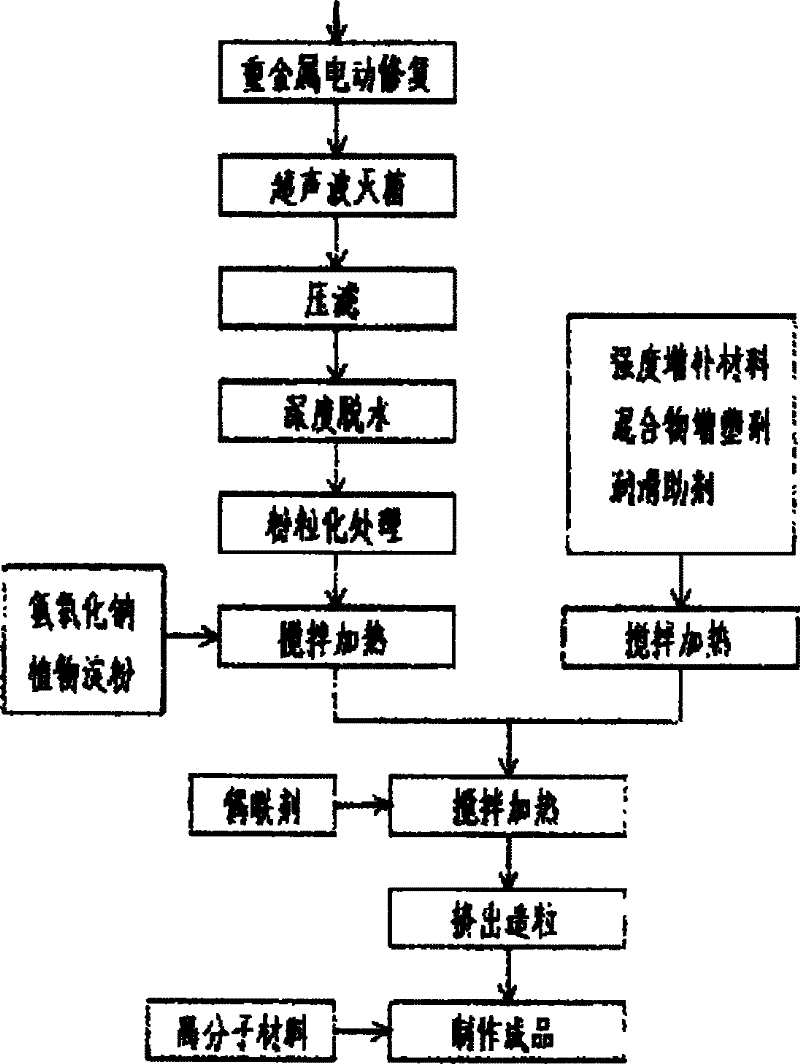

An environmentally friendly plastic and easy-to-degrade technology, applied in the field of biochemistry, can solve the problems of unresolved residual sludge pollution, difficulty in large-scale production, and non-degradable plastics. It achieves excellent molding performance, simple manufacturing process, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of easily degradable environmental protection plastics, it comprises the following components and the material of weight ratio is made:

[0034]

[0035] Wherein: the high-nutrition biodegradable material is mixed according to the weight ratio of 100: 1: 2 by remaining sludge granules with a water content of 8 to 15%, sodium hydroxide and plant starch, and an appropriate amount of starch is added to increase the Partitioned compatibility; the strength supplement material is mixed with natural mineral powder, natural fiber and polyvinyl alcohol in a weight ratio of 1:5:0.2, wherein the natural mineral powder is wollastonite crushed to 400-600 mesh Or pottery clay, described natural fiber is length between 0.2~hm, length / diameter ratio is between 2~10 plant source fiber; In mixture plasticizer, alkylsulfonate and ethylene glycol are according to the weight ratio of 1:1.5 Mixing; the polymer wax, calcium stearate and stearic acid in the lubricating ...

Embodiment 2

[0047] Embodiment 2: a kind of easily degradable environmental protection plastics, it comprises the following components and the material of weight ratio is made:

[0048]

[0049]

[0050] Wherein: the high-nutrition biodegradable material is mixed according to the weight ratio of 100: 1.25: 5.51 by remaining sludge powder with a moisture content of 8 to 15%, sodium hydroxide and plant starch, and an appropriate amount of starch is added to increase the Partitioned compatibility; the strength supplement material is mixed with natural mineral powder, natural fiber and polyvinyl alcohol in a weight ratio of 1:3:0.25, wherein the natural mineral powder is wollastonite crushed to 400-600 mesh Or pottery clay, the natural fiber is a plant-derived fiber with a length of 0.2 to 1 mm and a length / diameter ratio of 2 to 10; in the mixture plasticizer, alkyl sulfonate and ethylene glycol are in a weight ratio of 1:2 Mixing; the high molecular weight wax, calcium stearate and ste...

Embodiment 3

[0062] Embodiment 3: a kind of easily degradable environmental protection plastics, it comprises the following components and the material of weight ratio is made:

[0063]

[0064] Wherein: the high-nutrition biodegradable material is mixed according to the weight ratio of 100: 1.5: 8.5 by remaining sludge powder with a water content of 8 to 15%, sodium hydroxide and plant starch, and an appropriate amount of starch is added to increase the weight of each group. Partitioned compatibility; the strength supplement material is mixed with natural mineral powder, natural fiber and polyvinyl alcohol in a weight ratio of 1:4.5:0.3, wherein the natural mineral powder is wollastonite crushed to 400-600 mesh Or pottery clay, the natural fiber is a plant-derived fiber with a length of 0.2 to 1 mm and a length / diameter ratio of 2 to 10; in the mixture plasticizer, alkyl sulfonate and ethylene glycol are in a weight ratio of 1:3 Mixing; the polymer wax, calcium stearate and stearic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com