Alkali slag concrete water reducing agent

A technology of concrete water reducer and alkali slag, which is applied in the field of alkali slag concrete water reducer and water reducer, which can solve the problems of difficult construction and high viscosity of alkali slag concrete mixture, so as to achieve good adaptability and improve flow Sexuality and workability, the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The alkali slag concrete water reducer of this embodiment is composed of the following components by mass: Ba(NO 3 ) 2 : 2 parts; Pb(NO 3 ) 2 : 10 copies; (C 10 h 6 CH 2 NaSO 3 ) n : 22 copies; C 20 h 24 CaO 10 S 2 : 3 copies; C 18 h 29 NaO 3 S: 1 serving.

[0018] The alkali slag concrete water reducing agent of this embodiment is made by the following method:

[0019] a. Weigh the raw materials according to the ratio: the raw materials selected in this step are as follows:

[0020] Ba(NO 3 ) 2 : Produced by Chongqing Chuanjiang Chemical Reagent Factory, molecular weight 261.35, white powder, density 3.24g / cm 3 .

[0021] Pb(NO 3 ) 2 : Produced by Chongqing Chuanjiang Chemical Reagent Factory, molecular weight 331.23, white cubic or monoclinic crystal, hard and shiny, density 4.53g / cm 3 .

[0022] (C 10 h 6 CH 2 NaSO 3 ) n : Produced by Chongqing Jiangyun Concrete Admixture Co., Ltd., yellow powder.

[0023] C 20 h 24 CaO 10 S 2 : Produ...

Embodiment 2

[0027] The alkali slag concrete water reducer of this embodiment is composed of the following components by mass: Ba(NO 3 ) 2 : 1 part; Pb(NO 3 ) 2 : 20 copies; (C 10 h 6 CH 2 NaSO 3 ) n : 16 copies; C 20 h 24 CaO 10 S 2 : 3 copies; C 18 h 29 NaO 3 S: 1 serving.

[0028] This implementation alkali slag concrete water reducer is made by the following method:

[0029] a. Raw materials are weighed according to the proportioning ratio: the selected raw materials in this step are the same as those in Example 1.

[0030] b. Put the raw materials selected in step a into a vibration mill and grind for 5 minutes to obtain a product.

Embodiment 3

[0032] The alkali slag concrete water reducer of this embodiment is composed of the following components by mass: Ba(NO 3 ) 2 : 2 parts; Pb(NO 3 ) 2 : 15 copies; (C 10 h 6 CH 2 NaSO 3 ) n : 20 copies; C 20 h 24 CaO 10 S 2 : 4 copies; C 18 h 29 NaO 3 S: 1 serving.

[0033] The alkali slag concrete water reducing agent of this embodiment is made by the following method:

[0034] a. Raw materials are weighed according to the proportioning ratio: the selected raw materials in this step are the same as those in Example 1.

[0035] b. Put the raw materials selected in step a into a vibration mill and grind for 5 minutes to obtain a product.

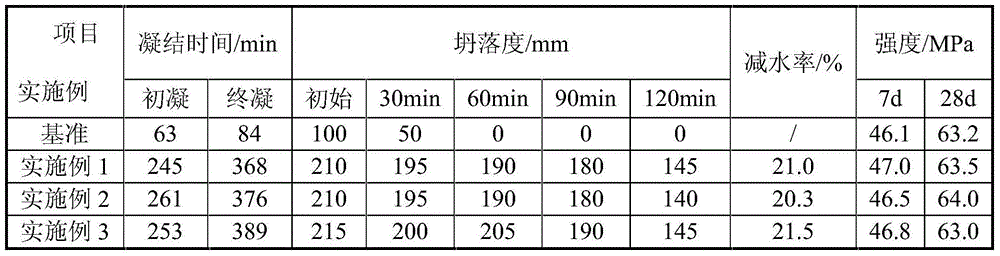

[0036] Utilize the water reducer of embodiment 1-3 respectively to prepare concrete according to the following steps:

[0037] A. Select raw materials: 100 parts of mineral powder, 40 parts of water, 5 parts of NaOH, 144 parts of medium sand, 256 parts of 5-20mm stones, 2 parts of water reducer;

[0038] in:

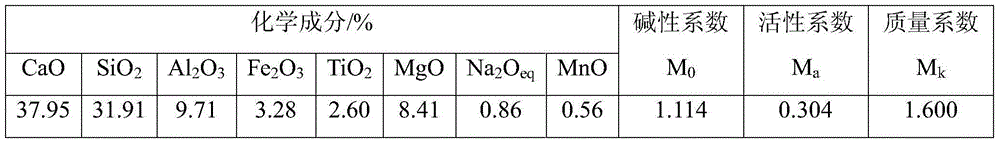

[0039] Mineral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com